Technical Contents

Engineering Guide: Cnc Wire Cut Electrical Discharge Machine

Engineering Insight Precision as the Non-Negotiable Core of CNC Wire Cut EDM

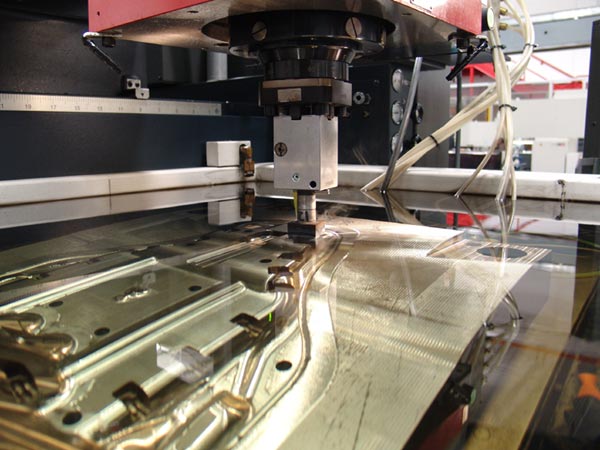

In the realm of ultra-precision manufacturing, the CNC wire cut electrical discharge machine (WEDM) transcends its role as a mere production tool. It becomes the definitive arbiter of dimensional integrity where conventional machining reaches its physical limits. The fundamental principle of WEDM—material removal via controlled electrical sparks between a moving wire electrode and the workpiece—eliminates mechanical cutting forces. This inherent characteristic is paramount. It allows for the machining of hardened alloys, exotic superalloys, and delicate geometries with micron-level accuracy, free from the deflection, chatter, or thermal distortion that plagues traditional milling or turning. For industries like aerospace turbine blade production, medical implant fabrication, and semiconductor tooling, where tolerances routinely reside in the single-digit micron range, this precision is not merely desirable; it is an absolute prerequisite for functional performance and safety. The wire EDM process achieves this by meticulously managing the spark gap, dielectric fluid dynamics, and wire tension, transforming electrical energy into geometric perfection with unparalleled repeatability.

Wuxi Lead Precision Machinery operates at this pinnacle of precision engineering. Our decades of dedicated WEDM development and application expertise are rigorously validated through mission-critical projects. We have engineered components meeting the exacting standards required for Olympic Games infrastructure, where timing systems and structural elements demand flawless dimensional stability under extreme conditions. Furthermore, our machines and processes are trusted within defense aerospace supply chains, producing parts where failure is inconceivable. This experience is not incidental; it is the direct result of an obsessive focus on the foundational elements that govern WEDM accuracy: exceptional machine rigidity, advanced thermal compensation systems, ultra-stable power generators, and sophisticated closed-loop control algorithms. We understand that true precision in wire EDM extends beyond the stated positioning accuracy; it encompasses surface integrity, corner fidelity, and the ability to maintain tolerances over extended production runs, regardless of material hardness.

The performance metrics of a high-end WEDM system are the tangible expression of this engineering commitment. At Wuxi Lead Precision Machinery, our flagship LPW-500 series embodies this philosophy, delivering specifications engineered for the most demanding applications.

| Key Performance Parameter | Specification (LPW-500 Series) | Industry Standard Relevance |

|---|---|---|

| Positioning Accuracy (ISO 230-2) | ± 0.002 mm | Critical for complex 3D profiles |

| Repeatability (ISO 230-2) | ± 0.001 mm | Ensures batch consistency |

| Maximum Taper Angle | ± 30° over 100 mm height | Enables intricate core/cavity work |

| Surface Roughness (Ra) | 0.1 – 1.6 μm (adjustable) | Meets stringent aerospace/medical |

| Core Material Stability | Zero-thermal-growth granite base | Eliminates drift during operation |

Achieving sub-micron tolerances consistently requires more than just machine capability; it demands profound process understanding. Our engineering team leverages extensive material science knowledge and proprietary machining strategies honed through Olympic and defense projects. We recognize that factors like workpiece fixturing, residual stress relief, and dielectric fluid purity are as critical as the machine’s linear scales. This holistic approach ensures that the precision engineered into our machines translates directly into the flawless components our clients require. When the cost of deviation is measured in system failure or patient safety, Wuxi Lead Precision Machinery provides the proven, reliable foundation for success. Precision here is not a feature—it is the uncompromising standard.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in precision CNC machining, leveraging state-of-the-art 5-axis CNC wire cut electrical discharge machining (EDM) technology to meet the most demanding manufacturing requirements. Our equipment portfolio is engineered for high accuracy, repeatability, and surface integrity, enabling the production of complex geometries in hard metals and exotic alloys where traditional machining methods fall short. The integration of 5-axis motion control allows for multi-faceted cutting with a single setup, significantly reducing cycle time while enhancing dimensional consistency and part integrity.

Our wire cut EDM systems utilize a continuously fed brass wire electrode to erode material through precisely controlled electrical discharges, achieving micron-level accuracy without mechanical contact. This non-contact process eliminates tool pressure and vibration, making it ideal for delicate, thin-walled, or highly stressed components. With taper cutting capabilities up to ±30° and the ability to produce intricate internal contours, sharp corners, and fine surface finishes, our machines support applications across aerospace, medical device manufacturing, mold & die, and high-performance automotive sectors.

All operations are supported by a rigorous quality control framework centered on CMM (Coordinate Measuring Machine) inspection. Every component undergoes comprehensive dimensional validation using Zeiss and Hexagon CMM systems, ensuring full compliance with ISO 10360 standards. Our inspection protocols include first-article inspection (FAI), in-process checks, and final certification, with detailed reports available upon request. Data traceability is maintained throughout the production lifecycle, providing customers with full transparency and assurance of quality.

Material versatility is a core strength of our wire cut EDM process. We routinely machine tool steels, tungsten carbide, Inconel, titanium, and other high-hardness alloys with hardness values exceeding 65 HRC. The process is equally effective on pre-hardened materials, eliminating the need for post-machining heat treatment that can distort dimensions.

The following table outlines the key technical specifications and achievable tolerances across our 5-axis CNC wire cut EDM operations:

| Parameter | Specification |

|---|---|

| Axis Configuration | 5-Axis (U, V, X, Y, Z) |

| Wire Diameter Range | 0.1 mm – 0.3 mm |

| Maximum Taper Angle | ±30° per axis (U/V) |

| Positioning Accuracy | ±0.001 mm |

| Repeatability | ±0.0008 mm |

| Surface Roughness (Ra) | 0.15 µm – 1.6 µm (adjustable by finish pass) |

| Minimum Corner Radius | 0.15 mm (dependent on material and height) |

| Material Thickness Range | 1 mm – 400 mm |

| Dimensional Tolerance | ±0.002 mm (standard), ±0.001 mm (tight) |

| Edge Quality | Burr-free, no recast layer (optimized mode) |

Wuxi Lead Precision Machinery combines advanced 5-axis wire EDM technology with disciplined quality assurance to deliver components where precision is non-negotiable. Our technical capabilities are designed to support high-mix, low-volume production and rapid prototyping with the same level of accuracy and reliability.

Material & Finish Options

Material Selection for Precision Wire EDM Applications

Material selection critically impacts wire electrical discharge machining (WEDM) performance, influencing machining speed, surface integrity, dimensional accuracy, and final part functionality. At Wuxi Lead Precision Machinery, our multi-axis wire EDM systems deliver micron-level precision, but optimal results require understanding material-specific interactions with the EDM process. Key considerations include electrical conductivity, thermal properties, hardness, and structural homogeneity. Below is a comparative analysis of common high-performance alloys processed on our Wuxi Lead WEDM platforms.

Aluminum alloys, particularly 6061 and 7075, exhibit high electrical and thermal conductivity. This facilitates efficient material removal and reduces thermal stress during WEDM, enabling faster cutting speeds compared to less conductive materials. However, aluminum’s softness can lead to dross adhesion on the cut surface, requiring precise flushing and parameter optimization. Achieving fine surface finishes (Ra < 0.8 µm) is readily achievable with our adaptive control systems, making aluminum ideal for complex aerospace brackets and fluidic components demanding tight tolerances per ISO 2768-mK.

Tool steels (e.g., D2, A2, 4140) present higher hardness and lower conductivity than aluminum. This necessitates reduced machining speeds to maintain stability and prevent wire breakage. Wuxi Lead’s intelligent power generators dynamically adjust pulse parameters to manage the increased thermal load, ensuring consistent kerf width and minimizing recast layer formation. Critical for dies, molds, and precision tooling, steel components processed on our machines consistently achieve sub-5µm positional accuracy and surface finishes down to Ra 0.4 µm after fine finishing passes.

Titanium alloys (Grade 5 Ti-6Al-4V) pose significant WEDM challenges due to extremely low electrical conductivity and high chemical reactivity at elevated temperatures. Cutting speeds are substantially slower, and meticulous control of dielectric fluid purity and flushing is non-negotiable to prevent arcing and surface oxidation. Our closed-loop filtration systems and low-energy finishing strategies are essential for producing biomedical implants or aerospace fixtures with titanium, achieving required surface integrities without micro-cracking.

Anodizing requires special attention. Never machine anodized parts on a wire EDM. The non-conductive oxide layer disrupts the electrical discharge process, causing severe arcing, dimensional inaccuracy, and surface damage. Anodizing must be performed as a final step after all EDM operations are complete. For components requiring anodized finishes, Wuxi Lead recommends final EDM machining with a slight oversize dimension to accommodate the anodizing layer thickness, typically 10-25 µm for standard Type II anodize.

Material properties directly dictate WEDM strategy. Selecting the appropriate alloy and understanding its EDM behavior is foundational to achieving cost-effective, high-precision results. Consult Wuxi Lead engineering for material-specific process validation.

| Material | Electrical Conductivity (% IACS) | Typical Hardness (HRC) | Key WEDM Considerations |

|---|---|---|---|

| Aluminum 6061 | 40-50 | 15-20 | Fast cutting speed; dross control critical; excellent surface finish potential |

| Steel 4140 (Annealed) | 8-10 | 20-25 | Moderate speed; requires stable parameters; manage recast layer |

| Titanium Grade 5 | 3.0-3.4 | 32-36 | Slow cutting speed; strict dielectric control essential; high oxidation risk |

Manufacturing Process & QC

The production process for a CNC wire cut electrical discharge machine (WEDM) at Wuxi Lead Precision Machinery follows a rigorously controlled sequence designed to achieve zero defects and uphold the highest standards of precision engineering. This process spans three critical phases: Design, Prototyping, and Mass Production, each integrated with advanced quality assurance protocols to ensure reliability, repeatability, and performance excellence.

The Design phase begins with comprehensive analysis of application requirements, material characteristics, and dimensional tolerances. Our engineering team employs advanced CAD/CAM software to develop machine architecture, motion control systems, and dielectric flushing mechanisms. Finite element analysis (FEA) and thermal stability simulations are conducted to optimize structural rigidity and minimize deformation under operational loads. Electrical discharge parameters such as pulse duration, peak current, and servo response are modeled to ensure micron-level cutting accuracy. All design data is reviewed through a cross-functional gate approval system, incorporating input from R&D, quality assurance, and manufacturing operations.

Following design validation, the Prototyping phase commences with the fabrication of a fully functional pilot unit. This prototype is built using the same materials, tooling, and assembly procedures intended for mass production. It undergoes a series of performance and endurance tests, including positional accuracy verification (measured via laser interferometry), surface finish evaluation, and long-duration cutting cycles using hardened tool steels and exotic alloys. Any deviations from target specifications are traced using root cause analysis, and corrective actions are implemented before progression. The prototype is also subjected to environmental stress screening, including temperature cycling and vibration testing, to validate robustness in diverse factory conditions.

Only after successful prototype certification does the process advance to Mass Production. Each machine is assembled on a lean manufacturing line with serialized component tracking and real-time quality data logging. Critical sub-assemblies—including the linear motor-driven axes, tension-controlled wire feed system, and closed-loop dielectric filtration—are calibrated using master gauges and verified against ISO 230-2 standards. In-process inspections are conducted at defined control points, supported by automated vision systems and electrical safety testing. Final validation includes a 72-hour continuous cutting test with statistical process control (SPC) monitoring to confirm dimensional stability and surface integrity.

Throughout all stages, Wuxi Lead enforces a zero-defect philosophy through Six Sigma methodologies, supplier quality management, and full traceability of components. This disciplined approach ensures every CNC wire cut EDM machine delivers consistent, high-precision performance in demanding industrial environments.

| Specification | Value |

|---|---|

| Positioning Accuracy | ±2 μm |

| Repeatability | ±1 μm |

| Maximum Cutting Speed | 400 mm²/min |

| Taper Cutting Capability | ±30° @ 300 mm height |

| Wire Diameter Range | 0.1–0.3 mm |

| Surface Roughness (Ra) | ≤0.8 μm |

| Control System | LeadTec CNC with 15” touchscreen HMI |

| Dielectric Filtration | Dual-stage automatic filtration (1 μm precision) |

| Power Supply Stability | ±0.5% fluctuation tolerance |

Why Choose Wuxi Lead Precision

Elevate Your Precision Manufacturing Partnership

In the demanding realm of ultra-precise component fabrication, selecting a wire EDM partner transcends mere equipment procurement. It demands a strategic alliance grounded in engineering excellence, unwavering reliability, and deep technical collaboration. Wuxi Lead Precision Machinery stands as your committed partner, engineered to transform your most challenging production requirements into tangible competitive advantages. We understand that sub-micron tolerances, complex geometries, and zero-defect deliverables are not aspirations—they are non-negotiable imperatives for leaders in aerospace, medical device manufacturing, and advanced tooling. Our CNC wire cut electrical discharge machines are not simply tools; they are the foundation of a partnership dedicated to your operational success and market leadership.

Our commitment begins with technology engineered for uncompromising performance. Lead Precision machines integrate advanced adaptive control systems, thermal stability management, and proprietary power supply architectures to deliver consistent micron-level accuracy across extended production runs. We prioritize machine rigidity, precision-guided linear motor drives, and intelligent wire tension control to eliminate variables that compromise surface integrity or dimensional fidelity. This focus translates directly to reduced scrap rates, extended electrode life, and accelerated throughput for your critical components. The result is a demonstrable improvement in your cost-per-part and time-to-market metrics.

Core Technical Specifications for Lead Precision Wire EDM Systems

| Specification | Performance Value | Industry Impact |

|---|---|---|

| Positioning Accuracy | ±1.0 µm (ISO 230-2) | Guarantees micron tolerance adherence |

| Repeatability | ±0.5 µm | Ensures batch consistency |

| Maximum Taper Angle | 30° per side | Enables complex core pin & mold cavities |

| Wire Diameter Range | Ø0.02 – Ø0.3 mm | Optimizes speed/surface finish trade-offs |

| Surface Roughness (Ra) | 0.1 – 0.8 µm | Meets stringent aerospace/medical specs |

Partnering with Lead Precision means accessing more than cutting-edge machinery. It means engaging with a team of veteran CNC engineers who speak your language of precision. We provide comprehensive process validation support, application-specific parameter optimization, and proactive maintenance protocols tailored to your unique production environment. Our global service network ensures rapid response times, minimizing downtime and maximizing your machine’s operational lifespan. We invest in understanding your specific challenges—from exotic material machining to multi-axis contouring—because your success is the ultimate measure of our technology’s value.

The next evolution in your precision manufacturing capability starts with a conversation. Do not navigate the complexities of high-tolerance wire EDM alone. Contact our engineering team today to discuss your specific application requirements and discover how Lead Precision machinery can deliver measurable improvements in quality, efficiency, and profitability. Request a detailed technical consultation or schedule an in-depth machine demonstration at our Wuxi facility.

Contact us immediately to initiate your precision transformation.

Email: [email protected]

Let Lead Precision become the strategic partner your most exacting projects demand.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.