Technical Contents

Engineering Guide: Black Stainless Steel Sheet Metal

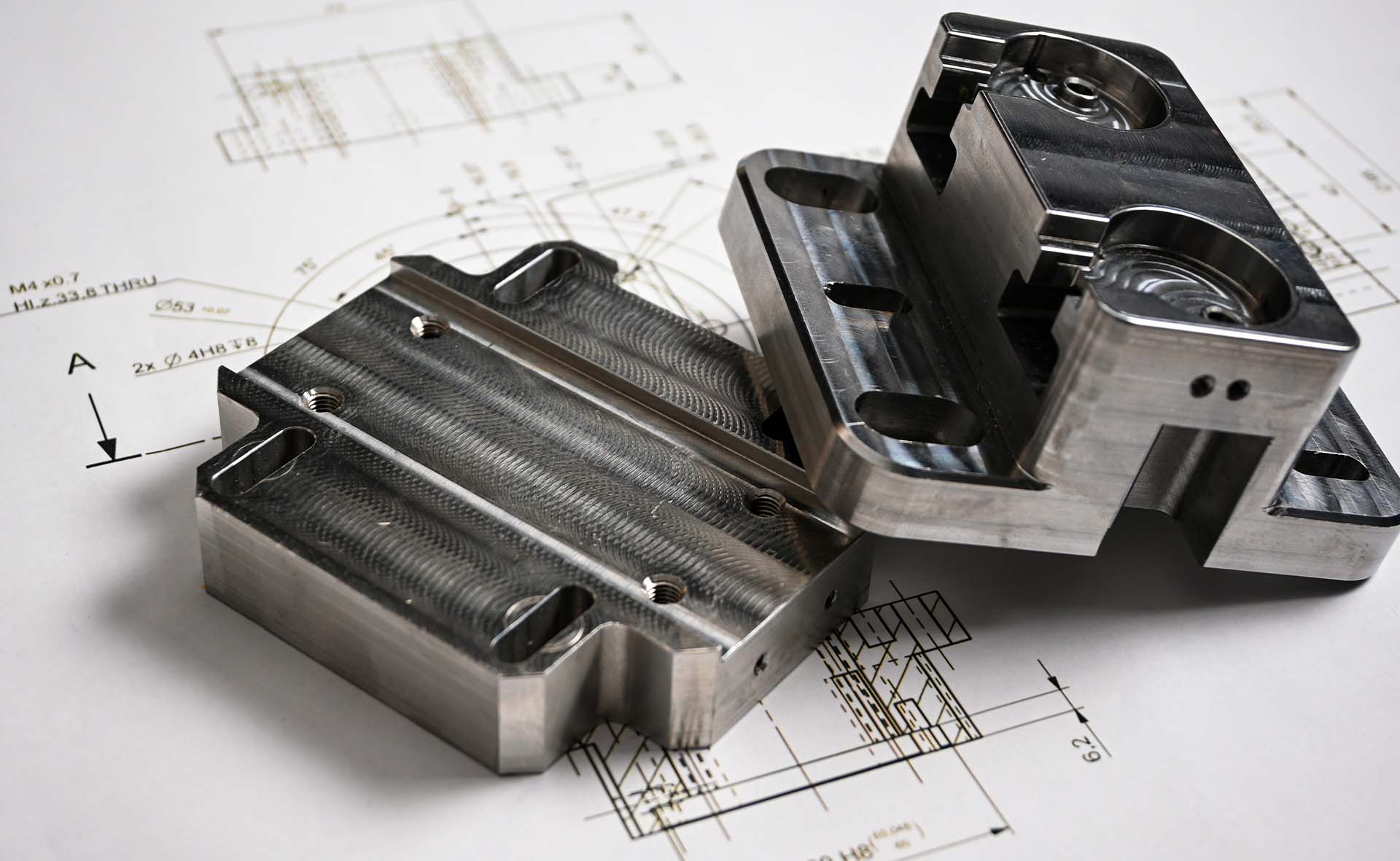

Engineering Insight: The Precision Imperative in Black Stainless Steel Sheet Metal Fabrication

In high-performance industries such as aerospace, defense, and premium architectural design, black stainless steel sheet metal is more than a material choice—it is a statement of engineering intent. The integration of aesthetic sophistication with structural resilience makes black stainless steel a preferred solution where both visual impact and mechanical reliability are non-negotiable. However, the complexity inherent in processing this material demands an uncompromising commitment to precision, a standard that Wuxi Lead Precision Machinery has consistently upheld across decades of advanced manufacturing.

Black stainless steel is typically produced through physical vapor deposition (PVD) coating or high-temperature thermal treatment, resulting in a durable, corrosion-resistant black oxide layer. This surface treatment enhances the material’s resistance to fingerprints, UV degradation, and chemical exposure, making it ideal for exterior cladding, control panels, and high-security enclosures. Yet, the coating process introduces dimensional and thermal sensitivities that require tightly controlled fabrication parameters. Even minor deviations in laser cutting tolerance or bending force can compromise coating integrity, leading to micro-cracking or delamination.

At Wuxi Lead, our engineering protocols are built around micron-level accuracy. Our CNC fiber laser cutting systems operate with ±0.05 mm positional repeatability, ensuring clean, burr-free edges that preserve the coated surface. Precision forming is achieved through adaptive press braking with real-time feedback loops, maintaining angular accuracy within ±0.2 degrees. These capabilities are not theoretical—they have been battle-tested in projects serving Olympic venue construction and military-grade enclosures, where failure is not an option.

Our experience with mission-critical applications has taught us that precision extends beyond machinery. It resides in material handling, fixturing strategy, and post-process inspection. Every black stainless steel component undergoes rigorous flatness and coating thickness verification using non-destructive testing methods, including eddy current and spectrophotometric analysis. This end-to-end control ensures that every part meets both functional and aesthetic specifications.

Wuxi Lead’s track record in high-stakes manufacturing environments underscores our ability to deliver not just components, but engineered confidence. When black stainless steel is specified, it is often because the application demands excellence. We ensure that excellence is realized in every cut, bend, and finish.

Material Specifications: Black Stainless Steel (304/316 Base)

| Property | Value | Test Standard |

|---|---|---|

| Base Material | AISI 304 / 316 Stainless Steel | ASTM A240 |

| Coating Type | PVD TiN-based (Black) | ISO 14577 |

| Coating Thickness | 2.5–3.5 µm | ISO 2360 |

| Hardness (Coating) | 2,200–2,600 HV | ASTM C1327 |

| Adhesion Strength | Class HF1 (Cross-cut Test) | ISO 2409 |

| Salt Spray Resistance | >500 hours (no red rust) | ASTM B117 |

| Tolerance (Laser Cutting) | ±0.05 mm | ISO 2768 |

| Angular Accuracy (Bending) | ±0.2° | ISO 7976-1 |

Precision Specs & Tolerances

Technical Capabilities for Black Stainless Steel Sheet Metal Fabrication

Wuxi Lead Precision Machinery delivers uncompromising precision in black stainless steel sheet metal fabrication, addressing the unique challenges of this specialized material. The black oxide finish—applied via electrolytic or chemical processes—demands meticulous handling to prevent micro-scratches, coating degradation, or thermal distortion during machining. Our integrated 5-axis CNC milling and turning centers eliminate secondary operations by executing complex geometries in a single setup. This reduces part handling, minimizes exposure to contaminants, and preserves the integrity of the black finish. High-speed spindles with adaptive control dynamically adjust feed rates and RPMs to maintain optimal cutting parameters, preventing heat buildup that could discolor or warp thin-gauge sheets. Laser cutting systems utilize nitrogen-assisted processes with tightly controlled kerf widths to avoid edge oxidation, ensuring clean, burr-free profiles without compromising the surface treatment.

Rigorous quality assurance is non-negotiable for black stainless steel components, where dimensional accuracy directly impacts functional performance and aesthetic consistency. Every critical feature undergoes 100% inspection via Zeiss CONTURA CMM systems, calibrated to ISO 17025 standards. Our metrology suite validates geometric dimensioning and tolerancing (GD&T) callouts, surface roughness (Ra ≤ 0.8 µm), and coating thickness uniformity across all axes. Statistical process control (SPC) data is logged in real-time, enabling traceability from raw material lot to finished part. This closed-loop verification ensures compliance with ASTM A480 for stainless steel flat products and client-specific finish requirements, such as ASTM B600 for decontamination.

The following table details achievable tolerances for black stainless steel sheet metal (grades 304/316, thickness 0.5–6.0 mm), reflecting our standard production capabilities under controlled environmental conditions:

| Feature Type | Standard Tolerance | Tight Tolerance Option | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.025 mm | Validated at 20°C ±2°C ambient |

| Hole Diameter | +0.03/-0.00 mm | +0.015/-0.00 mm | Includes countersinks & counterbores |

| Bend Angle | ±0.5° | ±0.25° | For angles ≤ 135°, t ≤ 3.0 mm |

| Positional Tolerance | ±0.08 mm | ±0.04 mm | Relative to primary datum |

| Surface Flatness | 0.1 mm/m² | 0.05 mm/m² | Measured per ISO 2768-mK |

Our end-to-end workflow—from nesting optimization to post-machining passivation—prioritizes finish retention. Deburring is performed using non-marring vibratory finishing with ceramic media, while final cleaning employs ultrasonic systems with pH-neutral solutions to avoid coating etching. This disciplined approach supports mission-critical applications in medical device housings, semiconductor tooling, and luxury automotive trim, where both micron-level precision and flawless aesthetics are mandated. Partner with Wuxi Lead to transform black stainless steel designs into production-ready components, backed by 15 years of aerospace and high-tech manufacturing expertise.

Material & Finish Options

When selecting materials for high-precision sheet metal fabrication, engineers and designers must balance mechanical performance, environmental resistance, and aesthetic requirements. At Wuxi Lead Precision Machinery, we specialize in advanced fabrication of critical materials including aluminum, steel, and titanium—each offering distinct advantages depending on the application. While black stainless steel sheet metal is often requested for its sleek appearance and corrosion resistance, it is typically achieved through surface finishing rather than being a base alloy. Understanding the core materials and compatible finishes ensures optimal performance and longevity in demanding industrial environments.

Aluminum is widely used for its excellent strength-to-weight ratio and natural corrosion resistance. It is ideal for aerospace, transportation, and electronics enclosures where weight savings and thermal conductivity are critical. The material readily accepts anodizing, a controlled electrochemical process that enhances surface hardness and wear resistance while allowing for color customization—including deep black finishes. Type 6061-T6 is a common grade used in precision sheet metal work due to its weldability and dimensional stability.

Steel, particularly cold-rolled steel (CRS) and stainless steel grades such as 304 and 316, remains a staple in industrial enclosures, structural components, and heavy machinery. While standard stainless steel offers inherent corrosion resistance, achieving a black finish requires additional processing. Methods include black oxide coating, PVD (Physical Vapor Deposition), or specialized powder coating. These treatments maintain the material’s durability while providing a modern, low-reflectivity surface suitable for architectural, medical, and high-end equipment applications.

Titanium stands at the premium end of the spectrum, offering exceptional strength-to-density ratio and outstanding resistance to extreme environments, including seawater and high-temperature operations. It is frequently used in aerospace, defense, and medical implant devices. Though more challenging to fabricate, titanium can be treated with thermal oxidation or PVD to produce a black surface without compromising biocompatibility or structural integrity.

Anodizing is most effective on aluminum but is not applicable to steel or titanium in the same way. For ferrous and titanium alloys, alternative surface treatments are required to achieve similar protective and aesthetic outcomes. At Wuxi Lead, we integrate material expertise with advanced finishing technologies to deliver components that meet rigorous functional and design standards.

The following table outlines key properties and finishing compatibility for common sheet metal materials:

| Material | Typical Thickness Range (mm) | Tensile Strength (MPa) | Corrosion Resistance | Compatible Black Finishes |

|---|---|---|---|---|

| Aluminum 6061 | 0.5 – 6.0 | 310 | Moderate to High | Anodizing (black), Powder Coating |

| Stainless 304 | 0.8 – 10.0 | 515 | High | PVD, Black Oxide, Electroplating |

| Stainless 316 | 0.8 – 10.0 | 520 | Very High | PVD, Electropolishing + Coating |

| Titanium Gr2 | 0.5 – 5.0 | 345 | Exceptional | Thermal Oxidation, PVD |

| Cold Rolled Steel | 0.5 – 12.0 | 380 | Low (uncoated) | Powder Coating, Black Oxide, Paint |

Material selection is not solely about mechanical specs—it must align with the environmental exposure, lifecycle demands, and visual requirements of the final product. Wuxi Lead Precision Machinery supports global clients with tailored fabrication and finishing solutions, ensuring every component meets both engineering and design intent.

Manufacturing Process & QC

Precision Black Stainless Steel Fabrication: From Concept to Flawless Production

At Wuxi Lead Precision Machinery, manufacturing black stainless steel sheet metal components demands an uncompromising, integrated process. Standard fabrication approaches fail with this specialized material due to the critical sensitivity of the black oxide or PVD coating to heat, stress, and handling. Our zero-defect methodology begins with rigorous design validation. Engineers utilize advanced CAD/CAM simulation to model laser cutting paths, bending sequences, and welding parameters before any material is touched. This phase specifically addresses thermal management to prevent coating discoloration or micro-cracking, optimizing kerf width for the black surface and ensuring forming radii avoid stress concentrations that compromise the finish. Material certification is non-negotiable; we source only certified 304 or 316L stainless with controlled surface roughness pre-coating to ensure adhesion integrity.

Prototyping is not optional for black stainless steel; it is the essential bridge to mass production success. We fabricate functional prototypes using the exact production-grade coated material and intended process parameters. Every step undergoes meticulous inspection: coating adhesion via cross-hatch testing per ASTM D3359, dimensional verification with CMM against the validated CAD model, and rigorous functional assessment. This phase identifies subtle interactions between the coating process and fabrication stresses that simulation alone cannot predict. Only when the prototype meets all optical, dimensional, and performance criteria – with the black finish intact and uniform – do we approve the final process documentation. This disciplined prototyping eliminates costly errors downstream.

Mass production leverages our integrated zero-defect ecosystem. CNC laser cutting employs specialized parameters: reduced power, optimized gas mixtures (often nitrogen with precise humidity control), and slower traverse speeds to minimize Heat Affected Zone (HAZ) impact on the black surface. Automated bending cells use coated tooling and real-time angle feedback to prevent marking. In-process inspection is continuous. Vision systems monitor cut edge quality and coating integrity inline. Critical dimensions are verified at defined intervals using automated CMMs linked directly to our SPC database. Every component undergoes final 100% visual inspection under controlled lighting to detect any micro-scratches or coating inconsistencies invisible to automated systems. Non-conforming parts are immediately quarantined and root-cause analyzed; they never reach the client. Our closed-loop system ensures process stability and continuous improvement, delivering black stainless steel components where aesthetic perfection meets absolute dimensional precision.

Wuxi Lead Black Stainless Steel Fabrication Capabilities

| Parameter | Specification | Testing Method |

|---|---|---|

| Material Grade | 304/316L (Certified) | Mill Cert + OES Verification |

| Thickness Range | 0.5mm – 6.0mm | Micrometer (Per Lot) |

| Cutting Tolerance | ±0.05mm (Up to 3mm thickness) | CMM Verification |

| Bend Angle Tolerance | ±0.5° | Laser Angle Sensor |

| Surface Roughness (Ra) | ≤ 0.4µm (Post-Coating) | Profilometer (Per Batch) |

| Coating Adhesion | Class 5B (ASTM D3359) | Cross-Hatch Test |

| Dimensional FAI | 100% Prototype, SPC in Production | CMM + Digital Documentation |

Why Choose Wuxi Lead Precision

When sourcing black stainless steel sheet metal for high-performance industrial applications, precision, consistency, and material integrity are non-negotiable. At Wuxi Lead Precision Machinery, we specialize in advanced sheet metal fabrication tailored to the exacting standards of aerospace, medical, automotive, and high-end architectural sectors. Our expertise in processing black stainless steel—known for its corrosion resistance, aesthetic finish, and durability—ensures your components meet both functional and design specifications.

Black stainless steel is more than a visual upgrade; it is an engineered solution. Through advanced PVD (Physical Vapor Deposition) coating or specialized chemical treatments, we deliver a surface that resists fingerprints, UV degradation, and harsh environments—ideal for applications where appearance and performance must coexist. Our in-house CNC punching, laser cutting, bending, and welding capabilities enable seamless transformation of raw black stainless sheet into complex, high-tolerance components.

We understand that every project begins with a unique set of challenges. That’s why our engineering team collaborates closely with clients from design through delivery. Whether you require small-batch prototyping or full-scale production, our flexible manufacturing systems adapt to your timeline and volume needs. Quality assurance is embedded at every stage, with ISO 9001-certified processes, rigorous material traceability, and in-process inspections ensuring compliance with international standards.

Partnering with Wuxi Lead means partnering with a manufacturer that treats your specifications as commitments. Our facility in Wuxi, China, is equipped with state-of-the-art machinery and staffed by technicians with over a decade of experience in precision metalworking. We maintain strict control over flatness, edge quality, and coating integrity—critical factors when working with black stainless steel, where surface imperfections are highly visible.

Below are typical material specifications we work with:

| Property | Value |

|---|---|

| Material Grade | 304, 316L, 430 (custom options available) |

| Surface Finish | PVD Black, Electroless Black, Brushed Black |

| Thickness Range | 0.5 mm – 6.0 mm |

| Tolerance (Laser Cutting) | ±0.1 mm |

| Minimum Bend Radius | 1.5× material thickness |

| Coating Hardness | 8–9 H (Pencil Hardness) |

| Corrosion Resistance | >500 hours salt spray test (ASTM B117) |

| Common Sheet Sizes | 1000×2000 mm, 1219×2438 mm (custom cuts available) |

We invite global OEMs, design engineers, and procurement managers to contact us for technical consultation or sample requests. Let us demonstrate how Wuxi Lead Precision Machinery can become your trusted partner in high-end sheet metal fabrication.

For project inquiries, material specifications, or to request a quote, contact us at [email protected]. Our engineering team responds within 24 hours to ensure your project moves forward without delay.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.