Technical Contents

Engineering Guide: Flexible Pvc Moulding

Engineering Insight: Precision Imperatives in Flexible PVC Moulding

Flexible PVC moulding presents unique engineering challenges distinct from rigid thermoplastics. Its viscoelastic nature demands exceptional process control to achieve consistent part geometry, sealing integrity, and functional performance. Minor deviations in temperature, pressure, or cycle timing directly impact material flow, shrinkage rates, and final part dimensions. Dimensional variance exceeding 0.2mm often leads to assembly failures, compromised seals in fluid handling systems, or accelerated wear in dynamic applications. This precision deficit translates directly to field failures, warranty claims, and reputational damage for end-product manufacturers. At the high-performance tier – aerospace seals, medical device components, or military-grade cable conduits – tolerances tighten further, demanding sub-0.1mm accuracy and absolute repeatability. Achieving this requires moving beyond standard moulding practices into the realm of metrology-grade process engineering.

Wuxi Lead Precision Machinery operates at this critical precision frontier. Our CNC-engineered mould bases and proprietary temperature control systems are designed specifically for the nuanced behavior of flexible PVC compounds. We implement closed-loop monitoring of melt viscosity, cavity pressure, and cooling rates in real-time, adjusting parameters dynamically to counteract material drift. This granular control ensures uniform wall thickness, minimizes internal stresses that cause warpage during viscoelastic recovery, and guarantees critical features like O-ring grooves or snap-fit interfaces meet stringent GD&T specifications. Our process validation protocols exceed standard ISO 9001 requirements, incorporating in-mould sensor arrays and post-mould CMM verification for every production batch.

The consequence of inadequate precision is demonstrably costly. Consider these critical parameters and their impact:

| Parameter | Critical Range for High-Performance Flexible PVC | Consequence of Deviation |

|---|---|---|

| Melt Temperature | ±2°C stability | Inconsistent flow, surface defects, degraded mechanical properties |

| Cavity Pressure | ±0.5 bar control | Flash, short shots, non-uniform density, sealing failure |

| Cooling Rate | Programmable gradient (not fixed time) | Excessive warpage, residual stress, dimensional instability |

| Clamp Force Profile | Matched to material viscosity curve | Parting line mismatch, flash at ejectors, core shift |

Our capability is rigorously proven in mission-critical applications. We engineered and produced flexible PVC sealing components operating under extreme vibration and temperature cycles for hydraulic systems in Olympic venue infrastructure, where failure was not an option. Similarly, our military-specification cable jacketing moulds consistently achieve IP68 ratings for field-deployable communication systems, surviving rigorous MIL-STD-810G environmental testing. These projects demanded not only initial precision but sustained repeatability across 500,000+ shot production runs – a benchmark standard we apply to every client engagement.

For manufacturers reliant on flexible PVC components, precision moulding is not a cost center but a strategic investment in product reliability and lifecycle value. Wuxi Lead Precision Machinery delivers this through CNC-honed tooling, scientifically validated processes, and engineering discipline forged in the most demanding global projects. Partner with us to transform flexible PVC from a processing challenge into a competitive advantage.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to meet the rigorous demands of high-precision industries such as aerospace, medical devices, and industrial automation. At the core of our production infrastructure is our 5-axis CNC machining technology, which enables the creation of complex geometries with exceptional accuracy and surface finish. Unlike conventional 3-axis systems, our 5-axis CNC centers allow simultaneous movement across five axes, minimizing setup time and part repositioning. This results in tighter tolerances, reduced cycle times, and superior consistency across both prototyping and high-volume production runs.

Our 5-axis CNC machines are equipped with high-speed spindles, advanced tool management systems, and real-time monitoring software, ensuring optimal performance and minimal thermal drift. These systems support a wide range of materials, including aluminum alloys, stainless steels, titanium, and high-strength nickel-based alloys—materials often required in environments where flexible PVC molding components interface with metal subassemblies. The integration of 5-axis capability allows us to machine undercuts, deep cavities, and contoured surfaces in a single setup, which is critical when producing molds, inserts, or support structures for flexible PVC molding processes.

Quality control is embedded into every phase of production. Each component undergoes comprehensive inspection using our Coordinate Measuring Machine (CMM), which provides metrology-grade verification of dimensional accuracy. The CMM system operates with sub-micron resolution and is programmed to follow ISO 10360 standards, ensuring traceable and repeatable measurement results. Features such as hole location, profile deviation, flatness, and angular precision are validated against engineering drawings and CAD models, with full inspection reports provided upon request. This level of scrutiny guarantees that every part conforms to the most stringent industry specifications.

In addition to CMM inspection, we employ first-article inspection (FAI), in-process checks, and final quality audits to maintain process stability. Our quality management system is ISO 9001 certified, reflecting our commitment to continuous improvement and customer satisfaction.

The following table outlines the standard tolerances achievable through our 5-axis CNC machining and inspection processes:

| Feature | Standard Tolerance | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM, Micrometers |

| Hole Diameter | ±0.01 mm | ±0.005 mm | Air Gauges, CMM |

| Positional Tolerance | ±0.02 mm | ±0.008 mm | CMM |

| Surface Flatness | 0.02 mm | 0.005 mm | CMM, Optical Flats |

| Angular Accuracy | ±0.05° | ±0.01° | CMM, Precision Protractors |

| Surface Finish (Ra) | 0.8 µm | 0.2 µm | Surface Roughness Tester |

These technical capabilities position Wuxi Lead Precision Machinery as a trusted partner for manufacturers requiring precision metal components designed for integration with flexible PVC molding systems.

Material & Finish Options

Material Selection for Precision Moulds in Flexible PVC Processing

Selecting the optimal material for moulds used in flexible PVC extrusion or injection moulding is critical for achieving consistent part quality, extended tool life, and operational efficiency. At Wuxi Lead Precision Machinery, we understand that the corrosive nature of PVC additives and the thermal demands of the process necessitate careful material engineering. While the final product is polymer-based, the mould tooling itself must be fabricated from high-performance metals capable of withstanding chemical exposure, thermal cycling, and mechanical stress. The wrong material choice leads to premature wear, surface degradation, increased downtime, and compromised part aesthetics or dimensional accuracy. Our engineering team evaluates thermal properties, hardness, corrosion resistance, and machinability to match the material precisely to your production volume, PVC formulation, and quality requirements.

The core materials we deploy for flexible PVC mould tooling are aluminum alloys, tool steels, and titanium alloys, each offering distinct advantages. Below is a comparative overview of key properties relevant to PVC moulding applications.

| Material | Hardness (HV) | Thermal Conductivity (W/mK) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|

| 7075-T6 Aluminum | 150 | 130 | Moderate | Prototypes, low-volume production, complex cores/cavities |

| H13 Tool Steel | 480 | 35 | Good (with finish) | Medium to high-volume production, demanding cores |

| Titanium Grade 5 | 350 | 7 | Excellent | Extreme corrosion resistance, specialized high-wear inserts |

7075-T6 aluminum is our preferred choice for rapid prototyping and lower-volume production runs. Its exceptional thermal conductivity ensures fast cycle times and uniform cooling, crucial for minimizing warpage in flexible PVC parts. While less inherently corrosion-resistant than steel, its performance is significantly enhanced through hard anodizing, creating a durable, non-stick surface that resists PVC degradation and simplifies part ejection. Aluminum’s machinability allows for intricate geometries at lower cost.

For high-volume production, H13 tool steel provides superior hardness and wear resistance. Its ability to maintain dimensional stability under prolonged thermal cycling is unmatched for demanding schedules. However, H13 requires precise heat treatment and benefits immensely from surface finishing. Standard anodizing is insufficient; we apply specialized hard chrome plating or PVD coatings alongside precision polishing to achieve the necessary corrosion barrier against chlorine byproducts generated during PVC processing.

Titanium Grade 5 (Ti-6Al-4V) is reserved for the most severe corrosion challenges, such as processing highly filled or specialty PVC compounds with aggressive stabilizers. Its natural passivation layer offers outstanding chemical resistance, eliminating the need for additional plating in many scenarios. While thermal conductivity is low, strategic cooling channel design mitigates this limitation. Titanium’s high cost is justified only when extreme longevity in corrosive environments is paramount.

Anodizing, particularly hard anodizing for aluminum moulds, is not merely a finish but a functional necessity. It transforms the surface into a hard, corrosion-resistant aluminum oxide layer, significantly extending tool life in PVC environments. This layer reduces adhesion, improves release, and maintains critical surface finishes over thousands of cycles. At Wuxi Lead, our anodizing processes are tightly controlled to ensure consistent thickness, hardness, and pore sealing, directly contributing to your production reliability and part quality consistency. Material selection combined with the correct engineered finish forms the foundation of a successful, cost-effective flexible PVC manufacturing operation.

Manufacturing Process & QC

The production process for flexible PVC moulding at Wuxi Lead Precision Machinery follows a disciplined, closed-loop methodology designed to achieve zero defects across every phase—Design, Prototyping, and Mass Production. Our approach integrates precision engineering, material science, and advanced quality control systems to ensure consistent, high-performance output tailored to industrial applications.

Design begins with a collaborative analysis of the client’s functional requirements, environmental conditions, and dimensional tolerances. Our engineering team utilizes 3D CAD modeling and finite element analysis (FEA) to simulate stress distribution, thermal behavior, and sealing performance under real-world operating conditions. This virtual validation ensures optimal geometry and material selection prior to physical development. Special attention is given to wall thickness uniformity, gate positioning, and draft angles to prevent warpage and ensure consistent flow during injection. The final design is reviewed against international standards, including ISO 9001 and IATF 16949, and approved through a formal sign-off process.

Prototyping leverages high-precision CNC-machined molds and short-run injection molding under production-equivalent parameters. This stage is not merely a form-fit check but a comprehensive functional validation. Each prototype undergoes rigorous testing for tensile strength, elongation at break, compression set, and chemical resistance according to ASTM and DIN protocols. Dimensional inspection is performed using coordinate measuring machines (CMM) with tolerances held to ±0.05 mm. Feedback from testing is systematically fed back into the design for refinement, ensuring the final mold design eliminates potential failure modes before scale-up.

Mass Production is executed on automated, servo-driven injection molding platforms equipped with real-time process monitoring. Each cycle is tracked for pressure, temperature, and cooling time, with deviations triggering immediate alerts. In-line vision systems and automated gauging stations inspect critical dimensions at a 100% rate on selected features. All materials are batch-traceable, and environmental controls maintain stable humidity and temperature in the production hall to prevent material degradation. Finished parts are subjected to first-article inspection, periodic sampling per AQL Level II, and accelerated aging tests for long-term reliability.

Our zero-defect philosophy is enforced through Statistical Process Control (SPC), root cause analysis for any non-conformance, and continuous operator training. Every stage is documented and auditable, ensuring full traceability from raw material to final shipment.

Key production specifications are maintained as follows:

| Parameter | Specification |

|---|---|

| Material Options | Flexible PVC (shore hardness 50A to 90A), flame-retardant, UV-stabilized, low-smoke variants |

| Tolerance Range | ±0.05 mm to ±0.2 mm, depending on part size and geometry |

| Mold Life | 500,000+ cycles (P20/H13 steel, hardened and polished) |

| Production Capacity | Up to 500,000 units per month (scalable with multi-cavity molds) |

| Quality Standards | ISO 9001, IATF 16949, RoHS, REACH compliant |

| Testing Protocols | Tensile strength, elongation, compression set, chemical resistance, dimensional CMM |

This end-to-end process ensures that every flexible PVC molding delivered meets the highest standards of reliability, consistency, and performance.

Why Choose Wuxi Lead Precision

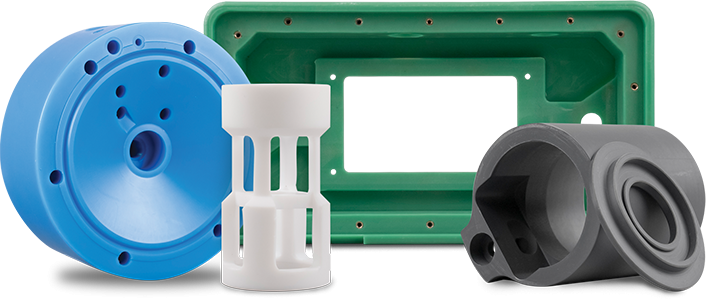

Elevate Your Flexible PVC Moulding with Engineering Precision

Flexible PVC components demand exceptional dimensional stability, material consistency, and repeatability—especially in mission-critical sectors like medical devices, automotive sealing systems, and industrial fluid handling. Generic manufacturing approaches often fail to address the nuanced thermal behavior and elastic recovery inherent in PVC compounds, leading to part warpage, inconsistent wall thickness, or premature failure. At Wuxi Lead Precision Machinery, we engineer solutions at the intersection of advanced CNC technology and deep polymer science expertise. Our dedicated flexible PVC moulding division operates under ISO 9001-certified protocols, utilizing climate-controlled production cells and real-time process monitoring to eliminate variability. We transform complex geometries—from micro-extruded tubing to multi-cavity gasket arrays—into high-yield, production-ready components that meet ASTM D1248 and ISO 188 standards without compromise.

Our technical advantage stems from purpose-built machinery and material-specific process algorithms. Unlike standard injection moulders, our CNC-controlled presses feature closed-loop pressure regulation and adaptive cooling channels calibrated for PVC’s narrow processing window. This ensures uniform molecular orientation and minimizes internal stress, directly enhancing product lifespan and sealing performance. Every project begins with rigorous material flow analysis using Moldex3D simulation, allowing us to preempt sink marks, weld lines, or flash before tool steel is cut. This proactive engineering approach reduces time-to-market by up to 30% while guaranteeing first-pass success rates exceeding 98.5%.

Key technical capabilities for flexible PVC applications include:

| Specification Category | Performance Standard |

|---|---|

| Dimensional Tolerance | ±0.05 mm for features < 50 mm |

| Material Compatibility | Phthalate-free, medical-grade, flame-retardant PVC compounds |

| Maximum Part Size | 450 x 300 x 120 mm |

| Surface Finish | Ra 0.8 µm to custom textures (VDI 3400) |

| Production Capacity | 50,000+ parts/week with automated in-line inspection |

| Secondary Operations | Ultrasonic welding, insert molding, cleanroom assembly |

Partnering with Lead Precision means accessing a strategic manufacturing ally, not just a vendor. Our engineering team collaborates directly with your R&D department during DFM analysis, identifying cost-saving design optimizations without sacrificing functional requirements. We maintain dedicated material storage with humidity control below 40% RH and conduct batch-specific MFR testing to ensure compound integrity. For regulated industries, we provide full traceability with lot-controlled documentation packages meeting FDA 21 CFR Part 820 and IATF 16949 requirements.

The cost of substandard flexible PVC components extends far beyond scrap rates—it risks product recalls, reputational damage, and compromised end-user safety. Wuxi Lead Precision Machinery delivers certified reliability through engineering rigor, not volume discounts. Our clients achieve 40% lower total cost of ownership through reduced rework, extended tool life, and supply chain continuity.

Initiate a technical consultation today to validate your flexible PVC component requirements against our proven manufacturing framework. Email [email protected] with your part specifications and target volumes. Our application engineers will respond within 4 business hours with a preliminary process feasibility assessment and timeline. Trust precision engineering where flexibility matters most.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.