Technical Contents

Engineering Guide: Plastic Injection Mold Company

Engineering Insight: The Non-Negotiable Role of Precision in Plastic Injection Molding

In plastic injection molding, success hinges on microscopic accuracy long before the first polymer pellet melts. The precision of the metal components within the mold assembly—ejector pins, cores, cavities, and guide bushings—dictates part consistency, cycle time, and ultimately, production viability. Even minute deviations, measured in microns, propagate catastrophic failures: part warpage, flash, dimensional non-conformance, or premature mold wear. These are not theoretical risks; they translate directly to scrap rates, machine downtime, and eroded profit margins. Achieving true repeatability demands metal components manufactured to tolerances far exceeding standard industrial practices, where thermal stability, material homogeneity, and geometric perfection are paramount.

At Wuxi Lead Precision Machinery, we engineer custom metal components specifically for the unforgiving environment of high-performance injection molding. Our focus is not merely on meeting specifications, but on anticipating the dynamic stresses of the molding process—thermal cycling, high clamp forces, and repetitive ejection cycles. This requires deep material science understanding and mastery of advanced CNC machining, grinding, and EDM processes. Our experience extends beyond commercial production; we have delivered mission-critical components for applications where failure is impossible. This includes precision elements for timing systems used in Olympic sporting events, demanding absolute reliability under global scrutiny, and specialized hardware for military-grade equipment, where environmental extremes and zero-failure operation are mandatory. These projects ingrained a culture of uncompromising precision that directly benefits our injection mold manufacturing partners.

The difference lies in the measurable execution. Standard mold components often operate within ±0.01mm tolerances. For high-cavity, tight-tolerance, or long-life molds, this is insufficient. We consistently achieve and verify micron-level accuracy across complex geometries. The table below outlines the precision benchmarks we routinely deliver for critical mold components:

| Specification Parameter | Standard Industry Practice | Wuxi Lead Precision Capability | Critical Impact for Molds |

|---|---|---|---|

| Dimensional Tolerance | ±0.01 mm to ±0.02 mm | ±0.002 mm to ±0.005 mm | Eliminates part flash, ensures precise fit-up, prevents core shift |

| Surface Roughness (Ra) | 0.8 µm to 1.6 µm | 0.05 µm to 0.2 µm | Reduces part sticking, minimizes wear, improves part surface finish |

| Geometric Accuracy (Flatness/Parallelism) | 0.01 mm per 100 mm | 0.001 mm per 100 mm | Prevents mold deflection, ensures uniform pressure distribution |

| Material Hardness Control | ±5 HRC | ±1 HRC | Guarantees consistent wear resistance and longevity under pressure |

This level of precision engineering mitigates the root causes of common molding defects. It ensures seamless part ejection, consistent cavity filling, and extended mold life—directly reducing total cost of ownership. When your mold components are manufactured to tolerances proven in Olympic and military applications, you gain more than a part; you gain a foundational element of production certainty. For plastic injection mold companies targeting high-reliability, high-value markets, partnering with a precision metal manufacturer that operates at this tier is not an option—it is the essential engineering foundation for sustained competitiveness and quality. Wuxi Lead Precision Machinery delivers this foundation, consistently.

Precision Specs & Tolerances

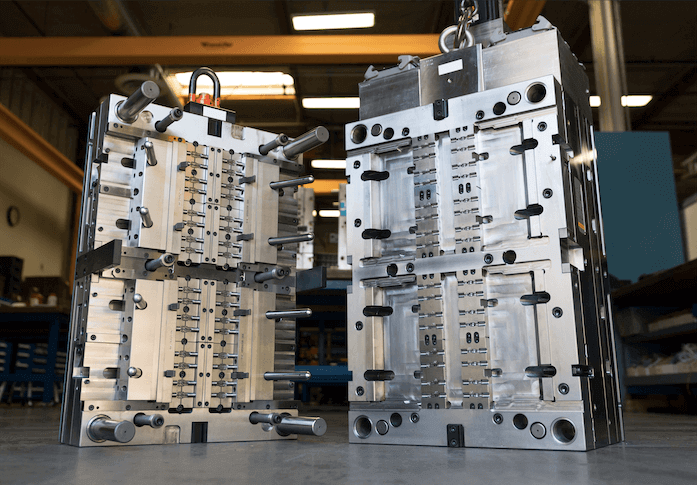

Wuxi Lead Precision Machinery stands at the forefront of custom metal manufacturing, delivering precision-engineered components tailored to the demanding requirements of plastic injection mold production. Our technical capabilities are anchored in advanced machining technologies, rigorous quality assurance protocols, and a deep understanding of mold-making engineering. We specialize in producing mold bases, inserts, cores, cavities, and related tooling components with exceptional accuracy and repeatability, ensuring optimal performance in high-cycle injection molding applications.

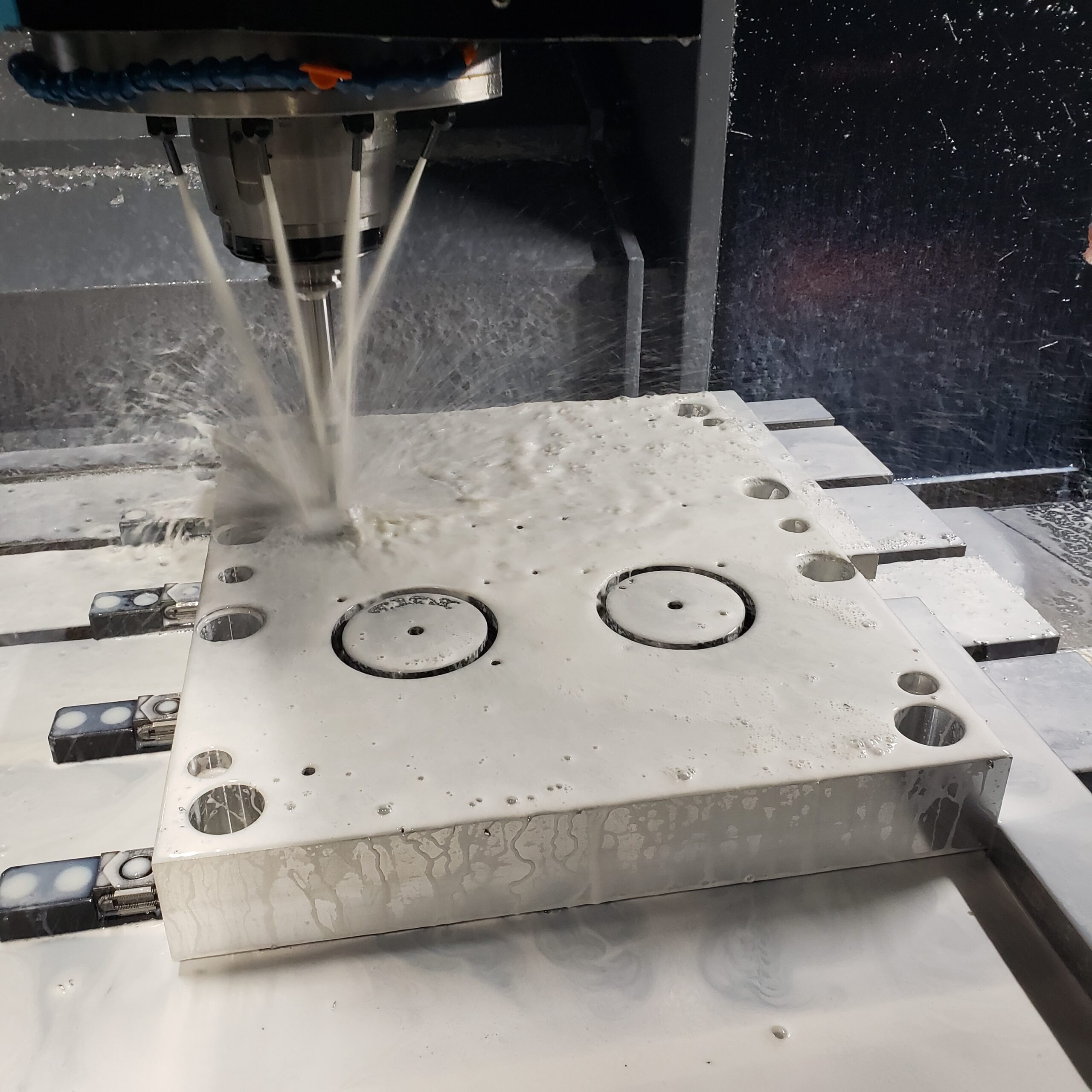

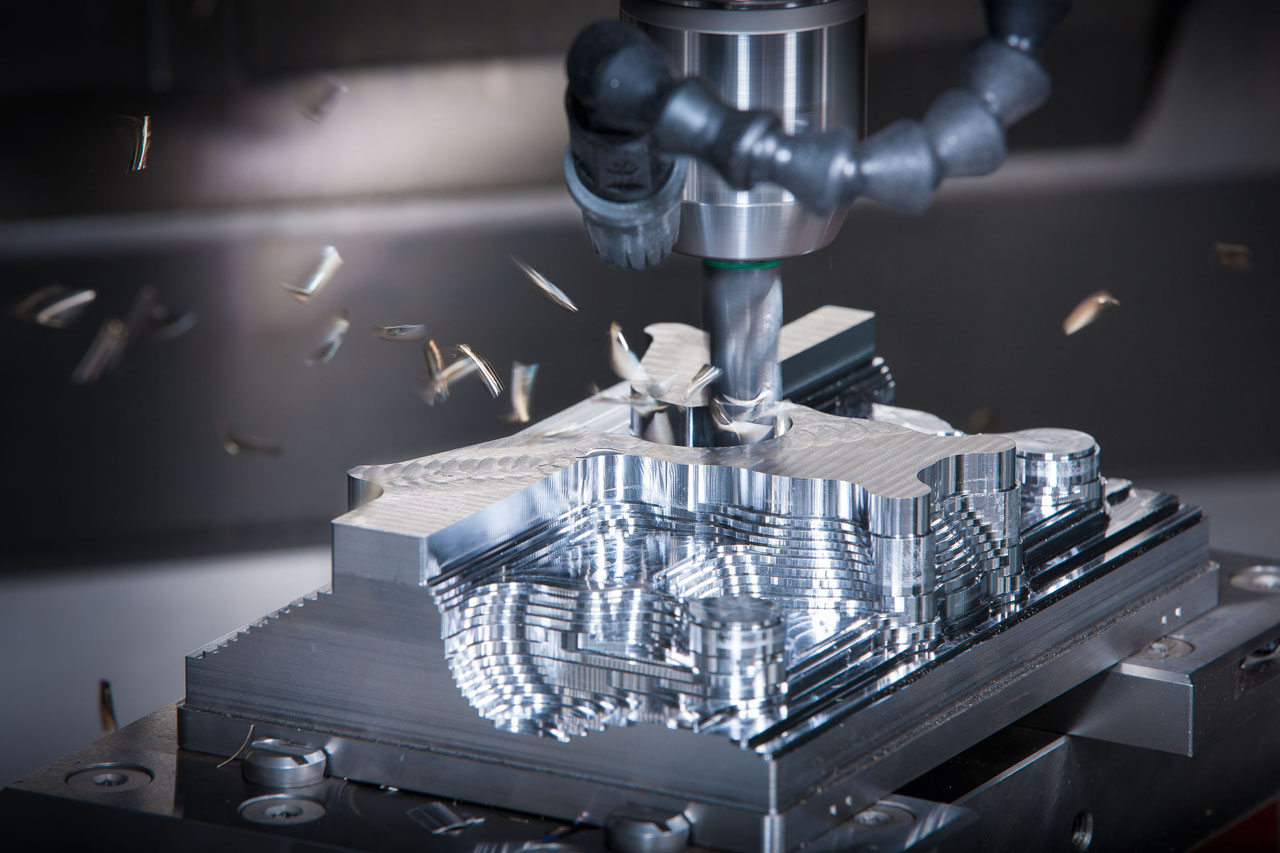

At the core of our manufacturing process is a fleet of state-of-the-art 5-axis CNC machining centers. These systems enable simultaneous multi-axis movement, allowing for complex geometries, undercuts, and intricate contours to be machined in a single setup. This not only enhances dimensional accuracy but also significantly reduces cycle times and minimizes human error. Our programming team utilizes advanced CAM software to optimize toolpaths, ensuring superior surface finishes and tight tolerances across even the most challenging part designs. Materials commonly processed include P20, 718H, S136, H13, and other mold-grade steels, as well as aluminum and copper alloys for prototype and EDM applications.

Quality is non-negotiable in precision mold manufacturing. To uphold the highest standards, every critical component undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM). Our CMM systems provide full 3D verification of geometric dimensions and tolerances (GD&T), ensuring conformance to customer specifications and international standards. Data from inspections is documented and traceable, supporting full quality traceability for each production batch. In addition to CMM, we employ optical comparators, surface roughness testers, and hardness testers to validate material and finish characteristics.

Our commitment to precision is reflected in the tolerances we consistently achieve across various machining operations. The following table outlines our standard technical capabilities:

| Feature | Capability |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.01 mm |

| Geometric Tolerance (Flatness, Parallelism, etc.) | 0.01 mm per 100 mm |

| Surface Roughness (Ra) | As low as 0.2 µm (polished finishes available) |

| Hole Diameter Tolerance | H7 (ISO) or ±0.008 mm |

| Angular Tolerance | ±0.05° |

| Maximum Work Envelope (5-axis) | 1200 mm × 800 mm × 750 mm |

| Minimum Wall Thickness (Steel) | 0.5 mm (geometry dependent) |

Wuxi Lead Precision Machinery combines engineering expertise with cutting-edge equipment and disciplined quality control to deliver mold components that meet the exacting demands of global injection molding industries. Our technical capabilities ensure reliability, longevity, and performance in even the most high-pressure molding environments.

Material & Finish Options

Strategic Material Selection for Injection Mold Tooling

Material selection fundamentally dictates the performance lifecycle and economic viability of plastic injection molds. At Wuxi Lead Precision Machinery, our engineering team emphasizes matching core mold components to specific production demands, balancing upfront cost against long-term durability and part quality. The optimal choice hinges on projected shot count, part complexity, resin abrasiveness, and required surface finish. Aluminum, steel, and titanium represent the primary structural options, each with distinct advantages.

Aluminum Alloys excel in rapid prototyping and low-to-medium volume production (typically under 100,000 shots). Grades like 7075-T6 offer exceptional machinability, significantly reducing lead times compared to steel. This speed is critical for design validation and market entry. While softer than tool steels, high-grade aluminum provides adequate wear resistance for many engineering plastics and allows efficient heat transfer for faster cycle times. Its lower density also simplifies mold handling.

Tool Steels are the industry standard for high-volume, long-life molds exceeding 500,000 shots. Pre-hardened steels like P20 (1.2311) offer good machinability and moderate wear resistance for general applications. For demanding resins (glass-filled, flame-retardant) or ultra-high volumes, hardened steels such as H13 (1.2344) or S136 (stainless) are essential. These provide superior hardness, thermal fatigue resistance, and polishability, maintaining critical tolerances and surface finishes over millions of cycles despite abrasive materials.

Titanium Alloys serve highly specialized applications where extreme corrosion resistance or non-magnetic properties are mandatory, such as medical or semiconductor molding with aggressive chemistries. While offering excellent strength-to-weight ratio and biocompatibility, titanium presents significant machining challenges and substantially higher material costs. Its use in mainstream injection molding is uncommon due to these factors and is typically reserved for specific insert components rather than full mold bases.

Material properties directly influence achievable finishes. Anodizing is a critical post-machining process, particularly for aluminum molds. Hard anodizing creates a dense, wear-resistant ceramic layer (up to 70+ HV) that dramatically enhances surface hardness and corrosion resistance, extending mold life in corrosive environments. It also provides excellent adhesion for subsequent coatings like PTFE for release. While primarily applied to aluminum, specialized anodizing processes exist for certain titanium grades.

The following table summarizes key comparative properties:

| Material | Hardness Range (HRC) | Corrosion Resistance | Typical Use Cases | Machining Notes |

|---|---|---|---|---|

| Aluminum 7075-T6 | 15-20 (Base) | Moderate | Prototypes, Low/Med Volume | Very Fast, Low Tool Wear |

| P20 Tool Steel | 28-32 (Pre-Hard) | Good | General Production (Med Volume) | Good Machinability Pre-Hardening |

| H13 Tool Steel | 48-52 (Hardened) | Very Good | High Volume, Abrasive Resins | Difficult Post-Hardening |

| S136 Stainless | 48-52 (Hardened) | Excellent | Corrosive Resins, Medical, Optics | Challenging, Requires Care |

| Titanium Grade 5 | 32-36 (Base) | Exceptional | Specialized Inserts, Extreme Corrosion | Very Slow, High Tool Cost, Complex |

Selecting the right material and finish is not merely a cost decision but a strategic investment in production stability. Wuxi Lead Precision Machinery leverages decades of experience to analyze your specific resin, part geometry, and volume requirements. We provide data-driven recommendations and precise machining capabilities to ensure your mold material selection maximizes uptime, part quality, and overall return on investment from the first shot through the end of the production run. Consult our engineering team for a tailored assessment.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our custom metal manufacturing process for plastic injection mold production is engineered for precision, consistency, and zero-defect outcomes. We integrate advanced design methodologies, rigorous prototyping, and tightly controlled mass production techniques to deliver molds that meet the most demanding industrial standards.

The process begins with precision design, where our engineering team collaborates closely with clients to translate product requirements into optimized mold architectures. Utilizing 3D CAD software such as UG, SolidWorks, and AutoCAD, we develop detailed mold designs that account for material flow, cooling efficiency, ejection dynamics, and part tolerances. Finite element analysis (FEA) is applied to simulate stress distribution and thermal behavior, ensuring structural integrity under production conditions. Design for manufacturability (DFM) reviews are conducted to eliminate potential defects before tooling begins.

Following design approval, we proceed to prototyping. A functional prototype mold is fabricated using CNC machining, EDM, and high-precision grinding to validate the design under real-world conditions. This stage allows for iterative testing of part geometry, surface finish, and dimensional accuracy. Prototypes are evaluated against strict quality benchmarks, including cavity pressure monitoring and first-article inspection reports (FAIR). Any deviations are corrected through design or process adjustments, ensuring that only validated molds advance to full-scale production.

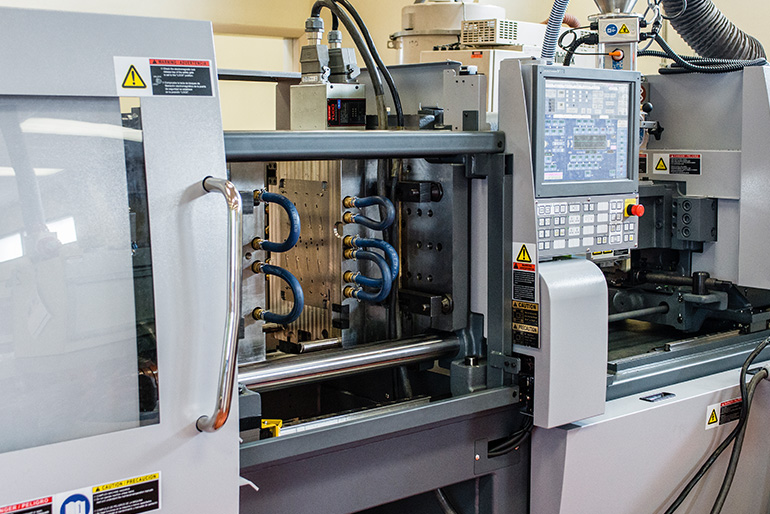

Mass production is executed on our state-of-the-art manufacturing floor, equipped with multi-axis CNC machines, robotic automation, and in-process quality monitoring systems. Each mold undergoes a comprehensive production control plan that includes real-time dimensional checks, automated defect detection, and statistical process control (SPC). Our cleanroom environments and climate-controlled assembly zones minimize contamination and thermal drift, critical for maintaining micron-level tolerances. Every mold is subjected to a full mold tryout, with documented evidence of cycle time, part consistency, and durability over 100,000+ cycles.

Our zero-defect philosophy is enforced through ISO 9001-certified quality management systems, traceable material sourcing, and operator certification programs. From raw material inspection to final packaging, every step is auditable and repeatable.

Key technical specifications for our plastic injection molds are summarized below:

| Parameter | Specification |

|---|---|

| Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.05 µm to Ra 0.4 µm (polished options) |

| Mold Life | 500,000 – 1,000,000 cycles |

| Materials | P20, 718, H13, S136, 420SS, Aluminum 7075 |

| Cooling Efficiency | Optimized conformal cooling channels |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Production) | 30–60 days (depending on complexity) |

| Quality Standards | ISO 9001, VDI 3400, SPC, FAIR, PPAP |

At Wuxi Lead Precision Machinery, we combine engineering excellence with industrial discipline to deliver plastic injection molds that perform flawlessly in high-volume manufacturing environments.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Engineered Solution for Injection Mold Excellence

In the high-stakes arena of plastic injection molding, mold performance dictates production efficiency, part quality, and ultimately, your competitive edge. Substandard tooling leads to costly downtime, scrap rates, and compromised product integrity. Wuxi Lead Precision Machinery exists to eliminate these risks. As engineers first, we specialize in custom metal manufacturing for injection molds where micron-level precision and unwavering durability are non-negotiable. Our decades of focused expertise in mold base fabrication, cavity/core production, and precision components ensure your tooling meets the most demanding specifications—on time and within budget.

We understand the critical interplay between mold design, material science, and machining tolerances. Our integrated approach combines advanced CNC milling, grinding, and EDM capabilities with rigorous quality control protocols. Every component undergoes multi-stage inspection using Zeiss CMMs and optical comparators, guaranteeing dimensional stability under cyclic loads. This precision engineering translates directly to longer mold life, reduced maintenance cycles, and consistent part replication for your production floor.

Our technical capabilities are engineered to exceed industry benchmarks. The following specifications demonstrate our commitment to delivering mold components that perform under real-world manufacturing pressures.

| Capability | Specification Detail | Industry Standard | Lead Precision Standard |

|---|---|---|---|

| Positional Accuracy | ±0.005 mm | ±0.010 mm | ±0.002 mm |

| Surface Finish (Cavity) | Ra 0.2 µm | Ra 0.4 µm | Ra 0.05 µm |

| Material Hardness Control | ±3 HRC | ±5 HRC | ±1 HRC |

| Thermal Stability Testing | 10,000 cycles | 5,000 cycles | 50,000 cycles |

Beyond technical execution, we function as a true extension of your engineering team. Our project managers—many with hands-on mold design backgrounds—collaborate during the feasibility phase to optimize manufacturability, identify potential failure points, and recommend material solutions for challenging resins or high-cavitation requirements. This proactive partnership prevents costly revisions and accelerates time-to-market. We maintain strict IP protocols and provide full traceability from raw material certification to final inspection reports, meeting stringent automotive, medical, and aerospace compliance demands.

The cost of mold failure extends far beyond initial tooling investment. It impacts production schedules, customer trust, and brand reputation. Partnering with Lead Precision mitigates these risks through engineering rigor, transparent communication, and a relentless focus on your operational success. We do not merely supply components; we deliver confidence in every cycle.

Initiate your next high-precision mold project with engineering certainty. Contact our technical sales team directly at Contact [email protected] to discuss your specific requirements. Include your part geometry, material specifications, and production volume targets for a tailored capability assessment. Our engineers will respond within 24 business hours with actionable insights—not generic proposals. Elevate your mold performance with a partner who speaks the language of precision manufacturing. The integrity of your production line depends on it.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.