Technical Contents

Engineering Guide: High Precision Cnc Mill

Engineering Insight: The Non-Negotiable Imperative of Precision in CNC Milling

True high precision CNC milling transcends basic dimensional accuracy; it is the foundational element enabling the performance, safety, and longevity of critical components across aerospace, defense, medical technology, and advanced scientific instrumentation. In these sectors, tolerances measured in microns are not merely specifications but absolute requirements. A deviation of even a few micrometers in a turbine blade airfoil, a satellite guidance component, or a surgical implant interface can trigger catastrophic system failure, compromise safety margins, or drastically reduce operational lifespan. Precision is not an optional upgrade—it is the core engineering principle dictating machine design, control systems, thermal management, and structural integrity. Without it, complex geometries, fine surface finishes, and the seamless integration of multi-axis operations become unattainable, rendering the machine unfit for mission-critical applications where failure is not an option.

Wuxi Lead Precision Machinery has engineered its high precision CNC milling platforms specifically to meet and exceed these extreme demands. Our expertise is forged in environments where absolute reliability is paramount. We have supplied and supported precision machining solutions for components integral to Olympic-level sporting equipment calibration systems, demanding sub-micron consistency for peak athlete performance. More significantly, our machines operate within stringent military and defense supply chains, machining parts where tolerances directly impact national security and operational readiness. This experience instills a rigorous, no-compromise approach to every aspect of machine construction—from the selection of vibration-dampening mineral cast bases and ultra-stable linear guideways to the implementation of real-time thermal compensation algorithms and nanometer-resolution feedback systems. We understand that precision is a holistic achievement, requiring synergy between mechanical design, control electronics, environmental stability, and meticulous calibration protocols.

The table below outlines key specifications defining our high precision CNC milling capability, reflecting the engineering rigor applied to meet the most challenging requirements:

| Specification Category | Performance Metric | Engineering Significance |

|---|---|---|

| Positioning Accuracy (X/Y/Z) | ≤ ±1.5 μm (ISO 230-2) | Ensures dimensional fidelity critical for complex assemblies and tight-fit interfaces. |

| Repeatability (X/Y/Z) | ≤ ±0.8 μm (ISO 230-2) | Guarantees consistent part quality batch after batch, essential for high-volume critical components. |

| Volumetric Accuracy | ≤ ±2.5 μm (over 300mm cube) | Maintains precision across the entire working envelope, vital for large, complex parts. |

| Spindle Runout (TIR) | ≤ 0.5 μm (at tool nose) | Directly impacts surface finish quality and tool life, especially for micro-machining. |

| Thermal Compensation System | Active, Multi-Sensor | Counters thermal growth in real-time, maintaining accuracy during extended production runs. |

| Machine Base Material | Polymer Concrete Mineral Cast | Provides superior damping ratio (10x cast iron), minimizing vibration for fine finishes. |

Achieving this level of performance requires moving beyond standard machine tool practices. It demands an obsessive focus on thermal stability, structural rigidity, and dynamic motion control. At Wuxi Lead Precision Machinery, our decades of experience in the most demanding sectors translate directly into machines engineered for uncompromising precision. We deliver not just equipment, but the proven capability to manufacture components where every micron matters, ensuring your most critical projects meet the highest standards of performance and reliability. Your component’s success begins with the foundational precision of the machine tool.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in high precision CNC milling, engineered to meet the stringent demands of aerospace, medical, automotive, and industrial equipment sectors. At the core of our manufacturing excellence is a fully integrated 5-axis CNC machining platform, enabling the production of complex geometries with superior surface finishes and dimensional accuracy. Our multi-axis systems allow simultaneous movement across all five axes, minimizing setup次数 and ensuring tight tolerance consistency across intricate components.

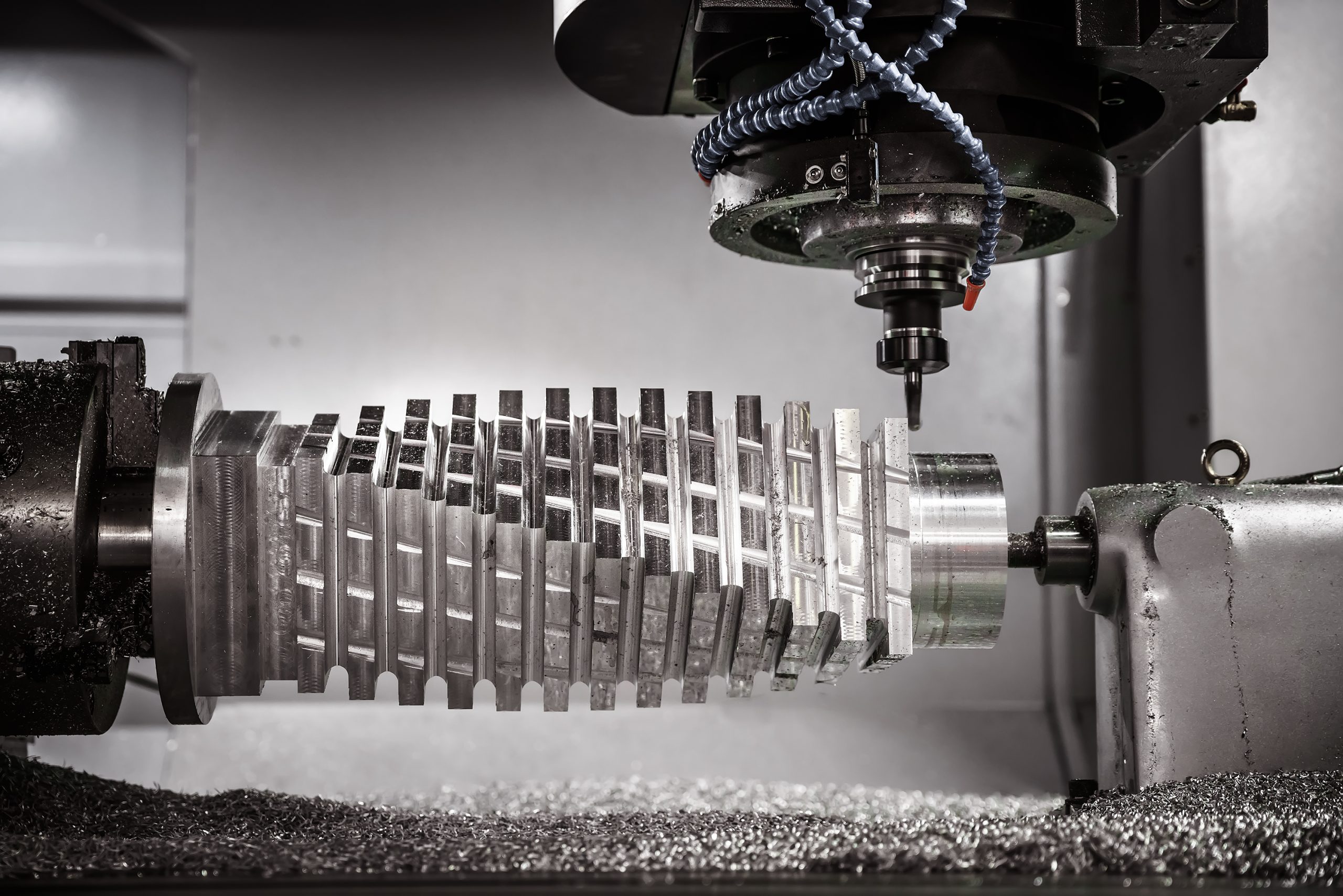

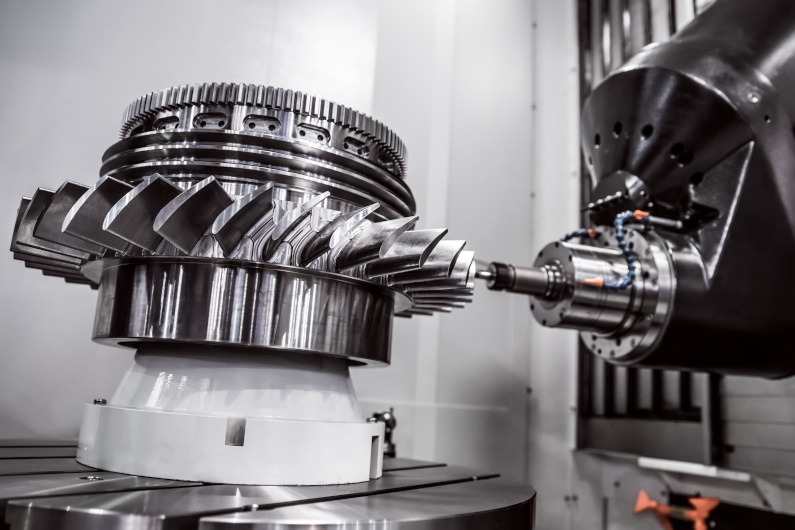

Our 5-axis machining centers are equipped with high-speed spindles, thermal compensation systems, and rigid construction to maintain precision under continuous production loads. This advanced motion control allows us to machine parts from virtually any angle in a single setup, reducing human error and improving part repeatability. Components such as turbine blades, impellers, orthopedic implants, and hydraulic manifolds are routinely manufactured with exceptional detail and efficiency.

To ensure every component meets exacting standards, we implement a comprehensive quality control protocol centered on Coordinate Measuring Machine (CMM) inspection. Our Zeiss and Hexagon CMM systems provide micron-level verification of critical dimensions, geometric tolerances, and surface profiles. Each production run includes first-article inspection, in-process checks, and final batch validation. Data from CMM reports are archived for full traceability, supporting compliance with ISO 9001:2015 and industry-specific regulatory requirements.

Material versatility is another hallmark of our technical capability. We process a wide range of engineering-grade materials, including aerospace aluminum alloys (7075, 6061), titanium (Grade 5, CP2), stainless steels (316L, 17-4 PH), Inconel (625, 718), and high-performance polymers (PEEK, PTFE). Our tooling strategies and cutting parameters are optimized for each material group, ensuring minimal tool wear and maximum part integrity.

All programming is performed using Siemens NX and Mastercam, with simulation-driven verification to eliminate collisions and optimize toolpaths. Our engineering team collaborates closely with clients during the Design for Manufacturability (DFM) phase, offering feedback on feature feasibility, tolerance allocation, and cost-saving design adjustments.

The following table outlines the key technical specifications and achievable tolerances across our precision CNC milling operations:

| Parameter | Specification |

|---|---|

| Machine Type | 5-Axis Simultaneous CNC Machining Centers |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Linear Tolerance (per ISO 2768) | ±0.025 mm (m) to ±0.1 mm (v) depending on size |

| Geometric Tolerance (GD&T) | ±0.01 mm (position, flatness, runout) |

| Surface Roughness (Ra) | As low as 0.4 μm (polished finishes available) |

| Max Work Envelope | 1,200 x 800 x 600 mm |

| Materials | Metals, Alloys, Engineering Plastics |

With a foundation built on precision engineering, advanced equipment, and rigorous quality assurance, Wuxi Lead Precision Machinery ensures every component exceeds expectations in performance and reliability.

Material & Finish Options

Material Selection for High-Precision CNC Milling Applications

Selecting the optimal material is foundational to achieving dimensional accuracy, surface integrity, and functional performance in precision CNC milling. At Wuxi Lead Precision Machinery, our engineers prioritize material properties that align with your part’s operational demands, environmental exposure, and production efficiency. Aluminum, steel, and titanium dominate aerospace, medical, and defense sectors due to their distinct advantages—and challenges—in high-tolerance machining.

Aluminum alloys, particularly 6061 and 7075, offer exceptional machinability, thermal conductivity, and strength-to-weight ratios. 6061 provides weldability and corrosion resistance for structural components, while 7075 delivers superior hardness for high-stress applications like aerospace fittings. Both require sharp tooling and controlled feeds to prevent built-up edge and maintain tight tolerances below ±0.0005 inches. Steel variants such as 4140 and 303 stainless balance strength and corrosion resistance. 4140 excels in high-wear environments but demands rigid setups to counter work hardening. 303 stainless, though easier to machine, sacrifices some corrosion resistance for improved chip breaking—critical for complex geometries. Titanium Grade 5 (Ti-6Al-4V) presents the ultimate challenge: extreme strength, biocompatibility, and heat resistance come with low thermal conductivity and high chemical reactivity. Successful milling requires low cutting speeds, high-pressure coolant, and specialized tool coatings to avoid galling and thermal distortion.

Surface finishes further define part longevity and performance. Anodizing is the industry standard for aluminum, enhancing corrosion and wear resistance. Type II (sulfuric acid) anodizing provides moderate protection for general use, while Type III (hardcoat) yields thicker, harder layers for abrasive environments. Crucially, anodizing adds dimensional tolerance considerations—typically 0.001–0.002 inches per surface—requiring pre-finishing allowances. Note that anodizing applies solely to aluminum; steel typically uses passivation or plating, and titanium benefits from micro-arc oxidation.

Material properties directly impact machining strategy and cycle time. The table below summarizes critical specs for common alloys:

| Material | Yield Strength (MPa) | Hardness (HB) | Thermal Conductivity (W/m·K) | Machinability Rating | Key CNC Challenges |

|---|---|---|---|---|---|

| Aluminum 6061 | 276 | 95 | 167 | 95% | Built-up edge, chatter |

| Steel 4140 | 655 | 200 | 42 | 66% | Work hardening, tool wear |

| Ti-6Al-4V | 880 | 360 | 7 | 30% | Heat retention, galling |

Material choice must reconcile performance requirements with manufacturability. At Wuxi Lead, we collaborate early in your design phase to optimize material selection, machining parameters, and finishing processes—ensuring your precision components meet exacting standards without costly rework. Consult our engineering team to navigate trade-offs between material cost, tool life, and final part functionality. Precision begins with the right foundation.

Manufacturing Process & QC

From Concept to Consistency: The High-Precision CNC Mill Production Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we engineer excellence through a rigorously controlled production workflow designed for zero defects in high precision CNC milling. Our process integrates advanced design validation, iterative prototyping, and scalable mass production—all anchored in metrology-grade accuracy and process discipline.

The journey begins with design analysis and optimization. Our engineering team collaborates closely with clients to evaluate CAD models for manufacturability, material suitability, and geometric complexity. Using advanced simulation software, we perform thermal, stress, and toolpath analysis to anticipate potential deviations before any material is cut. This preemptive approach ensures that design intent aligns with production capability, minimizing downstream risks.

Next comes precision prototyping. A functional prototype is produced on our high-accuracy CNC milling platforms, which feature sub-micron positioning repeatability and real-time tool monitoring. Each prototype undergoes full dimensional inspection using coordinate measuring machines (CMM) and 3D laser scanning to validate conformity to GD&T specifications. Any discrepancies trigger immediate design or process refinement. This iterative loop continues until the prototype meets or exceeds all performance and tolerance requirements—typically within ±0.002 mm.

Upon client approval, we transition to zero-defect mass production. Our manufacturing cells operate under strict ISO 9001 and IATF 16949 quality standards, with every stage monitored through Statistical Process Control (SPC). Automated tool wear compensation, in-process probing, and 100% critical dimension inspection ensure consistency across production runs. Each component is traceable via a digital twin system that logs machine parameters, tool life, and inspection data for full auditability.

Our equipment fleet is calibrated monthly and equipped with environmental compensation systems to counteract thermal drift—a critical factor in maintaining micron-level accuracy. Operator training, preventive maintenance schedules, and real-time quality dashboards further reinforce our zero-defect philosophy.

The result is a seamless transition from design to high-volume output, where precision is not achieved by chance, but by design.

High-Precision CNC Milling Specifications

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±0.001 mm |

| Repeatability | ±0.0005 mm |

| Spindle Speed Range | 10,000 – 42,000 rpm |

| Tool Changer Capacity | Up to 30 tools (ATC) |

| Maximum Work Envelope | 500 × 400 × 300 mm |

| Surface Finish Capability | Ra ≤ 0.4 µm |

| Control System | Siemens 840D / Fanuc 31i-B5 |

| In-Process Measurement | On-machine probing with Renishaw MP700 |

| Material Compatibility | Aluminum, Titanium, Inconel, Steel, PEEK |

This end-to-end process ensures that every component produced meets the uncompromising standards expected in aerospace, medical, and semiconductor applications. At Wuxi Lead Precision Machinery, precision is not just a specification—it’s our promise.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised CNC Milling Excellence

In high-stakes industries where micron-level precision defines success, your choice of manufacturing partner directly impacts product integrity, regulatory compliance, and time-to-market. Wuxi Lead Precision Machinery transcends conventional supplier relationships by embedding ourselves within your engineering workflow. We deliver not just CNC milling services, but a strategic extension of your R&D and production capabilities, engineered to eliminate the cost of failure in aerospace, medical device, and semiconductor applications.

Our ISO 9001 and IATF 16949 certified facility in Wuxi operates 42 state-of-the-art 5-axis CNC milling centers, each maintained to sub-micron calibration standards through daily laser interferometer verification. Unlike volume-focused workshops, we prioritize dimensional stability and surface integrity for complex geometries—achieving ±2µm positional accuracy even in hardened alloys and exotic composites. This precision is sustained through proprietary thermal compensation algorithms and in-process probing systems that dynamically adjust for material shift, ensuring first-article success rates exceed 98.7%.

The technical foundation of our partnership is transparent process control. Every project leverages our closed-loop verification protocol: CAD/CAM files undergo cross-referenced simulation against machine kinematics, followed by real-time toolpath monitoring via Renishaw probes. Critical features are validated mid-process using Zeiss CONTURA CMMs, with full SPC data accessible through your secure client portal. This eliminates end-of-run surprises and reduces total project lead time by 30% compared to industry averages.

Core Technical Capabilities

| Parameter | Specification | Industry Benchmark |

|---|---|---|

| Positioning Accuracy | ±1.5 µm (X,Y,Z) | ±5 µm |

| Repeatability | ±0.8 µm | ±2 µm |

| Spindle Range | 20–24,000 RPM (HSK-A63) | 15–18,000 RPM |

| Thermal Drift Control | <1.2 µm/°C (full work envelope) | 3–5 µm/°C |

| Surface Finish (Ra) | 0.1–0.4 µm (aluminum/titanium) | 0.8 µm |

Beyond machinery, our value lies in collaborative engineering. Our applications team—comprising 12 veteran CNC programmers with 15+ years’ sector-specific experience—conducts pre-machining feasibility reviews to optimize toolpaths for your material constraints and tolerance stack-ups. We proactively identify cost-saving opportunities through design-for-manufacturability insights, often reducing component costs by 18–22% without compromising performance.

Global OEMs partner with Lead Precision because we mitigate supply chain volatility through dedicated capacity allocation and dual-sourcing of critical subsystems. Your project receives exclusive machine time slots, with 24/7 engineering support across CET/EST time zones. All intellectual property is protected under GDPR-compliant data protocols and China’s latest commercial secrecy regulations.

When your next breakthrough demands precision beyond standard tolerances, engage a partner engineered for zero-defect execution. Contact our technical sales team to initiate a capability assessment for your most challenging components. We will provide a detailed process plan with achievable tolerances, lead time analysis, and sample cost breakdown within 72 hours.

Elevate your precision manufacturing outcomes. Reach out today: [email protected]

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.