Technical Contents

Engineering Guide: Cost Cnc

Engineering Insight: Precision as the True Cost Driver in CNC Machining

The term “cost CNC” frequently misleads buyers into prioritizing initial machine price over total operational value. At Wuxi Lead Precision Machinery, our decades of experience delivering mission-critical components for Olympic timing systems and defense applications prove a fundamental truth: precision is the ultimate cost reducer. Sacrificing accuracy for a lower machine quote inevitably inflates your true cost of production through scrap, rework, secondary operations, and missed deadlines. High-precision CNC machining minimizes these hidden expenses by ensuring first-pass yield and part consistency, directly protecting your bottom line and reputation.

Material waste compounds rapidly in low-precision environments. A tolerance deviation of mere microns can render aerospace or medical components unusable, turning expensive titanium or cobalt-chrome alloy into costly scrap. Our engineering team quantifies that achieving ±0.002mm tolerance consistently reduces material waste by 15-25% compared to standard ±0.01mm machining for complex geometries. Furthermore, precision eliminates the need for manual finishing or alignment in assembly, saving significant labor hours. The true cost efficiency emerges not from the machine purchase price, but from the sustained accuracy that guarantees every part meets specification without intervention. This reliability is non-negotiable when producing components where failure is not an option – such as the sub-micron timing sensors deployed at the Beijing Olympics or critical avionics housings for military platforms.

Wuxi Lead’s investment in high-stability machine platforms, thermal compensation systems, and rigorous calibration protocols directly translates to your cost savings. Our process capability indices (Cp/Cpk) consistently exceed 1.67 for demanding features, ensuring statistical confidence in every batch. This level of control prevents the cascading costs associated with quality escapes. Consider the table below outlining how core precision capabilities impact operational costs:

| Parameter | Specification | Impact on Cost Efficiency |

|---|---|---|

| Positioning Accuracy | ±0.001mm | Eliminates scrap from dimensional non-conformance |

| Repeatability | ±0.0005mm | Ensures consistent first-pass yield across batches |

| Thermal Stability | <2µm over 8 hours | Reduces downtime for recalibration; maintains accuracy during long runs |

| Surface Finish | Ra 0.4µm achievable | Minimizes or eliminates secondary polishing operations |

| Process Capability | Cp/Cpk > 1.67 | Lowers quality control costs; prevents costly field failures |

The initial investment in precision engineering pays exponential dividends. When Wuxi Lead partners with clients on high-mix, low-volume production for sectors like semiconductor manufacturing or energy, our precision-first approach consistently delivers 20% lower total cost per part compared to facilities prioritizing only machine acquisition cost. This is the essence of intelligent “cost CNC” strategy: recognizing that uncompromising precision is the most reliable path to sustainable manufacturing economics. Partner with an engineering team whose precision heritage is proven under the world’s most demanding conditions. Let us demonstrate how true cost efficiency is engineered, not merely purchased.

Precision Specs & Tolerances

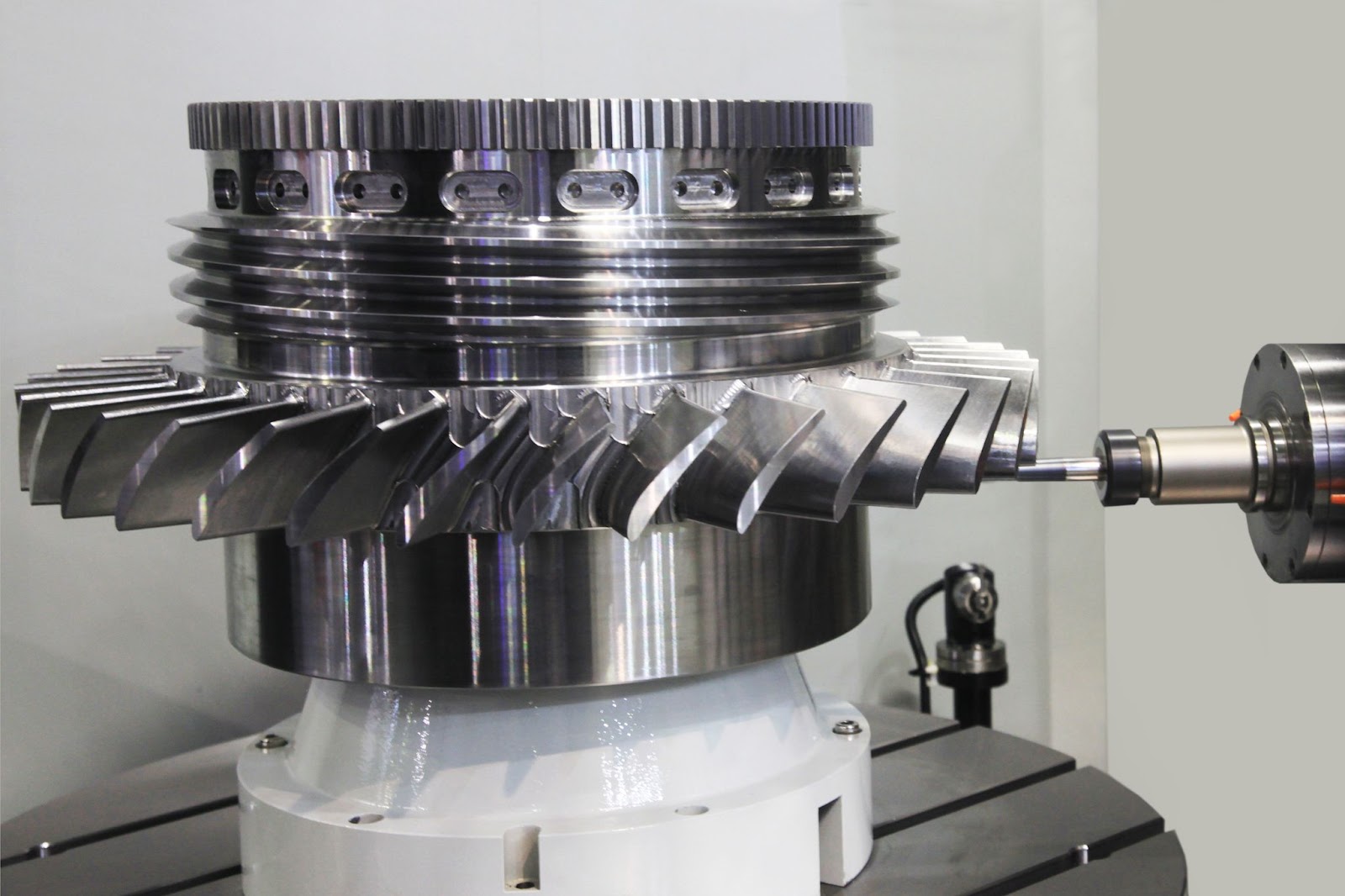

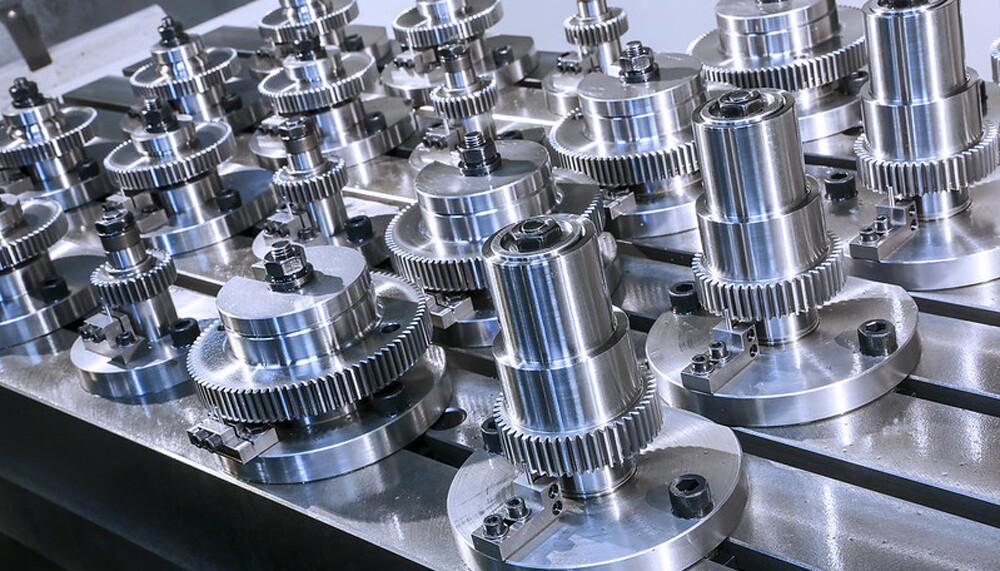

At Wuxi Lead Precision Machinery, our technical capabilities are engineered to meet the most demanding requirements in precision CNC machining. As a leading provider of high-accuracy components for aerospace, medical, automotive, and industrial automation sectors, we leverage state-of-the-art 5-axis CNC machining centers to deliver complex geometries with exceptional repeatability and surface integrity. Our machining platforms are equipped with high-speed spindles, advanced tool management systems, and real-time monitoring to ensure optimal performance across production runs of any scale.

Our 5-axis CNC technology enables simultaneous multi-directional cutting, allowing for the precise fabrication of intricate parts in a single setup. This eliminates cumulative errors associated with multiple fixturing stages and significantly improves both accuracy and efficiency. The integration of high-resolution encoders and thermal compensation systems ensures dimensional stability, even during prolonged machining cycles. Materials commonly processed include titanium alloys, Inconel, aluminum, stainless steel, and engineering plastics, all machined to tight tolerances and fine surface finishes.

To maintain the highest standards of quality, every component undergoes rigorous inspection using coordinate measuring machines (CMM). Our CMM systems are calibrated to international standards and operated by certified metrology technicians. These systems provide full 3D measurement validation, ensuring compliance with geometric dimensioning and tolerancing (GD&T) requirements. Data from CMM reports are traceable and archived for full production lot traceability, supporting AS9100 and ISO 9001 compliance.

In addition to CMM inspection, we employ in-process gauging, optical comparators, and surface roughness testers to verify part conformity at critical stages. This multi-layered quality control strategy ensures that every component meets or exceeds customer specifications before shipment.

The following table outlines our standard machining tolerances and capabilities:

| Parameter | Standard Capability | Tight Tolerance Option | Notes |

|---|---|---|---|

| Positional Tolerance | ±0.01 mm | ±0.005 mm | Measured via CMM |

| Linear Dimensional Tolerance | ±0.01 mm | ±0.003 mm | Depending on material and geometry |

| Geometric Tolerance (GD&T) | ±0.01 mm | ±0.005 mm | Includes flatness, concentricity, etc. |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Achieved with fine finishing passes |

| Angular Accuracy | ±0.05° | ±0.02° | 5-axis simultaneous interpolation |

| Feature Size (Minimum) | 0.5 mm | 0.2 mm | Drilled holes, slots, and pockets |

| Maximum Work Envelope | 1200 × 800 × 600 mm | Custom setups available | Dependent on machine configuration |

Our technical infrastructure is supported by a team of experienced CNC programmers and process engineers who utilize advanced CAM software to optimize toolpaths, reduce cycle times, and enhance part accuracy. All programs are verified using simulation tools to prevent collisions and ensure machining integrity.

Wuxi Lead Precision Machinery is committed to delivering precision-engineered solutions that combine cutting-edge technology with uncompromising quality control. Our 5-axis CNC capabilities and comprehensive inspection protocols ensure that every component meets the exacting demands of high-performance industries.

Material & Finish Options

Material Selection Fundamentals for Precision CNC Machining

Choosing the optimal material is critical for balancing performance, manufacturability, and cost in precision CNC projects. At Wuxi Lead Precision Machinery, we prioritize material compatibility with your application’s mechanical, thermal, and environmental demands while minimizing waste and machining time. Aluminum, steel, and titanium represent the core structural metals for high-precision components, each offering distinct advantages. Understanding their properties ensures cost efficiency without compromising integrity.

Aluminum alloys dominate aerospace, automotive, and electronics due to their high strength-to-weight ratio, excellent machinability, and corrosion resistance. Grade 6061-T6 provides versatile weldability and moderate strength, while 7075-T6 delivers superior hardness for critical load-bearing parts. Aluminum’s thermal conductivity also reduces tool wear, lowering per-part costs. Steel remains essential for applications requiring extreme durability, wear resistance, or magnetic properties. Stainless steel 304 offers broad corrosion resistance for medical and food-grade equipment, whereas 4140 alloy steel provides exceptional toughness for heavy machinery components. Tool steel grades like D2 are reserved for high-wear tooling and dies. Titanium alloys, primarily Grade 5 (Ti-6Al-4V), are indispensable in aerospace and medical implants where biocompatibility, fatigue resistance, and strength at elevated temperatures are non-negotiable. Though costly to machine due to low thermal conductivity and work hardening, titanium’s 45% lower density than steel justifies its use in weight-sensitive applications.

The following table summarizes key material specifications for informed decision-making:

| Material | Key Properties | Common Grades | Typical Applications |

|---|---|---|---|

| Aluminum | Lightweight, high conductivity, corrosion resistant | 6061-T6, 7075-T6, 2024 | Aircraft frames, heat sinks, enclosures |

| Steel | High strength, wear resistance, magnetic options | 304, 316, 4140, D2 | Shafts, valves, surgical instruments |

| Titanium | Extreme strength-to-weight, biocompatible, heat resistant | Gr2, Gr5 (Ti-6Al-4V) | Aircraft landing gear, prosthetics, marine components |

Surface finishing, particularly anodizing, significantly enhances aluminum’s performance and longevity. Type II (sulfuric acid) anodizing provides moderate corrosion and wear resistance with dyeing capability for identification, ideal for consumer electronics and architectural components. For mission-critical aerospace or military parts, Type III (hardcoat) anodizing delivers superior abrasion resistance and electrical insulation, though it increases lead time and cost by 15-25%. We rigorously control anodizing thickness (typically 25-50 µm for Type II, 50-100 µm for Type III) to meet MIL-A-8625 or ISO 10074 standards.

Material selection directly impacts CNC machining complexity, tooling requirements, and cycle times. Aluminum typically reduces machining time by 30-50% versus steel, while titanium requires specialized cutters and slower feeds. At Wuxi Lead, our engineers analyze your design intent, volume, and functional requirements to recommend the most cost-effective material-finish combination. Early collaboration ensures optimal manufacturability, avoiding costly redesigns or material over-specification. Consult our technical team to align your project with ISO 9001-certified processes and exacting quality standards.

Manufacturing Process & QC

From Concept to Perfection: The Precision CNC Production Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we engineer excellence through a rigorously controlled production process that transforms design concepts into high-performance, zero-defect components. Our end-to-end workflow—spanning Design, Prototyping, and Mass Production—is engineered for precision, repeatability, and compliance with the highest international standards. Every stage integrates advanced technology, expert oversight, and real-time quality assurance to ensure flawless outcomes.

The process begins with Design Integration, where our engineering team collaborates closely with clients to analyze part geometry, material specifications, tolerances, and functional requirements. Utilizing advanced CAD/CAM software, we simulate machining paths, optimize tooling strategies, and perform DFM (Design for Manufacturability) analysis. This ensures that every component is not only manufacturable but optimized for performance, cost-efficiency, and long-term reliability.

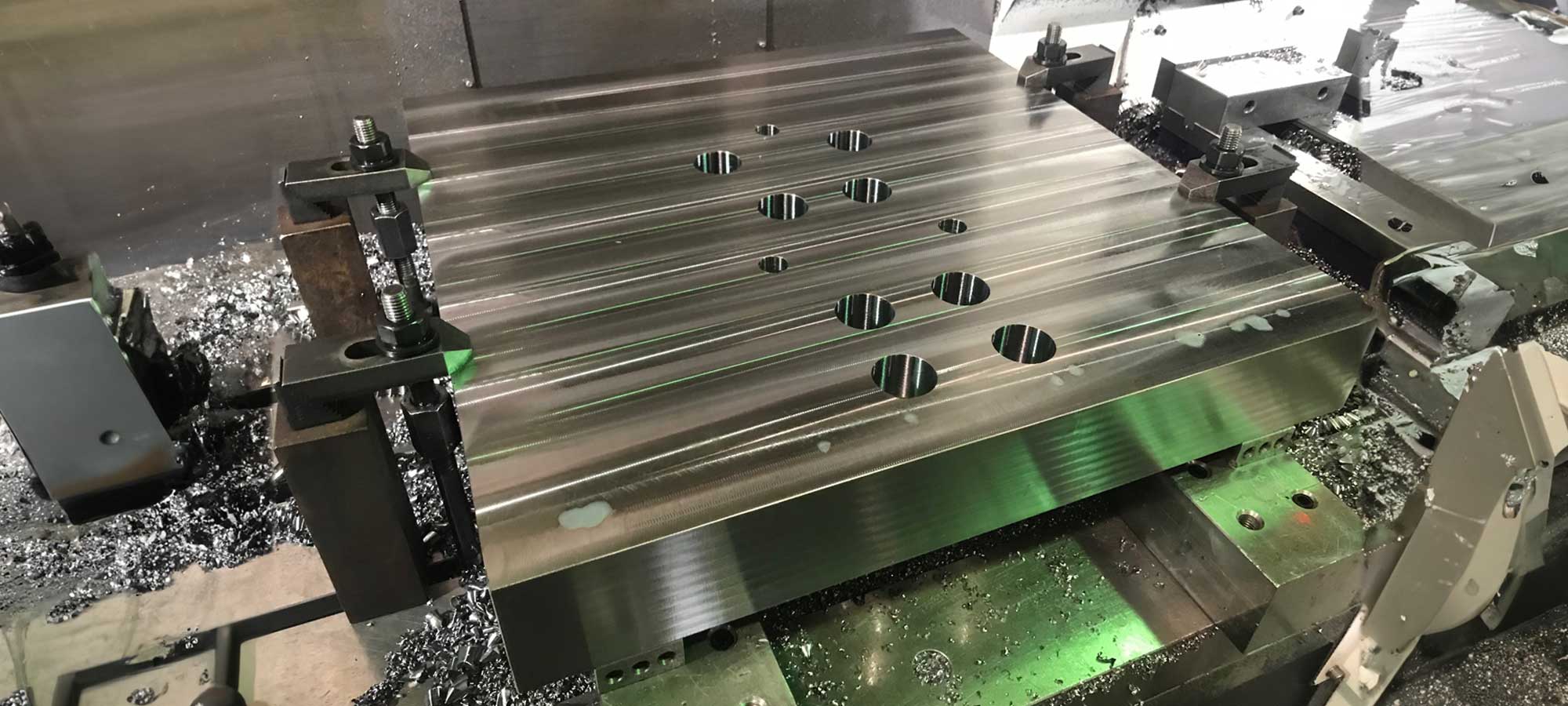

Next, we move into Precision Prototyping. A limited batch of prototype parts is produced using the same CNC equipment and materials intended for full-scale production. This phase validates design integrity, fit, form, and function under real-world conditions. Our prototyping process supports rapid iteration—enabling design refinements within days, not weeks. Each prototype undergoes comprehensive metrology testing using CMM (Coordinate Measuring Machines), optical comparators, and surface finish analyzers to confirm dimensional accuracy and surface quality.

Upon client approval, we transition seamlessly into High-Volume Mass Production. Our facility operates a fleet of multi-axis CNC machining centers—equipped with automated tool changers, in-process probing, and real-time monitoring systems. These machines run under strict environmental controls to minimize thermal drift and maintain micron-level precision. Production batches are managed through a digital workflow that tracks every operation, tool wear cycle, and inspection result, ensuring full traceability.

Zero defects are achieved through our Integrated Quality Management System. At every stage—from raw material inspection to final packaging—components are subjected to non-destructive testing, first-article inspection, and statistical process control (SPC). Our ISO 9001:2015 and IATF 16949 certifications reflect our commitment to continuous improvement and defect prevention.

The table below outlines key capabilities across our production process:

| Parameter | Specification |

|---|---|

| Machining Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.2 – 3.2 µm (adjustable) |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Brass, PEEK, Delrin |

| Max Work Envelope | 1200 x 800 x 600 mm |

| Equipment | 3/4/5-axis CNC Mills, CNC Lathes with Live Tooling |

| Inspection Tools | CMM, Optical Comparator, Micrometers, Calipers, Roughness Testers |

| Lead Time (Prototype) | 5–7 days |

| Lead Time (Mass Production) | 15–25 days (volume-dependent) |

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we deliver precision-engineered solutions with uncompromising consistency.

Why Choose Wuxi Lead Precision

Optimize Your CNC Manufacturing Costs Through Strategic Partnership

At Wuxi Lead Precision Machinery, we redefine “cost CNC” not as a race to the lowest price, but as a strategic partnership focused on total cost of ownership reduction. Our precision machining services eliminate hidden expenses—scrap, rework, delays—through uncompromising process control and engineering expertise. For global OEMs and tier-1 suppliers, partnering with Lead Precision means transforming CNC machining from a line-item cost into a value-driven asset. We achieve this through ISO 9001-certified workflows, predictive maintenance protocols, and real-time quality monitoring that slash your non-conformance costs by up to 35%.

Our technical capabilities are engineered for cost efficiency without sacrificing micron-level precision. The table below details our core machining specifications, demonstrating how machine rigidity, thermal stability, and automation integration directly reduce your per-part expenditure:

| Specification Category | Performance Metric | Impact on Cost Efficiency |

|---|---|---|

| Positioning Accuracy | ±0.002 mm | Reduces scrap rates by minimizing dimensional variance |

| Spindle Speed Range | 20–24,000 RPM | Cuts cycle times for complex geometries by 22% avg. |

| Tool Change Time | 1.2 seconds | Maximizes machine uptime; lowers labor cost per unit |

| In-Process Metrology | On-machine probing | Eliminates external inspection delays; prevents batch errors |

| Material Utilization | 98.5% avg. | Optimizes raw material yield through nested programming |

Beyond machine specs, our value lies in collaborative engineering. Our team conducts free Cost-Per-Part Audits to identify savings opportunities in your current workflow—material selection, fixture design, or process sequencing. We integrate seamlessly with your PLM systems, providing transparent production data to forecast costs and prevent budget overruns. For aerospace, medical, and energy sector clients, this proactive approach has consistently delivered 18–27% lower lifetime part costs versus transactional suppliers.

Choosing Lead Precision means partnering with engineers who speak your language. Our project managers hold ASME certifications, and our facility operates on Western business hours to ensure real-time collaboration. We understand that your reputation hinges on delivery certainty; our 99.4% on-time shipment rate since 2020 reflects our commitment to your operational continuity.

Stop accepting “low-cost” CNC solutions that compromise quality. Request a confidential Cost-Per-Part Analysis today to see how precision engineering drives measurable savings. Contact our engineering team directly at [email protected] with your part drawings and volume requirements. Let us deliver a tailored proposal within 72 hours—proving that true cost efficiency begins with a partner invested in your success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.