Technical Contents

Engineering Guide: Custom Injection Molding Companies

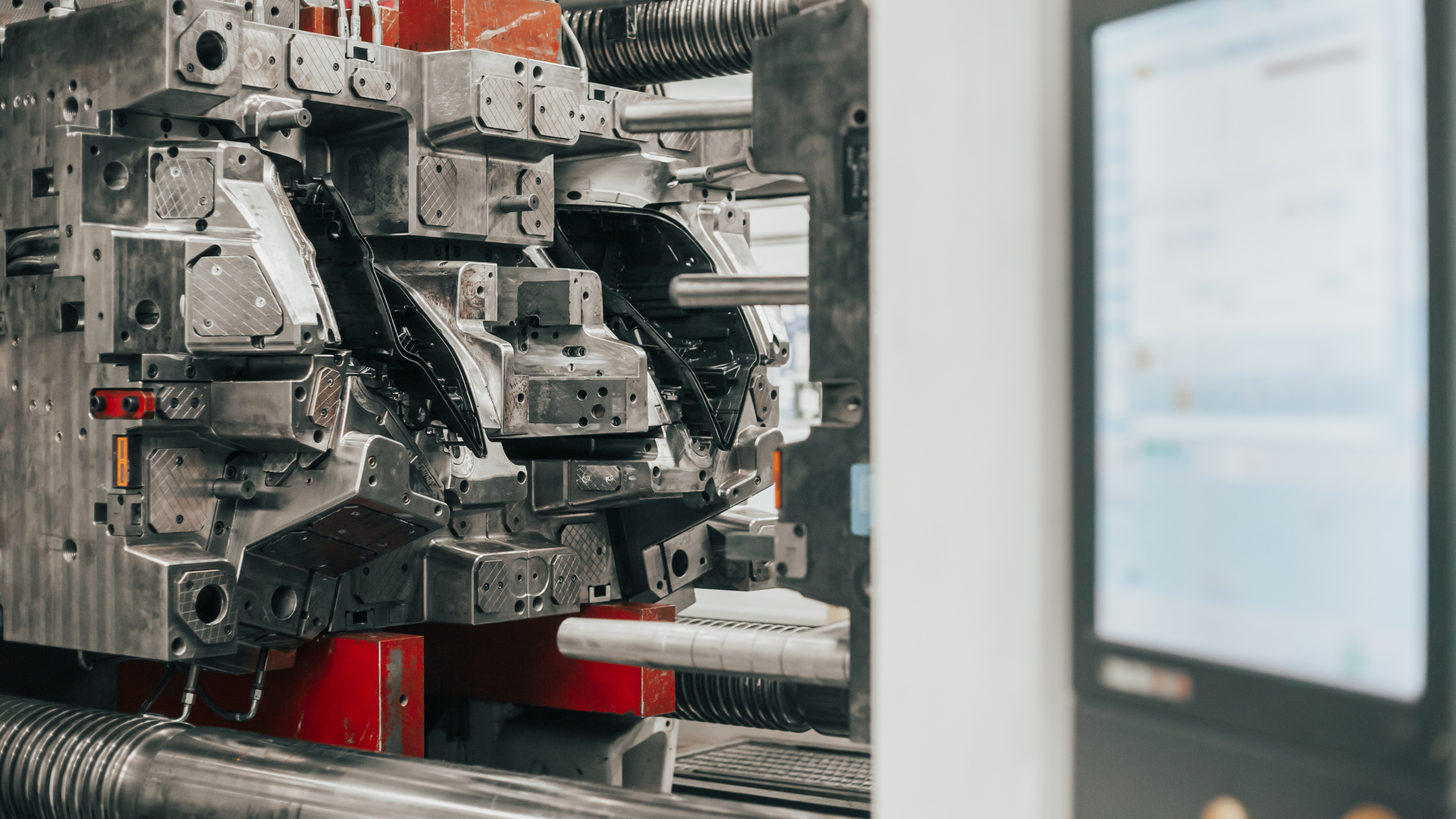

Engineering Insight Precision in Custom Injection Molding Tooling

Achieving dimensional accuracy and repeatability in injection molded components is non-negotiable for high-performance applications. The precision of the mold tooling itself is the absolute foundation. Minute deviations in cavity geometry, core alignment, or cooling channel placement directly translate into part warpage, sink marks, inconsistent wall thickness, and assembly failures downstream. Material behavior under high pressure and temperature cycles demands tooling engineered to exacting standards, where thermal stability and structural rigidity prevent drift during extended production runs. Tolerance stack-up across multiple mold components must be meticulously managed from the initial design phase through final assembly and polishing. For sectors like medical devices, aerospace, and advanced consumer electronics, where micro-features and tight assembly tolerances are commonplace, a variance of even 0.01mm can render a component unusable, leading to costly scrap, production delays, and compromised product integrity. The complexity of modern parts often necessitates multi-cavity molds or complex side-actions, exponentially increasing the precision requirements for seamless operation and consistent output.

At Wuxi Lead Precision Machinery, we engineer mold bases, cavities, cores, and critical inserts to the highest metrological standards, recognizing that the mold is the product. Our CNC machining centers, calibrated and maintained to sub-micron levels, ensure geometric accuracy and surface integrity essential for optimal part release and longevity. This commitment to precision engineering is not theoretical; it is proven in mission-critical applications. We have supplied tooling components meeting the stringent dimensional and material certification requirements for components used in Olympic-standard athletic equipment, where performance consistency is measured in milliseconds. Furthermore, our processes adhere to the rigorous traceability and quality assurance protocols demanded by select military subcontractors, where failure is not an option. This experience ingrained in our engineering culture directly benefits every custom injection molding project we undertake.

The table below outlines the precision capabilities inherent in our mold component manufacturing process, capabilities forged through demanding real-world applications:

| Parameter | Capability | Application Impact |

|---|---|---|

| Linear Tolerance | ±0.002 mm (±0.00008″) | Ensures precise fit for multi-cavity molds and tight assembly interfaces |

| Geometric Tolerance | < 0.005 mm (0.0002″) flatness | Critical for core/cavity alignment preventing flash and part distortion |

| Surface Finish (Ra) | 0.05 µm (2 µin) to 0.4 µm (16 µin) | Optimizes part release, reduces wear, achieves cosmetic requirements |

| Material Traceability | Full Mill Certificates & Batch Control | Mandatory for aerospace, medical, and defense compliance |

| In-Process Metrology | CMM, Vision Systems, Laser Scanning | Real-time verification ensures tolerance adherence before final assembly |

Precision in mold tooling is the decisive factor between a successful high-volume production run and costly rework. It directly impacts part quality, cycle time stability, tool life, and ultimately, the bottom line. Wuxi Lead Precision Machinery leverages its deep expertise in ultra-precise metal manufacturing, validated by projects serving the pinnacle of performance and reliability standards, to deliver the robust, accurate tooling foundation custom injection molding companies require for their most challenging applications. We understand that your success hinges on the unwavering accuracy of the tools we create.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions for industries requiring precision, reliability, and consistency. Our technical capabilities are built around high-performance 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, significantly enhancing machining flexibility and reducing setup times. This capability is particularly critical for components used in aerospace, medical devices, automotive, and industrial automation, where intricate contours and tight tolerances are non-negotiable.

Our 5-axis CNC platforms are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to ensure process stability and repeatability. This enables us to machine a wide range of metals, including aluminum alloys, stainless steel, titanium, tool steels, and high-temperature superalloys. Whether producing low-volume prototypes or scaling to high-volume production runs, our equipment and skilled engineering team ensure consistent part quality and on-time delivery.

Quality control is integrated at every stage of the manufacturing process. We employ Coordinate Measuring Machine (CMM) inspection to verify dimensional accuracy and geometric conformity. Our CMM systems are calibrated to international standards and operated by certified metrology technicians, ensuring traceable and repeatable results. In addition to first-article inspection reports (FAIR), we perform in-process and final inspections to maintain full compliance with customer specifications and industry standards such as ISO 9001 and AS9100.

All inspection data is documented and archived for full traceability, supporting stringent regulatory requirements in critical applications. We also utilize advanced CAD/CAM software and digital modeling tools to validate toolpaths and simulate machining operations prior to production, minimizing errors and optimizing cycle times.

The table below outlines the standard tolerance capabilities achievable through our 5-axis CNC machining and inspection processes:

| Dimension Type | Standard Tolerance | Precision Tolerance (Achievable) | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Up to 300 mm length |

| Angular Dimensions | ±0.1° | ±0.05° | Measured via CMM |

| Positional Tolerance | ±0.02 mm | ±0.01 mm | GD&T compliant |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | As machined or post-processed |

| Flatness | 0.02 mm | 0.005 mm | Over 100 mm surface |

| Circular Runout | 0.01 mm | 0.005 mm | Full CMM validation |

These capabilities reflect our commitment to delivering components that meet the highest standards of precision and performance. At Wuxi Lead Precision Machinery, we combine cutting-edge technology with rigorous quality assurance to serve as a trusted partner in custom metal manufacturing.

Material & Finish Options

Material Selection for High-Performance Injection Molds

Selecting the optimal material for injection mold components directly impacts tool longevity, part quality, and production economics. At Wuxi Lead Precision Machinery, we prioritize metallurgical properties that align with your resin type, volume requirements, and surface finish specifications. Aluminum, steel, and titanium each serve distinct roles in mold construction, with anodizing enhancing aluminum’s functional performance.

Aluminum alloys, particularly 7075-T6, offer superior thermal conductivity for rapid cycle times in prototyping or medium-volume production. This reduces cooling time by up to 30% compared to steel, accelerating time-to-market. However, aluminum’s lower hardness necessitates protective surface treatments like hard anodizing for abrasive or glass-filled resins. Its machinability also allows complex geometries at lower fabrication costs, making it ideal for low-corrosion applications under 100,000 cycles.

Tool steels dominate high-volume manufacturing due to exceptional wear resistance and dimensional stability. P20 steel (28-32 HRC) provides balanced toughness for general-purpose molds, while H13 (48-52 HRC) excels in high-temperature environments with corrosive resins like PVC. Pre-hardened steels minimize post-machining distortion, ensuring tight tolerances over millions of cycles. For extreme wear scenarios—such as engineering plastics with mineral fillers—through-hardened steels like S7 deliver unmatched durability but require precise heat treatment to avoid cracking.

Titanium Ti-6Al-4V is reserved for highly corrosive applications, such as medical-grade silicone molding, where its inertness prevents resin degradation. Though costly and challenging to machine, titanium’s strength-to-weight ratio and non-galling properties justify its use in niche, high-value tooling.

Anodizing: Critical for Aluminum Mold Performance

Anodizing transforms aluminum’s surface into a wear-resistant ceramic layer. Type II (sulfuric acid) anodizing (8-25 μm thickness) improves corrosion resistance for standard resins. For glass-filled or abrasive materials, Type III (hardcoat) anodizing (25-50 μm) achieves 60-70 HRC surface hardness—comparable to tool steel—while maintaining thermal conductivity. Proper sealing with nickel acetate or hot water is non-negotiable to prevent porosity and chemical ingress.

Comparative Material Properties for Injection Molds

| Material | Key Grades | Hardness (HRC) | Thermal Conductivity (W/mK) | Primary Application |

|---|---|---|---|---|

| Aluminum | 7075-T6 | 15 | 130 | Prototyping; low-volume production |

| Pre-hardened Steel | P20 | 28-32 | 28-36 | General-purpose high-volume molds |

| Hot-work Steel | H13 | 48-52 | 25-30 | High-temp/corrosive resins |

| Titanium | Ti-6Al-4V | 36 | 7 | Extreme corrosion resistance |

Material selection requires balancing thermal management, mechanical stress, and chemical exposure. Wuxi Lead Precision Machinery leverages 15+ years of metallurgical expertise to match your production goals with optimal material solutions, ensuring molds deliver maximum ROI. Contact our engineering team to analyze your specific application parameters and surface finish requirements.

Manufacturing Process & QC

From Concept to Perfection: The Precision Manufacturing Process at Wuxi Lead Precision Machinery

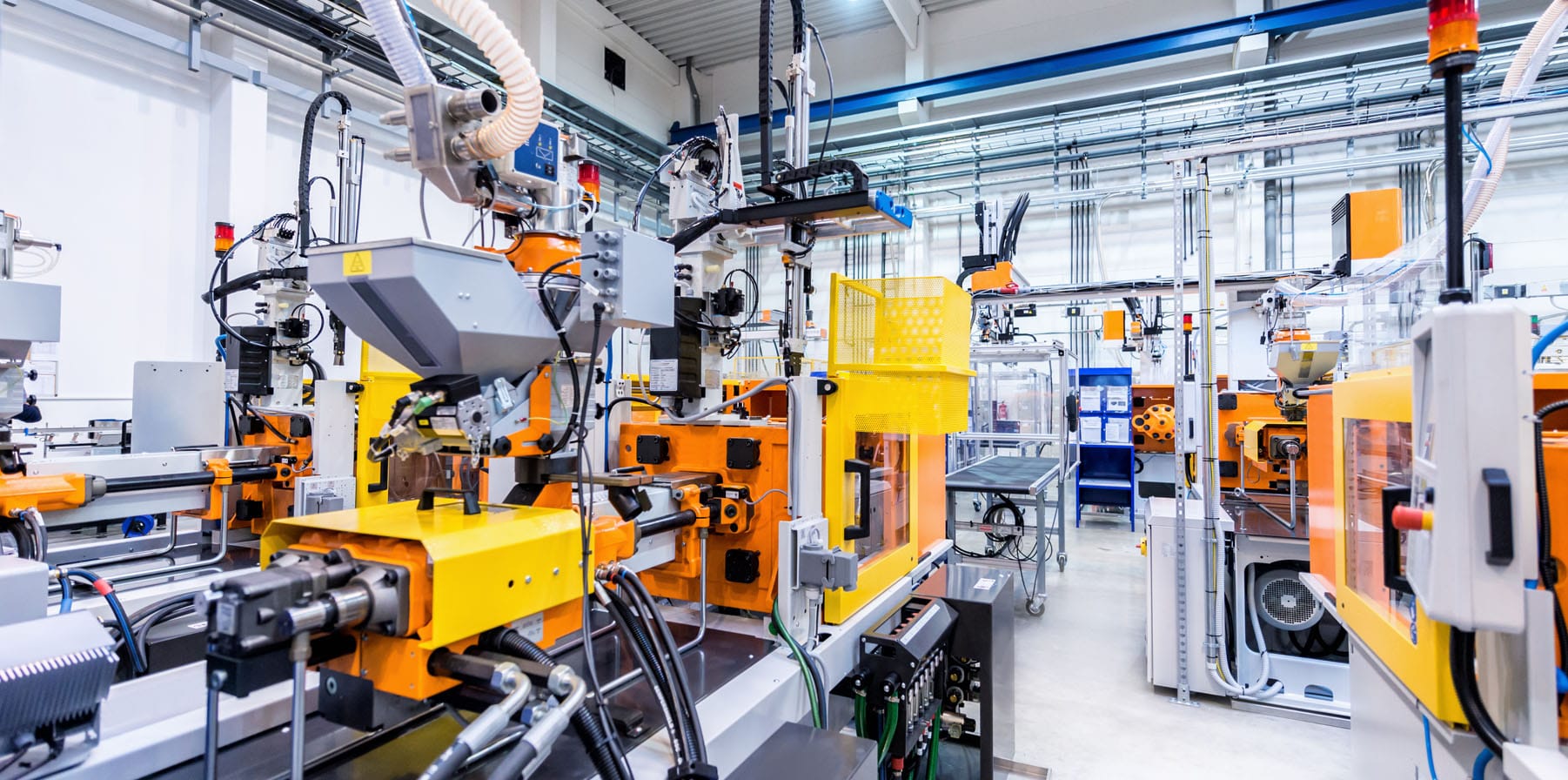

At Wuxi Lead Precision Machinery, we engineer excellence into every stage of custom metal manufacturing. Our end-to-end production process is built on a foundation of precision, consistency, and zero-defect performance—delivering mission-critical components for industries where failure is not an option. From initial design to full-scale mass production, our integrated workflow ensures that every part meets the highest standards of quality, functionality, and repeatability.

The journey begins with design collaboration. Our engineering team works closely with clients to translate concepts into manufacturable designs. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we optimize part geometry, material selection, and tooling strategies. This phase includes comprehensive design for manufacturability (DFM) reviews, ensuring that every component is not only functional but also efficient to produce at scale. Our engineers identify potential stress points, thermal behaviors, and assembly challenges early, eliminating costly revisions downstream.

Next comes prototyping, a critical validation step in our zero-defect philosophy. Using high-precision CNC machining and rapid tooling techniques, we produce functional prototypes that mirror final production parts. These prototypes undergo rigorous testing—dimensional inspection via coordinate measuring machines (CMM), material verification, and performance evaluation under real-world conditions. Feedback from this stage is incorporated into final design and process adjustments, ensuring that only fully validated designs advance to mass production.

Once approved, we transition seamlessly into high-volume manufacturing. Our state-of-the-art facility in Wuxi integrates automated CNC machining centers, robotic part handling, and real-time process monitoring to maintain tight tolerances and consistent quality. Every production run is governed by documented control plans, statistical process control (SPC), and in-line inspection protocols. Our quality management system is ISO 9001 certified, with traceability maintained at the batch and serial level.

Throughout the entire process, our commitment to zero defects is enforced through a culture of continuous improvement and error-proofing (poka-yoke). From raw material sourcing to final packaging, every step is documented, audited, and optimized.

Key Production Specifications

| Parameter | Capability |

|---|---|

| Material Compatibility | Stainless Steel, Aluminum, Titanium, Brass, Alloy Steel |

| Tolerance Range | ±0.005 mm |

| Surface Finish | Ra 0.2 – 3.2 μm (custom finishes available) |

| Maximum Part Size | 1200 mm × 800 mm × 600 mm |

| Production Capacity | Up to 500,000 units/month |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical), RoHS |

| Inspection Equipment | CMM, Optical Comparator, Hardness Tester, 2.5D Vision System |

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we deliver precision-engineered solutions with uncompromising reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Metal Components in Injection Molding

Custom injection molding demands metal components that meet exacting standards for durability, precision, and repeatability. Subpar tooling or structural parts lead to costly downtime, inconsistent part quality, and accelerated wear—directly impacting your production efficiency and bottom line. At Wuxi Lead Precision Machinery, we engineer mission-critical metal solutions specifically for the injection molding industry. Our CNC-machined inserts, cavities, ejector systems, and support frames are built to withstand high-pressure cycles while maintaining micron-level tolerances, ensuring your molds perform reliably over extended lifecycles. We eliminate the guesswork in metal component sourcing through rigorous material science expertise, in-house metrology, and processes validated by ISO 9001:2015 certification.

Our technical capabilities align precisely with the demands of modern injection molding applications. The table below details our core specifications for mold-critical components:

| Capability | Specification | Relevance to Injection Molding |

|---|---|---|

| Tolerance Control | ±0.001 mm (micron-level) | Ensures consistent part dimensions and reduces flash |

| Material Expertise | P20, H13, S136, 420SS, Titanium | Optimized for wear resistance, corrosion protection, and thermal stability |

| Max Work Envelope | 1200 x 800 x 650 mm | Accommodates large-scale mold bases and complex geometries |

| Surface Finish | Ra 0.05 µm to 0.8 µm (mirror-grade) | Minimizes part adhesion and ejection force |

| Lead Time (Standard) | 15–25 days (from approved CAD) | Reduces mold commissioning delays |

| Quality Assurance | 100% CMM + optical inspection | Guarantees dimensional integrity pre-shipment |

We integrate seamlessly into your workflow through collaborative engineering reviews, secure data handling protocols, and real-time production tracking. Unlike generic machine shops, our team speaks the language of mold designers and process engineers—anticipating challenges like thermal expansion compensation, venting optimization, and stress distribution in high-cavity molds. This domain-specific insight prevents costly redesigns and accelerates time-to-market for your end products.

Partnering with Lead Precision means investing in components that extend mold life by up to 30% while reducing scrap rates. Our clients—from tier-1 automotive suppliers to medical device innovators—rely on us to transform complex CAD models into production-ready metal assets without compromise. We handle the precision engineering; you focus on molding excellence.

Initiate a technical consultation today to discuss your current or upcoming project requirements. Email Contact [email protected] with your CAD files or specifications for a detailed capability assessment and formal quotation within 48 hours. Our engineering team stands ready to provide actionable solutions—not generic sales pitches—to elevate your injection molding performance. Let us prove why global leaders trust Wuxi Lead Precision Machinery as their strategic metal manufacturing partner.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.