Technical Contents

Engineering Guide: Polypropylene Mold

Engineering Insight: The Critical Role of Precision in Polypropylene Molds

In the realm of custom metal manufacturing, polypropylene molds represent a cornerstone of high-volume, precision-driven production. As one of the most widely used thermoplastics, polypropylene demands molds engineered to exacting standards to ensure consistent part quality, dimensional stability, and extended service life. At Wuxi Lead Precision Machinery, our decades of experience in producing mission-critical components for Olympic-standard equipment and military-grade systems have instilled a culture of uncompromising precision—principles we directly apply to every polypropylene mold we manufacture.

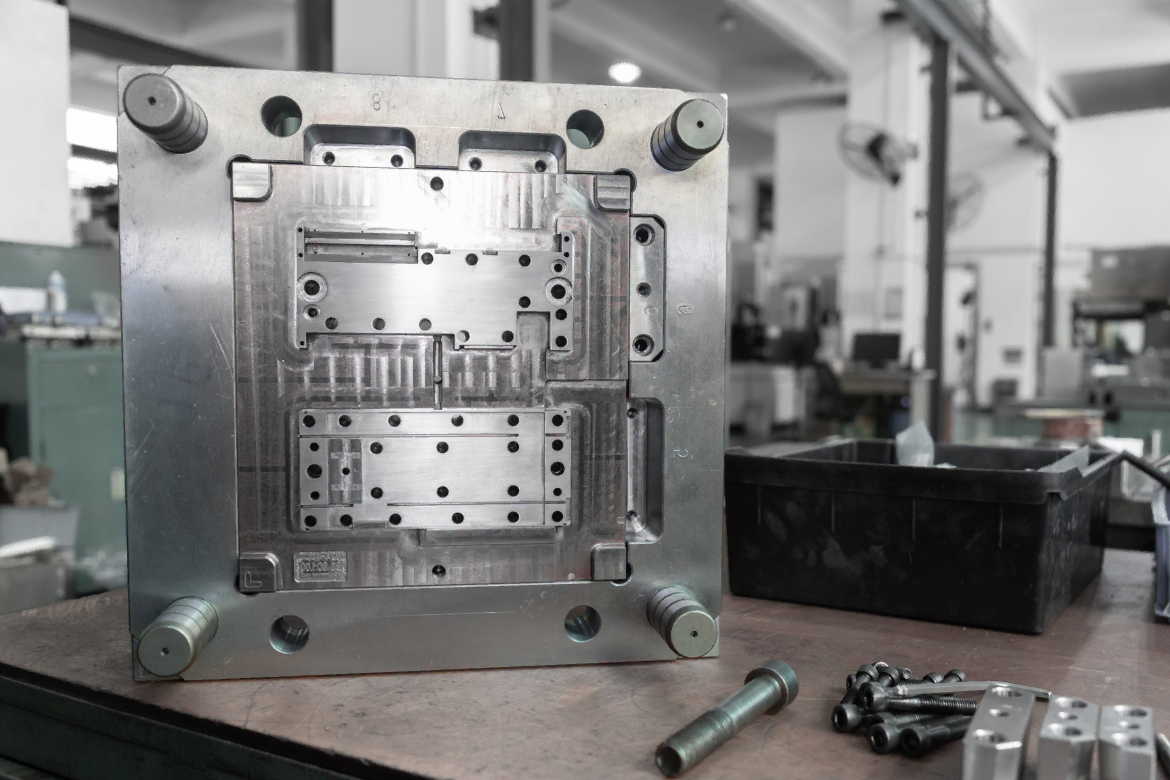

The performance of a polypropylene mold is intrinsically linked to its dimensional accuracy and thermal management. Even minor deviations in cavity geometry can result in warpage, sink marks, or incomplete filling due to polypropylene’s semi-crystalline structure and sensitivity to cooling rates. Our engineering team utilizes advanced 3D simulation software to model flow dynamics, optimize gate placement, and fine-tune cooling channel layouts. This predictive approach ensures uniform shrinkage control and minimizes cycle times, directly enhancing productivity and part repeatability.

Material selection is another pivotal factor. We employ high-grade tool steels such as P20, 718H, and H13, heat-treated to precise hardness levels, ensuring resistance to wear and thermal fatigue. Surface finishes are applied with micron-level consistency, ranging from mirror polishing to textured patterns, depending on the end application. Our in-house EDM, high-speed CNC machining, and coordinate measuring machines (CMM) guarantee tolerances within ±0.002 mm, a standard forged through our work on defense and high-performance sports equipment where failure is not an option.

At Lead Precision, we understand that a mold is not merely a tool but a long-term investment. Our design philosophy emphasizes modularity and ease of maintenance, enabling quick die changes and reduced downtime. Every mold undergoes rigorous quality validation, including mold flow analysis, first-article inspection, and trial runs under production-equivalent conditions.

| Specification | Detail |

|---|---|

| Material Options | P20, 718H, H13, S136 (stainless) |

| Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.05 μm to 3.2 μm (polished, textured, or as-machined) |

| Cooling Channel Design | Conformal or straight, optimized via thermal simulation |

| Mold Life Expectancy | 500,000 to 1,000,000 cycles (depending on configuration) |

| Standard Lead Time | 4–8 weeks (varies by complexity) |

| Quality Assurance | Full CMM report, mold trial video, dimensional certification |

Our proven expertise in high-stakes manufacturing environments translates seamlessly into the production of polypropylene molds that deliver reliability, precision, and longevity. For global OEMs and tier-one suppliers, partnering with Wuxi Lead Precision Machinery means securing a mold solution engineered not just to meet specifications—but to exceed operational expectations.

Precision Specs & Tolerances

Technical Capabilities for Polypropylene Mold Manufacturing

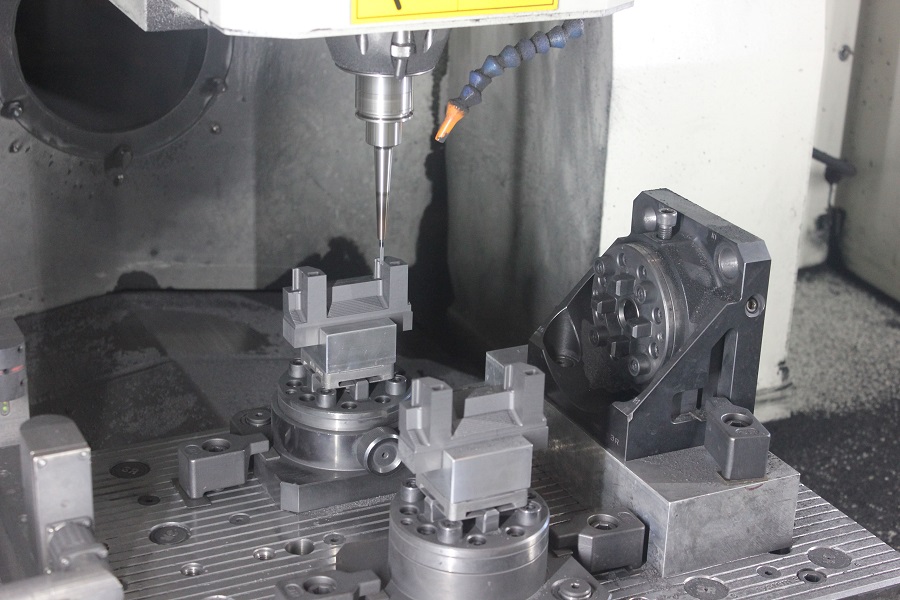

Wuxi Lead Precision Machinery delivers uncompromising precision in custom polypropylene mold production, leveraging advanced manufacturing infrastructure and rigorous quality control protocols. Our technical foundation centers on state-of-the-art 5-axis CNC machining centers, essential for achieving the complex geometries and stringent tolerances demanded by high-performance polypropylene injection molds. These systems enable simultaneous multi-directional tool movement, eliminating the need for multiple setups and significantly reducing cumulative error. This capability is critical for machining intricate cooling channels, undercuts, and fine surface textures inherent in polypropylene molds, where thermal management and dimensional stability directly impact part quality and cycle time. Our machining processes are optimized for the specific thermal expansion characteristics and wear resistance requirements of mold steels used with polypropylene, ensuring long-term cavity integrity under repeated high-temperature cycles.

Quality assurance is integrated throughout every phase of production. All critical mold components undergo comprehensive Coordinate Measuring Machine (CMM) inspection using calibrated Zeiss CONTURA systems within a temperature-controlled metrology lab maintained at 20°C ±0.5°C. This ensures measurement accuracy traceable to national standards, vital for verifying alignment of core and cavity inserts, runner systems, and ejection mechanisms. In-process CMM checks occur at defined milestones, not merely as a final step, allowing immediate correction of any deviations. Our inspection regime specifically targets polypropylene mold performance factors, including verification of draft angles to prevent part sticking, precise venting dimensions to avoid burn marks, and exact gate geometry for optimal melt flow and minimal stress.

The table below details our standard achievable tolerances for polypropylene mold manufacturing, reflecting our commitment to exceeding typical industry benchmarks. These specifications are validated through our CMM inspection process and form the baseline for all customer projects, with tighter tolerances available for critical features upon engineering review.

| Feature Category | Standard Industry Tolerance | Wuxi Lead Precision Capability |

|---|---|---|

| Linear Dimensions (Milling) | ±0.025 mm | ±0.005 mm |

| Linear Dimensions (Turning) | ±0.012 mm | ±0.003 mm |

| Core/Cavity Alignment | ±0.05 mm | ±0.01 mm |

| Surface Finish (Cavity) | Ra 0.8 μm | Ra 0.2 μm |

| Hole Positional Accuracy | ±0.05 mm | ±0.01 mm |

| Flatness (Per 100mm) | 0.02 mm | 0.005 mm |

Our engineering team collaborates closely with clients during the design phase to optimize mold geometry for manufacturability and performance with polypropylene. We utilize advanced simulation data to anticipate material behavior, ensuring the final mold delivers consistent part dimensions, minimal flash, and extended service life. This integrated approach—combining 5-axis precision, material-specific process knowledge, and metrology-grade verification—guarantees molds that meet the exacting demands of high-volume polypropylene production, reducing scrap rates and maximizing uptime for our customers. Wuxi Lead Precision Machinery provides the technical execution necessary to transform complex polypropylene mold designs into reliable, high-yield manufacturing assets.

Material & Finish Options

When selecting materials for polypropylene molds, precision, durability, and thermal performance are critical. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to high-volume and high-precision injection molding applications. The choice between aluminum, steel, and titanium directly impacts mold life, cycle time, surface finish, and overall production cost. Each material offers distinct advantages depending on the complexity and volume of the polypropylene parts being produced.

Aluminum is widely used for prototype molds and low- to medium-volume production due to its excellent thermal conductivity and ease of machining. It allows for faster cooling cycles, reducing overall production time during initial runs. While not as wear-resistant as steel, modern aluminum alloys such as 7075-T6 provide sufficient durability for up to 100,000 cycles when properly treated. This makes aluminum an ideal choice for rapid tooling and product validation phases.

Steel, particularly pre-hardened or tool-grade steels like P20, H13, or S136, remains the standard for high-volume polypropylene molding. These steels offer superior hardness, wear resistance, and longevity—capable of enduring over 1 million cycles with proper maintenance. Their enhanced durability ensures dimensional stability across extended production runs, making them suitable for complex geometries and tight tolerance requirements. Additionally, steel molds can be polished or textured to achieve a wide range of surface finishes, including mirror or matte effects.

Titanium is less common in standard mold construction but offers exceptional strength-to-density ratio and corrosion resistance. While its high cost and challenging machinability limit widespread use, titanium finds niche applications in specialized molds exposed to extreme conditions or where weight reduction is critical. It is typically considered only for highly engineered, mission-critical components.

Surface treatment plays a vital role in mold performance and part quality. Anodizing is a widely used finish for aluminum molds, significantly improving surface hardness, wear resistance, and corrosion protection. Hard anodizing, in particular, creates a durable oxide layer that enhances mold lifespan and facilitates easier ejection of polypropylene parts. For steel molds, alternatives such as nitriding or chrome plating are more common, though anodizing is not applicable due to material constraints.

Below is a comparative overview of key material properties relevant to polypropylene mold construction.

| Material | Hardness (HB) | Thermal Conductivity (W/m·K) | Typical Mold Life (Cycles) | Common Finishes | Best Use Case |

|---|---|---|---|---|---|

| Aluminum 7075-T6 | 150–200 | 130 | 50,000–100,000 | Hard Anodizing, Polishing | Prototypes, low-volume production |

| P20 Steel | 280–320 | 30 | 500,000–1,000,000 | Polishing, Texturing | Medium to high-volume production |

| H13 Steel | 480–520 | 35 | 1,000,000+ | Nitriding, Chrome Plating | High-stress, high-volume molds |

| Titanium Grade 5 | 300–350 | 7 | 100,000–500,000 (niche) | Coating (e.g., TiN) | Specialized, corrosive environments |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on production volume, part complexity, and lifecycle requirements, ensuring optimal performance and cost-efficiency in polypropylene mold manufacturing.

Manufacturing Process & QC

Polypropylene Mold Production Process: Achieving Zero Defects

At Wuxi Lead Precision Machinery, our polypropylene mold production adheres to a rigorously controlled three-phase methodology, engineered specifically for the material’s unique thermal and flow characteristics to guarantee zero defects in final components. This integrated approach ensures dimensional stability, surface perfection, and long-term mold reliability under demanding production cycles.

The Design phase forms the critical foundation. Our engineering team utilizes advanced CAD/CAM software combined with deep material science expertise in polypropylene behavior. We meticulously analyze part geometry, wall thickness variations, and gate locations to optimize melt flow and minimize internal stresses inherent in this semi-crystalline thermoplastic. Critical attention is paid to precise shrinkage compensation calculations – polypropylene exhibits significant and variable shrinkage rates (typically 1.0-2.5%) highly dependent on processing conditions and part design. Comprehensive Mold Flow Analysis (MFA) simulations are mandatory, predicting potential weld lines, air traps, and cooling inefficiencies. Thermal management design, including conformal cooling channel layouts, is prioritized to ensure uniform solidification and prevent warpage or sink marks, directly addressing polypropylene’s sensitivity to uneven cooling rates.

Prototyping transitions validated designs into physical reality under near-production conditions. We utilize high-precision CNC machining and EDM processes on premium mold steels (such as H13 or 2738HH) to fabricate the initial mold set. Crucially, this prototype is not a simplified version; it is a fully functional tool run on production-specification injection molding machines using the exact polypropylene grade and processing parameters intended for mass production. This phase focuses on empirical validation: verifying dimensional accuracy against CAD models, confirming optimal gate seal time, assessing surface finish replication, and measuring actual shrinkage. Any deviations trigger immediate design or process parameter adjustments. This step is non-negotiable for eliminating unforeseen defects before full-scale commitment.

Mass Production leverages the perfected design and validated process within our certified zero-defect manufacturing system. Molds are integrated into automated production cells with real-time monitoring of all critical parameters. Statistical Process Control (SPC) is continuously applied to key variables. Automated in-line vision systems perform 100% critical dimension and surface defect inspection on every molded part. Our integrated quality management system mandates traceability from raw material batch to final shipment, with comprehensive documentation for every production run. Preventative maintenance schedules, based on actual mold cycle counts and sensor data, ensure consistent performance and longevity, preventing wear-induced defects.

The table below details critical process specifications maintained throughout production to achieve zero defects with polypropylene:

| Parameter | Target Specification | Control Method | Tolerance Band |

|---|---|---|---|

| Mold Cavity Temperature | 20°C – 80°C (Grade Dep.) | Closed-loop oil/water systems | ±1.0°C |

| Melt Temperature | 200°C – 270°C | Barrel zone sensors + melt probe | ±2.0°C |

| Injection Pressure | 800 – 1500 bar | Hydraulic/pneumatic pressure transducers | ±10 bar |

| Cooling Time | Part-specific (sec) | PLC-controlled timers | ±0.5 sec |

| Cavity Pressure | Monitored at gate & end of fill | Embedded piezoelectric sensors | ±5 bar at critical points |

This disciplined progression from scientific design through empirical prototyping to tightly monitored mass production, underpinned by our proprietary quality protocols, is how Wuxi Lead Precision Machinery consistently delivers polypropylene molds that perform flawlessly from the first shot to the millionth cycle. Zero defects is not an aspiration; it is the engineered outcome of our process.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Your Polypropylene Mold Manufacturing Needs

When it comes to high-performance polypropylene molds, precision, durability, and repeatability are non-negotiable. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions engineered to meet the exacting demands of industries ranging from automotive and medical devices to consumer goods and industrial packaging. With over 15 years of experience in mold design and CNC precision engineering, we deliver molds that ensure optimal cycle times, consistent part quality, and long-term reliability.

Our engineering team works closely with clients from concept to production, applying deep material science expertise and advanced simulation software to optimize mold flow, cooling efficiency, and ejection systems specifically for polypropylene. This thermoplastic presents unique challenges—high shrinkage rates, sensitivity to cooling gradients, and the need for precise gate design—and our solutions are tailored to address them systematically. Whether you require single-cavity molds for prototyping or high-cavitation systems for mass production, we build every mold to exceed performance expectations.

We utilize premium-grade tool steels such as P20, 718H, and H13, combined with precision CNC machining, wire EDM, and surface treatments like nitriding or chrome plating, to ensure wear resistance and dimensional stability. Our quality assurance protocols include rigorous first-article inspections, cavity pressure testing, and mold validation under real production conditions. This end-to-end control guarantees that your polypropylene mold performs flawlessly on your press, minimizing downtime and scrap rates.

Wuxi Lead Precision Machinery is ISO 9001 certified and equipped with a 12,000-square-meter manufacturing facility in Jiangsu, China, housing over 80 CNC machines, 12 EDM units, and a dedicated project management team fluent in English and technical documentation. We support global clients with seamless communication, digital design reviews, and on-time delivery—typically 30–45 days for standard molds, depending on complexity.

Below are key technical specifications we routinely achieve for polypropylene mold projects:

| Specification | Capability |

|---|---|

| Mold Base Standards | LKM, FUTABO, DME, or custom |

| Maximum Mold Size | 1500 mm × 1200 mm × 1000 mm |

| Tolerance | ±0.005 mm |

| Surface Finish | SPI A1, A2, B1, B2, or customer-defined |

| Runner Systems | Cold runner, hot runner (Yudo, Hasco, Mold-Masters) |

| Cavitation Range | 1 to 32 cavities (standard), up to 64 upon request |

| Lead Time | 30–60 days (based on complexity) |

| Quality Standards | ISO 9001, First Article Inspection (FAI), Mold Flow Analysis Report |

Partnering with Wuxi Lead Precision Machinery means gaining a manufacturing ally focused on your success. We don’t just build molds—we engineer production efficiency. Contact us today at [email protected] to discuss your polypropylene mold requirements. Our engineering team is ready to review your CAD files, provide a detailed quotation, and support your project from design validation through full-scale production. Let us help you turn precision into performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.