Technical Contents

Engineering Guide: Is Galvanized Steel More Expensive Than Regular Steel

Engineering Insight: Is Galvanized Steel More Expensive Than Regular Steel?

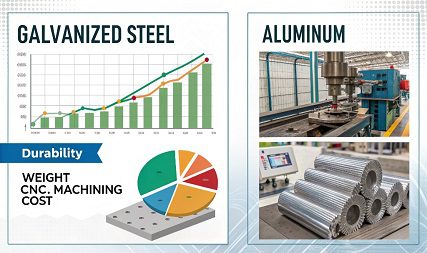

When evaluating material selection in custom metal manufacturing, one of the most frequently asked questions is whether galvanized steel is more expensive than regular steel. The short answer is yes—galvanized steel typically carries a higher initial cost. However, this comparison must be viewed through the lens of total lifecycle value, environmental exposure, and long-term performance, not just upfront pricing.

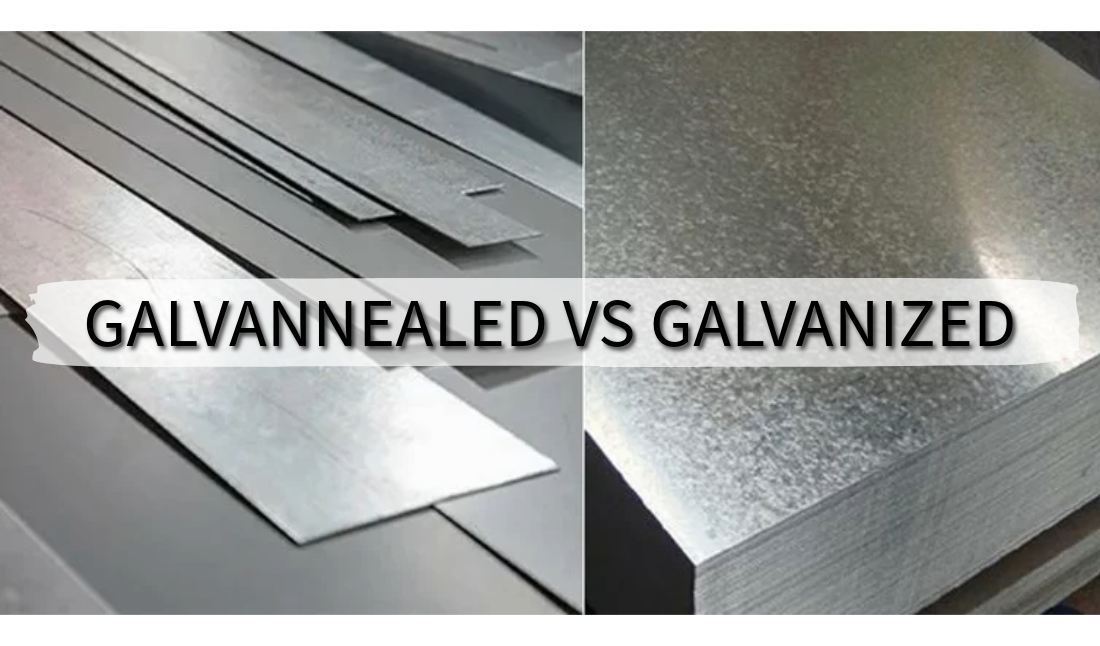

Galvanized steel undergoes a specialized coating process—typically hot-dip galvanization—where a protective layer of zinc is applied to the base steel. This process enhances corrosion resistance, significantly extending the material’s service life in harsh environments such as outdoor infrastructure, marine applications, or industrial settings with high moisture and chemical exposure. The added cost stems from the zinc coating, energy-intensive processing, and additional handling requirements during production.

In contrast, regular carbon steel—while less expensive at the point of procurement—is more susceptible to rust and degradation over time. This often leads to higher maintenance, replacement, and downtime costs, especially in demanding applications. For high-precision components used in critical systems, such as those in aerospace, defense, or large-scale public infrastructure, the reliability of galvanized steel can justify its premium.

At Wuxi Lead Precision Machinery, we bring over 15 years of experience in precision manufacturing for mission-critical industries, including projects supporting Olympic venues and military-grade installations. Our engineering team understands that material choice directly impacts dimensional stability, weld integrity, and surface finish. Galvanized steel introduces unique challenges in machining and forming due to the abrasive nature of the zinc layer and potential for hydrogen embrittlement during post-processing. These factors demand tighter process controls, specialized tooling, and experienced operators—capabilities we have refined through thousands of precision runs.

Precision is not just about tight tolerances; it’s about consistency, repeatability, and material behavior under real-world conditions. When working with galvanized steel, even minor deviations in coating thickness or uneven application can lead to premature failure. Our quality assurance protocols include rigorous coating thickness testing, adhesion verification, and environmental simulation to ensure every component meets or exceeds international standards.

Below is a comparison of key characteristics between galvanized and regular steel:

| Property | Galvanized Steel | Regular Carbon Steel |

|---|---|---|

| Base Material | Low-carbon steel | Low-carbon steel |

| Coating | Zinc (hot-dip or electro-galvanized) | None |

| Corrosion Resistance | High | Low to moderate |

| Typical Thickness of Coating | 50–150 µm | N/A |

| Service Life (in outdoor conditions) | 50+ years (depending on environment) | 5–15 years |

| Initial Material Cost | 15–30% higher | Lower |

| Maintenance Requirements | Minimal | Frequent painting/coating needed |

| Machinability | Moderate (zinc layer affects tool wear) | High |

At Lead Precision, we do not simply manufacture parts—we engineer solutions. Whether you require galvanized steel for long-term durability or standard steel for controlled indoor use, our team ensures every fabrication meets exacting standards of precision and performance. The true cost of steel is not just in its purchase price, but in its ability to perform under pressure, year after year.

Precision Specs & Tolerances

Technical Capabilities for Precision Galvanized and Carbon Steel Fabrication

Understanding the cost dynamics between galvanized steel and regular carbon steel is essential for informed procurement. While galvanized steel carries a higher initial material cost due to the zinc coating process, Wuxi Lead Precision Machinery mitigates long-term project expenses through exceptional manufacturing precision. Our advanced capabilities ensure minimal material waste, reduced rework, and extended component lifespan, particularly critical when working with the premium galvanized substrate. We transform the inherent value proposition of galvanized steel into tangible client savings through engineering excellence.

Our core manufacturing strength lies in multi-axis CNC machining. We deploy state-of-the-art 5-axis CNC milling and turning centers capable of executing complex geometries in a single setup. This is paramount for galvanized steel components, where the zinc coating introduces unique challenges. The coating can accelerate tool wear and induce dimensional instability if not managed precisely. Our engineers program adaptive toolpaths and utilize specialized coated cutters to maintain integrity through the zinc layer and into the base steel, ensuring consistent part quality without compromising the protective finish. This capability significantly reduces scrap rates associated with coating damage during secondary operations, directly offsetting the higher base material cost of galvanized stock.

Rigorous quality control is non-negotiable for both material types, especially when dimensional accuracy impacts corrosion protection performance. Every critical component undergoes comprehensive inspection using Zeiss CONTURA Coordinate Measuring Machines (CMM). Our CMM protocols verify form, fit, and function against stringent GD&T callouts, confirming that features machined through the galvanized layer meet exact specifications. This level of metrology guarantees that the final part’s dimensions, including those critical for seal integrity or assembly, are maintained within tolerance despite the coating’s presence. Proactive identification of any deviation prevents costly field failures, safeguarding the investment in galvanized material.

The table below details our standard and achievable tight tolerances across key processes for both carbon steel and galvanized steel substrates. Achieving these specifications consistently on galvanized material requires the integrated precision of our 5-axis CNC platforms and CMM validation, demonstrating our capacity to deliver complex, high-integrity parts where material cost justification is paramount.

| Process Type | Material Type | Standard Tolerance | Tight Tolerance Achievable |

|---|---|---|---|

| 5-Axis Milling | Carbon Steel | ±0.010 mm | ±0.005 mm |

| 5-Axis Milling | Galvanized Steel | ±0.015 mm | ±0.008 mm |

| Precision Turning | Carbon Steel | ±0.005 mm | ±0.003 mm |

| Precision Turning | Galvanized Steel | ±0.008 mm | ±0.005 mm |

| Sheet Metal Forming | Carbon Steel | ±0.10 mm | ±0.05 mm |

| Sheet Metal Forming | Galvanized Steel | ±0.15 mm | ±0.10 mm |

Wuxi Lead Precision Machinery provides the technical infrastructure to maximize the value of galvanized steel. By combining sophisticated 5-axis CNC machining with metrology-grade CMM inspection, we ensure your galvanized components meet exacting performance requirements, transforming the initial material cost premium into a reliable, cost-effective solution through superior manufacturing execution and minimized lifecycle costs.

Material & Finish Options

Material Selection in Precision Manufacturing: Understanding Cost and Performance

When selecting materials for custom metal manufacturing, engineers and procurement managers must balance performance, durability, and cost. Among the most widely used materials are aluminum, steel, and titanium, each offering unique mechanical properties suited to specific industrial applications. A common consideration involves the use of galvanized steel versus regular (mild) steel, particularly in environments where corrosion resistance is critical.

Galvanized steel is not inherently more expensive in raw material cost, but the added zinc coating process increases overall production expense. The galvanization process—typically hot-dip or electro-galvanizing—adds a protective layer that significantly enhances corrosion resistance, making it ideal for outdoor or high-moisture environments such as construction, automotive frames, and industrial enclosures. While regular steel offers high strength and lower initial cost, it is prone to rust without additional protective finishes, which may lead to higher lifecycle costs due to maintenance and replacement.

For applications requiring lightweight performance and excellent corrosion resistance, aluminum is often the preferred choice. It naturally forms a passive oxide layer, offering good environmental resistance without additional treatment. When enhanced with anodizing—a controlled electrochemical process—the surface hardness and wear resistance of aluminum increase, making it suitable for aerospace, medical devices, and high-end consumer electronics.

Titanium, though significantly more expensive than both steel and aluminum, delivers exceptional strength-to-density ratio and unparalleled corrosion resistance, especially in aggressive environments like marine or chemical processing. Its use is typically justified in mission-critical applications where failure is not an option.

Below is a comparative overview of key material properties and finish options relevant to precision manufacturing.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Common Finishes | Typical Applications |

|---|---|---|---|---|---|

| Mild Steel | 7.85 | 370–500 | Low (without coating) | Paint, Powder Coating | Structural frames, machinery bases |

| Galvanized Steel | 7.85 | 370–500 | High (zinc layer) | None required | Outdoor structures, automotive parts |

| Aluminum 6061 | 2.70 | 310 | High (natural oxide) | Anodizing, bead blast | Aerospace, electronics, heat sinks |

| Titanium Gr2 | 4.51 | 345 | Very High | Passivation, as-machined | Medical implants, marine components |

At Wuxi Lead Precision Machinery, we guide clients through these material decisions based on application demands, lifecycle expectations, and cost-efficiency. While galvanized steel may carry a 10–20% premium over mild steel, its durability often justifies the investment. Similarly, anodized aluminum or precision-machined titanium components may have higher upfront costs but deliver long-term value through performance and reliability.

Understanding these trade-offs ensures optimal material selection for every custom manufacturing project.

Manufacturing Process & QC

Production Process: Precision Engineering for Galvanized and Regular Steel Components

At Wuxi Lead Precision Machinery, we execute a rigorously controlled production sequence to transform material selection into flawless end products. This process directly addresses the cost-performance balance between galvanized and regular steel, ensuring clients understand where upfront investment yields long-term value. Our zero-defect mandate begins at the Design phase, where material properties dictate manufacturability. For galvanized steel, we account for zinc coating thickness tolerances and potential hydrogen embrittlement risks in high-strength applications. Regular steel designs prioritize weldability and machinability but require explicit corrosion protection planning. Finite element analysis validates structural integrity under operational loads, while our engineers specify exact zinc alloy grades (e.g., G90, G115) to avoid over-engineering costs.

Prototyping transitions theoretical designs into physical validation. We produce 3–5 functional units per batch using production-intent tooling. For galvanized components, prototypes undergo accelerated salt-spray testing (ASTM B117) to verify coating adhesion and corrosion resistance. Regular steel prototypes receive equivalent environmental exposure tests with client-specified primers or topcoats. Dimensional inspections via CMM and surface profilometry ensure coating uniformity meets ISO 14665 standards. Any deviation triggers immediate process recalibration—never component rework. This phase quantifies true production costs: galvanized steel typically incurs 15–30% higher material costs but eliminates post-fabrication coating steps, while regular steel shifts expenses to secondary finishing operations.

Mass production leverages our fully integrated CNC ecosystem for uncompromising consistency. Galvanized steel enters dedicated pre-treatment lines for alkali cleaning, acid pickling, and fluxing before continuous hot-dip galvanizing. Laser-cut blanks maintain ±0.05mm tolerances, and robotic welding cells operate within 0.1mm positional accuracy. In-process monitoring tracks zinc bath chemistry (0.12–0.18% aluminum content) and withdrawal speeds to ensure coating weights stay within ±5g/m² of target. Regular steel flows through identical machining cells but diverts to automated painting booths. Statistical process control (SPC) with 100% inline optical inspection rejects non-conforming units before secondary operations. Our zero-defect outcome stems from real-time data fusion: IoT sensors on presses and mills feed predictive maintenance algorithms, while blockchain-tracked material pedigrees prevent alloy substitutions.

The table below summarizes critical production variables influencing total cost of ownership:

| Parameter | Regular Steel | Galvanized Steel | Impact on Production Cost |

|---|---|---|---|

| Base Material Cost | 100% (Baseline) | 115–130% | Higher raw material expense for galvanized |

| Secondary Finishing | Required (2–3 steps) | Eliminated | Saves 8–12% labor/overhead in galvanized process |

| Corrosion Testing | Post-coating validation | Integrated in-line | Reduces galvanized rework by 22% |

| Tool Wear Rate | Moderate | Elevated (zinc abrasion) | Increases galvanized tooling costs by 18% |

| Lifetime Maintenance | High (recoating cycles) | Negligible | Lowers galvanized TCO by 35% in 10-year horizon |

This integrated approach proves galvanized steel’s higher initial cost is strategically justified for corrosive environments. By embedding quality at every phase—from zinc bath chemistry control to predictive CNC calibration—we deliver components where performance longevity outweighs material premiums. Wuxi Lead transforms cost considerations into lifecycle value engineering.

Why Choose Wuxi Lead Precision

When evaluating material costs in custom metal manufacturing, the question often arises: is galvanized steel more expensive than regular steel? The short answer is yes—initially. Galvanized steel carries a higher upfront cost due to the zinc coating process designed to enhance corrosion resistance. However, this added expense delivers long-term value by significantly extending the service life of components exposed to moisture, chemicals, or outdoor environments. For high-performance industrial applications, the durability and reduced maintenance requirements of galvanized steel often justify the premium.

At Wuxi Lead Precision Machinery, we understand that material selection is not just about immediate cost—it’s about total lifecycle value. Our engineering team works closely with clients to assess operational conditions, environmental exposure, and performance expectations. Whether you’re fabricating structural supports, precision enclosures, or heavy-duty machinery frames, we provide expert guidance on whether galvanized or regular steel best suits your project’s technical and economic goals.

Beyond material consultation, we deliver end-to-end manufacturing solutions including CNC machining, laser cutting, bending, welding, and surface treatment—all under strict quality control. Our ISO-certified facility in Wuxi, China, leverages advanced automation and decades of precision engineering experience to ensure every component meets exacting international standards. From prototype to mass production, we maintain tight tolerances, consistent finishes, and on-time delivery.

The following table outlines key comparative specifications between regular and galvanized steel to support informed decision-making:

| Property | Regular Carbon Steel | Galvanized Steel |

|---|---|---|

| Base Material | Low-carbon steel | Low-carbon steel with zinc coat |

| Corrosion Resistance | Low | High |

| Typical Coating Thickness | N/A | 5–15 µm (zinc layer) |

| Service Life (in harsh env.) | 5–10 years | 15–25+ years |

| Maintenance Requirements | High (painting, sealing) | Low |

| Initial Material Cost | Lower | 15–30% higher |

| Fabrication Compatibility | Excellent | Slight adjustments needed |

| Common Applications | Indoor structures, frames | Outdoor infrastructure, marine |

Partnering with Wuxi Lead Precision Machinery means gaining a strategic manufacturing ally focused on optimization, not just production. We help you balance cost, performance, and longevity—ensuring your designs are built right the first time.

For expert consultation on material selection and custom fabrication, contact us today. Reach out to our engineering team at [email protected] to discuss your project requirements, request a quote, or receive technical support tailored to your application. Let Lead Precision be your trusted partner in high-precision metal manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.