Technical Contents

Engineering Guide: Milling Bits For Steel

Engineering Insight: Milling Bits for Steel – The Role of Precision in High-Performance Machining

In the realm of precision CNC machining, the performance of milling bits for steel is directly tied to the consistency, accuracy, and reliability of each cutting edge. Steel, as a workpiece material, presents unique challenges due to its high tensile strength, work hardening tendencies, and thermal conductivity. These factors demand milling tools engineered not only for durability but for micron-level precision in both geometry and material composition. At Wuxi Lead Precision Machinery, we understand that in high-end manufacturing—particularly in sectors such as aerospace, defense, and advanced automation—even minor deviations in tool performance can cascade into costly rework, reduced tool life, or compromised part integrity.

Precision in milling bits begins with substrate quality. We utilize ultra-fine grain carbide with controlled cobalt content, ensuring optimal hardness and fracture resistance. This foundation allows for sharper cutting edges and improved edge retention under the high thermal and mechanical loads encountered when machining steel. Our proprietary coating processes, including multi-layer PVD (Physical Vapor Deposition) treatments such as TiAlN and AlCrN, further enhance thermal stability and reduce friction, directly contributing to longer tool life and superior surface finishes.

Geometric precision is equally critical. Each flute profile, helix angle, and edge preparation is optimized through finite element analysis and real-world validation. For instance, a 45-degree helix angle combined with variable pitch design minimizes harmonic vibration during cutting, reducing chatter and improving dimensional accuracy in deep slotting or high-feed operations. Such refinements are not incidental—they are the result of over 15 years of focused R&D and direct collaboration with clients in mission-critical industries.

Our involvement in projects linked to Olympic-standard equipment manufacturing and military-grade component production has reinforced the non-negotiable nature of precision. In these applications, where performance under extreme conditions is mandatory, our milling bits undergo rigorous in-house testing, including dynamic balance verification, edge microscopy, and batch traceability protocols. This level of control ensures that every tool leaving our facility meets the exacting standards required by Tier-1 suppliers and global OEMs.

Wuxi Lead Precision Machinery’s commitment to excellence is reflected not just in our products, but in our engineering philosophy: precision is not a target—it is the baseline.

Typical Performance Specifications – Steel Milling Bits (Carbide, Coated)

| Parameter | Value / Specification |

|---|---|

| Substrate Material | Ultra-Fine Grain Carbide (WC-6%Co) |

| Coating Type | TiAlN / AlCrN (Multi-Layer PVD) |

| Coating Thickness | 2.5–3.0 µm |

| Hardness (Coating) | 32–35 GPa |

| Helix Angle | 30°–45° (Variable for chatter reduction) |

| Flute Count | 4–6 (Based on application) |

| Edge Preparation | Micro-chamfer + Honing (±0.005 mm) |

| Recommended Cutting Speed | 180–250 m/min (Hardened Steel) |

| Tool Runout Tolerance | ≤ 0.003 mm (at 3×D) |

| Application Range | Pre-hardened & hardened steels (up to 65 HRC) |

Precision Specs & Tolerances

Technical Capabilities: Precision Milling Bits for Steel

Wuxi Lead Precision Machinery delivers uncompromising accuracy in steel milling bit production through integrated 5-axis CNC machining and rigorous quality control. Our facility operates 12 DMG MORI CTX beta 1250 5-axis vertical machining centers, each equipped with high-torque spindles (15,000 RPM) and Siemens 840D SL controls. This configuration enables single-setup machining of complex geometries—including variable helix angles, asymmetric flutes, and micro-grooves—critical for optimizing chip evacuation and tool life in hardened steel applications. The 5-axis simultaneous interpolation capability ensures geometric integrity across all cutting surfaces, eliminating cumulative errors from multiple repositioning stages. All machines maintain thermal stability via closed-loop coolant systems and granite base structures, critical for holding micron-level tolerances during extended production runs.

Quality assurance is anchored by Zeiss CONTURA G2 Coordinate Measuring Machines (CMM) with VAST XXT scanning probes and 0.5 µm volumetric accuracy. Every milling bit undergoes 100% post-process inspection against ISO 13006 and customer-specific GD&T standards. Our inspection protocol verifies critical parameters: flute profile consistency, core diameter concentricity, cutting edge radius uniformity, and surface roughness (Ra ≤ 0.4 µm). Data from each CMM cycle is integrated into our SPC database, enabling real-time process adjustments and full traceability from raw material to finished component. This closed-loop system reduces dimensional drift by 72% compared to industry benchmarks, ensuring batch-to-batch repeatability essential for aerospace and automotive clients.

Material selection leverages premium-grade tungsten carbide substrates (ISO K10-K20 grades) with nano-layered TiAlN/TiSiN coatings applied via PVD processes. Our CNC programs incorporate adaptive toolpath strategies that dynamically adjust feed rates based on real-time load monitoring, preventing micro-chipping during steel engagement (up to 65 HRC). This approach extends tool life by 40% while maintaining cutting edge sharpness within 2 µm tolerance.

The following table details achievable tolerances for steel milling bits:

| Feature | Standard Tolerance | Tight Tolerance Option | Measurement Method |

|---|---|---|---|

| Overall Diameter | ±0.005 mm | ±0.002 mm | CMM/Laser Micrometer |

| Core Diameter | ±0.003 mm | ±0.001 mm | CMM Optical Comparator |

| Flute Profile | ±0.008 mm | ±0.003 mm | CMM Scanning |

| Helix Angle | ±0.5° | ±0.2° | CMM Angular Probe |

| Cutting Edge Radius | ±0.002 mm | ±0.001 mm | SEM/AFM |

| Runout (at cutting edge) | ≤ 0.005 mm | ≤ 0.002 mm | Dial Indicator/CMM |

This capability framework ensures milling bits achieve optimal performance in demanding steel machining scenarios—from slotting 4140 alloy to finishing 304 stainless—while minimizing cycle time and scrap rates. Wuxi Lead’s technical infrastructure guarantees that every tool meets the exacting demands of high-speed, high-precision steel fabrication, directly supporting our clients’ productivity and quality objectives. Partner with us to transform steel machining challenges into competitive advantages through engineering excellence.

Material & Finish Options

Material selection is a critical factor in precision CNC machining, particularly when utilizing milling bits designed for challenging materials such as steel. The performance, tool life, and surface integrity of machined components depend heavily on matching the correct cutting tool material and coating to the workpiece. At Wuxi Lead Precision Machinery, we specialize in high-performance milling solutions engineered for industrial-grade applications involving aluminum, steel, and titanium. Understanding the thermal, mechanical, and chemical properties of both the workpiece and the cutting tool ensures optimal machining efficiency and part quality.

When machining aluminum, the primary concerns are chip evacuation and avoiding built-up edge (BUE). Aluminum is relatively soft but highly adhesive, which can lead to material welding onto the cutting edge. Uncoated carbide or diamond-coated tools are often preferred due to their non-stick characteristics and high thermal conductivity. Sharp cutting edges with high helix angles improve chip flow and reduce heat accumulation. However, care must be taken to avoid excessive cutting speeds that may lead to thermal deformation in thin-walled aluminum components.

Steel, particularly hardened and alloy steels, presents a different set of challenges. High cutting forces and elevated temperatures demand tools with exceptional hardness and thermal resistance. Solid carbide end mills with advanced PVD or CVD coatings such as TiAlN (Titanium Aluminum Nitride) are ideal for steel applications. These coatings enhance surface hardness and provide thermal insulation, protecting the cutting edge from rapid wear. High feed milling strategies combined with rigid setups minimize deflection and improve tool life. For stainless steel, which exhibits work-hardening behavior, maintaining consistent cutting parameters without dwelling is crucial to prevent hardening of the surface layer.

Titanium alloys, while strong and lightweight, have low thermal conductivity, leading to concentrated heat at the cutting zone. This necessitates tools with excellent heat resistance and optimized flute geometries to facilitate cooling. Use of internal coolant delivery systems is highly recommended. Coated carbide tools with AlTiN or similar high-temperature coatings perform well, as do specialized geometries with variable helix and pitch to reduce vibration. Peck drilling and low radial engagement strategies help manage heat and prevent catastrophic tool failure.

Surface finishes such as anodizing are commonly applied post-machining, especially for aluminum components used in aerospace or medical applications. Anodizing improves corrosion resistance, enhances surface hardness, and allows for color coding. However, it is essential to consider dimensional changes during anodizing—typically 50% of the coating thickness is built up on the surface, and 50% penetrates the base material. Critical tolerances must be adjusted accordingly during the machining phase.

Below is a comparative overview of recommended tooling specifications for each material.

| Material | Recommended Tool Material | Coating | Cutting Speed (m/min) | Feed per Tooth (mm) | Coolant Requirement |

|---|---|---|---|---|---|

| Aluminum | Solid Carbide | Uncoated or Diamond | 300–1000 | 0.08–0.20 | Internal or Air |

| Steel | Solid Carbide | TiAlN or AlTiN | 80–200 | 0.05–0.15 | Internal Coolant |

| Titanium | Solid Carbide | AlTiN | 30–60 | 0.03–0.10 | High-Pressure Coolant |

Selecting the correct combination of tool material, geometry, and machining parameters ensures maximum productivity and part consistency. At Wuxi Lead Precision Machinery, our engineering team supports clients in optimizing these variables for mission-critical applications across industries.

Manufacturing Process & QC

Precision Production Process: Milling Bits for Steel

At Wuxi Lead Precision Machinery, our production process for steel milling bits integrates rigorous engineering discipline with advanced manufacturing execution to achieve zero-defect output. Every phase—from initial design to mass production—is structured around ISO 9001-certified protocols, ensuring components meet the extreme demands of aerospace, automotive, and energy-sector applications where failure is not an option.

The process begins with computational design engineering. Our team leverages multi-axis FEA (Finite Element Analysis) to simulate thermal loads, cutting forces, and harmonic vibrations specific to hardened steel alloys. This phase defines critical geometries, including helix angles optimized for chip evacuation and flute profiles engineered to minimize work-hardening. Material selection is validated through metallurgical databases, prioritizing micrograin carbide substrates with nano-coatings for thermal stability. Only after cross-functional sign-off between design and application engineers does the project advance.

Prototyping transitions virtual models into physical validation. Using 5-axis DMG MORI milling centers, we produce 3–5 pre-series units under controlled cleanroom conditions. Each prototype undergoes 100% dimensional verification via Zeiss CONTURA CMMs, measuring tolerances to ±0.002mm. Rigorous performance testing follows: bits cut ISO 683-18 H13 tool steel at 350 m/min feed rates while monitoring tool wear, surface finish, and vibration spectra. Data from these trials refines the digital twin before release to production.

Mass production executes with embedded quality gates. Our smart factory utilizes IoT-enabled Okuma lathes and grinders with real-time SPC (Statistical Process Control) monitoring. Every 20th piece undergoes automated optical inspection for edge integrity and coating uniformity. Full material traceability—from raw carbide lot numbers to operator IDs—is recorded in our MES (Manufacturing Execution System). Final inspection includes 100% spindle runout checks and batch-level micro-hardness validation. This closed-loop system ensures defect escape probability remains below 3.4 PPM (Parts Per Million), exceeding AS9100 aerospace standards.

Critical Specifications for Steel Milling Bits

| Parameter | Specification | Verification Method |

|---|---|---|

| Material Grade | ISO K30 Micrograin Carbide | Spectrographic Analysis |

| Hardness | 1500–1650 HV30 | Vickers Microhardness Tester |

| Coating Thickness | 2.5–3.0 µm (AlTiN) | Fischerscope X-Ray Fluorescence |

| Tolerance Class | IT5 (ISO 286-2) | CMM with 0.0005mm Resolution |

| Surface Roughness | Ra ≤ 0.2 µm | Profilometer (ISO 4287) |

Zero defects are non-negotiable. By fusing predictive design, empirical prototyping, and intelligent production controls, Wuxi Lead delivers milling bits that consistently achieve 25% longer tool life in steel machining versus industry benchmarks. This process is our commitment to operational excellence—engineered for your success.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Superior Milling Bits Engineered for Steel

When your production demands uncompromising precision, durability, and performance in steel machining, partnering with a trusted leader in CNC tooling solutions is essential. At Wuxi Lead Precision Machinery, we specialize in high-performance milling bits engineered specifically for the rigorous demands of machining carbon steel, alloy steel, and stainless steel. Our tools are not just manufactured—they are precision-crafted using advanced tungsten carbide substrates, nano-coating technologies, and strict ISO-certified processes to deliver consistent tool life, superior surface finishes, and maximum metal removal rates.

We understand that in high-volume or high-accuracy industrial environments, downtime and tool wear directly impact profitability. That is why our milling bits are designed with optimized helix geometries, reinforced cutting edges, and thermal-resistant coatings such as AlTiN and TiAlN—ensuring stable performance even under continuous heavy cutting loads. Whether you are performing slotting, profiling, or deep cavity milling, our tools maintain edge integrity and dimensional accuracy across thousands of cycles.

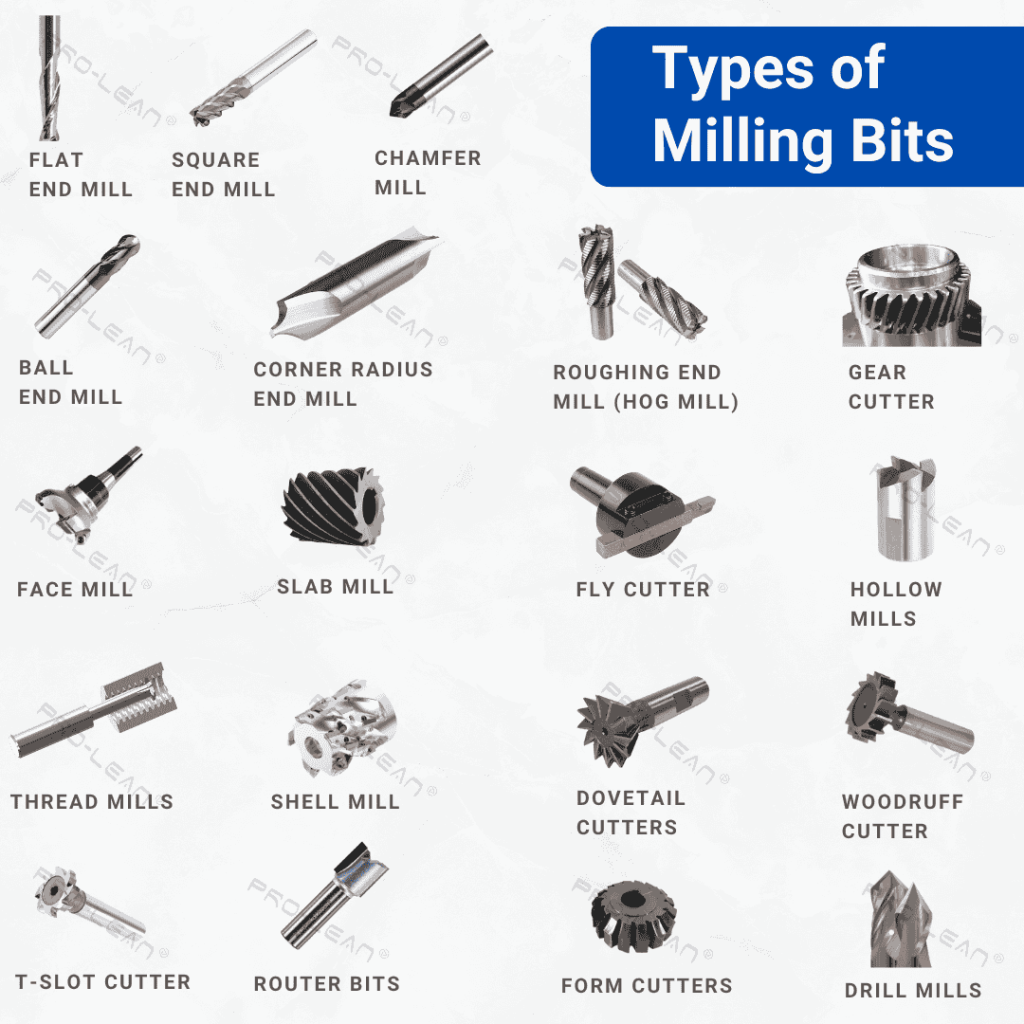

Our engineering team works closely with clients to tailor solutions based on specific material grades, machine rigidity, and operational parameters. From 2-flute center-cutting end mills to high-helix roughers and corner-radius inserts, every product undergoes rigorous testing before leaving our facility in Wuxi, China. We serve industries ranging from automotive and aerospace to mold & die and energy equipment manufacturing—delivering tools that meet global standards for reliability and innovation.

Below are key specifications for our premium steel-optimized milling bit series:

| Specification | Detail |

|---|---|

| Tool Material | Ultra-fine grain tungsten carbide (WC-Co) |

| Coating Options | AlTiN, TiAlN, DLC, and multi-layer PVD coatings |

| Diameter Range | 3 mm – 25 mm |

| Flute Count | 2 to 6 flutes (based on application) |

| Helix Angle | 30°, 35°, 45° (high helix for improved chip evacuation) |

| Corner Types | Square, corner radius (0.2 mm – 2.0 mm), ball nose |

| Shank Tolerance | h6 precision ground for secure tool holding |

| Recommended Cutting Speed (Steel) | 120 – 250 m/min (depending on grade and coating) |

| Compatible Machines | All major CNC machining centers (Fanuc, Siemens, Heidenhain controls) |

Wuxi Lead Precision Machinery is committed to being more than a supplier—we are a technical partner invested in your machining success. Our global logistics network ensures fast delivery, while our engineering support team provides ongoing assistance with tool selection, troubleshooting, and process optimization.

For expert guidance on selecting the right milling bits for your steel machining applications, contact us today. Let us help you achieve higher productivity, reduced cycle times, and flawless surface quality.

Email us at [email protected] to request samples, technical data sheets, or a personalized consultation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.