Technical Contents

Engineering Guide: 3D Print Replacement Parts

Engineering Insight: 3D Print Replacement Parts and the Critical Role of Precision

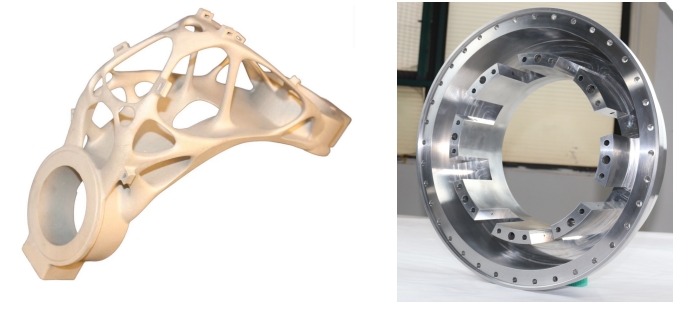

In the evolving landscape of industrial maintenance and equipment longevity, 3D printing has emerged as a promising solution for producing replacement parts on demand. While additive manufacturing offers speed and design flexibility, it often falls short in delivering the dimensional accuracy, material integrity, and long-term reliability required in high-stakes environments. This is where precision-engineered metal components from Wuxi Lead Precision Machinery provide a superior alternative to 3D printed parts—especially in mission-critical applications.

At Lead Precision, we specialize in custom metal manufacturing using advanced CNC machining, multi-axis milling, and tight-tolerance turning processes. Our expertise ensures that replacement parts not only match original equipment manufacturer (OEM) specifications but exceed them in durability and consistency. Unlike 3D printing, which can introduce porosity, anisotropic strength, and surface irregularities, our subtractive methods produce fully dense, structurally sound components with repeatable precision down to ±0.002 mm.

Our engineering team understands that replacement parts are more than physical duplicates—they are functional extensions of complex systems. Whether restoring legacy machinery or supporting active production lines, the performance of each component must align with rigorous operational demands. This is particularly true in sectors such as aerospace, defense, and high-performance sports equipment, where we have applied our capabilities to support Olympic-level athletes and military-grade systems.

For example, our involvement in supplying precision components for equipment used in Olympic training facilities required flawless execution under strict deadlines. Similarly, our work with defense contractors demanded adherence to MIL-STD specifications, including extreme environmental resistance and zero-failure tolerance. These experiences underscore our ability to deliver parts where failure is not an option—and where 3D printing alone cannot meet the required standards.

When evaluating replacement part solutions, engineers must consider not only form and fit but also fatigue life, thermal stability, and load-bearing performance. Our manufacturing process allows full material certification, heat treatment, and post-machining inspections using coordinate measuring machines (CMM) and optical profilometry, ensuring every part meets exacting quality benchmarks.

Below is a comparison of key performance metrics between standard 3D printed metal parts and those produced by Wuxi Lead Precision Machinery:

| Specification | 3D Printed Metal Parts | Lead Precision CNC-Machined Parts |

|---|---|---|

| Tolerance | ±0.1 mm typical | ±0.002 mm achievable |

| Surface Finish | 10–20 µm Ra | 0.4–1.6 µm Ra |

| Material Density | 90–99% (porosity risk) | 100% (fully dense) |

| Mechanical Strength | Anisotropic, layer-dependent | Isotropic, forged-equivalent |

| Production Lead Time | 3–7 days (small batches) | 5–10 days (with full QA) |

| Certification | Limited traceability | Full material & process certification |

At Wuxi Lead Precision Machinery, we bridge the gap between legacy part availability and modern performance requirements. Our engineering insight ensures that every replacement part we manufacture is not just a substitute—but a reliable, high-precision upgrade.

Precision Specs & Tolerances

Technical Capabilities: Precision Machining for Mission-Critical Replacement Parts

At Wuxi Lead Precision Machinery, we specialize in delivering CNC-machined metal replacement parts that surpass the limitations of additive manufacturing for demanding industrial applications. While 3D printing serves prototyping needs, operational integrity in high-stress environments demands the material density, fatigue resistance, and dimensional stability achievable only through precision subtractive processes. Our integrated manufacturing ecosystem ensures every component meets the exacting standards required for aerospace, energy, and heavy machinery sectors where failure is not an option.

Our foundation lies in advanced 5-axis simultaneous CNC machining centers, including DMG MORI CTX beta 1250 and Hermle C400 U. These platforms enable single-setup machining of complex geometries—such as turbine blades, hydraulic manifolds, and transmission housings—with sub-micron repeatability. Unlike layered additive processes, our milling and turning operations produce homogeneous grain structures in hardened tool steels, nickel alloys, and titanium, eliminating anisotropy risks inherent in printed parts. Full-axis interpolation allows undercuts, compound angles, and organic contours to be machined with zero manual intervention, ensuring consistency across batches of 1 to 10,000 units. Material removal rates exceed additive build speeds by 15x for metals, accelerating time-to-assembly without compromising metallurgical integrity.

Quality validation is non-negotiable. Every critical dimension undergoes verification via Zeiss CONTURA G2 Coordinate Measuring Machines (CMMs), certified to ISO 10360-2 standards. Our metrology lab performs full 3D scanning against CAD nominal data, generating AS9102-compliant First Article Inspection reports with GD&T analysis. Real-time SPC monitoring during machining corrects thermal drift and tool wear deviations before they impact output, maintaining process capability indices (Cpk) above 1.67. This closed-loop system guarantees that surface finishes, positional tolerances, and form accuracy align with the most stringent OEM specifications.

The following table details our standard achievable tolerances for common features. Custom tolerances beyond these ranges are attainable through process refinement and dedicated metrology protocols:

| Feature Type | Standard Tolerance (Metric) | Standard Tolerance (Imperial) | Measurement Method |

|---|---|---|---|

| Bore Diameter | H7 (e.g., Ø25 +0.021/0) | H7 (e.g., Ø1.000 +0.0008/0) | Air Gage / CMM |

| Shaft Diameter | h6 (e.g., Ø25 -0.013/-0.002) | h6 (e.g., Ø1.000 -0.0005/-0.0001) | Micrometer / CMM |

| Positional Accuracy | ±0.005 mm | ±0.0002 in | CMM (3D Vector Analysis) |

| Flatness | 0.003 mm per 100 mm | 0.0001 in per 4 in | Optical Flat / CMM |

| Surface Roughness | Ra 0.8 μm (32 μin) | Ra 32 μin | Profilometer |

Lead Precision’s end-to-end control—from raw material certification (mill test reports traceable to heat number) through heat treatment oversight and final inspection—eliminates the variability that plagues outsourced 3D printing workflows. When your machinery requires replacement parts that endure extreme loads, temperatures, and cyclic stress, our CNC capabilities deliver the proven reliability additive manufacturing cannot yet match. Contact our engineering team to discuss tolerance stack-up analysis and material suitability for your specific application.

Material & Finish Options

Material selection is a critical step in the production of precision 3D-printed replacement parts, especially when transitioning from prototyping to high-performance end-use components. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions that ensure durability, accuracy, and long-term reliability. When replacing traditionally manufactured parts with 3D-printed alternatives, the choice of material directly impacts mechanical performance, environmental resistance, and cost-efficiency. The most widely used metals in industrial additive manufacturing—aluminum, steel, and titanium—each offer distinct advantages depending on application requirements.

Aluminum alloys, particularly AlSi10Mg, are favored for lightweight structural components requiring good thermal conductivity and moderate strength. They are ideal for aerospace, automotive, and consumer electronics applications where weight reduction is a priority. Aluminum’s low density and excellent machinability make it suitable for complex geometries produced via selective laser melting (SLM). However, its lower tensile strength and wear resistance compared to steel or titanium may limit use in high-stress environments.

Stainless steel, especially grades like 316L and 17-4 PH, delivers superior strength, corrosion resistance, and temperature tolerance. These properties make steel an optimal choice for industrial machinery parts, fluid systems, and marine applications. 316L stainless steel offers excellent resistance to chloride-induced corrosion, while 17-4 PH provides high yield strength through precipitation hardening, making it suitable for load-bearing components. Steel’s durability ensures long service life even under harsh operating conditions.

Titanium alloys, primarily Ti6Al4V (Grade 5), represent the pinnacle of performance in critical engineering applications. With an exceptional strength-to-density ratio and outstanding resistance to fatigue, creep, and corrosion, titanium is extensively used in aerospace, medical implants, and high-performance automotive systems. Its biocompatibility and ability to withstand extreme temperatures further enhance its value in mission-critical environments. While more expensive and challenging to process, titanium’s long-term reliability justifies its use where failure is not an option.

Surface finishing plays a pivotal role in enhancing both functionality and aesthetics. Anodizing, particularly for aluminum parts, increases surface hardness, improves wear resistance, and allows for color coding or branding. Type II and Type III (hardcoat) anodizing are commonly applied, with the latter providing thicker, more durable oxide layers suitable for industrial use. Additional post-processing options such as shot peening, polishing, or coating can further tailor part performance.

Below is a comparative overview of key material properties for common 3D-printed metals:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Elongation (%) | Common Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 400–450 | 250–280 | 2.67 | 5–8 | Automotive, heat exchangers |

| 316L Stainless Steel | 550–650 | 350–450 | 7.9 | 30–50 | Marine, chemical processing |

| 17-4 PH Steel | 950–1300 | 750–1100 | 7.8 | 10–15 | Aerospace, tooling, valves |

| Ti6Al4V | 900–1050 | 800–900 | 4.43 | 8–12 | Aerospace, medical, racing systems |

Selecting the right material and finish ensures that 3D-printed replacement parts meet or exceed the performance of their traditionally manufactured counterparts. At Wuxi Lead Precision Machinery, we support clients in making informed decisions based on application demands, environmental conditions, and lifecycle requirements.

Manufacturing Process & QC

Precision Metal Replacement for 3D Printed Components: A Zero-Defect Production Framework

Transitioning from 3D printed polymer prototypes to high-integrity metal production components demands rigorous engineering discipline. At Wuxi Lead Precision Machinery, we execute a closed-loop process ensuring metallurgical integrity, dimensional stability, and absolute compliance with operational requirements. This methodology eliminates the inherent limitations of additive manufacturing for end-use parts—such as anisotropic strength, surface porosity, and thermal instability—through precision subtractive techniques.

Design Phase: Engineering for Manufacturability

Our engineers collaborate with clients to deconstruct 3D printed designs, identifying critical functional surfaces, load paths, and environmental stressors. We apply advanced DFM analysis to optimize geometry for CNC milling, turning, or multi-axis machining, ensuring material utilization aligns with aerospace, medical, or industrial grade alloys. Finite element analysis validates structural performance under real-world conditions, while tolerance stack-up studies guarantee assembly compatibility. This phase establishes the foundation for zero-defect production by resolving design ambiguities before metal contact.

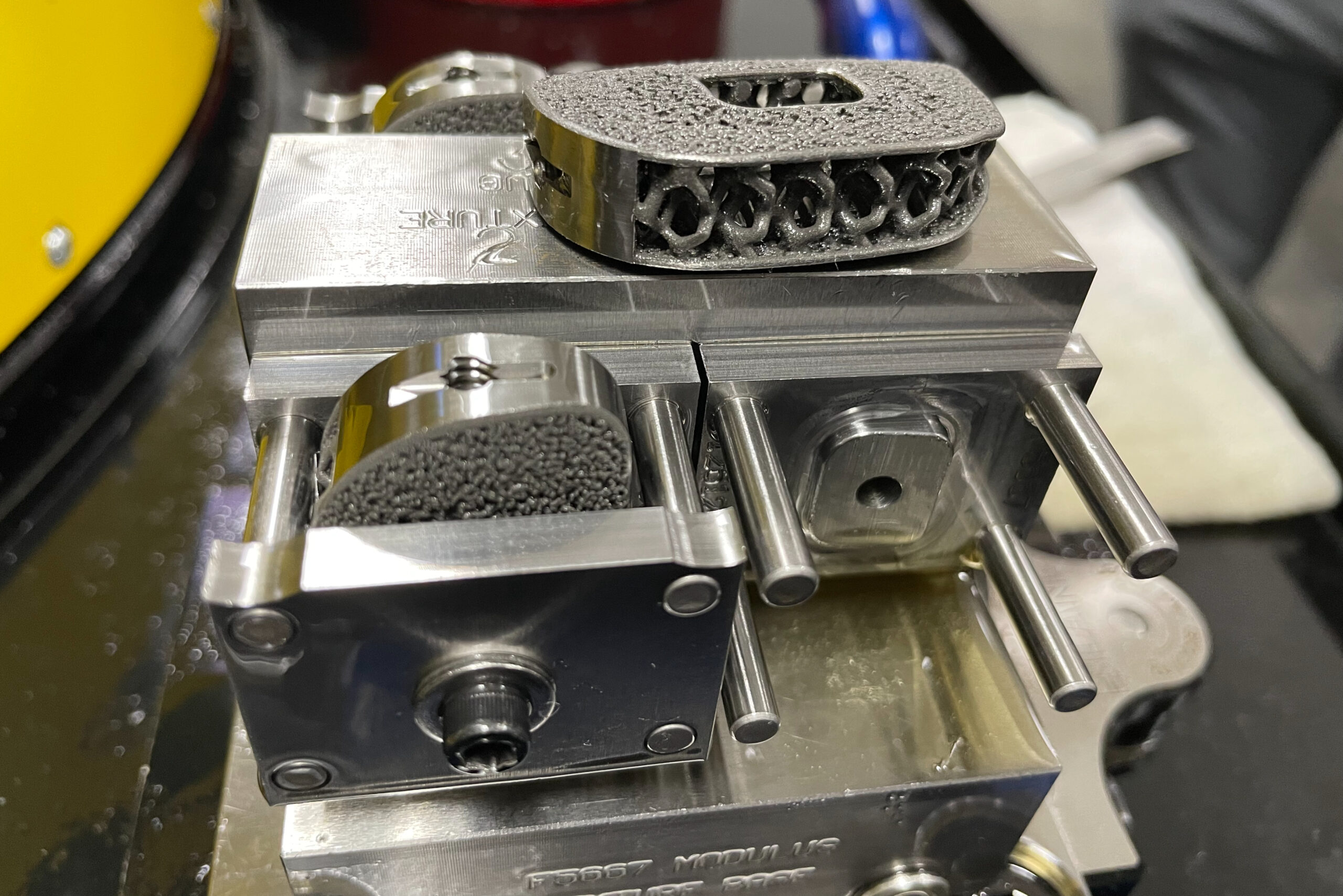

Prototyping: Validation Under Production Conditions

Rapid prototyping occurs using the exact production tooling, materials, and CNC programs intended for mass production—not scaled-down additive processes. Each prototype undergoes comprehensive metrology: CMM inspections verify geometric dimensioning and tolerancing (GD&T) to ISO 2768-mK standards, while destructive testing confirms material properties per ASTM E8. Surface roughness, hardness, and residual stress are quantified against application-specific thresholds. Only when prototypes exceed 3D printed part performance in fatigue resistance, thermal stability, and wear characteristics do we approve the process for scale-up.

Mass Production: Institutionalizing Zero Defects

Full-scale manufacturing integrates automated in-process inspection, statistical process control (SPC), and 100% first-article verification. Our CNC cells employ tool wear sensors and real-time thermal compensation to maintain micron-level accuracy across 10,000+ part runs. Every component receives traceable material certification (e.g., EN 10204 3.1), and final inspection includes non-destructive testing (NDT) where required. This closed-loop system—validated by PPAP Level 3 documentation—ensures zero escapes by design, not inspection.

Performance Comparison: Metal vs. Polymer Additive Production

| Parameter | Typical 3D Printed Polymer | Wuxi Lead Precision Metal |

|---|---|---|

| Tensile Strength | 30-50 MPa | 600-1200 MPa (e.g., 17-4PH SS) |

| Dimensional Tolerance | ±0.3 mm | ±0.005 mm |

| Surface Roughness (Ra) | 15-25 µm | 0.4-1.6 µm |

| Max Continuous Temp | 80-150°C | 600-900°C (alloy-dependent) |

This production framework transforms conceptual 3D models into mission-critical metal components where failure is not an option. By anchoring every phase in metrology-driven validation and process control, Wuxi Lead delivers parts that outperform additive alternatives in durability, precision, and lifecycle cost—ensuring your application operates at peak reliability from pilot to full production.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

When your operations demand precision-engineered replacement parts that outperform and outlast conventional solutions, Wuxi Lead Precision Machinery stands as your trusted manufacturing partner. Specializing in high-end custom metal components, we bridge the gap between advanced 3D printing capabilities and traditional metal manufacturing to deliver parts that meet the most stringent industrial requirements. Our engineering-driven approach ensures that every component we produce is optimized for performance, durability, and seamless integration into your existing systems.

At Lead Precision, we understand that downtime is costly and off-the-shelf solutions often fall short. That’s why we focus on delivering custom-manufactured replacement parts tailored to your exact specifications—whether you require high-strength alloys, complex geometries, or tight-tolerance components for aerospace, energy, automotive, or industrial equipment applications. By combining CNC machining, precision casting, and selective laser melting (SLM) technologies, we offer a hybrid manufacturing solution that surpasses the limitations of standalone 3D printing while maintaining design flexibility and rapid turnaround.

Our facility in Wuxi, China, operates under ISO 9001-certified quality management systems, ensuring full traceability, rigorous inspection protocols, and adherence to international standards. Every project begins with a collaborative engineering review, where our team analyzes your part’s function, load conditions, material requirements, and environmental exposure to recommend the optimal manufacturing method and material selection.

We specialize in producing components from high-performance materials such as titanium alloys, Inconel, tool steels, and aluminum alloys—each processed using state-of-the-art equipment and validated through comprehensive quality testing. From prototype to full-scale production, Lead Precision delivers consistency, precision, and scalability.

Below are key specifications that define our manufacturing capabilities:

| Capability | Specification |

|---|---|

| Dimensional Accuracy | Up to ±0.005 mm |

| Maximum Part Size | 600 × 600 × 500 mm |

| Material Options | Titanium (Ti6Al4V), Inconel 718, Stainless Steel 316L, AlSi10Mg, Tool Steel (H13, M2) |

| Surface Finish | As-printed: Ra ≤ 12 μm; Post-processed: Ra ≤ 1.6 μm |

| Post-Processing | Heat treatment, HIP, CNC finishing, shot peening, polishing |

| Quality Standards | ISO 9001, Full material certification, 3D scanning inspection |

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain an engineering ally committed to solving your most complex manufacturing challenges. We don’t just replicate parts; we enhance them through intelligent design improvements, material optimization, and precision execution.

Contact us today at [email protected] to discuss your replacement part requirements. Our engineering team is ready to assist with design evaluation, feasibility analysis, and rapid quoting to keep your operations running at peak efficiency. Let Lead Precision be your strategic partner in advanced metal manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.