Technical Contents

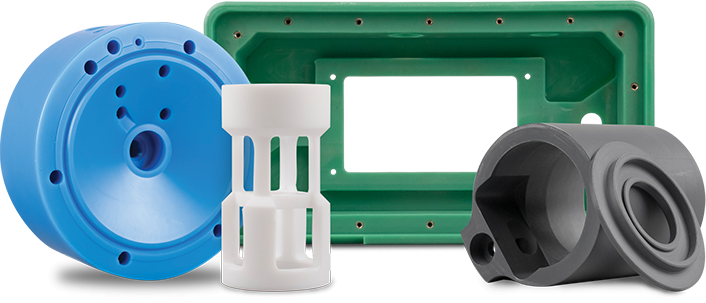

Engineering Guide: Plastic Processing Company

Engineering Insight: Precision as the Foundation of Advanced Plastic Processing

In the realm of high-performance plastic component manufacturing, precision transcends mere specification; it is the critical determinant of functional integrity, assembly success, and end-product longevity. Plastic materials present unique engineering challenges distinct from metals, including significant thermal expansion coefficients, sensitivity to residual stress, and variable flow characteristics during molding or machining. Even micron-level deviations in critical dimensions can trigger catastrophic part failure under operational loads, accelerate wear in moving assemblies, or compromise sealing surfaces. For industries demanding reliability—medical devices, aerospace fluid systems, or semiconductor handling—the cost of imprecise components extends far beyond scrap rates, impacting brand reputation and regulatory compliance. Achieving true precision requires not only advanced machinery but a deep understanding of polymer behavior integrated into every process phase, from material selection and toolpath generation to environmental control during machining.

Wuxi Lead Precision Machinery addresses these complexities through a systems engineering approach honed over 15 years of specializing in mission-critical metal and polymer components. Our CNC machining centers operate within ISO 10531 Class 1 environmental chambers, maintaining temperature stability at ±0.5°C to counteract plastic’s thermal sensitivity. We implement adaptive machining strategies that dynamically adjust feed rates and spindle loads based on real-time material feedback, minimizing internal stresses that cause warpage post-machining. This methodology is rigorously validated through in-process metrology using calibrated CMMs and optical comparators, ensuring conformance before parts leave the production floor.

The table below illustrates the precision benchmarks achievable for engineered plastics like PEEK, PPSU, and Ultem compared to standard industry practices:

Precision Requirements Comparison for Engineered Plastics

| Parameter | Standard Industry Tolerance | Wuxi Lead Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimension | ±0.05 mm | ±0.005 mm | CMM (ISO 10360-2) |

| Geometric Form | ±0.1 mm | ±0.01 mm | Optical Comparator |

| Surface Roughness | Ra 1.6 µm | Ra 0.2 µm | Profilometer (ISO 4287) |

| Hole Concentricity | ±0.03 mm | ±0.003 mm | CMM (ISO 1101) |

Our capability to consistently meet these stringent tolerances is not theoretical. Empirical evidence stems from documented production for applications where failure is non-negotiable. We supplied precision-machined polymer components for the hydraulic control systems of the Beijing 2022 Winter Olympics snowmaking infrastructure, operating reliably at -35°C. Similarly, our military-grade PEEK manifolds, featuring complex internal geometries held to ±0.008 mm, are deployed in naval propulsion systems where saltwater corrosion resistance and dimensional stability are paramount. These projects demanded zero-defect delivery under rigorous AS9100 and MIL-STD-883 protocols—standards we treat as baseline requirements.

For plastic processing companies targeting high-value markets, partnering with a manufacturer possessing this level of precision mastery transforms potential vulnerabilities into competitive advantages. It enables the production of lighter, more complex polymer components that replace metals without sacrificing performance. At Wuxi Lead Precision Machinery, we engineer not just parts, but the confidence that every component will perform exactly as designed, in the most demanding environments. This is the tangible value of true precision engineering.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the demanding requirements of high-performance industries, including automotive, aerospace, medical, and industrial equipment. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling the production of complex, high-precision components with superior surface finishes and geometric accuracy. Our machining centers operate with simultaneous multi-axis movement, allowing for intricate contours, deep cavities, and compound angles that are unattainable with conventional 3-axis systems. This technology significantly reduces setup times, improves part consistency, and supports the efficient production of both prototypes and high-volume runs.

All machining operations are supported by a rigorous quality control framework, anchored by Coordinate Measuring Machine (CMM) inspection. Our CMM systems provide non-contact and tactile measurement with micron-level precision, ensuring that every component conforms to the original engineering specifications. Full first-article inspection reports (FAIR) and production batch certifications are available upon request, supporting traceability and compliance with ISO 9001 and IATF 16949 standards. In addition to CMM, our quality assurance process includes in-process inspections, surface roughness testing, and material verification to guarantee reliability across all deliverables.

Our facility is equipped with a range of high-torque, high-speed 5-axis CNC machines capable of machining a wide array of metals, including aluminum alloys, stainless steel, titanium, brass, and specialty alloys. We support tight-tolerance requirements for critical sealing surfaces, bearing fits, and mating interfaces commonly found in plastic processing equipment such as extruder barrels, feed zones, and injection manifolds. With extensive experience in custom part fabrication, we collaborate closely with engineering teams to optimize designs for manufacturability, reducing lead times and minimizing material waste.

The following table outlines the standard technical specifications and achievable tolerances for our 5-axis CNC machining process:

| Parameter | Specification |

|---|---|

| Maximum Work Envelope | 1200 mm × 800 mm × 750 mm |

| Spindle Speed | Up to 24,000 rpm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Linear Tolerance (per ISO 2768) | ±0.05 mm (m), ±0.02 mm (fine) |

| Geometric Tolerance (GD&T) | ±0.01 mm (typical) |

| Surface Roughness (Ra) | As low as 0.4 µm (polished finish available) |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Brass, PEEK, Delrin (for hybrid assemblies) |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with disciplined quality assurance to deliver components that meet the exacting demands of modern plastic processing systems. Our technical capabilities ensure dimensional integrity, long service life, and seamless integration into complex machinery.

Material & Finish Options

Material Selection for Hybrid Plastic-Metal Manufacturing Systems

Selecting optimal metals for integration with plastic components demands rigorous evaluation of mechanical behavior thermal properties and environmental resistance. At Wuxi Lead Precision Machinery we observe plastic processing companies frequently underestimate metal-plastic interface challenges leading to premature assembly failure. Aluminum steel and titanium each present distinct advantages but require alignment with your specific operational parameters including load cycles temperature exposure and chemical contact.

Aluminum 6061-T6 remains the dominant choice for structural frames and mold bases due to its exceptional strength-to-weight ratio and thermal conductivity. Its machinability reduces production lead times by 30% compared to steel making it ideal for high-volume plastic molding equipment. However aluminum lacks the wear resistance required for high-abrasion zones. Steel alloys like 304 stainless provide superior hardness and dimensional stability under heavy loads but introduce weight penalties and corrosion vulnerabilities in chloride-rich environments common in medical or marine plastic processing. Titanium Ti-6Al-4V delivers unparalleled corrosion resistance and strength at elevated temperatures yet commands a 4x material cost versus aluminum necessitating strict justification for aerospace or biomedical applications where plastic-metal biocompatibility is critical.

Anodizing stands as the essential surface treatment for aluminum components interfacing with plastics. Unlike painted finishes anodized layers bond metallurgically with the substrate preventing flaking that could contaminate plastic extrusion or injection streams. Type II sulfuric acid anodizing (5-25μm thickness) offers balanced corrosion resistance for general industrial use while Type III hardcoat anodizing (50+μm) withstands abrasive plastic pellets in hopper systems. Crucially anodizing is exclusive to aluminum—steel requires passivation or electropolishing and titanium needs specialized oxide layering neither of which achieves comparable wear resistance for plastic contact surfaces.

Our engineering team emphasizes validating material-chemical compatibility early. PVC processing releases hydrochloric acid accelerating aluminum corrosion by 200% without proper anodizing. Below are key comparative metrics for common alloys:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Key Applications in Plastic Processing |

|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | Moderate (Anodized) | Mold bases conveyor frames extrusion guides |

| Steel 304 | 8.0 | 515 | Low (Passivated) | High-load platens hydraulic components |

| Titanium Gr5 | 4.4 | 900 | Exceptional | Medical implant molds chemical processing parts |

Material selection directly impacts your plastic system’s lifecycle cost. We recommend prototyping critical metal-plastic interfaces with anodized aluminum for 80% of applications where weight reduction and thermal management outweigh extreme wear demands. For specialized requirements contact our application engineers to conduct joint failure mode analysis—we provide material certification and anodizing validation reports meeting ISO 9001:2015 standards.

Manufacturing Process & QC

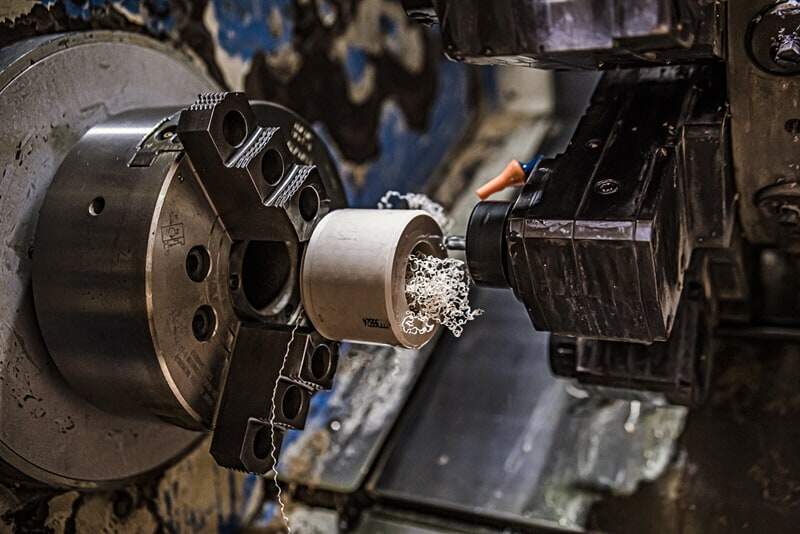

At Wuxi Lead Precision Machinery, our custom metal manufacturing process is engineered to deliver precision, consistency, and zero-defect performance for high-demand applications in the plastic processing industry. Every component we produce follows a rigorously controlled workflow that spans from initial design to prototyping and full-scale mass production. This structured approach ensures that every part meets exacting technical standards and performs reliably in real-world operational environments.

The process begins with collaborative design engineering. Our team works closely with clients to analyze functional requirements, environmental conditions, and integration needs within plastic processing systems. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we develop optimized 3D models that balance performance, durability, and manufacturability. Design validation includes thermal, stress, and wear simulations to preemptively identify potential failure points, ensuring robustness before any metal is cut.

Once the design is finalized, we proceed to precision prototyping. Using CNC milling, turning, and wire EDM technologies, we fabricate functional prototypes from the intended production-grade materials. These prototypes undergo comprehensive in-house testing, including dimensional inspection via coordinate measuring machines (CMM), surface finish analysis, and operational trials under simulated processing conditions. Client feedback is integrated at this stage, allowing for rapid iteration and refinement. This phase is critical to verifying form, fit, and function, minimizing risk during scale-up.

With prototype approval, we transition to mass production using automated CNC machining cells, monitored in real time by integrated quality control systems. Our production floor operates under ISO 9001-certified protocols, with every工序 (process step) documented and traceable. In-process inspections occur at defined intervals, while statistical process control (SPC) ensures dimensional stability across batches. We employ a zero-defect philosophy, supported by root cause analysis and corrective action procedures for any non-conformance.

All finished components undergo final inspection against the original technical specifications, including material certification, geometric dimensioning and tolerancing (GD&T) verification, and surface treatment validation. Only parts that pass 100% inspection criteria are released for shipment.

The table below outlines key capabilities and specifications across our production workflow.

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.2 µm |

| Materials Processed | Stainless Steel, Tool Steel, Aluminum Alloys, Brass, Titanium |

| Max Workpiece Size | 800 × 600 × 500 mm |

| Prototyping Lead Time | 7–10 working days |

| Production Capacity | Up to 50,000 units/month |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical-grade options) |

Our end-to-end control over the production process enables Wuxi Lead Precision Machinery to deliver custom metal components that meet the exacting demands of modern plastic processing equipment—on time, every time.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Metal Solutions in Plastic Processing

In high-precision plastic processing, the performance of your metal components directly dictates the quality, efficiency, and longevity of your final products. Injection molds, extrusion dies, and precision tooling demand sub-micron repeatability, exceptional thermal stability, and flawless surface integrity—requirements only achievable through advanced metal manufacturing expertise. Wuxi Lead Precision Machinery specializes in delivering custom CNC-machined metal solutions engineered explicitly for the rigorous demands of the plastic processing industry. We bridge the gap between theoretical design and production-ready reality, ensuring your metal components withstand cyclic stresses, corrosive environments, and high-volume output without compromise.

Our integrated approach combines decades of metallurgical knowledge with state-of-the-art 5-axis milling, turning, and grinding capabilities. Every component undergoes rigorous in-process metrology using Zeiss CMMs and laser interferometers, guaranteeing adherence to tolerances as tight as ±1.0μm. We prioritize material science—selecting and treating alloys like H13, S136, and beryllium-copper to optimize hardness, polishability, and resistance to wear in plastic molding applications. This precision eliminates costly downtime, reduces scrap rates, and extends tool life, directly improving your operational ROI.

The following specifications reflect the baseline capabilities we deploy for critical plastic processing tooling:

| Specification | Performance Value | Relevance to Plastic Processing |

|---|---|---|

| Spindle Speed Range | 20 – 30,000 RPM | Enables high-speed finishing for mirror-polish cavity surfaces |

| Positioning Accuracy | ±1.0μm (ISO 230-2) | Ensures precise alignment of mold cores/cavities |

| Max Work Envelope | 1,200 x 800 x 750 mm | Accommodates large-scale extrusion dies and multi-cavity molds |

| Surface Roughness (Ra) | 0.05μm (post-polishing) | Critical for defect-free part ejection and aesthetics |

| Control System | Siemens 840D Solutionline | Real-time thermal compensation for dimensional stability |

Choosing Lead Precision means partnering with engineers who speak the language of polymers and metals fluently. We collaborate from the initial design phase, offering DFM insights to prevent sink marks, warpage, or premature wear—transforming your engineering challenges into robust, production-proven solutions. Our facility in Wuxi operates under ISO 9001:2015 certification, with dedicated project managers providing transparent communication and on-time delivery for global supply chains.

Do not let substandard metal components undermine your plastic processing excellence. Contact our engineering team today to discuss how Lead Precision can elevate your tooling performance. Send your project specifications, CAD files, or material requirements to [email protected]. We respond to all technical inquiries within 24 business hours, providing actionable feedback and a detailed quotation tailored to your production goals. Partner with certainty—where precision metal manufacturing meets the uncompromising standards of modern plastic processing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.