Technical Contents

Engineering Guide: Mould Vs Mold Casting

Engineering Insight: Precision Defines the Casting Reality Beyond Spelling

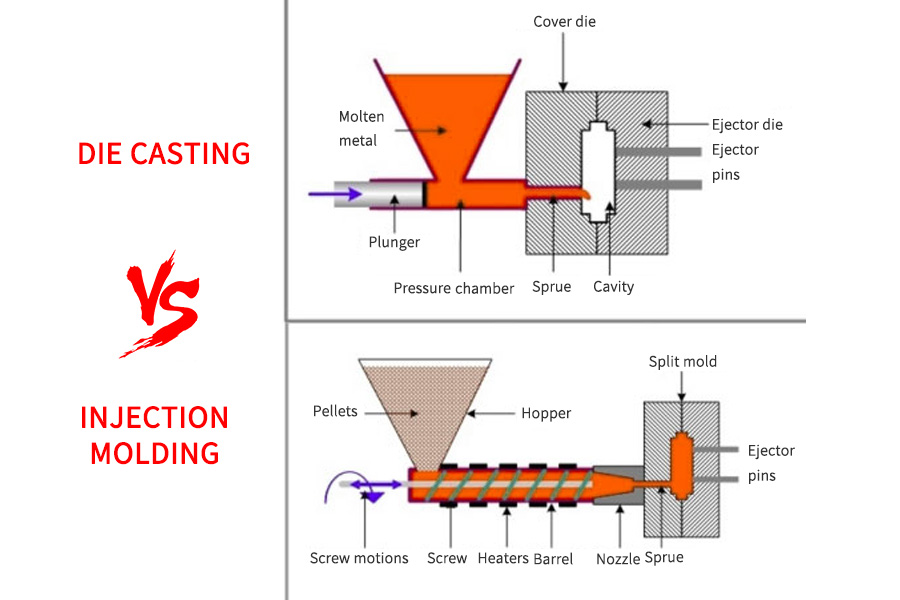

The persistent question “mould vs mold casting” often stems from regional spelling variations—British English favors mould, American English mold—not a fundamental technical distinction in the casting process itself. The critical differentiator for high-stakes manufacturing lies not in orthography, but in the uncompromising precision achieved during production. At Wuxi Lead Precision Machinery, we understand that for aerospace components, Olympic infrastructure, or military systems, the difference between a functional part and catastrophic failure resides in microns. Standard casting processes may suffice for non-critical applications, but mission-critical sectors demand engineered accuracy where dimensional stability, material integrity, and repeatability are non-negotiable.

Precision casting transcends basic shape replication. It requires rigorous control over thermal dynamics, material composition, and solidification rates to eliminate internal defects like porosity or shrinkage that compromise structural integrity. Surface finish must meet exacting specifications to ensure proper fit, fatigue resistance, and often, direct functionality without extensive post-processing. Tolerances frequently held to ±0.05mm or tighter necessitate advanced metrology integrated into every production phase—not final inspection alone. Consider a turbine blade for military aviation: a deviation of 0.02mm in cooling channel geometry can trigger overheating and engine failure. Similarly, structural nodes for Olympic venues must maintain exact load-bearing characteristics across thousands of identical units under extreme environmental stress. Our work on certified military hardware and landmark Olympic projects exemplifies this reality, where our process validation protocols and in-house CMM laboratories ensure every casting meets or exceeds stringent AS9100 and MIL-STD requirements.

Wuxi Lead Precision Machinery leverages decades of expertise in managing these complexities. We deploy proprietary simulation software for mold filling and solidification analysis, coupled with real-time process monitoring systems that adjust parameters dynamically. Our foundry operations utilize vacuum-assisted and low-pressure techniques specifically chosen to minimize turbulence and gas entrapment, directly enhancing material density. This systematic approach to precision engineering transforms casting from a mere shaping process into a guaranteed delivery of performance-critical metal components.

The following table highlights key differentiators between standard and precision casting outputs relevant to demanding industrial applications:

| Parameter | Standard Casting | Precision Casting (Wuxi Lead Standard) |

|---|---|---|

| Dimensional Tolerance | ±0.3mm – ±0.5mm | ±0.03mm – ±0.08mm (Critical Features) |

| Surface Roughness (Ra) | 6.3 μm – 12.5 μm | 1.6 μm – 3.2 μm (As-Cast) |

| Internal Porosity | Acceptable per ASTM B276 | Zero detectable porosity (X-ray/Vac) |

| Material Integrity | Basic mechanical specs | Full traceability, certified chemistry |

| Process Control | Batch inspection | Real-time monitoring, SPC on all runs |

| Typical Applications | Non-structural brackets | Aerospace actuators, hydraulic valves |

True value in metal casting is measured by the part’s ability to perform flawlessly in its operational environment. For Wuxi Lead Precision Machinery, the spelling of mould/mold is irrelevant; our commitment is to deliver castings where precision is engineered into every molecule, proven by our track record in the world’s most demanding sectors. Partner with us when failure is not an option.

Precision Specs & Tolerances

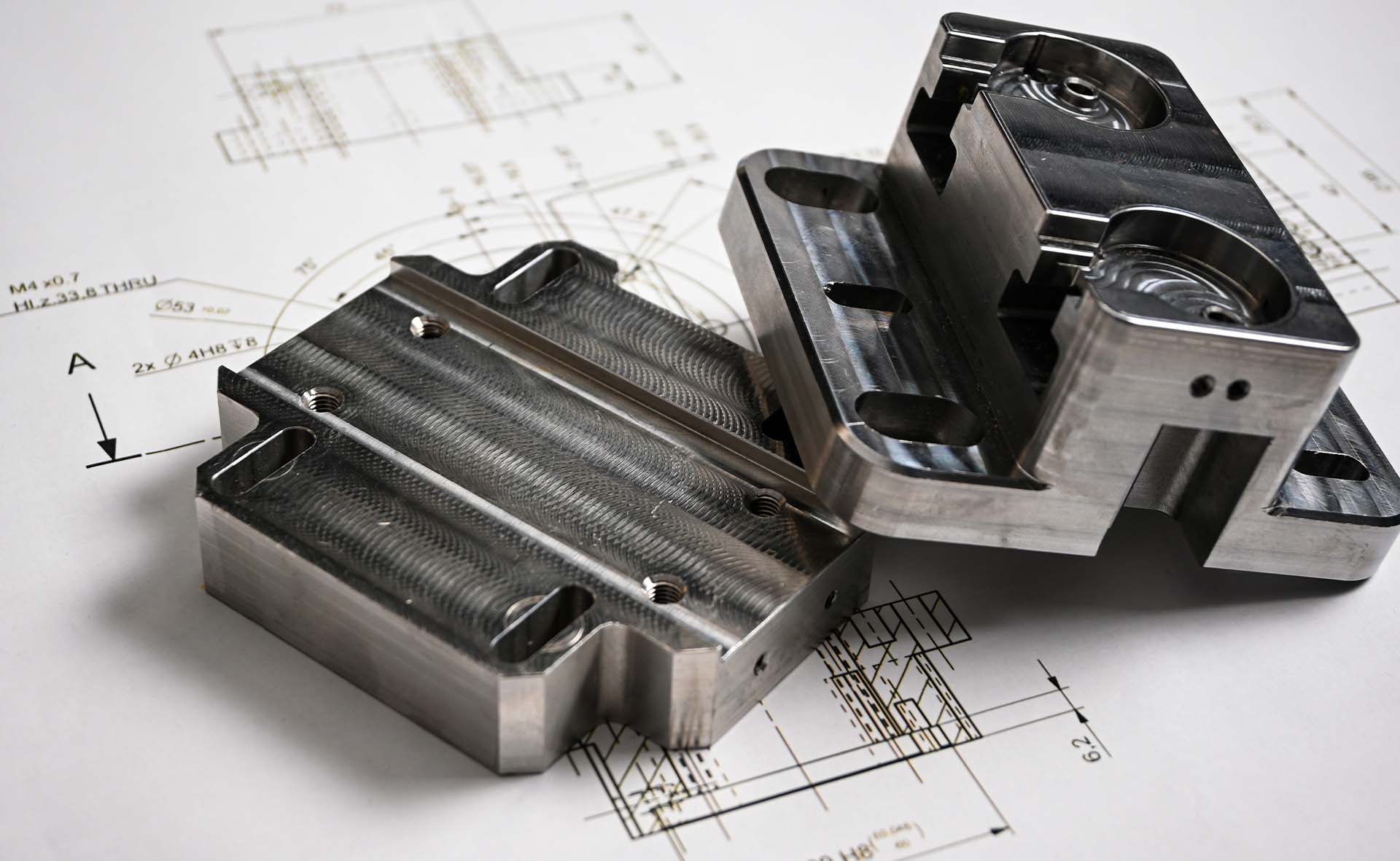

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions with a focus on precision, repeatability, and technical excellence. Our expertise in both mold and mould casting processes—terms used interchangeably depending on regional language preferences—enables us to serve global clients with consistent quality and engineering integrity. At the core of our technical capabilities is a fully integrated production workflow that combines high-performance 5-axis CNC machining with stringent quality control protocols, ensuring every component meets exacting specifications.

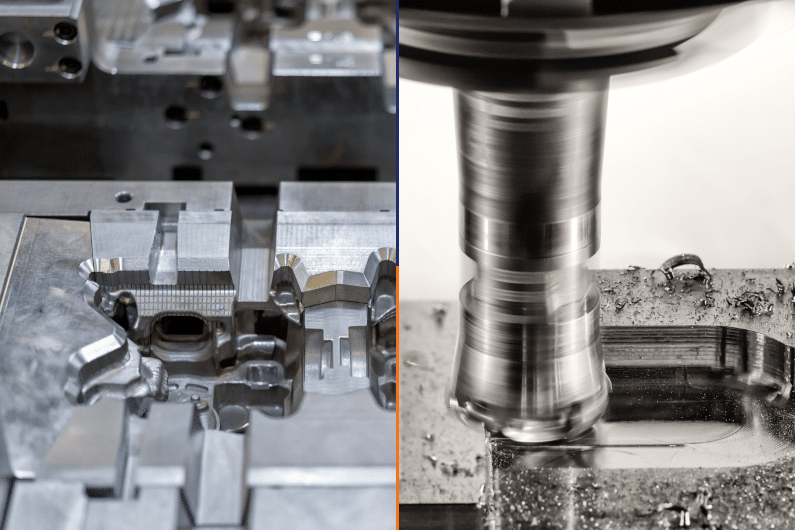

Our 5-axis CNC machining centers provide unparalleled flexibility in producing complex geometries commonly required in aerospace, medical, automotive, and industrial tooling applications. With simultaneous multi-axis movement, we achieve superior surface finishes, tighter tolerances, and reduced setup times compared to conventional 3-axis systems. This capability is particularly critical in mold and mould casting, where intricate cavity and core designs demand micron-level accuracy. The use of high-rigidity machines, coupled with adaptive toolpath strategies and real-time cutting condition monitoring, ensures optimal material removal rates while preserving dimensional stability.

All molds and moulds produced at Wuxi Lead undergo comprehensive dimensional validation using state-of-the-art Coordinate Measuring Machine (CMM) inspection. Our CMM systems operate in temperature-controlled environments to eliminate thermal drift, providing repeatable and traceable measurement data. Each component is verified against CAD models using 3D scanning and probe-based inspection routines, ensuring conformity to design intent. Full inspection reports, including GD&T analysis, are provided with every production batch, supporting full compliance with ISO 9001 and customer-specific quality requirements.

We specialize in both prototype development and high-volume production tooling, supporting materials ranging from tool steels and stainless steels to aluminum and high-temperature alloys. Our in-house heat treatment, surface finishing, and electrode EDM capabilities further enhance mold longevity and performance in demanding casting environments.

The following table outlines our standard machining and casting tolerances, reflecting the precision achievable through our integrated manufacturing system.

| Feature | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.025 mm | ±0.005 mm |

| Hole Diameter (drilled) | ±0.03 mm | ±0.01 mm (reamed) |

| Positional Tolerance | ±0.02 mm | ±0.008 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm (polished) |

| Angular Tolerance | ±0.05° | ±0.02° |

| Mold Cavity Matching | ±0.03 mm | ±0.01 mm |

| Wall Thickness (casting) | ±0.1 mm | ±0.05 mm |

Wuxi Lead Precision Machinery maintains full control over the entire manufacturing cycle—from initial design review and material selection to final inspection and customer delivery. Our technical team collaborates closely with clients to optimize mold design for manufacturability, minimizing cycle times and maximizing part consistency. With a foundation built on precision engineering and quality assurance, we deliver mold and mould casting solutions that meet the highest standards of performance and reliability in global industrial markets.

Material & Finish Options

Material Selection for Precision Casting: Aluminum Steel Titanium and Anodizing Finishes

Understanding regional terminology is critical in global manufacturing. While “mould” (British English) and “mold” (American English) refer to identical casting processes, material selection remains paramount for performance and longevity. At Wuxi Lead Precision Machinery we prioritize material properties aligned with your specific application demands including mechanical loads thermal cycles and environmental exposure. Aluminum alloys like 6061-T6 offer exceptional strength-to-weight ratios and thermal conductivity making them ideal for aerospace components and heat sinks where weight reduction is essential. Steel variants particularly 4140 and H13 provide superior hardness wear resistance and structural integrity for high-pressure die casting dies or tooling subjected to extreme mechanical stress. Titanium 6Al-4V stands unmatched for corrosion resistance and biocompatibility in aggressive environments such as marine or medical implants though its higher cost and machining complexity require careful justification.

Anodizing transforms aluminum surfaces into durable engineered finishes critical for both protection and functionality. Standard sulfuric acid anodizing Type II creates a porous oxide layer typically 0.0004 to 0.001 inches thick suitable for dyeing and moderate wear resistance. For mission-critical applications demanding maximum surface hardness and abrasion resistance hardcoat anodizing Type III produces dense non-porous layers ranging from 0.002 to 0.003 inches thick with hardness approaching sapphire. This finish is non-conductive and essential for hydraulic pistons aircraft landing gear or military hardware operating under severe friction. Note that anodizing applies exclusively to aluminum and its alloys steel and titanium require alternative treatments like nitriding or passivation.

Material performance characteristics directly impact casting success and part lifespan. The following table summarizes key properties for common selections:

| Material | Tensile Strength (psi) | Density (g/cm³) | Key Advantages | Primary Casting Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 45,000 | 2.7 | Lightweight excellent thermal conductivity good machinability | Aerospace housings heat exchangers automotive parts |

| Steel 4140 | 100,000 | 7.85 | High strength wear resistance toughness | Tooling dies structural components high-stress fittings |

| Titanium 6Al-4V | 130,000 | 4.43 | Exceptional corrosion resistance high strength-to-weight biocompatible | Marine components medical implants jet engine parts |

Selecting the optimal material and finish requires balancing performance requirements lifecycle costs and manufacturability. Wuxi Lead Precision Machinery leverages advanced CNC machining and metallurgical expertise to ensure your casting material selection translates into flawless production outcomes. Our engineering team collaborates closely with clients to analyze operational parameters and recommend validated solutions that minimize total cost of ownership while exceeding performance expectations. Contact us for a technical consultation to optimize your next precision casting project.

Manufacturing Process & QC

Design Phase: Precision Engineering for Optimal Casting Performance

The foundation of any successful casting process—whether labeled mould or mold, depending on regional spelling—begins with meticulous design engineering. At Wuxi Lead Precision Machinery, we initiate every project with a collaborative design review, integrating customer specifications, material properties, and casting methodology. Using advanced 3D CAD and simulation software such as SolidWorks and MAGMAsoft, our engineers analyze thermal gradients, flow dynamics, and potential shrinkage zones to optimize geometry and gating systems. This virtual prototyping ensures that the final mold design minimizes defects such as porosity, cold shuts, and inclusions. Tolerance analysis, surface finish requirements, and draft angles are all factored in to align with ISO 9001 and IATF 16949 standards. The result is a digitally validated mold design that maximizes yield and repeatability before any metal is poured.

Prototyping: Validating Design in Real-World Conditions

Once the digital model is approved, we proceed to prototype tooling and initial casting runs. This stage is critical for verifying design assumptions under actual production conditions. Using rapid tooling techniques—including CNC-machined prototype molds from aluminum or soft steel—we produce small batches for dimensional inspection, mechanical testing, and functional validation. Each prototype undergoes rigorous CMM (Coordinate Measuring Machine) inspection, metallurgical analysis, and non-destructive testing (NDT) such as X-ray or ultrasonic evaluation. Feedback from this phase informs final adjustments to the mold geometry, cycle time, and process parameters. This iterative approach reduces risk and ensures that the transition to mass production is seamless, with no compromise on quality.

Mass Production: Zero Defects Through Process Control

With design and prototype stages complete, we scale to full-volume manufacturing using hardened steel molds built for longevity and consistency. Our production lines integrate real-time monitoring systems that track temperature, pressure, injection speed, and cooling rates for every cycle. Automated robotic handling ensures repeatability, while statistical process control (SPC) enables immediate detection of deviations. Every casting is visually inspected and subjected to inline metrology, with data logged for full traceability. Our zero-defect philosophy is enforced through preventive maintenance schedules, operator training, and a closed-loop corrective action (CAPA) system. This disciplined approach ensures that every component meets exacting standards for aerospace, automotive, and industrial applications.

Typical Casting Process Specifications

| Parameter | Sand Casting | Die Casting | Investment Casting |

|---|---|---|---|

| Tolerance (mm) | ±0.5 – ±1.0 | ±0.1 – ±0.3 | ±0.05 – ±0.1 |

| Surface Finish (Ra, µm) | 6.3 – 12.5 | 0.8 – 3.2 | 1.6 – 3.2 |

| Common Materials | Cast Iron, Al, Cu | Aluminum, Zinc, Mg | Stainless Steel, Ti |

| Production Volume | Low to Medium | High | Medium to High |

| Tooling Life (cycles) | 1,000 – 10,000 | 100,000+ | 1,000 – 5,000 |

| Lead Time (tooling) | 2–6 weeks | 8–12 weeks | 4–8 weeks |

At Wuxi Lead Precision Machinery, we combine engineering excellence with disciplined manufacturing to deliver defect-free cast components, on time and to specification.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Definitive Casting Solutions

The spelling difference between mould and mold is trivial—merely regional convention. What matters profoundly is the engineering precision, material integrity, and process control behind every casting your operation produces. At Wuxi Lead Precision Machinery, we transcend linguistic nuances to deliver quantifiable excellence in custom metal casting. Whether your project demands aerospace-grade aluminum housings or medical-grade stainless steel components, our integrated approach eliminates the costly ambiguities that plague conventional casting partnerships.

Traditional casting processes often compromise dimensional stability, surface finish, and yield rates due to inconsistent tooling, suboptimal gating systems, or inadequate process validation. These flaws cascade into scrap costs, delayed time-to-market, and compromised part performance. Lead Precision engineers bypass these pitfalls through proprietary simulation-driven workflows and closed-loop CNC-machined tooling. We treat every casting as a high-stakes precision component—not a commodity—applying metrology-grade tolerances to both mold fabrication and final part production. Our ISO 9001-certified facility leverages real-time melt analysis, pressure-controlled pouring, and in-process CMM verification to ensure repeatability you can measure, not just promise.

Consider how our methodology transforms critical casting parameters:

| Parameter | Industry Standard | Lead Precision Standard | Verification Method |

|---|---|---|---|

| Dimensional Tolerance | ±0.5 mm | ±0.02 mm | 3D Laser Scanning + CMM |

| Surface Roughness | Ra 6.3 µm | Ra 0.8 µm | Profilometer (ISO 4287) |

| Yield Rate | 60-75% | ≥92% | Real-Time Melt Monitoring |

| Lead Time (Tooling) | 8-12 weeks | 4-6 weeks | Digital Twin Simulation |

This rigor stems from our dual expertise as both casting specialists and CNC machine builders. We design molds with the same precision we demand in finished parts—using hardened H13 tool steel, conformal cooling channels, and modular inserts that extend tool life by 40%. Our engineers collaborate with you from DFM review through PPAP submission, ensuring casting geometry aligns with manufacturability and end-use performance. For industries where failure is not an option—such as energy, defense, or life sciences—this integration of casting science and machine tool mastery is non-negotiable.

Stop accepting trade-offs between speed, cost, and precision. Partner with a manufacturer that treats your casting requirements as engineering challenges to solve, not orders to fulfill. Contact our technical team directly at [email protected] to initiate a casting evaluation. Include your part drawings or application specifications, and we will provide a detailed process proposal within 48 hours—including tolerance analysis, tooling strategy, and a validated timeline. With 15 years of experience serving Tier-1 global manufacturers, we are prepared to become your silent engineering partner, ensuring every casting meets the uncompromising standards your brand demands. Your journey toward zero-defect casting starts with one precise step: reach out today.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.