Technical Contents

Engineering Guide: Abs Plastic 3D Printing Service

Engineering Insight: ABS Plastic 3D Printing Service

In the realm of advanced prototyping and low-volume production, ABS plastic 3D printing services have become a cornerstone for industries demanding functional, durable, and dimensionally stable components. At Wuxi Lead Precision Machinery, we recognize that the true value of additive manufacturing lies not just in rapid fabrication, but in the precision, repeatability, and material integrity achieved throughout the process. Our engineering approach to ABS 3D printing is rooted in over a decade of experience serving high-stakes sectors, including defense and Olympic-grade equipment development, where tolerances are non-negotiable and performance under stress is paramount.

ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic polymer renowned for its excellent strength-to-weight ratio, impact resistance, and thermal stability. These properties make it ideal for functional prototypes, jigs, fixtures, and end-use parts in automotive, aerospace, and industrial equipment applications. However, maximizing these benefits requires more than just access to 3D printing hardware—it demands a deep understanding of material behavior, thermal management, and post-processing techniques. At Lead Precision, our engineers apply precision calibration protocols to ensure layer adhesion, minimize warping, and maintain dimensional accuracy within ±0.1 mm for critical features.

Our in-house ABS printing processes are integrated within a broader custom metal manufacturing ecosystem, enabling hybrid solutions where plastic and metal components are designed and produced in tandem. This synergy allows for optimized assemblies, reduced lead times, and enhanced structural performance. For instance, in military-grade drone development, we have produced ABS housings with embedded metal inserts, ensuring secure mounting points while maintaining lightweight design. Similarly, components developed for Olympic training devices required exact ergonomics and fatigue resistance—achievable only through precise print orientation, controlled chamber temperatures, and stress-relief annealing.

Precision in 3D printing also extends to design for manufacturability (DFM). Our engineering team collaborates closely with clients to refine geometries, suggest wall thicknesses, and optimize support structures—ensuring that each ABS part not only meets specification but performs reliably in real-world conditions. All prints undergo rigorous inspection, including first-article reporting and, when required, coordinate measuring machine (CMM) validation.

The following table outlines the technical specifications of our ABS plastic 3D printing service:

| Parameter | Specification |

|---|---|

| Material | ABS (Standard, High-Impact, Flame-Retardant variants) |

| Layer Resolution | 50 – 300 microns (adjustable) |

| Build Volume | Up to 600 x 600 x 600 mm |

| Dimensional Accuracy | ±0.1 mm (typical) |

| Surface Finish | Matte, smooth; post-processing available (sanding, vapor smoothing) |

| Post-Processing Options | Support removal, heat treatment, tapping, insert installation |

| Lead Time | 3–7 days (depending on complexity) |

| Quality Standards | ISO 9001:2015 compliant, full traceability |

At Wuxi Lead Precision Machinery, we treat every ABS 3D printing project as an engineering challenge—not merely a production task. Our commitment to precision, backed by proven performance in mission-critical applications, ensures that your components are not just built to print, but built to perform.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing

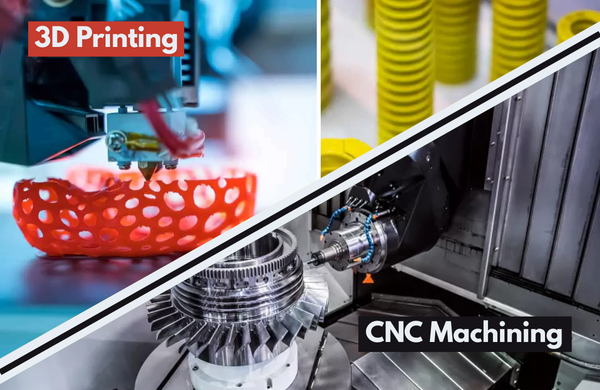

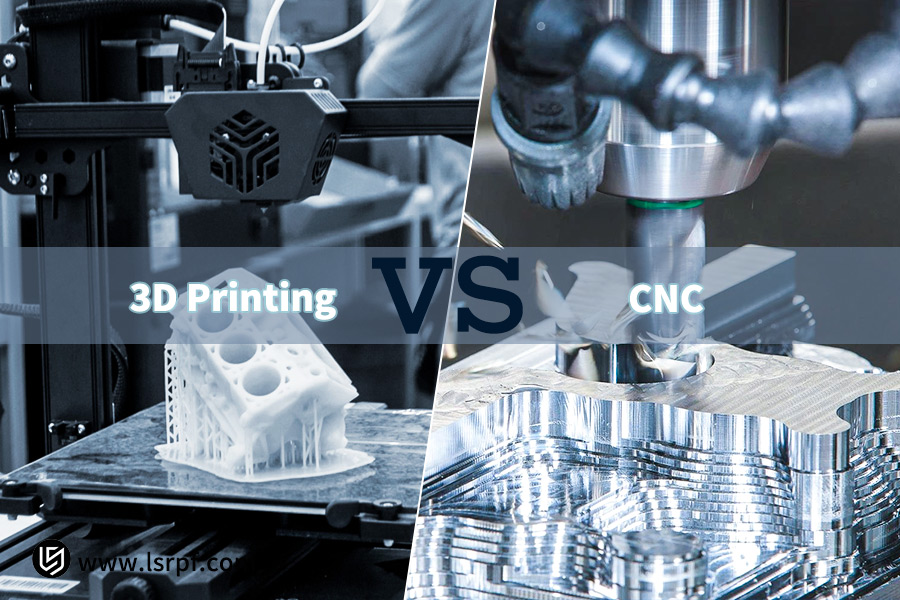

Wuxi Lead Precision Machinery specializes in high-accuracy custom metal manufacturing, leveraging advanced 5-axis CNC machining to produce complex geometries unattainable with conventional methods. Our technical expertise centers on aerospace, medical, and industrial components requiring micron-level precision. While ABS plastic 3D printing serves prototyping niches, our core strength lies in transforming premium metals—including titanium, Inconel, aluminum alloys, and stainless steel—into mission-critical parts. We integrate additive design principles with subtractive precision, ensuring structural integrity and repeatability for end-use applications.

Our 5-axis CNC fleet features Siemens-controlled machines with simultaneous multi-axis movement, enabling single-setup machining of intricate contours, undercuts, and organic shapes. This eliminates manual repositioning errors and reduces lead times by up to 40% versus 3- or 4-axis alternatives. All equipment operates within ISO Class 8 cleanrooms, maintaining thermal stability for dimensional consistency. Toolpath optimization via Mastercam and hyperMILL software minimizes material stress, critical for thin-walled or high-strength components. Crucially, we do not offer ABS plastic 3D printing; our value proposition is rooted in certified metal fabrication where tolerances, fatigue resistance, and regulatory compliance are non-negotiable.

Quality control is engineered into every process stage. Post-machining, parts undergo rigorous validation using Zeiss CONTURA CMM systems with 0.0001mm resolution. Automated scanning compares as-built geometry against CAD models via GOM Inspect software, generating AS9100-compliant inspection reports with GD&T analysis. Surface finish verification employs Perthometer devices to validate Ra values, while material certifications and hardness testing ensure conformance to AMS, ASTM, and EN standards. This closed-loop QC system achieves first-pass yield rates exceeding 98.5%.

The table below details achievable tolerances for critical features, reflecting our capability to meet stringent industry requirements. These values assume optimal material selection, part geometry, and fixturing—factors our engineering team evaluates during DFM analysis.

| Feature Type | Standard Tolerance (mm) | Tight Tolerance (mm) | Material Consideration |

|---|---|---|---|

| Linear Dimensions | ±0.01 | ±0.005 | Aluminum alloys, mild steel |

| Geometric (GD&T) | ±0.02 | ±0.008 | All metals |

| Hole Diameter | ±0.01 | ±0.005 | Deep holes >10x diameter |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Critical sealing surfaces |

| Flatness | 0.02/100mm | 0.005/100mm | Large base plates |

Our technical differentiator is the fusion of 5-axis agility with metrology-grade validation. For clients requiring production-ready metal components—not plastic prototypes—this infrastructure guarantees performance under extreme thermal, vibrational, and load conditions. We collaborate from initial design review through fatigue testing, ensuring parts exceed functional expectations while minimizing total cost of ownership. Contact our engineering team to discuss tolerance optimization for your specific application.

Material & Finish Options

Material selection is a critical phase in custom metal manufacturing, especially when integrating components with additive elements such as ABS plastic 3D printed parts. At Wuxi Lead Precision Machinery, we emphasize compatibility, performance, and longevity in every engineered solution. While ABS plastic 3D printing services offer rapid prototyping and functional part production, the surrounding or supporting structural components often require high-strength metals. Our expertise in precision machining enables seamless integration between 3D printed polymers and machined metals, ensuring thermal stability, mechanical integrity, and dimensional accuracy.

Aluminum stands out as the preferred choice for applications requiring a balance of strength, weight, and machinability. Its excellent thermal and electrical conductivity, combined with natural corrosion resistance, makes it ideal for enclosures, brackets, and prototype housings that interface with ABS components. We primarily use 6061-T6 and 7075-T6 aluminum alloys, selected based on load requirements and environmental exposure. These alloys accept anodizing exceptionally well, enhancing surface hardness and wear resistance.

Steel, particularly stainless steel grades such as 304 and 316, delivers superior strength and resistance to high temperatures and corrosive environments. It is best suited for industrial fixtures, medical devices, and structural supports where long-term durability is non-negotiable. When paired with ABS plastic assemblies, steel provides rigid anchoring points and ensures mechanical stability under dynamic loads. Our CNC machining processes guarantee micron-level tolerances, enabling precise fitment between dissimilar materials.

Titanium, though more costly, offers an unmatched strength-to-density ratio and exceptional resistance to fatigue and corrosion. It is frequently specified in aerospace, defense, and high-performance automotive applications. Titanium components machined at Wuxi Lead are typically used in high-stress environments where weight reduction is critical and where ABS plastic parts serve as non-load-bearing housings or ducting elements.

Surface finishing, particularly anodizing, plays a vital role in enhancing aluminum components. Anodizing creates a durable, non-conductive oxide layer that improves wear resistance and allows for color coding or branding. Type II and Type III (hardcoat) anodizing are available depending on the operational demands.

Below is a comparative overview of the key materials we machine for integration with ABS plastic 3D printed assemblies.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Typical Applications | Compatible Finishes |

|---|---|---|---|---|---|

| Aluminum | 310 – 570 | 2.7 | 6061-T6, 7075-T6 | Enclosures, brackets, heat sinks | Anodizing (Type II/III), Powder Coating |

| Stainless Steel | 505 – 860 | 7.9 – 8.0 | 304, 316 | Medical tools, industrial fixtures | Passivation, Electropolishing |

| Titanium | 900 – 1100 | 4.5 | Grade 5 (Ti-6Al-4V) | Aerospace, defense, motorsports | Shot Peening, Anodizing (decorative) |

At Wuxi Lead Precision Machinery, we support engineers in selecting the optimal metal and finish to complement ABS plastic 3D printed components, ensuring reliability and performance in end-use applications.

Manufacturing Process & QC

Precision ABS Plastic 3D Printing: The Zero-Defect Production Pathway

At Wuxi Lead Precision Machinery, our ABS plastic 3D printing service integrates seamlessly with advanced metal manufacturing workflows, delivering production-ready components with uncompromising quality. We execute a rigorously controlled three-phase process—Design, Prototyping, Mass Production—engineered to eliminate defects before they reach your assembly line. This methodology ensures dimensional stability, mechanical consistency, and full compliance with aerospace, automotive, and industrial equipment standards.

Design Phase: Precision Engineering from Concept

Our process begins with collaborative Design for Manufacturing (DFM) analysis. Engineers scrutinize CAD models for thermal stress points, warpage risks, and support structure optimization specific to ABS material behavior. Finite element analysis (FEA) validates structural integrity under operational loads, while thermal simulation predicts cooling-induced shrinkage. Critical tolerances are cross-referenced against ISO 2768-mK standards, and wall thicknesses are adjusted to prevent sink marks. This phase concludes with a formal design sign-off, ensuring the digital blueprint is flawless before physical production begins.

Prototyping Phase: Validation Under Real Conditions

Prototypes are manufactured using calibrated industrial-grade FDM systems with enclosed, temperature-stabilized chambers. Each build undergoes in-process monitoring: thermal cameras track layer adhesion temperatures within ±1°C of the ABS glass transition point (105°C), while laser micrometers verify layer height consistency at 20–100 µm resolution. Post-build, prototypes endure functional testing—thermal cycling from -20°C to 80°C, tensile strength validation (≥40 MPa), and dimensional inspection via CMM against the original CAD. Only units passing all criteria advance; failure triggers immediate root-cause analysis and design iteration.

Mass Production Phase: Statistical Process Control for Zero Defects

Full-scale production leverages our automated SLS and FDM cells, each governed by Statistical Process Control (SPC) protocols. Material lots are certified for moisture content (<0.02%) and melt flow index consistency. During printing, closed-loop systems adjust nozzle pressure and bed leveling in real-time based on ultrasonic layer adhesion feedback. Every 50th part undergoes non-destructive CT scanning to detect internal voids, while surface finish is validated against Ra ≤ 3.2 µm. Final parts receive stress-relief annealing and vapor smoothing, followed by 100% visual inspection under ISO Class 8 cleanroom conditions.

Key ABS 3D Printing Specifications

| Parameter | Specification | Industry Standard |

|————————–|———————————–|——————-|

| Layer Resolution | 20–100 µm | ASTM F2921 |

| Build Volume | 450 x 450 x 600 mm | Customizable |

| Tensile Strength | ≥ 40 MPa | ISO 527 |

| Heat Deflection Temp | 95–105°C @ 0.45 MPa | ISO 75 |

| Dimensional Accuracy | ±0.1% (min ±0.1 mm) | ISO 2768-mK |

| Surface Roughness (Ra) | ≤ 3.2 µm (post-processed) | ISO 4287 |

This closed-loop production system—where design insights feed prototyping, and prototyping data governs mass production—ensures zero-defect delivery for mission-critical applications. Wuxi Lead’s integration of ABS 3D printing within our broader precision metal ecosystem guarantees that every component, whether polymer or metal, meets the exacting demands of global industrial supply chains. Partner with us to transform prototyping agility into production certainty.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced ABS Plastic 3D Printing Services

At Wuxi Lead Precision Machinery, we specialize in high-precision manufacturing solutions tailored to the evolving demands of modern industry. While our core expertise lies in custom metal manufacturing, we integrate advanced polymer technologies—including industrial-grade ABS plastic 3D printing—into our comprehensive service portfolio. This hybrid capability enables us to support clients across aerospace, automotive, medical, and industrial equipment sectors with end-to-end prototyping and production solutions.

Our ABS plastic 3D printing service is engineered for performance. Using premium-grade acrylonitrile butadiene styrene (ABS) material, we deliver parts with exceptional dimensional stability, impact resistance, and thermal performance. These characteristics make ABS ideal for functional prototypes, jigs, fixtures, and low-volume end-use components that must endure rigorous operational environments. Every print is executed on state-of-the-art FDM (Fused Deposition Modeling) systems calibrated to maintain tight tolerances and consistent layer adhesion, ensuring repeatable quality across batches.

We understand that precision is non-negotiable in industrial applications. That’s why our engineering team applies the same rigorous standards to plastic fabrication as we do to CNC-machined metal components. All 3D printed parts undergo post-processing evaluation, including stress-relief annealing where applicable, support removal, and surface finishing to meet client specifications. Whether you require rapid iteration for design validation or bridge production before tooling, our ABS printing service accelerates your development timeline without compromising integrity.

Below are the technical specifications for our ABS plastic 3D printing process:

| Parameter | Specification |

|---|---|

| Material | Industrial-Grade ABS (Natural, Black) |

| Build Volume | Up to 900 x 600 x 900 mm |

| Layer Resolution | 50 – 300 microns (adjustable) |

| Typical Tolerance | ±0.1 mm (for features < 100 mm) |

| Surface Finish | Matte, Post-Processed Options Available |

| Post-Processing | Support Removal, Sanding, Vapour Smoothing |

| Lead Time | 3–7 days (standard), expedited available |

| File Formats Accepted | STEP, IGES, STL, Parasolid, DWG, PDF |

Our facility in Wuxi, China, operates under ISO 9001-certified quality management protocols, ensuring every project meets international standards for traceability, process control, and documentation. We serve global clients with secure data handling, NDA protection, and direct engineering support throughout the project lifecycle.

Partnering with Lead Precision means accessing a single source for both high-precision metal components and advanced polymer solutions. Let us help you streamline development, reduce time-to-market, and achieve manufacturing excellence.

Contact us today at [email protected] to discuss your next project. Our engineering team is ready to provide technical consultation, material recommendations, and a competitive quote tailored to your requirements.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.