Technical Contents

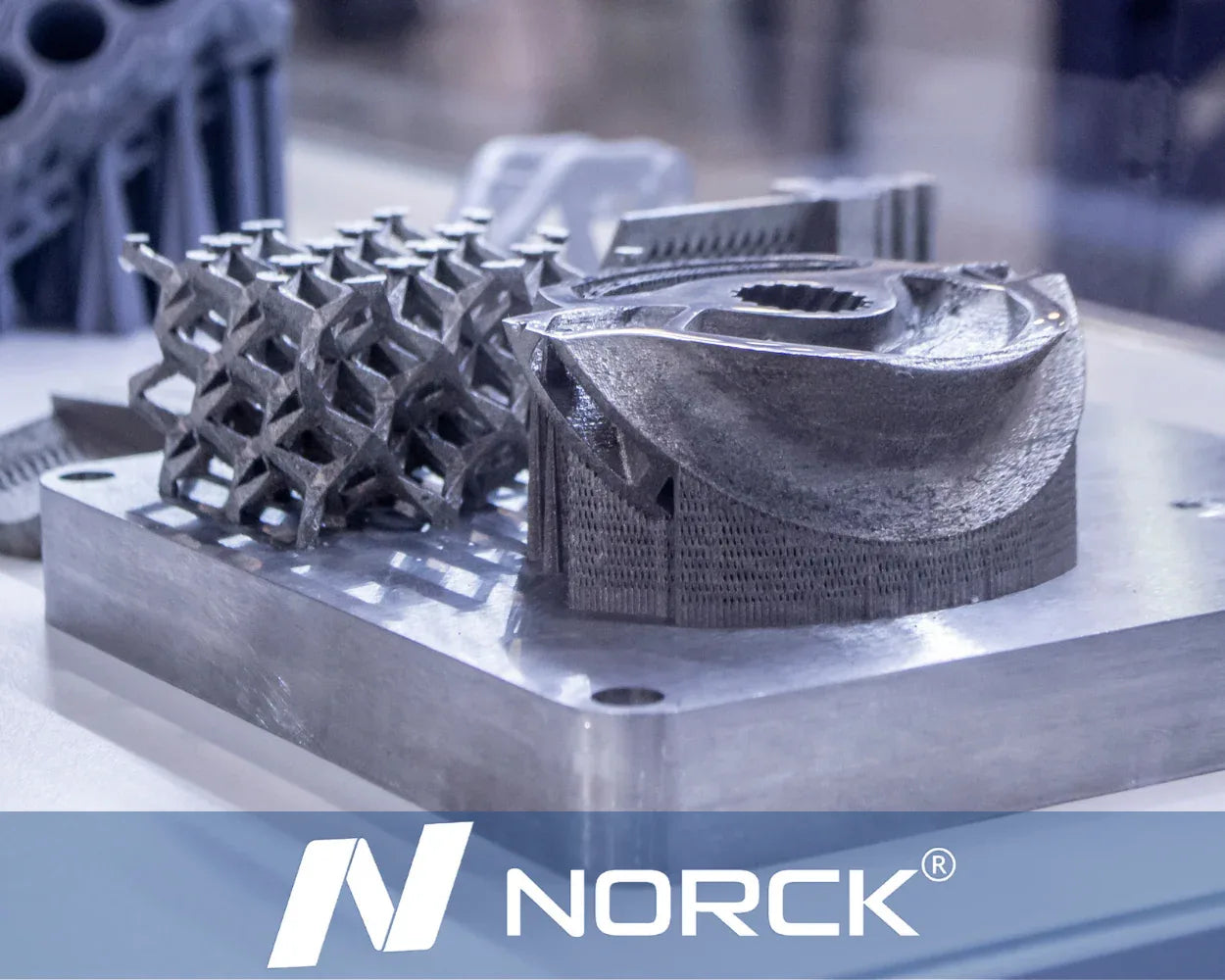

Engineering Guide: Pla Printing Service

Engineering Insight Precision in PLA Printing Services and Beyond

While PLA printing services represent a valuable prototyping tool in modern manufacturing workflows, true engineering excellence demands rigorous precision that extends far beyond initial polymer models. At Wuxi Lead Precision Machinery, we observe a critical gap: many clients transition directly from PLA prototypes to final production without addressing the fundamental dimensional and material limitations inherent in additive polymer processes. PLA parts, while useful for form and fit checks, lack the thermal stability, mechanical strength, and micron-level tolerances required for functional metal components in demanding aerospace, defense, or high-performance sporting goods applications. The real engineering challenge begins when translating a concept into a mission-critical metal part capable of withstanding extreme operational stresses.

Precision is not merely a specification; it is the cornerstone of reliability and performance. In applications where failure is not an option – such as components for military unmanned systems or the structural elements of Olympic-caliber equipment – tolerances measured in microns directly impact safety, efficiency, and longevity. Our experience delivering precision-machined titanium components for the 2022 Beijing Winter Olympics ski jump bindings and critical subsystems for defense contractors underscores this reality. These projects demanded absolute adherence to geometric dimensioning and tolerancing (GD&T) standards, zero-defect manufacturing protocols, and materials traceability far exceeding what any PLA prototype can validate. The jump from a polymer model to a flight-certified or competition-grade metal part requires advanced CNC machining capabilities, deep materials science understanding, and unwavering process control.

Wuxi Lead Precision Machinery bridges this gap. We leverage PLA prototypes as a starting point for design refinement, but our core expertise lies in transforming those concepts into high-integrity metal components using multi-axis milling, turning, and grinding technologies. Our facility operates under stringent AS9100 and ISO 9001 quality management systems, ensuring every part meets or exceeds the most demanding aerospace and defense specifications. We understand that the tolerances achievable in polymer printing are insufficient for final metal production; our value is in achieving and certifying the precision that PLA cannot.

The following table outlines key precision capabilities essential for transitioning from concept to certified metal production:

| Specification Category | Capability | Relevance to High-End Manufacturing |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm (±0.00008″) | Critical for press-fit assemblies, dynamic sealing surfaces, and high-RPM components where minute deviations cause catastrophic failure |

| Surface Finish (Ra) | As low as 0.2 µm (8 µin) | Essential for fatigue resistance in aerospace structures, hydraulic sealing, and optical mounting surfaces |

| Material Certification | Full traceability to mill certs; AMS, ASTM, MIL spec compliance | Mandatory for defense, aerospace, and medical applications requiring material property validation |

| Geometric Accuracy (GD&T) | Capable of complex profile tolerances < 0.005 mm | Ensures functional interchangeability and performance in multi-part systems like turbine engines |

| Process Control | Real-time in-process gauging; Cpk ≥ 1.67 standard | Guarantees consistency across production runs for mission-critical applications |

Precision engineering separates functional prototypes from reliable, certified products. Wuxi Lead Precision Machinery provides the advanced metal manufacturing expertise and rigorous quality systems necessary to transform initial PLA concepts into components trusted by Olympic athletes and military operators worldwide. We ensure your design’s integrity survives the transition from polymer model to high-performance metal reality.

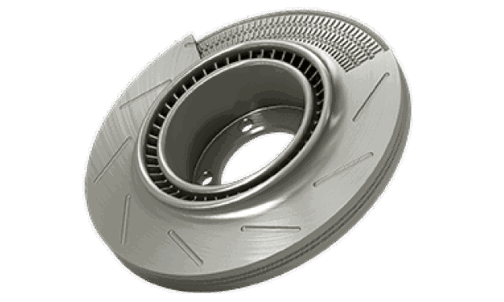

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the most demanding industrial applications. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling the production of highly complex geometries with exceptional accuracy and surface finish. Our machining centers operate with simultaneous multi-axis motion, allowing for intricate contours, deep cavities, and compound angles that are unattainable with conventional 3-axis systems. This level of precision ensures that even the most sophisticated components meet exact design specifications, reducing the need for secondary operations and assembly adjustments.

All machining processes are supported by a robust digital workflow, beginning with CAD/CAM integration and ending with comprehensive quality verification. Our engineers utilize industry-leading software to simulate tool paths and optimize cutting strategies, minimizing cycle time while maximizing material efficiency and part integrity. Materials commonly processed include aerospace-grade aluminum, stainless steel, titanium, tool steels, and high-performance alloys, all machined under strict environmental and procedural controls to maintain consistency across production runs.

Quality assurance is embedded at every stage of manufacturing. Each component undergoes rigorous inspection using a Coordinate Measuring Machine (CMM) to verify dimensional accuracy and geometric conformity. Our CMM systems are calibrated to international standards and operated by certified metrology technicians, ensuring traceable and repeatable results. This inspection process confirms compliance with customer-specified tolerances and industry regulations, particularly critical in sectors such as aerospace, medical devices, and high-precision automation.

The following table outlines the standard tolerance capabilities achievable through our 5-axis CNC machining and inspection processes:

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Depending on part size and material |

| Hole Diameter | +0.025 / -0.000 mm | +0.010 / -0.000 mm | Reamed or precision bored |

| Positional Tolerance | ±0.02 mm | ±0.01 mm | Relative to datum |

| Flatness | 0.02 mm per 100 mm | 0.005 mm per 100 mm | Verified via CMM and surface plate |

| Surface Finish | Ra 3.2 µm | Ra 0.4 µm | Achieved through fine tooling and finishing passes |

| Angular Features | ±0.05° | ±0.02° | Critical for mating surfaces and assemblies |

Our technical capabilities are further enhanced by in-house project management and engineering support, ensuring seamless communication and technical alignment from prototype to full-scale production. Wuxi Lead Precision Machinery maintains a continuous improvement philosophy, investing in the latest machine tool technology, operator training, and quality systems to remain at the forefront of precision manufacturing. With a focus on repeatability, accuracy, and on-time delivery, we serve global clients requiring mission-critical metal components built to exacting standards.

Material & Finish Options

Material Selection for Precision Metal Components

Selecting appropriate materials is critical for achieving optimal performance in custom metal manufacturing. While PLA printing services cater to prototyping with thermoplastics, Wuxi Lead Precision Machinery specializes in high-tolerance CNC-machined metal components where material properties directly impact durability, thermal stability, and functional longevity. For industrial applications requiring structural integrity under stress, heat, or corrosion, metals remain irreplaceable. Below we detail key considerations for aluminum, steel, and titanium alloys, alongside essential finishing processes like anodizing.

Aluminum alloys (e.g., 6061-T6, 7075-T6) offer an exceptional strength-to-weight ratio and natural corrosion resistance, making them ideal for aerospace brackets, automotive housings, and heat sinks. Their machinability allows for complex geometries at lower production costs compared to steel or titanium. However, aluminum lacks the wear resistance required for high-friction applications. Anodizing is highly recommended to enhance surface hardness, corrosion protection, and aesthetic consistency—particularly Type II (sulfuric acid) for general use or Type III (hardcoat) for industrial wear resistance.

Steel variants, including 304/316 stainless and 4140 alloy steel, deliver superior strength, hardness, and temperature resilience. Stainless grades excel in medical devices and marine environments due to passive oxide layer corrosion resistance, while 4140 provides exceptional toughness for hydraulic components and tooling. Steel’s density necessitates robust machining strategies to maintain precision, but its versatility supports stringent load-bearing demands. Passivation is standard for stainless steel to remove free iron, though powder coating or electropolishing may supplement specific environmental requirements.

Titanium (Grade 5 Ti-6Al-4V) dominates extreme-condition applications like aerospace landing gear and biomedical implants. Its unparalleled strength-to-weight ratio, biocompatibility, and resistance to saltwater/chemical corrosion justify higher material and machining costs. Titanium’s low thermal conductivity demands specialized tooling and slower cutting speeds to prevent work hardening. Anodizing is not applicable; instead, chemical etching or laser marking ensures surface integrity without compromising corrosion resistance.

Material properties must align with operational stresses. The table below summarizes critical specifications for common alloys:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Key Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Moderate | Enclosures, heat exchangers |

| Stainless 316 | 8.0 | 570 | Excellent | Marine hardware, surgical tools |

| Steel 4140 | 7.85 | 655 | Low (uncoated) | Shafts, valves, tooling |

| Titanium Ti-6Al-4V | 4.43 | 900 | Exceptional | Aircraft components, implants |

Finishing processes like anodizing extend component life by 30–50% in corrosive environments. For aluminum, anodizing thickness (5–25µm) must match exposure severity—thin films suit indoor electronics, while thick hardcoat anodizing withstands abrasive industrial use. Always consult material datasheets against your operational parameters: temperature cycles, load profiles, and regulatory standards (e.g., ASTM, ISO). At Wuxi Lead, our engineering team collaborates to validate material-finish pairings, ensuring your components meet lifetime performance targets without over-engineering costs. Material selection is not merely a technical choice—it is a strategic investment in product reliability and total cost of ownership.

Manufacturing Process & QC

Design Phase: Precision Engineering from Concept to CAD

At Wuxi Lead Precision Machinery, the production journey begins with a meticulous design phase, where engineering excellence meets client-specific requirements. Our team of senior CNC engineers collaborates closely with clients to interpret technical drawings, 3D models, and functional specifications. Utilizing advanced CAD/CAM software such as SolidWorks, AutoCAD, and Mastercam, we develop precision-optimized designs tailored for manufacturability, structural integrity, and performance under real-world conditions. Finite element analysis (FEA) and thermal stress simulations are applied to validate design robustness before any material is cut. This proactive approach ensures dimensional accuracy, minimizes material waste, and eliminates potential failure points at the earliest stage.

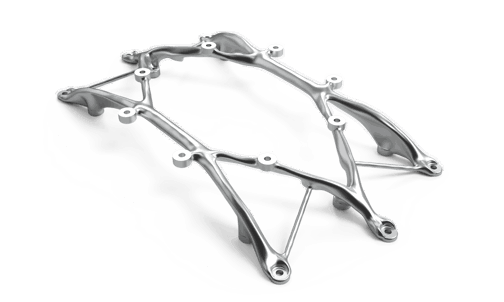

Prototyping: Validating Performance and Fit

Once the design is finalized, we transition into the prototyping phase—a critical step in our zero-defect manufacturing philosophy. Using high-speed CNC milling, precision turning, and multi-axis machining centers, we produce functional prototypes in the actual production-grade materials—such as aluminum 6061-T6, stainless steel 316L, or titanium Ti-6Al-4V. These prototypes undergo rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers to verify conformance to GD&T specifications. Clients receive detailed inspection reports and physical samples for form, fit, and function testing. Any necessary design refinements are implemented digitally and re-validated, ensuring full alignment before scaling to mass production.

Mass Production: Scalable Precision with Zero Defects

With prototype approval, we initiate mass production on our automated CNC production lines, integrating lean manufacturing principles and real-time quality monitoring. Each component is machined under strict environmental controls, with tool wear compensation and in-process gauging to maintain tolerances down to ±0.005 mm. Our production cells operate under a closed-loop feedback system, where data from inspection devices automatically adjusts machining parameters to prevent deviations. Every batch is accompanied by full material certification, first-article inspection reports (FAIR), and batch traceability logs. Our quality management system is ISO 9001-certified, and we enforce a zero-defect culture through continuous operator training, Six Sigma methodologies, and 100% final inspection for critical features.

Production Specifications

| Parameter | Capability |

|---|---|

| Materials | Aluminum, Stainless Steel, Titanium, Brass, Copper, Alloy Steel |

| Tolerances | ±0.005 mm (standard), ±0.002 mm (tight) |

| Surface Finish | Ra 0.8 µm (standard), down to Ra 0.2 µm |

| Max Part Size | 1200 x 800 x 600 mm |

| CNC Machines | 3-axis to 5-axis, Swiss-type, Turning Centers |

| Lead Time (Prototype) | 7–10 working days |

| Lead Time (Mass Production) | 15–25 working days (volume-dependent) |

| Quality Standards | ISO 9001, GD&T, AS9100 (aerospace available) |

This seamless integration of design, prototyping, and high-volume production ensures every component meets the highest standards of precision, reliability, and consistency—delivering excellence on every order.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Metal Manufacturing Excellence

When your application demands micron-level accuracy, material integrity under extreme conditions, or complex geometries that defy conventional machining, Wuxi Lead Precision Machinery delivers engineered certainty. As your dedicated manufacturing partner, we merge 20+ years of aerospace and medical-grade CNC expertise with cutting-edge multi-axis technology to transform your most demanding designs into flawless physical realities. Our facility operates under ISO 9001:2015 and AS9100D certifications, ensuring every component meets stringent global quality benchmarks through rigorous in-process inspection and final validation via Zeiss CMM systems. We do not merely produce parts—we guarantee performance-critical solutions backed by full material traceability and NADCAP-accredited processes.

Our technical capabilities are engineered for your highest-stakes projects. The table below summarizes core specifications achievable across aluminum, titanium, Inconel, stainless steel, and exotic alloys:

| Capability | Specification Range |

|---|---|

| Tolerance Control | ±0.005 mm (±0.0002″) |

| Surface Finish | Ra 0.2 µm to 3.2 µm |

| Max Work Envelope | 1,200 x 800 x 750 mm |

| Material Thickness Range | 0.5 mm to 150 mm |

| Lead Time (Prototype) | 10–15 business days |

| Lead Time (Production) | 20–30 business days |

| Quality Validation | Full CMM reporting + First Article Inspection |

This precision is not incidental. Our team of senior CNC engineers collaborates directly with your design staff during DFM analysis to eliminate manufacturability risks before metal is cut. We deploy 5-axis milling, Swiss-type turning, and wire EDM with sub-micron repeatability—supported by real-time thermal compensation systems that maintain accuracy across extended production runs. When your project requires hermetic sealing, biocompatible finishes, or fatigue-resistant microstructures, our material science specialists optimize parameters to exceed ASTM and ISO performance criteria.

Choosing Lead Precision means aligning with a partner invested in your long-term success. We absorb the complexity of precision manufacturing so you can focus on innovation. Our responsive engineering team provides actionable feedback within 72 hours of receiving CAD data, while dedicated project managers ensure seamless communication from RFQ to delivery. For industries where failure is not an option—from satellite propulsion systems to implantable medical devices—we deliver documented reliability that protects your reputation and accelerates time-to-market.

Initiate your precision manufacturing partnership today. Email [email protected] with your project specifications and engineering requirements. Our technical sales engineers will respond within one business day with a detailed capability assessment, feasibility analysis, and formal quotation. Do not compromise on critical components. Trust Wuxi Lead Precision Machinery to execute with the exacting standards your application demands. Your next breakthrough begins with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.