Technical Contents

Engineering Guide: Injection Molding Problems

Engineering Insight: Injection Molding Problems and the Critical Role of Precision

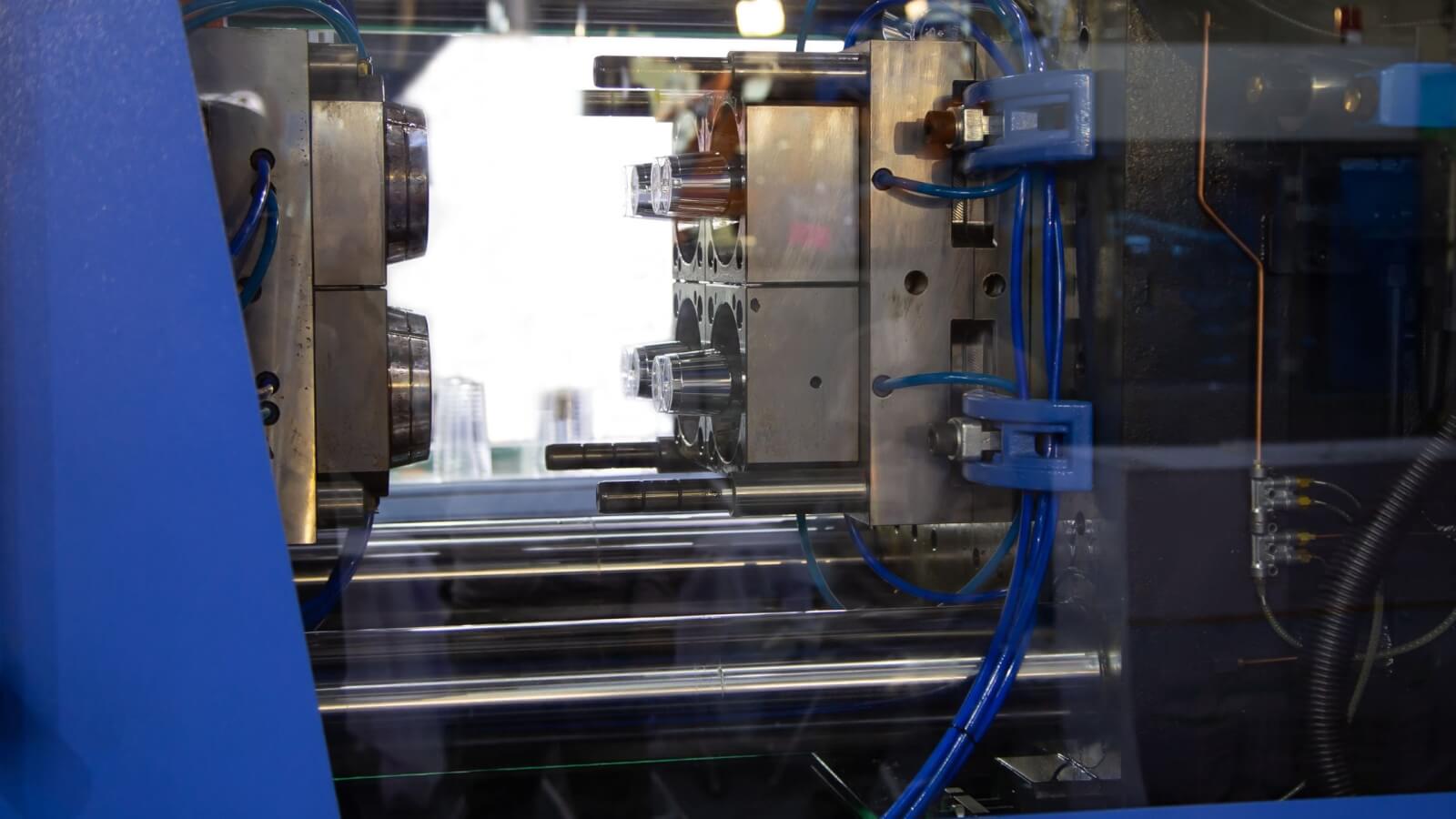

In the high-stakes world of custom metal manufacturing, injection molding remains a cornerstone process for producing complex, high-volume components with consistent accuracy. However, even minor deviations in tooling, material control, or machine calibration can lead to significant injection molding problems—ranging from flash and sink marks to warpage and incomplete filling. These defects not only compromise part integrity but also increase scrap rates, delay production cycles, and elevate overall costs. At Wuxi Lead Precision Machinery, we recognize that the root cause of most injection molding issues lies not in the process itself, but in the precision of the tooling and the consistency of the manufacturing environment.

Precision is non-negotiable in injection molding. The mold must be machined to exacting tolerances, often within ±0.002 mm, to ensure uniform material flow, proper cooling, and repeatable ejection. Any inconsistency in cavity geometry, surface finish, or thermal management can trigger defects. For example, uneven cooling channels—often the result of subpar machining—lead to differential shrinkage, which manifests as warpage or internal stress. Similarly, poorly aligned mold inserts cause flash, particularly when high injection pressures are required for engineering-grade resins.

At Wuxi Lead Precision Machinery, our expertise in high-precision CNC machining and advanced mold design directly addresses these challenges. With over 15 years of experience serving aerospace, defense, and high-performance industrial sectors—including components used in Olympic-standard equipment and military-grade systems—we apply the same rigor to every injection mold we produce. Our engineering team leverages multi-axis machining centers, in-process metrology, and finite element analysis (FEA) to simulate mold behavior under real-world conditions, preempting potential failures before the first shot is molded.

Our facility maintains ISO 9001 and IATF 16949 certifications, ensuring that every mold meets stringent quality benchmarks. We utilize premium-grade tool steels such as H13, S136, and 2738, selected based on thermal stability, wear resistance, and corrosion performance. All molds undergo rigorous validation, including mold flow analysis, cavity pressure testing, and first-article inspection reports (FAIR), guaranteeing reliability from prototype to full-scale production.

The following table outlines key specifications that define our precision molding capabilities:

| Parameter | Specification |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Surface Finish (cavity/core) | Ra ≤ 0.2 µm (polished to SPI A1) |

| Mold Materials | H13, S136, 2738, NAK80, P20 |

| Maximum Mold Size | 1200 × 800 × 700 mm |

| Tooling Life Expectancy | 500,000+ cycles (depending on material) |

| Cooling Channel Accuracy | ±0.01 mm (conformal cooling available) |

| Quality Standards | ISO 9001, IATF 16949, FAIR, PPAP |

By integrating precision engineering with deep domain experience, Wuxi Lead Precision Machinery ensures that injection molding problems are not corrected—they are prevented. For manufacturers demanding zero-defect performance, the mold is not just a tool; it is the foundation of quality.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineering for Injection Mold Excellence

At Wuxi Lead Precision Machinery, we understand that the root cause of persistent injection molding defects—such as sink marks, warpage, flash, or inconsistent part dimensions—often originates in the mold itself. Imperfect cavity geometry, inconsistent cooling channels, or inadequate venting directly translate to production instability and scrap. Our core mission is to eliminate these foundational issues through uncompromising precision in custom metal mold and component manufacturing. We achieve this by integrating advanced multi-axis machining with rigorous, data-driven quality validation, ensuring your molds perform reliably from the first shot.

Our primary manufacturing capability centers on state-of-the-art 5-axis CNC machining centers. This technology is fundamental for producing complex mold bases, intricate cores, cavities, and slides with exceptional accuracy and surface finish. The simultaneous movement across five axes allows us to machine highly contoured geometries in a single setup, drastically reducing cumulative error inherent in multi-setup processes. This capability is critical for achieving the precise draft angles, tight radii, and seamless parting lines necessary to prevent drag marks, ejection problems, and flash. We utilize high-rigidity machines with thermal compensation systems, operating under strict environmental controls to maintain dimensional stability throughout the machining cycle. Material versatility spans tool steels (P20, H13, S7), stainless steels, aluminum alloys, and specialized pre-hardened blocks, all processed to meet the demanding thermal and wear requirements of high-volume molding.

Precision machining alone is insufficient without equally rigorous verification. Every critical feature undergoes comprehensive inspection using our fleet of calibrated Coordinate Measuring Machines (CMMs). These systems provide full 3D geometric dimensioning and tolerancing (GD&T) analysis, generating detailed inspection reports traceable to international standards. We verify cavity dimensions, core pin locations, cooling channel placement and diameter, ejector pin bores, and parting surface flatness with micron-level accuracy. This data-driven QC process ensures that the physical mold precisely matches the engineered CAD model, directly addressing the dimensional inconsistencies that lead to molding defects like short shots or dimensional drift. Our QC protocols are certified under ISO 9001, providing documented evidence of conformance for every component.

The tolerances we consistently achieve are the bedrock of mold performance. Below are the standard capabilities we deliver for critical mold features, reflecting our commitment to solving the dimensional root causes of injection molding problems. These specifications represent our routine production capability under controlled conditions.

| Feature Type | Standard Tolerance | Precision Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm (±0.0004″) | ±0.005 mm (±0.0002″) | CMM |

| Geometric (GD&T) | ±0.015 mm (±0.0006″) | ±0.008 mm (±0.0003″) | CMM |

| Hole Diameter (Machined) | +0.010 / -0.000 mm | +0.005 / -0.000 mm | CMM / Air Gage |

| Surface Roughness (Ra) | 0.8 μm (32 μin) | 0.4 μm (16 μin) | Profilometer |

| Parting Line Flatness | 0.020 mm (0.0008″) | 0.010 mm (0.0004″) | CMM / Surface Plate |

This level of dimensional control, executed through integrated 5-axis CNC manufacturing and validated by CMM inspection, directly translates to mold performance. It minimizes setup time, reduces scrap rates, extends mold life, and ensures consistent production of high-quality plastic parts, solving the critical injection molding problems that impact your bottom line. Wuxi Lead Precision Machinery delivers the metal foundation for your molding success.

Material & Finish Options

Material Selection in High-Performance Injection Molding: Aluminum, Steel, and Titanium

Selecting the appropriate material for injection molding tooling is critical to achieving long-term performance, dimensional accuracy, and cost efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the rigorous demands of precision molding applications. Our expertise spans aluminum, steel, and titanium—each offering distinct advantages depending on production volume, part complexity, and environmental conditions.

Aluminum is widely used in prototype and low-to-medium volume production due to its excellent thermal conductivity and machinability. It allows for rapid heat dissipation, reducing cycle times during molding. Its lightweight nature also simplifies handling and reduces wear on molding equipment. However, aluminum’s lower hardness makes it less suitable for abrasive resins or long production runs exceeding 100,000 cycles. For applications requiring fast turnaround and cost-effective tooling, aluminum remains a preferred choice.

Steel, particularly tool steels such as P20, H13, and S136, is the standard for high-volume injection molding. It offers superior hardness, wear resistance, and durability, supporting production runs well beyond 1 million cycles when properly maintained. Stainless variants like 420 or S136 provide enhanced corrosion resistance, making them ideal for molding medical-grade or chemically sensitive plastics. While steel molds require longer machining times and higher initial investment, their longevity and dimensional stability deliver lower cost-per-part over time.

Titanium, though less common, presents unique benefits in specialized applications. Its exceptional strength-to-density ratio and resistance to corrosion make it suitable for extreme environments, such as aerospace or marine component molding. Titanium’s low thermal expansion ensures dimensional consistency under fluctuating temperatures. However, its high cost and challenging machinability limit its use to niche, high-value applications where performance outweighs cost considerations.

Surface finishing plays a pivotal role in mold performance and part quality. Anodizing, particularly hard anodizing, is a key treatment for aluminum molds. It increases surface hardness, improves wear resistance, and enhances corrosion protection. Type III anodizing (hard coat) can achieve thicknesses of 50–75 µm with hardness values exceeding 60 HRC, significantly extending mold life. For steel molds, nitriding or chrome plating is typically preferred, though anodizing aluminum components remains a cost-effective solution for improving durability without compromising thermal performance.

The following table summarizes key mechanical and thermal properties of the three materials:

| Material | Hardness (HRC) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Mold Life (cycles) | Common Finishes |

|---|---|---|---|---|---|

| Aluminum (7075-T6) | 40–45 | 570 | 130 | 10,000–100,000 | Hard Anodizing (Type III) |

| Steel (P20) | 28–32 | 900 | 30 | 100,000–500,000 | Nitriding, Chrome Plating |

| Steel (H13) | 48–52 | 1,500 | 35 | 500,000–1M+ | PVD Coating, Polishing |

| Titanium (Ti-6Al-4V) | 35–40 | 900 | 7 | 100,000–500,000 | Anodizing, Nitriding |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on application-specific requirements, ensuring optimal tool performance and return on investment.

Manufacturing Process & QC

Precision Metal Injection Molding: The Zero Defects Production Framework

At Wuxi Lead Precision Machinery, we address core injection molding challenges in metal manufacturing through a rigorously controlled three-phase production system. This integrated approach eliminates defects at origin, ensuring dimensional stability and material integrity for demanding aerospace, medical, and automotive applications. Our methodology transcends conventional plastic molding, focusing specifically on the complexities of Metal Injection Molding (MIM) where material behavior during debinding and sintering introduces unique failure modes.

The Design phase is foundational for defect prevention. Our engineering team conducts exhaustive Design for Manufacturing (DFM) analysis using advanced simulation software to model metal powder flow, thermal gradients, and sintering shrinkage. We identify potential weak points like weld lines, sink marks, or non-uniform density distribution before tooling begins. Critical parameters such as gate location, runner geometry, and parting line placement are optimized to ensure homogeneous material packing and minimize internal stresses. This proactive simulation prevents 80% of common MIM defects, including delamination and cracking during thermal processing.

Prototyping transforms validated designs into tangible, testable components under production-intent conditions. We utilize our high-precision MIM presses and controlled sintering furnaces to produce functional prototypes from the actual production alloy. Rigorous metrology, including CMM and micro-CT scanning, verifies dimensional accuracy against the simulated shrinkage model. Material properties like density, tensile strength, and microstructure are tested per ASTM standards. Any deviation triggers immediate design or process refinement. This phase is non-negotiable for validating sintering distortion control and ensuring the final part meets zero-defect specifications under real-world thermal cycles.

Mass Production executes the perfected process with relentless statistical control. Our automated MIM cells operate under strict environmental monitoring, with real-time sensors tracking injection pressure, temperature profiles, and cycle times. Every batch undergoes 100% in-process dimensional checks at critical features, coupled with periodic destructive testing for material certification. Our proprietary Statistical Process Control (SPC) protocols detect minute process drifts before they manifest as defects like porosity, surface roughness, or dimensional non-conformance. Traceability from raw powder lot to finished part is maintained, enabling root-cause analysis if any anomaly occurs. This closed-loop system guarantees consistent output meeting the most stringent zero-defect requirements.

Wuxi Lead’s commitment to zero defects is quantified through measurable precision standards across our MIM process:

| Parameter | Typical Capability | Measurement Standard |

|---|---|---|

| Dimensional Tolerance | ±0.3% of dimension | ISO 2768-mK |

| Critical Feature Tol | ±0.005 mm | ASME Y14.5 GD&T |

| Density | 98-99.5% theoretical | ASTM B962 |

| Surface Roughness (Ra) | 0.8 – 3.2 µm | ISO 4287 |

| Material Consistency | ±0.5% density variation | In-house protocol |

This seamless integration of predictive design, validated prototyping, and statistically controlled mass production forms the backbone of Wuxi Lead’s zero-defect guarantee. We eliminate injection molding problems not through inspection, but by engineering perfection into every phase of the metal component lifecycle.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Precision-Engineered Solutions in Injection Molding

When injection molding challenges threaten production timelines, product integrity, or profitability, partnering with a trusted engineering leader becomes essential. At Wuxi Lead Precision Machinery, we specialize in resolving complex manufacturing issues through precision-crafted metal components and proactive engineering support. Our expertise spans die casting molds, injection mold tooling, and custom automation systems, all manufactured to exacting international standards. We don’t just supply parts—we deliver reliability, repeatability, and long-term performance.

Injection molding problems such as flash, short shots, warpage, or inconsistent cycle times often stem from suboptimal tooling, material flow imbalances, or thermal management deficiencies. These are not merely operational hiccups—they are symptoms of deeper design or manufacturing flaws. At Lead Precision, our engineers conduct comprehensive root-cause analysis, combining simulation software with hands-on testing to identify and correct the source of failure. Whether you’re facing ejection issues, gate vestige, or premature wear in mold cavities, our team develops targeted solutions that enhance mold life, reduce downtime, and improve part consistency.

Our manufacturing facility in Wuxi integrates advanced CNC machining, wire EDM, and surface treatment technologies to produce molds and components with micron-level accuracy. We work with a wide range of tool steels and high-performance alloys, ensuring compatibility with demanding resins and production environments. Every project undergoes strict quality control, including CMM inspection, hardness testing, and mold flow validation, before shipment.

We understand that global supply chains require more than precision parts—they demand responsive communication, technical transparency, and on-time delivery. That’s why our engineering team collaborates directly with clients from concept through production, offering real-time updates, 3D design reviews, and post-installation support. Our clients in automotive, medical device, and industrial equipment sectors rely on us not as a vendor, but as an extension of their own engineering capability.

For manufacturers seeking to eliminate recurring injection molding failures, the right partnership can transform outcomes. Lead Precision delivers engineering rigor, manufacturing excellence, and a commitment to solving your most persistent challenges.

Contact us today to discuss your application. Send detailed inquiries, drawings, or failure reports to [email protected]. Our technical team responds within 12 business hours to provide actionable feedback and project feasibility assessment.

Key Manufacturing Specifications

| Specification | Capability |

|---|---|

| CNC Machining Accuracy | ±0.002 mm |

| Maximum Workpiece Size | 1200 × 800 × 600 mm |

| Materials Processed | P20, 718, H13, S136, 420SS, Aluminum Alloys, Titanium Alloys |

| Surface Finish | Ra 0.1 – 1.6 μm (polished to mirror finish if required) |

| Tolerance Control | ISO 2768-mK, DIN 16901 |

| Quality Inspection | Full CMM report, 3D scanning, hardness and roughness testing |

| Lead Time (Standard Mold) | 25–35 days (based on complexity) |

Let Lead Precision be your strategic partner in overcoming injection molding challenges with engineered precision and proven results.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.