Technical Contents

Engineering Guide: Best Practices In Metal Fabrication

Engineering Insight: Best Practices in Metal Fabrication – The Critical Role of Precision

In the realm of sheet metal fabrication, precision is not merely a performance metric—it is the foundation upon which quality, reliability, and long-term value are built. For high-stakes industries such as aerospace, defense, and advanced industrial equipment, even micron-level deviations can compromise structural integrity, assembly compatibility, and operational safety. At Wuxi Lead Precision Machinery, we treat precision as a non-negotiable standard, refined through decades of engineering excellence and validated by our contributions to mission-critical projects, including components for Olympic-standard facilities and military-grade systems.

Our experience in delivering for such demanding applications has reinforced a fundamental truth: precision begins long before the first cut is made. It starts with meticulous design validation, material selection, and process planning. Advanced CAD/CAM integration ensures that every dimension, bend, and tolerance is simulated and optimized prior to production. This proactive approach minimizes rework, reduces waste, and ensures repeatability across production runs—key factors in maintaining consistency at scale.

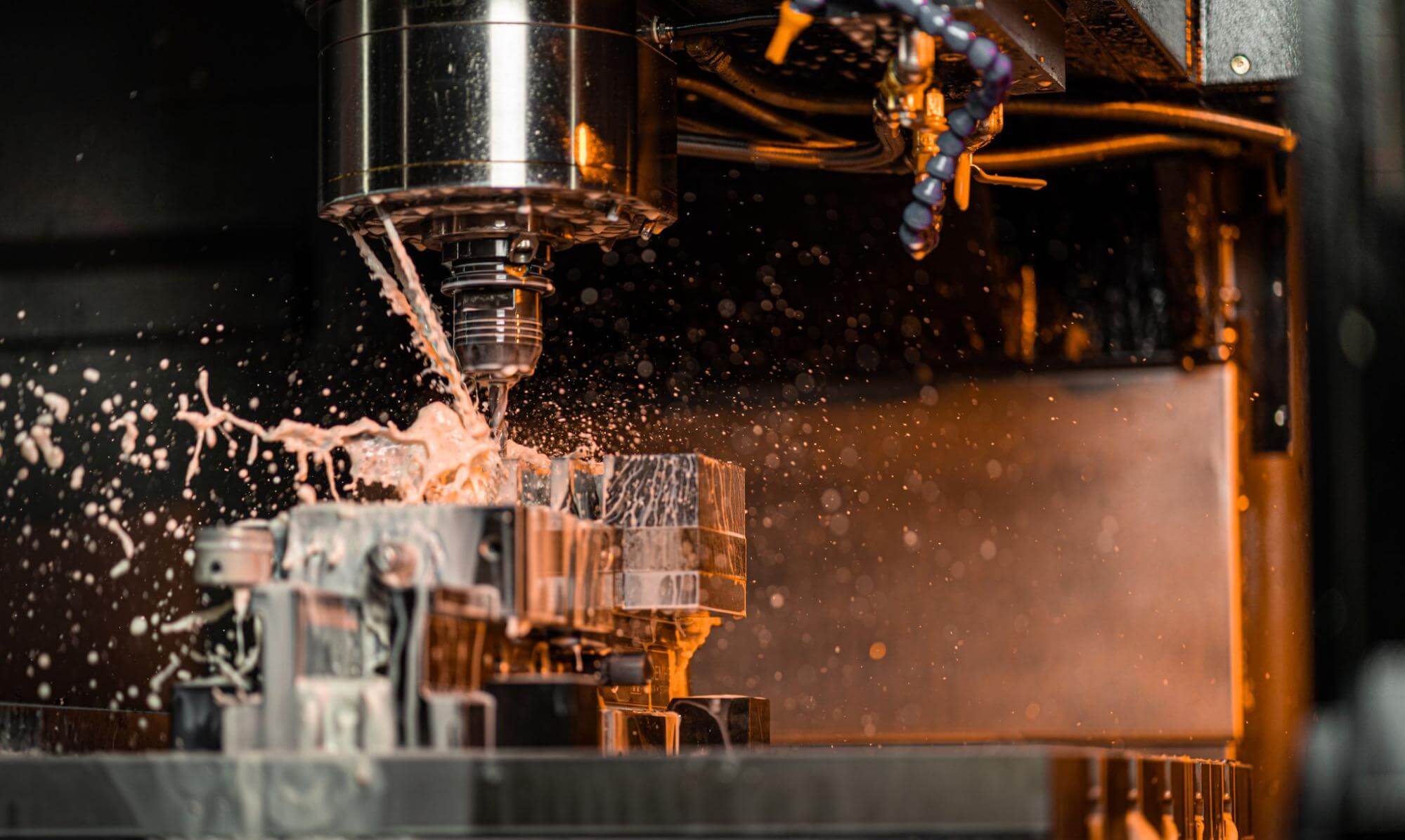

At the core of our fabrication process are state-of-the-art CNC punching, laser cutting, and press brake systems, all calibrated to maintain tight tolerances. Our facility operates under strict ISO 9001 quality management protocols, with continuous in-process inspections using coordinate measuring machines (CMM) and laser tracking systems. This end-to-end control allows us to consistently achieve fabrication tolerances that meet or exceed international standards.

One of the most critical aspects of precision in sheet metal work is managing material behavior. Factors such as spring-back in bending, thermal distortion during cutting, and grain orientation must be anticipated and compensated for in programming. Our engineering team applies material-specific correction algorithms and leverages real-time feedback loops to adjust parameters dynamically, ensuring the final part matches the digital model with minimal deviation.

Our track record in supplying components for Olympic infrastructure—where architectural precision meets functional durability—and military applications—where failure is not an option—demonstrates our capability to meet the highest demands. These projects required not only technical precision but also rigorous documentation, traceability, and compliance with stringent regulatory frameworks.

Below is a summary of our standard precision capabilities for sheet metal fabrication:

| Specification | Capability |

|---|---|

| Laser Cutting Tolerance | ±0.1 mm |

| CNC Punching Tolerance | ±0.1 mm |

| Press Brake Bending Tolerance | ±0.2° / ±0.1 mm |

| Hole Position Accuracy | ±0.05 mm |

| Surface Flatness (per 300 mm) | 0.1 mm |

| Material Thickness Range | 0.5 – 6.0 mm (steel, stainless, aluminum) |

| Maximum Forming Length | 3000 mm |

Precision in metal fabrication is not an isolated objective—it is the result of integrated engineering, disciplined process control, and a culture of continuous improvement. At Wuxi Lead Precision Machinery, we apply these principles daily, ensuring that every component we produce meets the exacting standards required by the world’s most advanced industries.

Precision Specs & Tolerances

Technical Capabilities: Precision Sheet Metal Fabrication at Scale

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions engineered for the most demanding industrial applications. Our technical foundation integrates cutting-edge multi-axis machining with rigorous quality assurance protocols, ensuring components meet exacting dimensional and functional requirements critical for aerospace, medical, and high-tech sectors. This capability set transcends basic forming and cutting, providing clients with a single-source partner for complex, high-integrity parts from prototype to volume production.

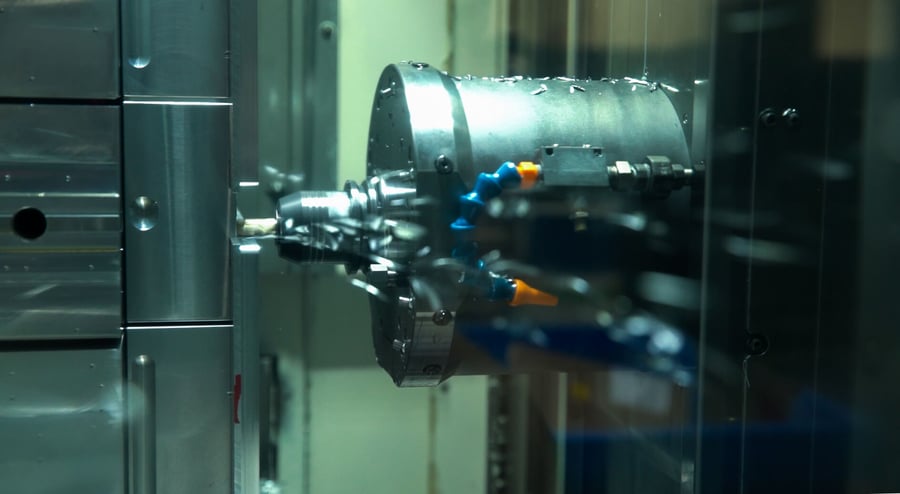

Our core manufacturing strength resides in a modern fleet of 5-axis CNC milling and turning centers. This technology enables simultaneous, coordinated movement across five axes, allowing for the precise machining of intricate geometries, deep cavities, and complex contours in a single setup. The elimination of multiple fixturing stages significantly reduces cumulative error, enhances part accuracy, and improves surface finish consistency. We routinely machine challenging materials including aerospace-grade aluminum alloys, medical stainless steels (316L, 17-4PH), titanium, and high-strength engineering plastics with exceptional repeatability. The strategic deployment of 5-axis capability minimizes lead times, reduces work-in-process inventory, and ensures superior part integrity compared to traditional 3-axis methods requiring secondary operations.

Quality is not an endpoint but an integrated process at Wuxi Lead. Every critical component undergoes comprehensive verification using state-of-the-art Coordinate Measuring Machines (CMM). Our Zeiss and Mitutoyo CMM systems, operating within a climate-controlled metrology lab, provide traceable, nanometer-level measurement accuracy. This allows for full first-article inspection reports (FAIR) per AS9102 or client-specific requirements, detailed geometric dimensioning and tolerancing (GD&T) validation, and thorough process capability studies (Cp/Cpk). Real-time data from CMM inspections feeds directly into our statistical process control (SPC) systems, enabling proactive adjustments and continuous process refinement to maintain stability and predictability throughout production runs.

The precision achievable through our integrated 5-axis machining and metrology systems is reflected in the consistent tolerances we deliver across diverse sheet metal fabrication and precision machining operations. Key capability ranges are summarized below:

| Material Thickness Range | Feature Type | Standard Capability (mm) | Precision Capability (mm) |

|---|---|---|---|

| 0.5 mm – 25.0 mm | Linear Dimensions | ±0.05 | ±0.01 to ±0.025 |

| 0.5 mm – 25.0 mm | Hole Diameter | ±0.05 | ±0.01 to ±0.02 |

| All Thicknesses | Positional Tolerance | ±0.08 | ±0.02 to ±0.05 |

| All Thicknesses | Flatness | 0.1 mm / 100 mm | 0.025 mm / 100 mm |

| All Thicknesses | Profile of a Surface | ±0.1 | ±0.025 to ±0.05 |

These tolerances represent typical achievable results under standard production conditions for qualified materials and geometries. Tighter specifications are attainable through specialized process development and dedicated inspection protocols, subject to design review and feasibility analysis. Our engineering team collaborates closely with clients during the design for manufacturability (DFM) phase to optimize part geometry for maximum precision and cost efficiency within the intended application context. This integrated approach to capability and quality assurance ensures Wuxi Lead consistently delivers sheet metal components that perform reliably in the most critical assemblies.

Material & Finish Options

Material Selection in Precision Sheet Metal Fabrication

Selecting the appropriate material is a foundational step in achieving optimal performance, durability, and cost-efficiency in sheet metal fabrication. At Wuxi Lead Precision Machinery, we emphasize material compatibility with design intent, environmental exposure, and functional requirements. The most widely used metals in high-precision applications are aluminum, steel, and titanium, each offering distinct mechanical and chemical properties.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is ideal for aerospace, electronics, and transportation applications where weight reduction is critical. Grade 6061-T6 is commonly selected for structural components due to its weldability and moderate strength, while 5052-H32 is preferred for its superior formability in complex sheet metal bends. Aluminum naturally forms a protective oxide layer, but for enhanced surface durability and aesthetic control, anodizing is recommended.

Steel remains the backbone of industrial fabrication, with carbon steel and stainless steel serving different purposes. Carbon steel, such as ASTM A36 or SPCC, offers high tensile strength and affordability, making it suitable for enclosures, frames, and machinery parts. However, it requires protective finishes like powder coating or plating to resist corrosion. In contrast, stainless steel—particularly grades 304 and 316—provides inherent corrosion resistance and is widely used in medical, food processing, and marine environments. Its higher hardness demands precise tooling and forming techniques.

Titanium, though more costly, delivers unmatched performance in extreme conditions. With exceptional strength-to-density ratio and resistance to high temperatures and corrosive media, Grade 2 and Grade 5 (Ti-6Al-4V) titanium are used in aerospace, defense, and high-performance automotive sectors. Its low thermal conductivity and high reactivity during machining require specialized CNC processes and tooling, which Wuxi Lead Precision Machinery is equipped to handle with strict process controls.

Surface Finishing: The Role of Anodizing

Anodizing is a critical electrochemical finishing process primarily applied to aluminum. It enhances surface hardness, improves wear resistance, and allows for color coding through dye integration. Type II (sulfuric acid) anodizing is standard for decorative and moderate-duty applications, while Type III (hardcoat anodizing) delivers thicker, more durable layers suitable for high-wear environments. Anodized finishes are non-conductive, making them ideal for electrical enclosures requiring insulation.

Material selection must align with fabrication processes, lifecycle expectations, and regulatory standards. At Wuxi Lead, we support clients in evaluating these factors through DFM analysis and material traceability, ensuring every component meets exacting industry benchmarks.

| Material | Common Grades | Tensile Strength (MPa) | Key Applications | Recommended Finishes |

|---|---|---|---|---|

| Aluminum | 6061-T6, 5052-H32 | 290–320 | Aerospace, Electronics | Anodizing, Powder Coating |

| Carbon Steel | SPCC, ASTM A36 | 360–500 | Industrial Frames, Machinery | Zinc Plating, Paint, Powder Coat |

| Stainless Steel | 304, 316 | 505–580 | Medical, Food Processing | Passivation, Brushed Finish |

| Titanium | Grade 2, Grade 5 | 345–900 | Aerospace, Defense | Anodizing, Passivation |

Manufacturing Process & QC

Precision Sheet Metal Fabrication: The Zero Defects Production Pathway

Achieving true zero defects in sheet metal fabrication demands a meticulously controlled, integrated production pathway. At Wuxi Lead Precision Machinery, we enforce a non-negotiable sequence: Design rigor, Prototyping validation, and Mass Production execution. This structured approach eliminates downstream errors, ensuring first-time-right outcomes for critical components.

The foundation is Design for Manufacturability (DFM) Integration. Our engineering team collaborates directly with client CAD models, utilizing SolidWorks and AutoCAD to conduct rigorous DFM analysis before any material is cut. We scrutinize bend allowances, kerf widths, grain direction, and tooling accessibility. This proactive review identifies potential stress points, weld accessibility issues, and tolerance stack-ups early. Crucially, we validate material suitability against operational stresses and environmental factors, ensuring the design is not just functional on paper but inherently manufacturable to micron-level precision. Skipping this step guarantees costly rework; embedding it prevents 80% of common fabrication failures.

Prototyping is not optional; it is functional validation. Leveraging our rapid prototyping cells, we produce 1-5 physical units using the exact production-grade materials and near-identical processes intended for volume. These prototypes undergo comprehensive metrology in our dedicated lab, verifying all critical dimensions against the validated DFM model using CMM and optical comparators. More importantly, we subject prototypes to simulated operational loads and environmental testing where applicable. This phase catches subtle design oversights or material behavior anomalies invisible in simulation. Client sign-off on these rigorously tested prototypes is the mandatory gateway to mass production, transforming theoretical design into proven manufacturability.

Mass Production executes the validated process with statistical discipline. Every parameter established during prototyping – laser power, press brake tonnage, weld amperage, robotic pathing – is locked into our CNC systems. Real-time monitoring via integrated sensors tracks critical variables like temperature, pressure, and positional accuracy. Statistical Process Control (SPC) charts are continuously analyzed; any deviation beyond established control limits triggers immediate process correction, not just part rejection. This closed-loop system ensures consistency. Our commitment to zero defects means investing in the capability to hold tolerances consistently, as demonstrated below.

| Process Capability | Tolerance Range | Material Range | Key Equipment |

|---|---|---|---|

| Laser Cutting | ±0.05 mm | Mild Steel, SS, Aluminum (0.5-6mm) | 6kW Fiber Laser, Automated Loader |

| Precision Press Brake | ±0.1° Bend Angle | As per Cutting | CNC Tonnage-Controlled Brakes |

| Robotic MIG/TIG Welding | ±0.2 mm Gap Control | Full Range | FANUC Robots, Pulsed Power Sources |

| Full-Process Metrology | Sub-10µm Accuracy | N/A | 7-Axis CMM, Vision Systems |

This integrated Design-Prototype-Production framework, underpinned by advanced equipment and SPC discipline, is how Wuxi Lead delivers true zero defects. We transform complex sheet metal requirements into flawless, high-reliability components, making precision manufacturing a strategic partnership, not a procurement transaction.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Sheet Metal Fabrication Excellence

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and consistency are non-negotiable in high-end manufacturing. As a trusted leader in sheet metal fabrication, we specialize in delivering engineered solutions that meet the exacting standards of industries such as aerospace, automotive, medical devices, and advanced industrial equipment. Our commitment to quality is embedded in every process, from raw material selection to final inspection, ensuring that your components perform flawlessly in demanding applications.

Our state-of-the-art facility in Wuxi, China, is equipped with advanced CNC laser cutting, precision bending, and automated welding systems. These technologies are operated by a team of highly trained engineers and technicians who bring decades of collective experience in complex fabrication projects. We integrate lean manufacturing principles and real-time quality control to minimize lead times and eliminate defects—giving you a competitive edge in your market.

What sets Wuxi Lead apart is our end-to-end engineering support. We don’t just manufacture parts—we collaborate. From design for manufacturability (DFM) analysis to prototyping and full-scale production, our engineering team works closely with your design and supply chain teams to optimize performance, reduce costs, and accelerate time to market. Whether you require low-volume, high-mix production or high-volume runs with tight tolerances, we have the flexibility and scalability to meet your needs.

Our quality management system is ISO 9001:2015 certified, and we adhere to international standards including ASTM, DIN, and JIS. Every component undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and in-process gauging to ensure dimensional accuracy and material integrity.

Below are key capabilities that define our sheet metal fabrication services:

| Capability | Specification |

|---|---|

| Material Types | Stainless Steel, Aluminum, Carbon Steel, Galvanized, Copper, Brass |

| Thickness Range | 0.5 mm – 25 mm |

| Laser Cutting Accuracy | ±0.1 mm |

| Max Laser Cutting Size | 4000 mm × 2000 mm |

| CNC Bending Tolerance | ±0.2° angular, ±0.1 mm linear |

| Max Bending Length | 6000 mm |

| Welding Processes | TIG, MIG, Spot, Robotic Welding |

| Surface Finishes | Powder Coating, Anodizing, Passivation, Brushing, Plating |

We invite global manufacturers to experience the Lead Precision difference. Partnering with us means gaining a true extension of your engineering and production team—one that prioritizes precision, transparency, and on-time delivery.

For inquiries, project submissions, or technical consultations, contact us today at [email protected]. Let’s build precision together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.