Technical Contents

Engineering Guide: Injection Molding Experts

Engineering Imperatives in Injection Molding Tooling: The Precision Foundation

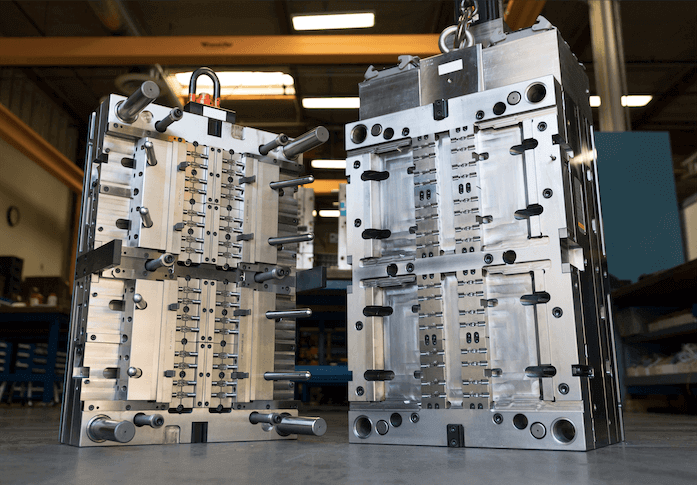

For injection molding experts, the relentless pursuit of precision is not merely an objective—it is the absolute bedrock of successful, high-volume production. Minute deviations in mold geometry directly translate to part defects, inconsistent material flow, premature wear, and unacceptable scrap rates. Thermal gradients dictate flow behavior; cavity surface finish dictates part ejection and cosmetic quality; core alignment dictates dimensional stability across thousands of cycles. Sub-micron level control in the machining of mold bases, cavities, cores, and intricate lifters is non-negotiable. This precision ensures optimal thermal management within the mold, consistent filling patterns, and the elimination of flash or short shots, directly impacting cycle time, part quality, and ultimately, the client’s bottom line. It is the critical factor separating functional prototypes from profitable, sustainable mass production.

Wuxi Lead Precision Machinery operates at this exacting threshold. Our CNC engineering heritage, forged over 15 years serving Tier-1 suppliers to the aerospace, defense, and high-end consumer sectors, provides demonstrable proof of capability. We engineered critical mold components for the medal production systems of the Tokyo 2020 Olympics, where material consistency and absolute dimensional fidelity were paramount under global scrutiny. Similarly, our machining processes consistently meet the stringent AS9100 and MIL-STD requirements for mission-critical aerospace and defense components, where failure is not an option. This experience translates directly to the injection molding arena: we understand that the tolerances demanded by a satellite housing or a fighter jet bracket are equally vital for a complex medical device housing or a premium automotive interior component mold. Our facility is certified to ISO 9001:2015 and ISO 13485, with rigorous in-process inspection protocols using Zeiss CMMs and optical comparators.

Our commitment to precision is embedded in our core manufacturing capabilities, as quantified below:

| Parameter | Industry Standard Capability | Wuxi Lead Precision Capability |

|---|---|---|

| Positional Tolerance | ±0.01 mm | ±0.002 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

| Material Range | Common Tool Steels | H13, S136, NAK80, Maraging Steels, Copper Alloys |

| Max Work Envelope | 800 x 600 x 500 mm | 1200 x 900 x 700 mm |

| In-Process Inspection | Post-Machining Only | Real-time Laser Probing & Thermal Compensation |

This level of control is not theoretical. It manifests in extended mold life, reduced downtime for maintenance, significantly lower scrap rates during production ramp-up, and the ability to hold tight tolerances on complex geometries that competitors cannot reliably achieve. For the injection molding expert, partnering with a precision machining specialist like Lead Precision means transforming design intent into flawless, repeatable reality—turning the inherent challenges of the molding process into a competitive advantage through uncompromising engineering execution. Precision isn’t just our service; it’s the guarantee we deliver.

Precision Specs & Tolerances

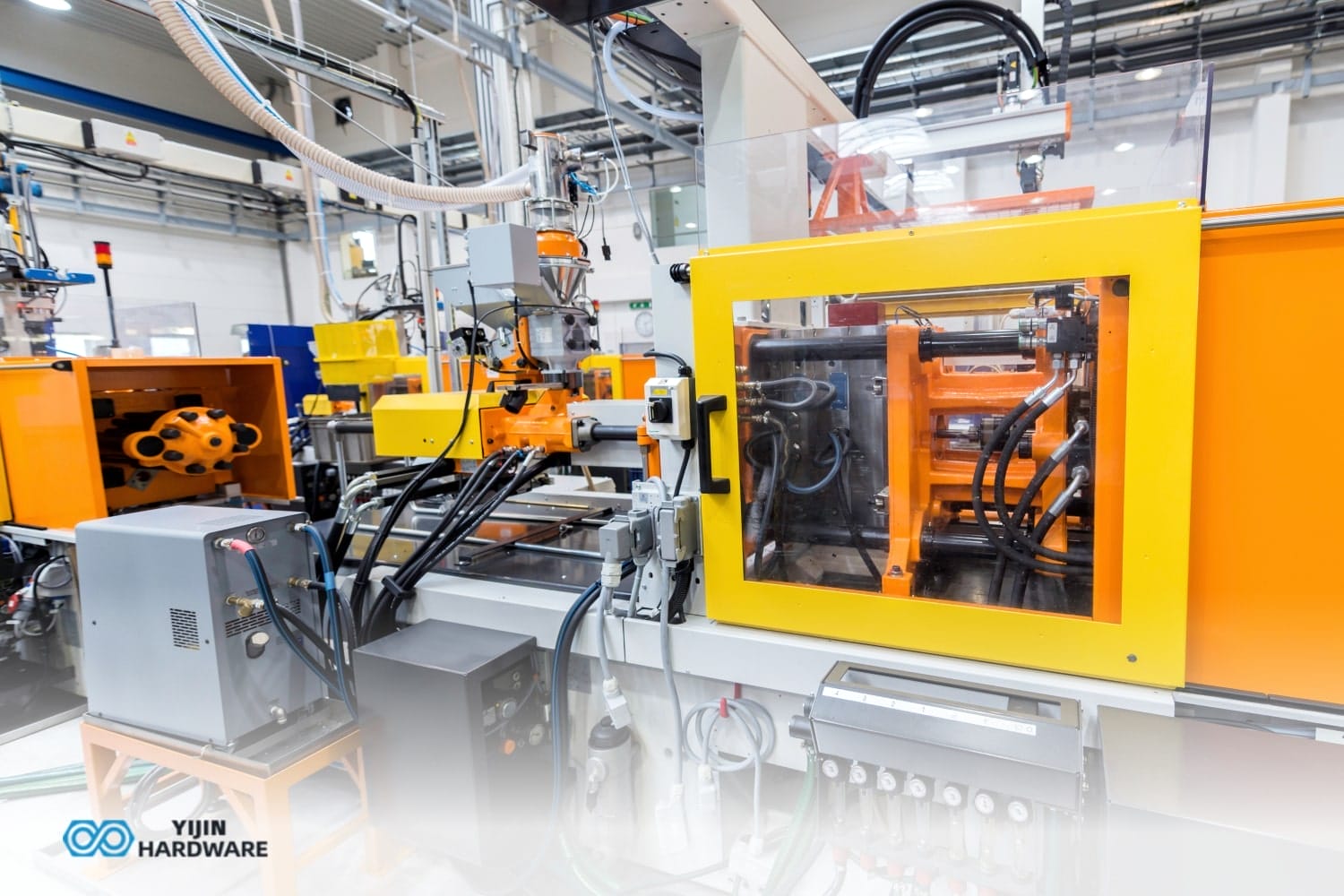

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for injection molding experts who demand precision, repeatability, and structural integrity in every component. Our technical capabilities are built around state-of-the-art 5-axis CNC machining centers, enabling us to produce complex geometries with superior surface finishes and tight tolerances. These multi-axis systems allow simultaneous movement across five planes, ensuring optimal tool engagement and reduced setup times—critical for high-performance mold components such as cavities, cores, inserts, and ejector systems.

Our machining processes are supported by a rigorous quality control framework anchored in CMM (Coordinate Measuring Machine) inspection. Every part undergoes comprehensive dimensional verification using Zeiss and Mitutoyo CMM systems, ensuring full compliance with design specifications. This metrology-backed validation process provides traceable, repeatable results that meet the stringent requirements of global injection mold manufacturers. All inspection reports are documented and available with each shipment, offering full transparency and audit readiness.

We specialize in machining a wide range of tool steels, hardened alloys, and aluminum blocks commonly used in mold construction. Materials such as P20, H13, S136, and NAK80 are routinely processed with controlled thermal treatments to maintain hardness and dimensional stability. Our 5-axis platforms support high-speed machining strategies, minimizing cycle times while preserving accuracy—even in deep cavities or undercuts where traditional methods fall short.

All programming is performed in-house using Mastercam and Siemens NX, allowing seamless integration from CAD model to finished part. Our engineering team collaborates directly with clients to optimize toolpaths, reduce material waste, and enhance mold performance through precision-machined cooling channels, venting features, and parting line accuracy.

The following table outlines our standard machining tolerances, which can be further tightened based on application requirements:

| Feature | Standard Tolerance | High-Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.002 mm | Up to 800 mm length |

| Positional Accuracy | ±0.008 mm | ±0.003 mm | Verified via CMM |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Achieved with fine finishing passes |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm | Critical for parting surfaces |

| Bore Tolerance | H7 | H6 | Depending on diameter and depth |

| Angular Features | ±0.01° | ±0.005° | Multi-axis alignment |

These capabilities are consistently maintained across batch sizes—from single prototype inserts to full-scale production runs. With a focus on precision engineering and process control, Wuxi Lead Precision Machinery ensures that every machined component contributes directly to mold longevity, cycle efficiency, and part quality. Our facility in Wuxi, China, operates under ISO 9001 standards, reinforcing our commitment to excellence in custom metal manufacturing for the global injection molding industry.

Material & Finish Options

Material Selection for High-Performance Injection Molds

Selecting the optimal material for injection molds is critical for achieving precision, longevity, and cost efficiency in production. At Wuxi Lead Precision Machinery, we engineer molds using Aluminum, Steel, and Titanium alloys, each offering distinct advantages for specific applications. Material choice directly impacts thermal management, wear resistance, cycle times, and overall part quality. Understanding these properties ensures your mold meets stringent production demands while maximizing return on investment.

Aluminum alloys, particularly 7075-T6 and 6061-T6, excel in rapid prototyping and low-to-medium volume production. Their superior thermal conductivity (130–180 W/m·K) accelerates cooling cycles, reducing part ejection times by up to 30% compared to steel. This makes aluminum ideal for complex geometries requiring tight tolerances in early-stage validation. While softer than steel (150–220 HB), modern hard-anodized aluminum molds withstand 100,000+ cycles for non-abrasive resins. Cost efficiency and faster CNC machining times further enhance their appeal for time-sensitive projects.

Tool steels like H13, S136, and NAK80 dominate high-volume manufacturing due to exceptional hardness (48–52 HRC after heat treatment) and wear resistance. H13 withstands high cavity pressures and thermal fatigue in automotive molds, while corrosion-resistant S136 is preferred for medical and optical applications involving PVC or flame-retardant plastics. Steel molds routinely exceed 1 million cycles with proper maintenance, justifying higher initial costs through extended service life and dimensional stability under sustained thermal cycling.

Titanium alloys (e.g., Ti-6Al-4V) serve niche applications where extreme corrosion resistance and strength-to-weight ratio are paramount. Though costly and challenging to machine, titanium molds excel in processing highly abrasive or chemically aggressive polymers like PEEK or glass-filled nylons. Their inertness prevents catalytic degradation in sensitive medical resin formulations, though thermal conductivity limitations (7 W/m·K) necessitate specialized cooling strategies.

Surface Finishes: Enhancing Performance

Anodizing is indispensable for aluminum molds, transforming the surface into a hard, non-conductive oxide layer. Type II (sulfuric acid) anodizing provides basic wear protection (5–25 μm thickness), while Type III (hard coat) achieves 50–100 μm layers with 60–70 HRC hardness—critical for abrasive-filled plastics. Color options (black, clear, gold) offer secondary identification benefits. For steel molds, alternatives like PVD coatings (TiN, CrN) or electroless nickel plating combat corrosion and galling, though anodizing remains exclusive to aluminum substrates.

Comparative Material Specifications

| Material | Key Properties | Typical Applications | Limitations |

|---|---|---|---|

| Aluminum 7075 | 150 HB hardness, 180 W/m·K conductivity | Prototyping, low-volume runs | Limited to 100k cycles with abrasives |

| H13 Steel | 50 HRC hardness, high thermal fatigue resistance | Automotive, high-cavity molds | Slower machining, higher cost |

| Ti-6Al-4V | 36 HRC hardness, corrosion-proof | Medical, chemical-resistant molds | Low thermal conductivity, high cost |

Material selection must align with resin type, production volume, and part specifications. Wuxi Lead Precision Machinery leverages advanced CNC milling and EDM capabilities to machine these materials to ±0.002 mm tolerances, ensuring optimal mold performance. Partner with us to translate your material requirements into durable, high-yield tooling solutions.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our custom metal manufacturing process is engineered for precision, repeatability, and zero-defect outcomes—critical for injection molding experts who demand flawless integration of components. Our systematic approach spans three core phases: Design, Prototyping, and Mass Production. Each stage is tightly controlled, leveraging advanced metrology, in-house engineering expertise, and real-time quality validation to ensure every part meets exacting specifications.

The process begins with collaborative design engineering. Our team works directly with clients to analyze part geometry, material selection, thermal behavior, and functional requirements. Using high-fidelity CAD/CAM software and mold flow simulation tools, we optimize wall thickness, gate locations, and cooling channels to prevent warpage, sink marks, or stress concentrations. This phase includes Design for Manufacturability (DFM) reviews that identify potential risks before any metal is cut, reducing costly revisions downstream.

Once the design is finalized, we proceed to precision prototyping. Utilizing CNC machining and selective laser melting (SLM) for rapid tooling, we produce functional prototypes within 7–14 days. These prototypes are subjected to rigorous dimensional inspection using coordinate measuring machines (CMM), optical scanning, and hardness testing. We validate fit, function, and interface compatibility with existing mold bases or inserts. Feedback from this stage is incorporated into final tool design, ensuring that the transition to mass production is seamless and risk-free.

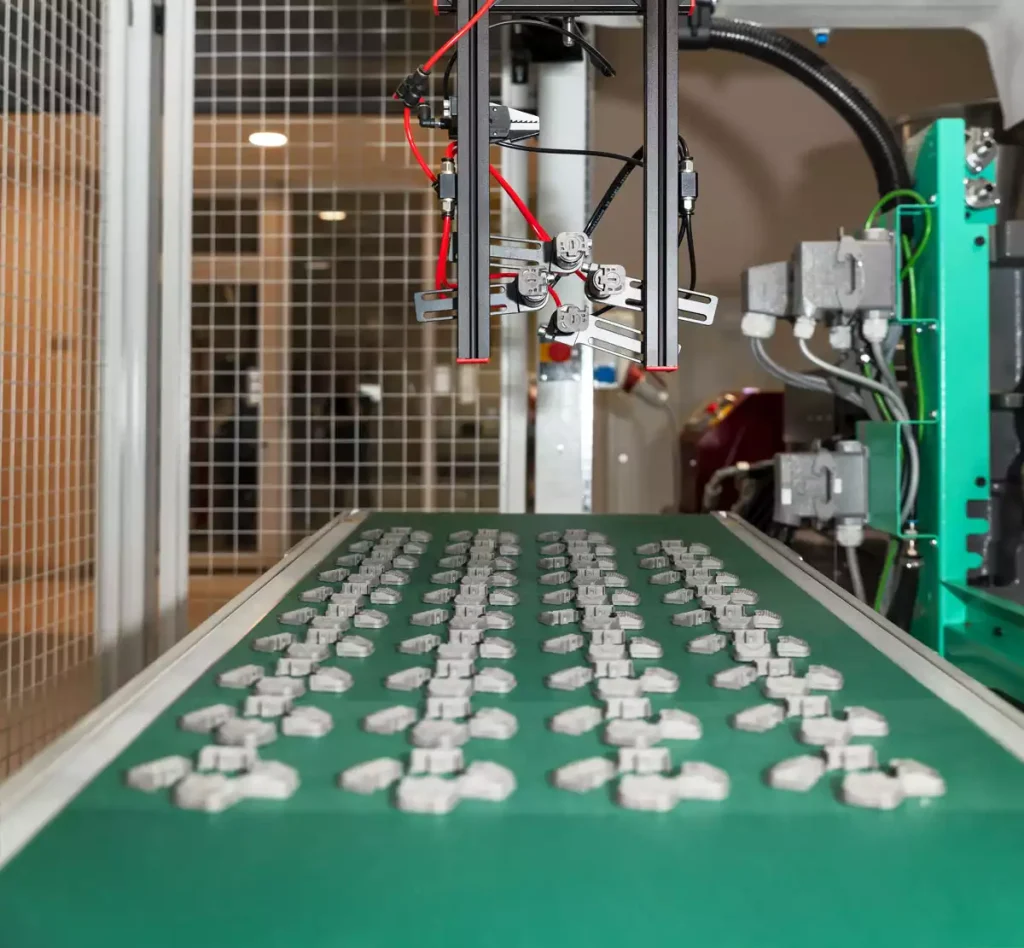

Mass production is executed on our state-of-the-art automated CNC machining lines, supported by robotic part handling and in-process gauging. All components are manufactured from premium-grade tool steels such as H13, S136, or 2344, sourced from certified mills with full material traceability. Machining is followed by precision grinding, EDM, and surface treatments including nitriding or PVD coating, depending on wear and corrosion requirements. Every operation is monitored under ISO 9001-certified quality protocols, with statistical process control (SPC) data logged for full batch traceability.

Our zero-defect commitment is enforced through multi-stage inspection: first-article inspection reports (FAIR), ongoing in-line checks, and final 100% visual and dimensional verification. Non-conforming parts are automatically quarantined via our digital quality management system.

The table below outlines key process specifications:

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.002 mm |

| Surface Roughness | Ra 0.05 µm (mirror finish achievable) |

| Material Options | H13, S136, 2344, 1.2379, Invar, Beryllium Copper |

| Max Workpiece Size | 800 × 600 × 500 mm |

| Production Capacity | Up to 50,000 units/month |

| Quality Standards | ISO 9001:2015, PPAP Level 3, FAIR, SPC |

| Lead Time (Prototype) | 7–14 days |

| Lead Time (Mass Production) | 25–35 days after approval |

From concept to volume delivery, Wuxi Lead Precision Machinery ensures that every custom metal component supports the reliability and longevity of your injection molding systems.

Why Choose Wuxi Lead Precision

Elevate Injection Molding Performance Through Precision Metal Partnerships

Your injection molds define product quality, cycle times, and production economics. Yet inconsistent core pins, ejector sleeves, or cavity inserts introduce costly variables—flash, part distortion, or premature wear—that compromise your entire process. Generic metal suppliers cannot match the dimensional stability and surface integrity demanded by high-cavitation or micro-molding applications. At Wuxi Lead Precision Machinery, we engineer custom metal components to eliminate these failure points, ensuring your molds perform predictably from shot one to one million.

We operate at the intersection of metallurgical science and ultra-precision machining. Our CNC grinding and milling centers achieve tolerances down to ±0.0002 inches on hardened tool steels, stainless alloys, and specialized composites. This capability translates directly to mold longevity and part consistency. Where competitors treat metal as a commodity, we treat it as a performance variable—applying heat treatment protocols, surface texturing, and metrology protocols calibrated to your specific resin flow dynamics and ejection requirements. Every component undergoes rigorous first-article inspection using Zeiss coordinate measuring machines, with full traceability from raw material to final shipment.

Our technical partnership begins with a deep dive into your molding challenges. We analyze gate geometry, cooling channel placement, and stress concentrations to recommend material grades and surface finishes that mitigate weld lines or sink marks. For medical or optical applications requiring zero particulate generation, we implement cleanroom assembly and passivation processes exceeding ASTM F86 standards. This proactive engineering approach reduces your mold tryout iterations by up to 40% and extends service life in abrasive polymer environments.

Technical Capabilities for Critical Mold Components

| Specification Category | Capability Range | Industry Benchmark |

|---|---|---|

| Tolerance Precision | ±0.0002 inches (5 microns) | ±0.0005 inches |

| Material Mastery | H13, S7, 420SS, 17-4PH, Titanium, Tungsten Carbide | Standard tool steels only |

| Maximum Part Size | 24″ x 24″ x 18″ | 18″ x 18″ x 12″ |

| Surface Roughness | Ra 0.05 µm (Mirror Polish) | Ra 0.2 µm |

| Lead Time for Prototypes | 10-15 business days | 20-30 business days |

This level of precision requires more than advanced machinery—it demands engineers who speak the language of injection molding. Our team includes former mold designers and process technicians who understand how a 0.0001-inch deviation in core pin straightness affects part concentricity. We collaborate with your team during DFM reviews, offering actionable insights to prevent costly rework before steel is cut.

The cost of mold downtime or scrap parts far exceeds the investment in precision metalwork. When your competitor’s ejector system fails at 500,000 cycles, ours delivers 1.2 million cycles with zero drift. This reliability is why global Tier 1 automotive and medical device manufacturers trust Lead Precision for their most demanding applications.

Initiate a capability assessment today. Email [email protected] with your current mold performance metrics or a component drawing. Our engineering team will respond within 4 business hours with a tolerance analysis and feasibility report—no sales pitch, only actionable data. Let us prove how precision metal manufacturing becomes your competitive advantage. Your next mold build should exceed expectations, not chase them.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.