Technical Contents

Engineering Guide: Cnc Machining Austin Tx

Engineering Insight: The Uncompromising Demand for Precision in CNC Machining – Austin TX and Beyond

In the high-stakes world of advanced manufacturing, precision is not merely a quality objective—it is a foundational requirement. Whether serving the aerospace, defense, or medical sectors, CNC machining operations must deliver micron-level accuracy, repeatable consistency, and flawless surface finishes. This standard holds true whether the facility is located in Austin, TX, a growing hub for technology and advanced manufacturing, or in global production centers like Wuxi, China. At Wuxi Lead Precision Machinery, we understand that precision transcends geography; it is defined by engineering rigor, process control, and a culture of excellence.

Austin, TX, has emerged as a critical node in the U.S. advanced manufacturing ecosystem, drawing innovation-driven firms that demand high-integrity components. However, even with localized production advantages, the complexity of modern designs and the performance requirements of next-generation systems often exceed the capabilities of conventional CNC shops. This is where global expertise, honed through mission-critical applications, becomes indispensable.

At Wuxi Lead Precision Machinery, our engineering team brings decades of experience in delivering precision-machined components for Olympic-grade equipment and military defense systems. These applications tolerate zero margin for error. A misaligned bracket in a satellite deployment mechanism or a tolerance deviation in a tactical communication housing can lead to system failure under operational stress. Our work on Olympic projects—where milliseconds and microns determine podium finishes—has further sharpened our focus on dimensional stability, material integrity, and process repeatability.

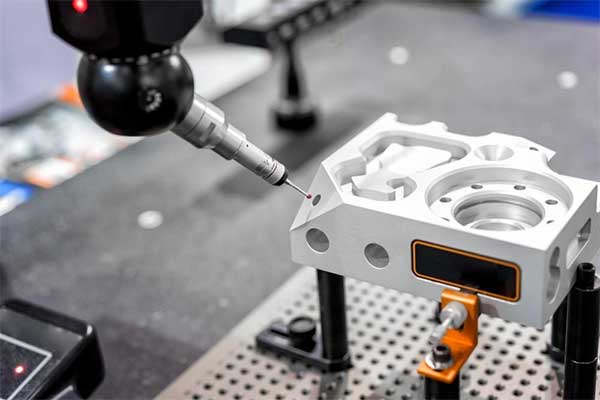

Our CNC machining capabilities are built around multi-axis milling, turning, and mill-turn technologies, supported by in-house metrology including CMM, optical comparators, and surface roughness testers. Every component undergoes rigorous first-article inspection and batch traceability protocols, ensuring compliance with AS9100, ISO 9001, and MIL-STD standards.

Below are key specifications that define our precision machining performance:

| Specification | Capability |

|---|---|

| Positional Accuracy | ±0.0025 mm (±0.0001″) |

| Surface Roughness (Ra) | As low as 0.4 μm (16 μin) |

| Maximum Work Envelope | 1200 x 800 x 600 mm (47 x 31 x 24″) |

| Tolerance Range | IT6 to IT7 (ISO 286-1) |

| Materials Processed | Aluminum 7075-T6, Titanium Grade 5, Inconel 718, Stainless Steel 316/17-4 PH, PEEK, and engineered composites |

| Quality Standards | ISO 9001:2015, AS9100D, NADCAP (pending) |

Precision is not achieved through machinery alone—it is engineered into every process, from CAM programming to final inspection. As demand grows in markets like Austin for high-performance, low-volume, and rapid-turnaround CNC work, global partners with proven experience in extreme reliability offer a strategic advantage. Wuxi Lead Precision Machinery stands ready to support U.S. innovation with precision that meets the highest global benchmarks.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Austin’s Demanding Applications

Wuxi Lead Precision Machinery delivers advanced CNC machining solutions tailored to the rigorous demands of Austin’s aerospace, medical, and semiconductor sectors. Our technical infrastructure centers on state-of-the-art 5-axis CNC technology, enabling complex geometries and single-setup machining that eliminate cumulative errors inherent in multi-operation processes. This capability is critical for Austin manufacturers requiring high-integrity components with stringent GD&T compliance. Our facility operates DMG MORI NTX 1000 and MAZAK INTEGREX i-200S 5-axis milling-turning centers, featuring sub-micron repeatability and integrated probing systems for in-process verification. These machines handle materials from titanium alloys and Inconel to medical-grade PEEK and aluminum 7075-T7351, ensuring dimensional stability even in thin-walled or high-precision assemblies common in Austin’s defense and robotics industries.

Quality control is non-negotiable. Every component undergoes comprehensive inspection via Zeiss CONTURA G2 Coordinate Measuring Machines (CMM), programmed to ISO 10360-2 standards. Our AS9100-compliant workflow includes first-article inspection reports (FAIR), real-time SPC data logging, and full 3D scan comparisons against CAD models. This eliminates guesswork for Austin clients, providing auditable traceability from raw material to finished part. We further integrate optical comparators and surface roughness testers to validate micro-finish requirements, particularly for hydraulic components and surgical instruments where surface integrity impacts performance.

Our tolerance capabilities reflect decades of refinement in high-mix, low-volume production. The table below outlines achievable specifications under controlled environmental conditions (20°C ±0.5°C):

| Feature | Standard Capability | Tight Capability | Typical Application Example |

|---|---|---|---|

| Linear Dimension | ±0.005 mm (±0.0002″) | ±0.002 mm (±0.00008″) | Aerospace bracket interfaces |

| Angular Tolerance | ±0.005° | ±0.001° | Turbine blade root forms |

| Positional (GD&T) | ±0.010 mm (±0.0004″) | ±0.003 mm (±0.00012″) | Medical implant mating surfaces |

| Surface Roughness (Ra) | 0.8 μm (32 μin) | 0.2 μm (8 μin) | Semiconductor chamber seals |

| Concentricity | 0.015 mm (0.0006″) | 0.005 mm (0.0002″) | Fuel system nozzles |

These specifications are validated across batch sizes from 1 to 5,000 units, with statistical process control ensuring consistency. For Austin clients, we emphasize seamless time zone coordination—providing real-time inspection data via secure portals during U.S. business hours—and dedicated engineering support for DFM optimization. Our process reduces total cost of ownership by minimizing scrap, rework, and supply chain complexity, while meeting ITAR and NADCAP requirements critical to Texas’ defense ecosystem. Partner with Wuxi Lead to transform your most challenging designs into certified, production-ready components without compromising on speed or precision.

Material & Finish Options

Material Selection in Precision CNC Machining: Aluminum, Steel, and Titanium

Selecting the appropriate material is a critical decision in precision CNC machining, directly influencing the performance, durability, and cost-efficiency of the final component. For high-performance applications in industries such as aerospace, medical, and advanced automation, three materials stand out: aluminum, steel, and titanium. Each offers distinct mechanical properties, machinability characteristics, and compatibility with finishing processes such as anodizing.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and high thermal conductivity. It is particularly suitable for components requiring lightweight construction without sacrificing structural integrity. Grade 6061-T6 is among the most commonly used aluminum alloys in CNC machining due to its balanced mechanical properties and weldability. Aluminum is also highly compatible with anodizing, a process that enhances surface hardness and corrosion resistance while allowing for color customization. Type II (sulfuric acid) and Type III (hardcoat) anodizing are frequently specified for aluminum parts in demanding environments.

Steel, particularly in alloy and stainless forms, offers superior strength, wear resistance, and thermal stability. Alloy steels like 4140 and 4340 are often selected for high-stress mechanical components, while stainless steels such as 304 and 17-4 PH provide excellent corrosion resistance and are commonly used in medical and food-grade applications. Although steel is more challenging to machine than aluminum due to higher tool wear and cutting forces, modern CNC systems with optimized toolpaths and cooling strategies ensure precision and repeatability. Steel components are typically finished through passivation, plating, or powder coating rather than anodizing, which is not applicable to ferrous materials.

Titanium, especially Grade 5 (Ti-6Al-4V), is the material of choice for extreme environments where high strength, low density, and exceptional corrosion resistance are paramount. Commonly used in aerospace and biomedical implants, titanium’s biocompatibility and fatigue resistance make it ideal for mission-critical components. However, its low thermal conductivity and high chemical reactivity require specialized tooling and slower machining parameters to prevent work hardening and tool degradation. While titanium cannot be anodized in the conventional sense, it does undergo a form of anodic oxidation for color coding and mild surface enhancement in medical and aerospace applications.

The table below summarizes key properties and machining characteristics of these materials:

| Material | Common Grades | Tensile Strength (MPa) | Density (g/cm³) | Machinability Rating | Anodizing Compatibility |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310–570 | 2.7 | Excellent | Yes (Type II & III) |

| Steel | 4140, 17-4 PH | 655–1400 | 7.8 | Moderate to Good | No |

| Titanium | Ti-6Al-4V (Grade 5) | 900–1000 | 4.4 | Fair | Limited (anodic coloring) |

Understanding the interplay between material properties, application requirements, and finishing options ensures optimal part performance and cost-effective manufacturing. At Wuxi Lead Precision Machinery, we support clients in selecting the right material and finish combination to meet exacting technical standards and production goals.

Manufacturing Process & QC

Precision Production Process: From Design to Zero-Defect Delivery for Austin TX Manufacturing

At Wuxi Lead Precision Machinery, our CNC machining process for Austin TX clients is engineered for uncompromising quality and seamless integration into demanding production environments. We understand that Austin’s aerospace, medical device, and advanced technology sectors require parts that perform flawlessly under rigorous conditions. Our methodology eliminates guesswork and defects through a rigorously controlled sequence: Design Integration, Precision Prototyping, and Zero-Defect Mass Production.

Design Integration begins with deep collaboration. We actively engage with your engineering team during the design phase, leveraging DFM (Design for Manufacturability) expertise specific to high-precision CNC machining. Our engineers analyze CAD models for optimal material utilization, toolpath efficiency, and inherent manufacturability, identifying potential stress points or tolerance challenges before metal is cut. This proactive review, conducted using the latest simulation software, prevents costly revisions later and ensures the design is fundamentally sound for precision execution, aligning perfectly with Austin’s high-specification requirements.

Precision Prototyping transforms validated designs into tangible reality. Utilizing identical materials and processes planned for full production, we manufacture functional prototypes on our high-end CNC equipment. This critical phase allows for rigorous physical validation against your specifications – dimensional accuracy, surface finish, material properties, and form/function testing. Prototypes undergo our comprehensive First Article Inspection (FAI) per AS9102 or customer-specific standards. Feedback from this stage is incorporated immediately, refining the process parameters and ensuring the production run starts with zero unresolved issues, a non-negotiable for Austin’s quality-driven industries.

Zero-Defect Mass Production is where our integrated quality management system delivers consistent excellence. Every component progresses through a defined workflow with in-process inspections at critical control points, not just final checks. Our statistical process control (SPC) monitors key dimensions in real-time, enabling immediate corrective action. Full traceability, from raw material lot to finished part, is maintained. Final inspection utilizes calibrated CMMs, optical comparators, and surface roughness testers against the original blueprint. This systematic approach, certified to ISO 9001:2015 and adhering to stringent aerospace standards, guarantees parts meet or exceed Austin TX specifications consistently, batch after batch, eliminating scrap and rework costs for our clients.

Wuxi Lead Precision Capabilities for Austin TX Projects

| Parameter | Specification | Relevance for Austin TX Clients |

|---|---|---|

| Tolerance Range | ±0.0002″ (5µm) standard | Meets critical aerospace & medical device demands |

| Materials | Aluminum, Titanium, Stainless, Inconel, Plastics | Supports diverse Austin tech & defense applications |

| Max Work Envelope | 40″ x 20″ x 20″ (1016 x 508 x 508 mm) | Handles complex structural & enclosure components |

| Key Equipment | 5-Axis DMG MORI, Makino, Okuma | Ensures complex geometry accuracy & surface finish |

| Quality Certs | ISO 9001:2015, PPAP, FAI, Full Traceability | Provides documented compliance for stringent audits |

| Lead Time | Prototype: 7-10 days; Production: Optimized | Supports agile Austin project timelines |

This disciplined transition from collaborative design through validated prototyping to statistically controlled mass production forms the bedrock of our zero-defect commitment. We deliver precision-machined components that integrate seamlessly into your Austin TX operations, reducing risk and ensuring your end products perform with absolute reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence

When your manufacturing operations demand precision, consistency, and global scalability, partnering with Wuxi Lead Precision Machinery offers a strategic advantage. As a leader in high-end CNC machining based in China, we serve forward-thinking industries worldwide—including aerospace, medical device manufacturing, automation, and advanced industrial equipment. Our clients in Austin, TX, and across North America rely on our technical expertise, advanced infrastructure, and responsive service to meet tight tolerances, complex geometries, and demanding delivery schedules.

Our CNC machining capabilities are built on a foundation of state-of-the-art technology and engineering discipline. We operate a fully integrated facility equipped with multi-axis CNC machining centers, high-speed milling systems, and precision turning equipment. Every process is supported by rigorous quality control protocols, including CMM inspection, surface roughness testing, and first-article reporting. Whether you require prototype development, low-volume custom runs, or high-volume production, our team ensures every component meets exacting specifications.

We understand the unique challenges faced by manufacturers in dynamic markets such as Austin, where innovation cycles are rapid and supply chain responsiveness is critical. By partnering with Lead Precision, you gain access to a trusted offshore manufacturing partner that operates with the standards of a domestic supplier—without the overhead. Our streamlined communication, English-speaking engineering team, and digital workflow integration make collaboration seamless, regardless of time zone or geography.

Our commitment extends beyond machining. We provide comprehensive DFM analysis, material sourcing support, and assembly integration services to optimize your product development cycle. From initial concept to final delivery, we act as an extension of your engineering team, ensuring cost-efficiency, repeatability, and compliance with ISO 9001:2015 standards.

Below are key specifications that define our CNC machining capabilities:

| Specification | Detail |

|---|---|

| Machining Processes | 3-axis, 4-axis, 5-axis milling, CNC turning, mill-turn, EDM |

| Tolerances | ±0.005 mm (±0.0002″) |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, Plastics (PEEK, Delrin, Nylon) |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Quality Standards | ISO 9001:2015, Full inspection reports, First article inspection (FAI), PPAP |

| Lead Times | Prototypes: 7–10 days; Production: 15–25 days (varies by volume) |

| Finishes | As-machined, Anodizing (Type II & III), Plating, Powder Coating, Passivation |

For engineering firms, OEMs, and contract manufacturers in Austin, TX, seeking a reliable, high-precision machining partner, Wuxi Lead Precision Machinery delivers performance you can count on. We bridge the gap between domestic design innovation and offshore manufacturing efficiency.

Contact us today at [email protected] to discuss your next project. Let Lead Precision become your trusted partner in precision manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.