Technical Contents

Engineering Guide: Pp Injection Molding

Engineering Insight: Precision in PP Injection Molding for Demanding Industrial Applications

Polypropylene (PP) injection molding is a cornerstone process in modern custom metal and plastic component manufacturing, particularly where chemical resistance, thermal stability, and mechanical durability are critical. At Wuxi Lead Precision Machinery, we recognize that the performance of PP-molded parts is not solely determined by material selection—engineering precision at every stage of the injection molding process is paramount. Our decades of experience in high-tolerance manufacturing for sectors including Olympic-standard equipment and military-grade systems underscore the non-negotiable role of precision in achieving consistent, reliable outcomes.

In PP injection molding, even minor deviations in mold design, temperature control, or injection pressure can result in warping, sink marks, or dimensional inaccuracies—failures that are unacceptable in mission-critical applications. The semi-crystalline nature of polypropylene demands exact control over cooling rates and mold geometry to ensure uniform shrinkage and structural integrity. At Lead Precision, we employ closed-loop monitoring systems, CNC-machined steel molds with micron-level tolerances, and real-time process validation to maintain repeatability across production runs. This level of control is what enables our components to meet ISO 9001 and MIL-STD-810 specifications, where failure is not an option.

Our engineering team integrates finite element analysis (FEA) and mold flow simulation during the design phase to predict material behavior and optimize gate placement, venting, and cooling channels. This proactive approach minimizes trial-and-error, reduces waste, and accelerates time-to-market—all while ensuring that the final part meets exact dimensional and functional requirements. Whether producing lightweight housings for defense electronics or corrosion-resistant manifolds for industrial fluid systems, our PP injection molding process is built around precision as a foundational principle.

Furthermore, our facility’s integration of custom metal manufacturing with polymer processing allows for hybrid component solutions—such as overmolded metal inserts or thermally managed composite housings—where alignment between metallic and polymeric elements must be maintained within tight tolerances. This synergy between metal and plastic processing capabilities sets Wuxi Lead apart in the high-end manufacturing landscape.

The following table outlines key process parameters and capabilities for PP injection molding at Wuxi Lead Precision Machinery:

| Parameter | Specification |

|---|---|

| Material | Homopolymer and copolymer polypropylene |

| Molding Tonnage Range | 50–1,200 tons |

| Typical Tolerance | ±0.05 mm (standard), ±0.02 mm (high precision) |

| Mold Steel Types | P20, 718H, S136, 2344 (stainless & hardened) |

| Surface Finish Options | SPI A1, A2, B1, B2, textured, custom coatings |

| Secondary Operations | CNC trimming, ultrasonic welding, metrology |

| Quality Standards | ISO 9001, ISO 13485, MIL-STD-810 compliant |

Precision in PP injection molding is not an incremental advantage—it is the defining factor in performance, reliability, and compliance. At Wuxi Lead Precision Machinery, our engineering rigor, advanced tooling, and proven track record in elite manufacturing environments ensure that every component we produce meets the highest standards of quality and consistency.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing for Demanding Applications

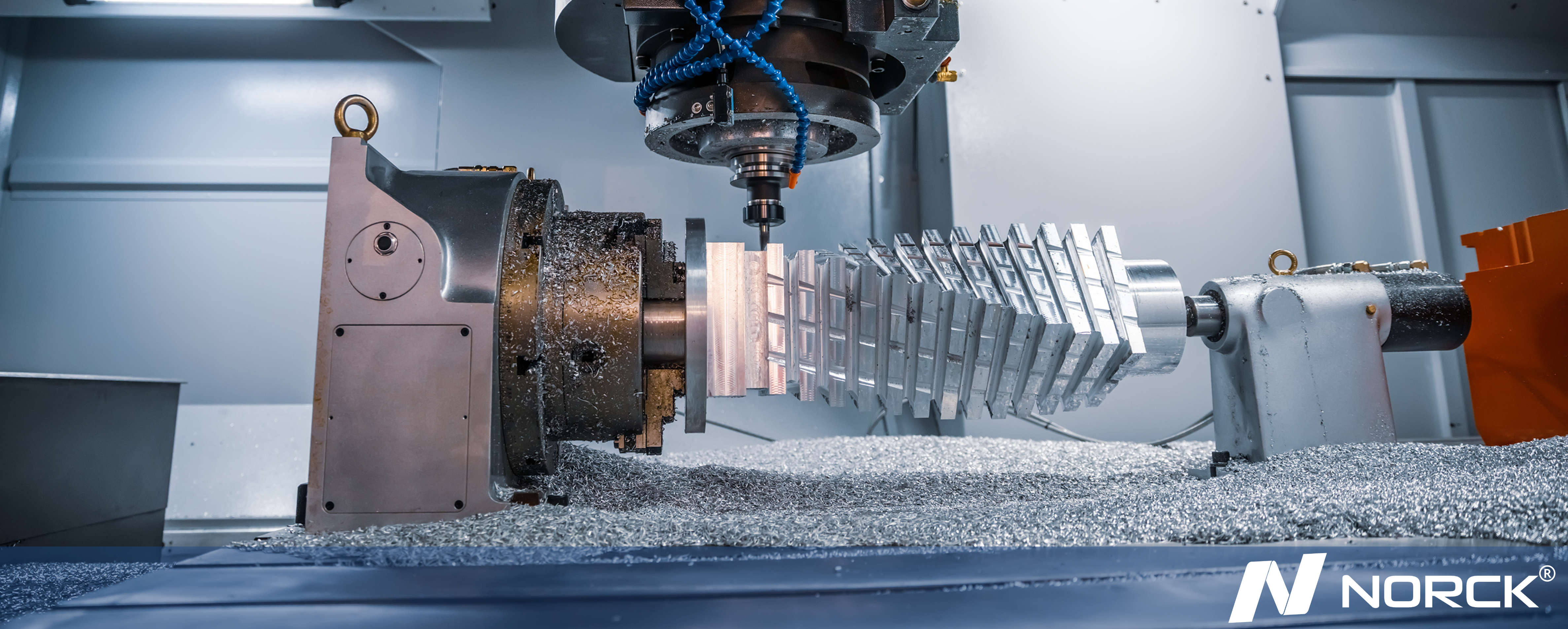

Wuxi Lead Precision Machinery specializes in high-precision custom metal manufacturing, leveraging advanced CNC technology to deliver components meeting the most stringent industrial requirements. It is critical to clarify a common point of confusion: while polypropylene (PP) injection molding is a plastic manufacturing process, our core expertise and equipment are dedicated to metal machining. We do not produce plastic injection molded parts; our focus is on creating complex, high-tolerance metal components essential for sectors like aerospace, medical devices, and advanced automation. Our capabilities are built around state-of-the-art 5-axis CNC machining centers, which provide the foundation for exceptional geometric complexity and surface finish on challenging materials including aluminum alloys, stainless steels, titanium, and high-temperature superalloys.

The integration of 5-axis simultaneous machining allows us to produce intricate features—such as undercuts, deep cavities, and organic contours—in a single setup. This eliminates cumulative errors from multiple fixturing operations, significantly improving part accuracy and repeatability while reducing lead times. Our Haas, DMG MORI, and Makino 5-axis platforms are maintained to OEM specifications and operated by certified engineers with deep process knowledge, ensuring optimal material removal rates and surface integrity for critical applications. Every component undergoes rigorous quality control protocols, with Coordinate Measuring Machine (CMM) inspection being non-negotiable for critical dimensions. Our Zeiss and Hexagon GLOBAL S CMMs provide full 3D verification against CAD models, generating comprehensive inspection reports traceable to NIST standards. This data-driven QC approach guarantees dimensional compliance and provides full transparency for our clients’ quality documentation needs.

Achieving and verifying tight tolerances is central to our value proposition. The table below outlines our standard and precision machining capabilities for milled and turned metal components, reflecting achievable results under controlled production conditions for typical geometries and materials. Tolerances are always qualified by part complexity, material stability, and feature size.

| Tolerance Class | Linear Dimensions (mm) | Linear Dimensions (in) | Geometric Tolerances (GD&T) | Surface Roughness (Ra) |

|---|---|---|---|---|

| Standard Production | ±0.05 mm | ±0.002 in | ±0.1 mm profile | 1.6 – 3.2 µm (63 – 125 µin) |

| Precision Machining | ±0.01 mm | ±0.0004 in | ±0.025 mm position/profile | 0.8 – 1.6 µm (32 – 63 µin) |

| Ultra-Precision | ±0.005 mm | ±0.0002 in | ±0.01 mm true position | 0.4 – 0.8 µm (16 – 32 µin) |

These specifications represent achievable production standards for qualified parts. Actual tolerances for a specific component are determined during engineering review, considering material behavior, thermal effects, and functional requirements. Our process engineers collaborate closely with clients during the Design for Manufacturability (DFM) phase to optimize geometry for precision machining, ensuring the final part meets all performance criteria without unnecessary cost. Wuxi Lead’s commitment to metrology-backed precision ensures that every component shipped exceeds baseline industry standards and fulfills the exacting demands of advanced engineering applications. This integrated capability—from complex 5-axis programming to certified CMM validation—forms the bedrock of our service for global OEMs requiring uncompromising metal part quality.

Material & Finish Options

Material Selection in High-Precision PP Injection Molding Components

When engineering components for polypropylene (PP) injection molding applications, material selection is critical to ensuring long-term durability, dimensional stability, and performance under repeated thermal and mechanical stress. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for high-end mold tooling, where the choice between aluminum, steel, and titanium directly impacts mold life, surface finish quality, and production efficiency.

Aluminum alloys, particularly 7075 and 6061-T6, offer excellent machinability and thermal conductivity, making them ideal for rapid prototyping and low-to-medium volume production runs. Their lightweight nature reduces overall mold weight, facilitating faster mold changes and improved handling. However, aluminum’s lower hardness limits its use in high-wear environments or with abrasive fillers in PP compounds. For applications demanding extended service life, steel—especially pre-hardened P20 or hardened H13 tool steel—provides superior wear resistance and structural integrity. P20 steel is commonly used for medium-run molds due to its balance of toughness and polishability, while H13 excels in high-temperature environments thanks to its excellent thermal fatigue resistance.

Titanium alloys, though less common due to higher cost and machining complexity, are employed in specialized applications requiring extreme corrosion resistance and high strength-to-density ratios. In aggressive chemical environments or when processing halogenated PP formulations, titanium’s inert nature prevents degradation and extends mold service intervals.

Surface finishing, particularly anodizing, plays a pivotal role in enhancing aluminum mold components. Type II (sulfuric acid) anodizing increases surface hardness and wear resistance while providing a porous layer suitable for dyeing and sealing. For critical sealing surfaces or sliding components, Type III (hardcoat) anodizing delivers a dense, abrasion-resistant layer up to 50–75 µm thick, significantly improving longevity in dynamic mold areas. While steel components are typically treated with nitriding or chrome plating, anodizing remains exclusive to aluminum and its alloys.

The following table outlines key mechanical and thermal properties of commonly used materials in PP injection mold manufacturing:

| Material | Tensile Strength (MPa) | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Mold Life (Cycles) | Common Use Case |

|---|---|---|---|---|---|

| 7075 Aluminum | 570 | 15–20 HB | 130 | 10,000–50,000 | Prototyping, low-volume runs |

| 6061-T6 Aluminum | 310 | 10–15 HB | 167 | 10,000–30,000 | Jigs, fixtures, cooling inserts |

| P20 Steel | 1,100 | 28–32 HRC | 30 | 100,000–500,000 | Medium-run production molds |

| H13 Steel | 1,500 | 48–52 HRC | 35 | 500,000–1,000,000+ | High-volume, high-temp molds |

| Titanium (Ti-6Al-4V) | 900 | 36 HRC | 7 | 500,000+ (corrosive env.) | Specialized, corrosive PP processing |

Material and finish selection must be aligned with production volume, part geometry, and polymer characteristics. At Wuxi Lead Precision Machinery, our engineering team supports clients in optimizing these parameters to achieve maximum ROI in PP injection molding operations.

Manufacturing Process & QC

Precision PP Injection Molding: From Concept to Zero-Defect Production

Polypropylene (PP) injection molding remains a cornerstone for demanding industrial applications requiring chemical resistance, fatigue strength, and cost efficiency. At Wuxi Lead Precision Machinery, we execute a rigorously controlled process ensuring every component meets exacting specifications from initial concept through high-volume manufacturing. Our methodology eliminates defects at the source, not through final inspection.

The journey begins with collaborative design engineering. Our team integrates deep material science knowledge with advanced Moldflow simulation software during the Design for Manufacturing (DFM) phase. We meticulously analyze part geometry, gate placement, cooling channel design, and material flow characteristics specific to the chosen PP grade. This proactive analysis identifies potential sinks, warpage, or knit lines before tooling commences, optimizing the design for manufacturability and inherent quality. Close client partnership at this stage is non-negotiable for success.

Prototyping transitions validated designs into physical reality under production-intent conditions. Utilizing CNC-machined aluminum or soft steel molds on our precision Allrounder injection presses, we produce functional prototypes mirroring the final part’s properties. This stage validates the DFM analysis, confirms dimensional accuracy against CAD models, and allows rigorous functional and environmental testing. Crucially, it provides the data to fine-tune process parameters and verify the mold’s capability to consistently produce within tolerance, significantly de-risking full-scale production.

Mass production leverages our zero-defect philosophy through integrated process control. Production-grade molds, crafted from hardened tool steels using our in-house 5-axis CNC capabilities, are mounted on state-of-the-art electric or hybrid injection molding machines. Real-time monitoring of critical parameters is mandatory. Every shot is tracked against predefined windows for melt temperature, injection pressure, pack pressure, cooling time, and clamp force. Statistical Process Control (SPC) systems instantly flag deviations, triggering automatic corrective actions or halting production to prevent non-conforming parts from progressing. Automated vision inspection systems provide 100% surface defect screening on critical features, while in-process metrology ensures dimensional integrity.

This closed-loop system, combining superior tooling, precise machine control, and continuous monitoring, is the foundation of our zero-defect commitment. It transforms quality from an outcome into an inherent characteristic of the manufacturing process itself. The table below outlines key process parameters essential for high-integrity PP components.

| Critical Parameter | Typical Range for PP | Control Tolerance | Measurement Method |

|---|---|---|---|

| Melt Temperature | 200°C – 270°C | ± 3°C | Barrel Thermocouples |

| Injection Pressure | 70 – 150 MPa | ± 2 MPa | Hydraulic/Pneumatic Sensors |

| Pack Pressure | 40 – 80% of Inj. | ± 1.5 MPa | Integrated Machine Sensors |

| Cooling Time | 15 – 60 seconds | ± 0.5 seconds | Machine Timer/SPC |

| Mold Temperature | 20°C – 80°C | ± 1.5°C | Thermocouples in Mold |

| Dimensional Tolerance (Typical) | – | ISO 2768-mK | CMM / Optical Comparator |

Wuxi Lead Precision Machinery delivers more than molded parts; we deliver engineered reliability. Our integrated Design-Prototyping-Production workflow, governed by uncompromising process discipline and advanced metrology, ensures your PP components perform flawlessly in the most challenging industrial environments, batch after batch.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced PP Injection Molding Solutions

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal manufacturing solutions tailored to the demanding requirements of modern industrial applications. As a trusted leader in the field, we combine advanced engineering, state-of-the-art CNC technology, and deep expertise in polypropylene (PP) injection molding to provide end-to-end manufacturing services that exceed expectations. Whether you are developing complex automotive components, medical devices, or industrial enclosures, our team ensures every product meets the highest standards of accuracy, durability, and repeatability.

Our integrated manufacturing ecosystem supports clients from concept to production, offering design optimization, mold development, material selection, and full-scale production runs. With a focus on PP injection molding, we leverage high-performance machinery and real-time process monitoring to maintain tight tolerances and consistent material properties. Our facility is equipped with advanced temperature and pressure control systems, ensuring optimal flow and minimal warpage—critical for achieving dimensionally stable parts in high-volume production.

We understand that every client has unique performance and regulatory requirements. That’s why we offer fully customizable solutions, including multi-cavity molds, insert molding, and overmolding capabilities. Our engineering team works closely with your design staff to refine part geometry, select the appropriate grade of polypropylene, and validate prototypes through rigorous testing protocols. This collaborative approach minimizes time-to-market and reduces development costs.

Our commitment to quality is reinforced by ISO 9001 certification and a comprehensive in-house quality control lab equipped with CMMs, optical comparators, and material testing instruments. Every component produced undergoes strict inspection to ensure compliance with international standards and customer-specific specifications.

Below are key technical specifications of our PP injection molding capabilities:

| Specification | Detail |

|---|---|

| Clamping Force Range | 80 to 1,200 tons |

| Shot Weight (Maximum) | Up to 2,500 grams |

| Tolerance | ±0.02 mm |

| Mold Accuracy | ±0.01 mm |

| Production Capacity | Up to 5 million parts annually |

| Material Compatibility | Homopolymer, copolymer, glass-filled, and flame-retardant PP grades |

| Secondary Operations | CNC trimming, ultrasonic welding, labeling, packaging |

Partnering with Wuxi Lead Precision Machinery means gaining a strategic manufacturing ally with proven expertise in high-integrity PP injection molding. We serve global clients across Europe, North America, and Southeast Asia, delivering on-time, high-quality components with responsive customer support.

To discuss your next project or request a detailed quotation, contact us today at [email protected]. Our engineering team is ready to assist with design reviews, material recommendations, and production planning—ensuring your vision becomes a precision-engineered reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.