Technical Contents

Engineering Guide: Custom Laser Cut Steel Plate

Engineering Insight: Custom Laser Cut Steel Plate

In high-precision sheet metal fabrication, the integrity of a final product is only as strong as the accuracy of its initial cut. Custom laser cutting of steel plates is not merely a step in production—it is the foundation upon which structural reliability, dimensional consistency, and assembly efficiency are built. At Wuxi Lead Precision Machinery, we understand that in industries ranging from advanced machinery to defense systems, even a deviation of 0.1 millimeters can lead to cascading failures in performance and safety.

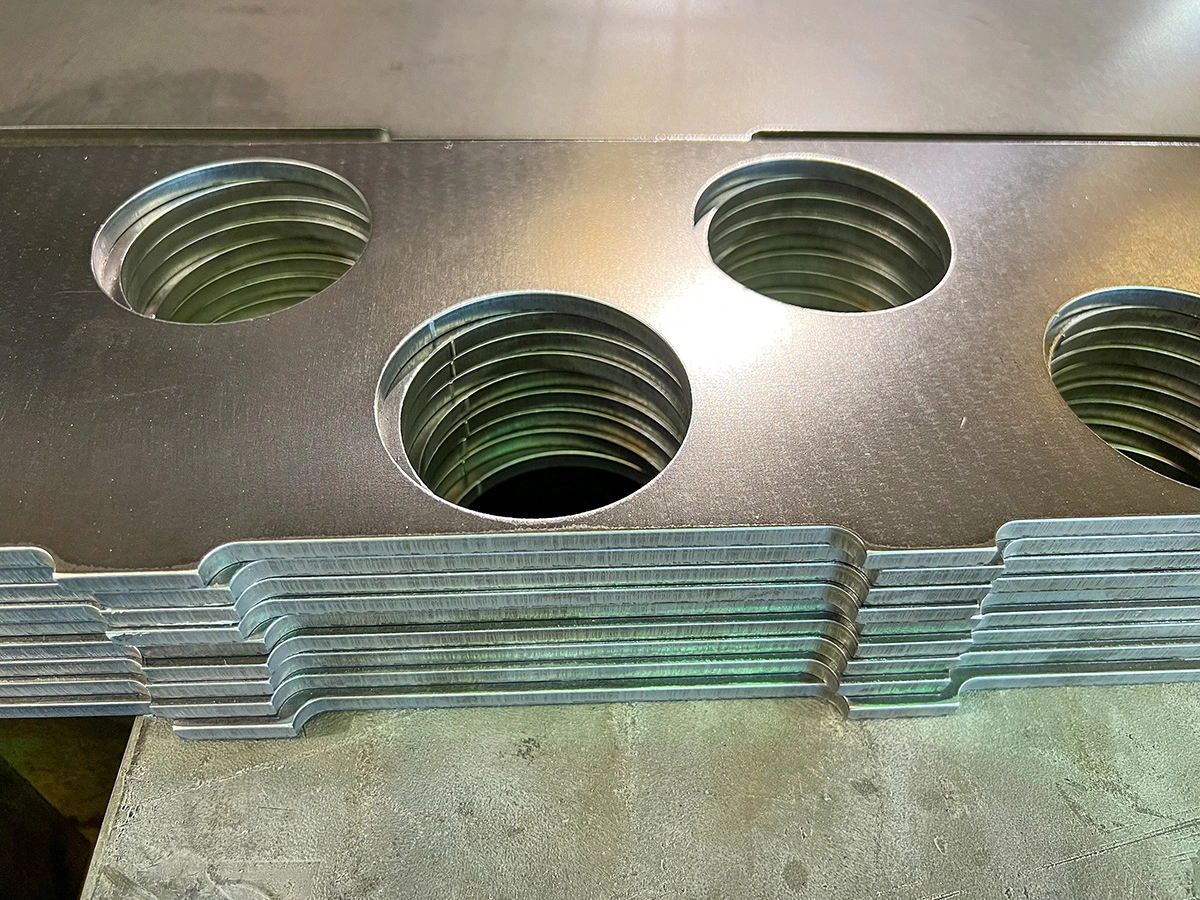

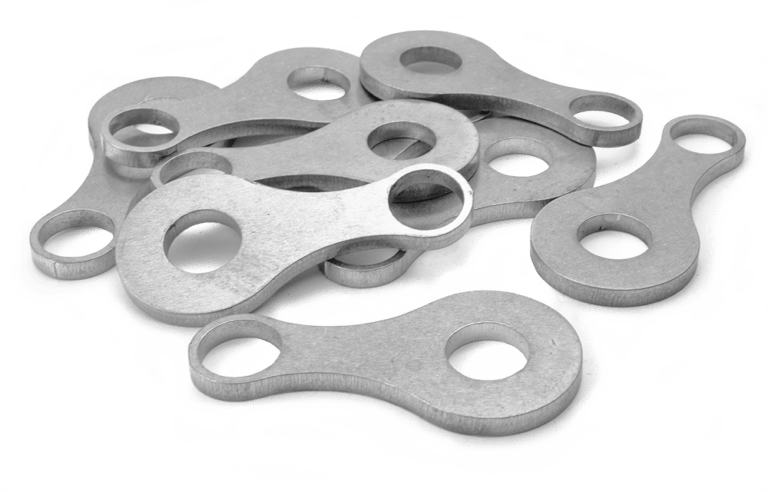

Our approach to custom laser cutting integrates state-of-the-art fiber laser technology with decades of engineering expertise. This ensures clean, burr-free edges, tight tolerances, and repeatability across large production runs. The non-contact nature of laser cutting minimizes material distortion, preserving the metallurgical properties of the steel—critical when working with high-strength or heat-treated alloys. Whether processing mild steel, stainless steel, or abrasion-resistant grades up to 25 mm in thickness, our systems deliver precision that meets or exceeds international standards.

Precision in laser cutting extends beyond the machine—it involves meticulous programming, material handling, and quality verification. Our CNC-controlled systems utilize advanced nesting software to optimize material usage while maintaining part integrity. Each job undergoes rigorous pre-production simulation and post-cut inspection using coordinate measuring machines (CMM) and laser scanning, ensuring every component conforms to the client’s engineering specifications.

Wuxi Lead Precision Machinery has been entrusted with projects where failure is not an option. Our work has contributed to structural components for Olympic-grade sports facilities, where architectural aesthetics meet seismic resilience, and to specialized enclosures and support frames for military-grade mobile command units. These applications demand not only dimensional accuracy but also consistency under extreme environmental and operational stress—conditions our processes are engineered to meet.

Our facility maintains ISO 9001 certification and adheres to strict in-house quality control protocols. Every laser-cut steel plate is traceable, with full documentation of material origin, cutting parameters, and inspection results. This level of accountability is essential for clients in aerospace, defense, and high-end industrial automation sectors.

Below are the technical capabilities of our laser cutting systems:

| Parameter | Specification |

|---|---|

| Maximum Cutting Thickness | 25 mm (mild steel) |

| Laser Source | High-power fiber laser (up to 12 kW) |

| Positioning Accuracy | ±0.03 mm/m |

| Repeatability | ±0.02 mm |

| Minimum Hole Diameter | 1.0 × material thickness |

| Cutting Speed (max) | Up to 60 m/min (thin sheet, < 3 mm) |

| Supported Formats | DXF, DWG, STEP, IGES |

| Material Compatibility | Mild steel, stainless steel, aluminum, alloy steel |

At Wuxi Lead Precision Machinery, precision is not a claim—it is a measurable outcome, proven through performance in the most demanding applications. When your project requires custom laser cut steel plates that perform under pressure, our engineering rigor ensures every cut meets the highest standard.

Precision Specs & Tolerances

Advanced Laser Cutting Capabilities

Wuxi Lead Precision Machinery delivers uncompromising precision for custom laser cut steel plate fabrication through integrated 5-axis CNC fiber laser systems. Our TRUMPF TruLaser Series 7000 platforms process carbon steel, stainless steel, and aluminum alloys with thicknesses ranging from 0.5 mm to 25 mm. These systems utilize 6 kW to 12 kW resonators to achieve clean kerf widths as narrow as 0.1 mm, eliminating secondary finishing for critical applications in aerospace, medical device housings, and semiconductor tooling. The 5-axis capability enables complex bevel cuts, countersinks, and 3D contouring in a single setup—reducing handling errors and accelerating throughput for geometrically intricate components. Material efficiency is maximized via intelligent nesting software that optimizes yield by 15–22% compared to conventional methods, directly lowering project costs without sacrificing edge quality or dimensional integrity.

Tolerances are rigorously maintained across all production runs, validated through real-time process monitoring and post-cut verification. The table below specifies achievable precision parameters for steel plate fabrication:

| Feature | Specification | Applicable Materials |

|---|---|---|

| Thickness Range | 0.5 mm – 25 mm | Mild Steel, Stainless Steel (304/316), Aluminum |

| Dimensional Tolerance | ±0.05 mm (up to 10 mm thickness) | All |

| ±0.10 mm (10–25 mm thickness) | All | |

| Hole Diameter Tolerance | +0.025 mm / -0.000 mm | All |

| Edge Perpendicularity | ≤ 0.05 mm per 10 mm thickness | All |

| Surface Roughness (Ra) | ≤ 3.2 µm (fine cut mode) | Mild/Stainless Steel |

Quality assurance is anchored in our ISO 17025-accredited metrology lab, where every critical batch undergoes 100% CMM inspection using Zeiss CONTURA systems. This ensures geometric dimensioning and tolerancing (GD&T) compliance per ASME Y14.5 standards, with full traceability via digital inspection reports. Our CMM protocols detect micro-deformations from thermal stress during cutting, allowing immediate process correction—critical for components requiring press-fit assembly or multi-stage machining. Statistical process control (SPC) data is shared transparently with clients, providing actionable insights for continuous improvement in high-volume contracts.

Beyond cutting, we integrate bending, welding, and surface treatment under one roof, ensuring seamless transition from flat pattern to finished assembly. This vertical integration eliminates supply chain handoffs that typically introduce tolerance stack-up errors. For mission-critical steel plate components—such as robotic end-effectors or hydraulic manifolds—our process guarantees repeatability of ±0.03 mm across 10,000+ units. Partner with Wuxi Lead to transform complex steel plate designs into production-ready solutions where micron-level accuracy directly impacts your product performance and lifecycle costs.

Material & Finish Options

Material Selection for Custom Laser Cut Steel Plate: A Precision Engineering Guide

Selecting the appropriate material for custom laser cut steel plate components is critical to ensuring performance, durability, and cost-efficiency in industrial applications. While the term “steel plate” is commonly used, modern fabrication often involves alternative metals such as aluminum and titanium, depending on functional requirements. At Wuxi Lead Precision Machinery, we support a range of materials tailored to meet specific mechanical, environmental, and aesthetic demands.

Steel remains the most widely used material in sheet metal fabrication due to its high strength, availability, and cost-effectiveness. Mild steel, particularly grades like Q235 and Q345, offers excellent weldability and machinability, making it ideal for structural components, enclosures, and industrial machinery frames. For applications requiring enhanced corrosion resistance, stainless steel grades such as 304 and 316 are preferred. These alloys contain chromium and nickel, providing superior oxidation and chemical resistance, especially in harsh environments like marine or food processing industries.

Aluminum is favored when weight reduction is a priority without sacrificing strength. Grades such as 5052 and 6061 offer good formability, excellent corrosion resistance, and high thermal and electrical conductivity. Aluminum is commonly used in aerospace, transportation, and electronics enclosures. Its reflective surface also enhances laser cutting efficiency, allowing for faster processing and cleaner edges. However, aluminum requires precise parameter control during laser cutting to avoid melting or dross formation.

Titanium is selected for extreme performance applications, including aerospace, medical implants, and high-temperature environments. With an exceptional strength-to-density ratio and outstanding resistance to corrosion and heat, titanium offers longevity in demanding conditions. However, its high cost and challenging machinability mean it is typically reserved for mission-critical components where performance outweighs budget considerations.

Surface finish plays a crucial role in both protection and aesthetics. Anodizing is a common post-processing method for aluminum components. This electrochemical process thickens the natural oxide layer, significantly improving wear and corrosion resistance while allowing for color customization. Anodized finishes are non-conductive and ideal for components exposed to outdoor conditions or frequent handling. While anodizing is specific to aluminum, steel components can be treated with powder coating, galvanization, or passivation to achieve similar protective benefits.

Below is a comparison of key material properties relevant to laser cutting and application performance.

| Material | Typical Grades | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Common Applications |

|---|---|---|---|---|---|

| Mild Steel | Q235, Q345 | 370–500 | 7.85 | Low (without coating) | Industrial frames, brackets |

| Stainless Steel | 304, 316 | 515–620 | 8.00 | High | Food equipment, marine parts |

| Aluminum | 5052, 6061 | 290–310 | 2.70 | High | Aerospace, electronics housings |

| Titanium | Gr2, Gr5 (Ti-6Al-4V) | 345–1000 | 4.51 | Exceptional | Medical devices, jet engines |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on application environment, mechanical loads, and lifecycle expectations. Our advanced fiber laser cutting systems ensure precision across all materials, delivering tight tolerances and clean edges for high-end manufacturing needs.

Manufacturing Process & QC

Custom Laser Cut Steel Plate Production Process: Zero Defects Execution

At Wuxi Lead Precision Machinery, our custom laser cutting process for steel plates is engineered for uncompromising quality and repeatability, adhering strictly to the Zero Defects philosophy. This disciplined approach spans three critical, interlocked phases: Design, Prototyping, and Mass Production. Each stage incorporates rigorous validation to eliminate errors before they progress, ensuring the final product meets exacting industrial specifications and minimizes client risk.

The Design phase begins with comprehensive engineering collaboration. Our team conducts detailed Design for Manufacturability (DFM) analysis on client CAD files, scrutinizing geometric complexity, feature density, and material suitability against the specific steel grade and thickness. We verify critical parameters including kerf width compensation, heat-affected zone (HAZ) implications for secondary operations, and nesting efficiency to optimize material yield. Material certification documentation is cross-referenced against purchase orders, confirming compliance with standards such as ASTM A36, AISI 304, or client-specific alloys. This stage concludes with finalized, process-approved digital toolpaths and a documented quality plan, establishing the baseline for zero deviations.

Prototyping transforms the validated design into a tangible reference. A single prototype part is produced under controlled conditions mirroring mass production parameters. This sample undergoes exhaustive metrology using calibrated CMMs and optical comparators to verify dimensional accuracy against the original CAD model. Critical aspects like hole concentricity, slot widths, edge perpendicularity, and surface finish are measured. Crucially, the prototype validates edge quality—assessing dross levels, striation patterns, and thermal distortion—to confirm the laser settings produce clean, burr-free cuts suitable for welding or coating. Only after the prototype passes all criteria and receives formal client sign-off does the project advance. Key prototype validation specifications include:

| Parameter | Specification | Measurement Method |

|---|---|---|

| Material | As per certified client order | Mill Cert Review |

| Thickness Range | 0.5 mm – 25 mm | Ultrasonic Gauge |

| Dimensional Tolerance | ±0.1 mm (standard) | CMM / Optical Comparator |

| Edge Perpendicularity | ≤ 0.05 mm deviation | Surface Plate & Height Gauge |

| Edge Quality | Burr-free; Minimal dross (≤ 0.05 mm) | Visual & Tactile Inspection |

Mass Production executes the approved process with embedded, real-time quality control. Production runs utilize calibrated fiber laser systems with automated nozzle cleaning and pierce control to maintain consistent cut quality. Statistical Process Control (SPC) monitors critical parameters like laser power, gas pressure, and cutting speed, triggering immediate alerts for any drift beyond established control limits. Every plate undergoes 100% first-article inspection at the start of the run, followed by systematic in-process checks at defined intervals using go/no-go gauges and spot CMM verification. Full traceability is maintained via laser-etched part IDs linked to material certs and process logs. Final inspection validates flatness, dimensional conformance across the entire batch, and absence of surface defects before packaging. This closed-loop system, combined with operator certification and rigorous machine maintenance, ensures every steel plate shipped meets the Zero Defects standard, delivering reliability your assembly line demands.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Expertise in Custom Laser Cut Steel Plate Fabrication

When precision, reliability, and performance define your manufacturing standards, partnering with a trusted leader in sheet metal fabrication becomes essential. At Wuxi Lead Precision Machinery, we specialize in delivering high-accuracy custom laser cut steel plates tailored to the exacting demands of aerospace, automotive, industrial equipment, and advanced electronics sectors. Our state-of-the-art facility in Wuxi, China, combines cutting-edge fiber laser technology with decades of engineering experience to ensure every component meets the highest quality benchmarks.

Our commitment begins with a deep understanding of your project requirements. Whether you need low-volume prototypes or high-volume production runs, our team works closely with engineers and design teams to optimize material selection, cut geometry, and finishing processes. We process a wide range of steel grades—including mild steel, stainless steel, and high-strength low-alloy (HSLA) steels—with thicknesses ranging from 0.5 mm to 25 mm. Our advanced laser systems achieve tolerances as tight as ±0.1 mm, ensuring dimensional accuracy and seamless integration into your final assembly.

What sets Wuxi Lead apart is our end-to-end control over the manufacturing process. From digital nesting and laser cutting to deburring, bending, welding, and surface treatment, every step is monitored for consistency and precision. Our ISO 9001-certified quality management system ensures compliance with international standards, while our agile production workflow supports rapid turnaround times without compromising on quality.

We understand that today’s manufacturers operate in a global, fast-moving environment. That’s why we offer seamless collaboration through secure file sharing, real-time project tracking, and direct engineering support. Our team is fluent in English and experienced in working with international clients across North America, Europe, and Asia, ensuring clear communication and on-time delivery—every time.

For demanding applications where material integrity and edge quality are critical, our fiber laser cutting technology delivers clean, dross-free cuts with minimal heat-affected zones. This precision reduces post-processing requirements and accelerates time to market.

Below are key technical capabilities for our custom laser cutting services:

| Specification | Detail |

|---|---|

| Material Types | Mild Steel, Stainless Steel, HSLA Steel |

| Thickness Range | 0.5 mm – 25 mm |

| Maximum Cutting Area | 4000 mm × 2000 mm |

| Positioning Accuracy | ±0.05 mm |

| Repeatability | ±0.03 mm |

| Cutting Tolerance | ±0.1 mm |

| Laser Type | High-Power Fiber Laser (up to 12 kW) |

| Edge Quality | Burr-free, minimal dross, precision square edges |

Partner with Wuxi Lead Precision Machinery to transform your steel plate fabrication requirements into reality. Contact us today at [email protected] to discuss your project, request a quote, or receive technical support from our engineering team.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.