Technical Contents

Engineering Guide: Printing Services Jersey City

Engineering Insight: The Role of Precision in Advanced Printing Services – Jersey City and Beyond

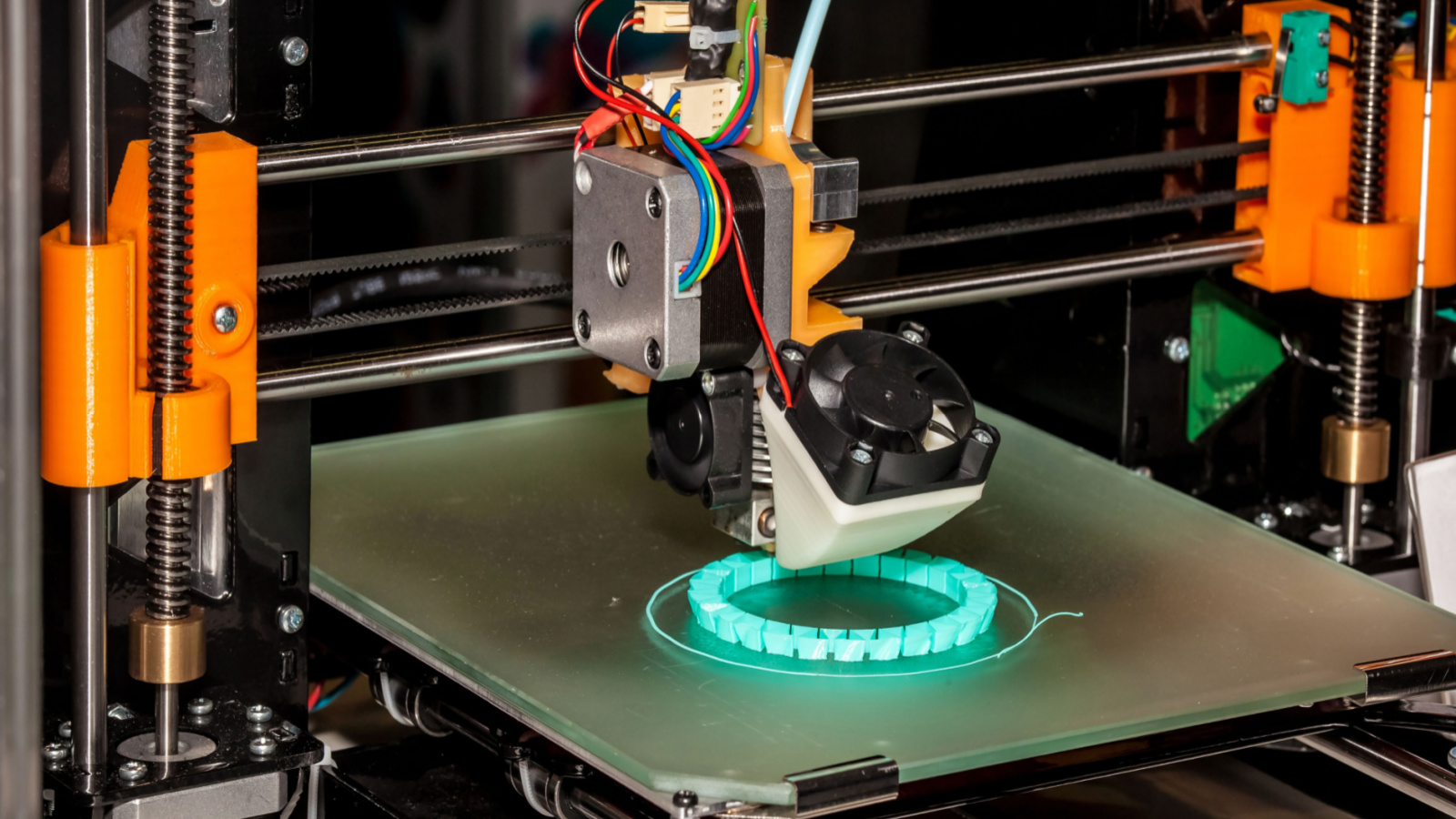

In the evolving landscape of industrial printing services in Jersey City, where demands for speed, consistency, and quality intersect, the foundation of success lies in precision engineering. While printing may traditionally be associated with graphic output or packaging, high-end manufacturing sectors—including aerospace, defense, and advanced electronics—rely on precision-based printing technologies such as screen printing for conductive inks, laser marking, and pad printing for micro-components. These applications demand micron-level accuracy, repeatable performance, and material integrity, all of which are governed by the underlying precision of the supporting mechanical systems.

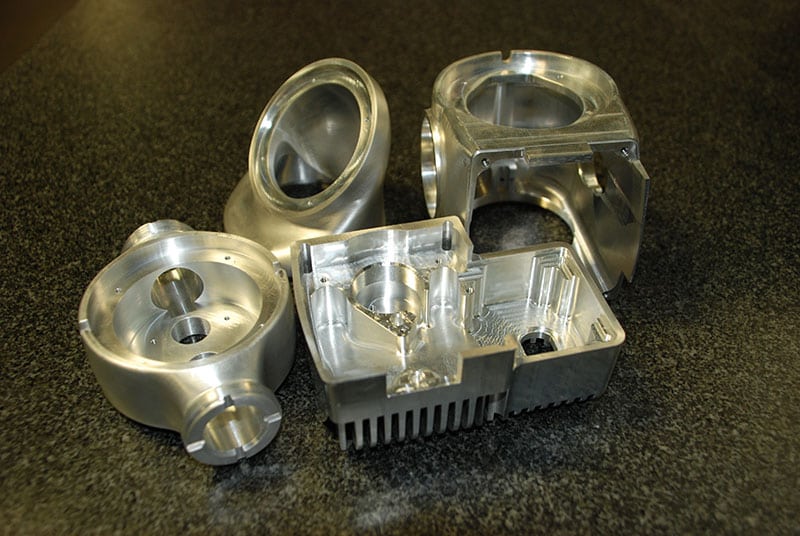

At Wuxi Lead Precision Machinery, we recognize that true precision begins long before the print head engages. It starts with the design and fabrication of the components that enable these systems to perform under rigorous industrial conditions. Our experience in custom metal manufacturing has positioned us as a trusted partner for clients requiring mission-critical parts used in advanced printing equipment. From motion stages to alignment fixtures and enclosures for high-resolution imaging systems, every component is engineered to ensure thermal stability, minimal deflection, and long-term durability.

Our track record includes supplying precision-machined components for equipment used in Olympic-grade timing systems and military communication devices—environments where failure is not an option. These projects required tolerances within ±0.005 mm, surface finishes under Ra 0.8 µm, and strict adherence to material certifications. The same engineering rigor we apply to these elite applications directly benefits the performance of industrial printing systems, where even sub-micron deviations can result in misregistration, reduced print clarity, or system downtime.

For providers of printing services in Jersey City, partnering with manufacturers who understand the mechanical demands of high-speed, high-accuracy printing is essential. As the industry shifts toward smart manufacturing and Industry 4.0 integration, the need for precision components that support real-time feedback, automated calibration, and thermal compensation becomes increasingly critical. Wuxi Lead Precision Machinery brings over 15 years of experience in CNC milling, turning, and multi-axis machining to ensure that every part meets the exacting standards required by modern printing technology.

Below are key specifications that define our precision manufacturing capabilities for components used in advanced printing systems.

| Specification | Detail |

|---|---|

| Dimensional Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.4 – 1.6 µm (adjustable) |

| Materials Processed | Aluminum 6061/7075, Stainless Steel 304/316, Brass, Copper, Titanium, Plastics (PEEK, Delrin) |

| Maximum Part Size | 800 x 500 x 400 mm |

| Machining Processes | 3-axis, 4-axis, 5-axis CNC milling, CNC turning, Wire EDM |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), CMM Reporting |

Precision is not a feature—it is a requirement. In the competitive ecosystem of industrial printing services, the reliability and accuracy of the machinery are only as strong as the components that comprise it. Wuxi Lead Precision Machinery stands ready to support innovation in Jersey City and beyond with engineering excellence rooted in real-world performance.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Printing Applications

Wuxi Lead Precision Machinery delivers mission-critical metal components engineered to sustain the rigorous operational demands of modern printing equipment. Our advanced manufacturing ecosystem integrates cutting-edge 5-axis CNC machining centers with stringent quality control protocols, ensuring every part meets the exacting tolerances required for high-speed, precision printing systems. This capability is essential for producing complex geometries found in printing press rollers, registration components, feeder mechanisms, and custom jigs where micron-level accuracy directly impacts print fidelity and machine uptime.

Our fleet of DMG MORI and MAZAK 5-axis CNC machining centers provides unparalleled flexibility for single-setup machining of intricate 3D contours, deep cavities, and undercuts. This eliminates cumulative error from multiple fixtures, critical for components like rotary printing cylinders or embossing dies requiring perfect concentricity. High-speed spindles (up to 24,000 RPM) and rigid construction enable efficient material removal in aerospace-grade aluminum, hardened tool steels, and corrosion-resistant stainless alloys—materials chosen for durability in ink-laden, high-vibration printing environments. Real-time tool monitoring and adaptive control systems maintain dimensional stability across production runs, ensuring batch consistency vital for OEM printing equipment manufacturers.

Quality assurance is non-negotiable. Every critical dimension undergoes verification via Zeiss CONTURA Coordinate Measuring Machines (CMM), operating in a climate-controlled metrology lab (20°C ±0.5°C). Our CMM inspection process validates geometric dimensioning and tolerancing (GD&T) per ASME Y14.5 standards, generating full first-article inspection (FAI) reports with traceable NIST-certified data. Surface roughness is quantified using Mitutoyo SJ-410 profilometers, guaranteeing finishes compatible with ink transfer and roller sealing requirements. All processes adhere to ISO 9001:2015 and IATF 16949 standards, with dedicated quality engineers embedded in production cells.

The following table details achievable precision for key printing industry materials:

| Material Category | Linear Tolerance (mm) | Angular Tolerance (°) | Surface Roughness (Ra μm) | Max Feature Size (mm) |

|---|---|---|---|---|

| Aluminum Alloys (7075, 6061) | ±0.005 | ±0.001 | 0.4 | 850 x 600 x 500 |

| Stainless Steel (304, 17-4PH) | ±0.008 | ±0.002 | 0.8 | 700 x 500 x 400 |

| Tool Steel (D2, H13) | ±0.005 | ±0.001 | 0.4 | 600 x 400 x 300 |

| Brass (C36000) | ±0.003 | ±0.001 | 0.2 | 500 x 350 x 250 |

This technical foundation enables Jersey City printing service providers and equipment integrators to source components that minimize registration drift, reduce substrate waste, and extend service intervals. We support accelerated prototyping through digital twin simulation and offer US-based engineering collaboration during Jersey City business hours. Partner with Wuxi Lead for components where precision isn’t optional—it’s the foundation of print quality. All deliverables include comprehensive material certifications and inspection dossiers for seamless integration into your supply chain.

Material & Finish Options

Material selection is a critical step in custom metal manufacturing, directly influencing the performance, durability, and cost-efficiency of the final component. At Wuxi Lead Precision Machinery, we specialize in precision-engineered metal parts tailored to meet the exacting demands of industries ranging from aerospace to medical devices. When selecting materials for your application, three primary metals stand out: aluminum, steel, and titanium. Each offers distinct mechanical properties, weight characteristics, and corrosion resistance, making them suitable for different operational environments.

Aluminum is widely favored for its excellent strength-to-weight ratio and natural corrosion resistance. It is particularly well-suited for applications where weight reduction is essential, such as in aerospace and automotive components. Aluminum also demonstrates high thermal and electrical conductivity, making it ideal for heat sinks and electrical enclosures. However, its lower hardness compared to steel requires careful consideration in high-wear environments.

Steel, particularly stainless and alloy variants, provides superior strength, hardness, and wear resistance. It is the preferred choice for structural components, industrial machinery, and parts exposed to high stress or elevated temperatures. Stainless steel grades such as 304 and 316 offer excellent resistance to oxidation and chemical exposure, making them suitable for use in harsh or sanitary environments. While heavier than aluminum, steel’s durability and cost-effectiveness make it a staple in industrial manufacturing.

Titanium is the premium option for high-performance applications. With an exceptional strength-to-density ratio and outstanding resistance to corrosion—even in seawater and chloride environments—it is extensively used in aerospace, marine, and medical implant industries. Though more expensive and challenging to machine, titanium’s longevity and reliability under extreme conditions justify its use in mission-critical components.

Surface finishing further enhances material performance. Anodizing, primarily applied to aluminum, is an electrochemical process that increases surface hardness and corrosion resistance while allowing for color customization. Type II (sulfuric acid) and Type III (hardcoat) anodizing provide varying levels of thickness and durability, with Type III suitable for high-wear applications. Anodized finishes are non-conductive and maintain dimensional stability, making them ideal for precision parts.

The following table summarizes key mechanical and physical properties of these materials:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Corrosion Resistance | Common Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | 276 | High | Aerospace, automotive, enclosures |

| Stainless Steel 304 | 8.0 | 505 | 215 | Very High | Food processing, chemical, medical |

| Titanium Grade 5 | 4.4 | 900 | 830 | Exceptional | Aerospace, medical implants, marine |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish based on functional requirements, environmental exposure, and lifecycle demands. Our engineering team ensures every component meets international quality standards while delivering precision and reliability.

Manufacturing Process & QC

Precision Metal Manufacturing: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our production process for custom metal components is engineered for uncompromising quality and repeatability. We integrate advanced engineering with rigorous quality control across three critical phases: Design, Prototyping, and Mass Production. This structured approach ensures every part meets exacting aerospace, medical, and industrial specifications while achieving zero-defect outcomes.

The Design phase begins with collaborative engineering analysis. Our team reviews 3D CAD models for manufacturability, optimizing geometries for CNC milling, turning, or multi-axis machining. We conduct thorough DFM (Design for Manufacturability) assessments, material compatibility studies, and GD&T validation to eliminate potential flaws before physical production. Critical parameters like stress points, thermal behavior, and surface finish requirements are simulated using industry-standard software, ensuring the design is both functional and production-ready.

Prototyping transforms validated designs into tangible first articles. Utilizing our HAAS and DMG MORI machining centers, we produce 1–5 prototype units under full production conditions. Each prototype undergoes comprehensive metrology: CMM (Coordinate Measuring Machine) inspections verify dimensional accuracy against CAD data, while surface roughness testers and material hardness checks confirm compliance. Clients receive a detailed First Article Inspection Report (FAIR) with all critical dimensions certified. This phase identifies micro-adjustments needed for mass production, reducing downstream risks.

Mass Production leverages our zero-defect philosophy through embedded quality gates. Every batch runs on dedicated CNC cells with real-time SPC (Statistical Process Control) monitoring. In-process checks occur at 5% intervals using calibrated micrometers, optical comparators, and vision systems. Final inspection includes 100% critical dimension verification and batch-level material traceability. Non-conforming parts trigger immediate root-cause analysis via our 8D corrective action protocol, ensuring defects never progress to shipment. Our closed-loop system guarantees consistent output meeting the strictest industry tolerances.

Critical Production Specifications

| Parameter | Capability | Measurement Standard |

|——————–|——————————–|———————-|

| Dimensional Tolerance | ±0.005 mm | ISO 2768-mK |

| Surface Finish | Ra 0.4 μm (mirror polish) | ISO 1302 |

| Materials | Titanium, Inconel, Aluminum 7075, Stainless Steel 316L | ASTM/AMS Certified |

| Max Part Size | Ø600 mm x 1,200 mm | Custom fixturing |

| Quality Certifications | ISO 9001:2015, AS9100D, NADCAP | Full traceability |

This end-to-end process—grounded in predictive engineering, empirical validation, and relentless quality enforcement—delivers components where failure is not an option. Wuxi Lead’s commitment to zero defects starts at the drawing board and concludes only when your specifications are exceeded, batch after batch. Partner with us for mission-critical metal manufacturing executed with uncompromised precision.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

When your operations demand precision-engineered metal components, partnering with Wuxi Lead Precision Machinery ensures access to world-class manufacturing capabilities rooted in advanced technology and decades of industrial experience. As a leading provider of custom metal solutions based in China, we specialize in delivering high-integrity parts tailored to the exacting standards of global industries including aerospace, automotive, energy, and advanced electronics. Our strategic location enables seamless integration into international supply chains, offering competitive lead times and cost efficiency without compromising quality.

At Wuxi Lead Precision Machinery, we understand that reliability, consistency, and technical precision are non-negotiable in high-performance applications. Our facility is equipped with state-of-the-art CNC machining centers, multi-axis lathes, and automated inspection systems, all operated by a team of certified engineers and skilled technicians. From prototype development to full-scale production runs, we maintain strict adherence to ISO 9001 standards and implement rigorous quality control protocols at every stage of the manufacturing process.

Our clients benefit from a comprehensive service offering that includes precision milling, turning, grinding, and surface treatment processes such as anodizing, plating, and passivation. Whether you require small-batch, high-mix production or large-volume output with tight tolerances, our flexible manufacturing systems are designed to scale with your needs. We work with a broad range of materials, including aluminum alloys, stainless steel, titanium, brass, and specialty alloys, ensuring optimal performance under demanding operational conditions.

What sets us apart is our commitment to engineering collaboration. We don’t just manufacture parts—we partner with your team to optimize designs for manufacturability, reduce material waste, and improve component longevity. This consultative approach results in faster time-to-market, lower total cost of ownership, and superior product performance.

Below are key specifications that define our manufacturing capabilities:

| Capability | Specification |

|---|---|

| Maximum Machining Size | 2000 mm × 1200 mm × 800 mm |

| Tolerance Control | ±0.005 mm |

| Surface Finish | Ra 0.2 to Ra 3.2 µm (custom finishes available) |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Brass, Copper, Inconel, Tool Steels |

| Production Capacity | Up to 50,000 units/month |

| Quality Standards | ISO 9001:2015 certified, Full CMM inspection, First Article Inspection (FAI) |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

If you are seeking a trusted partner for precision metal components that meet the highest standards of performance and reliability, we invite you to contact us today. Our engineering and sales team is ready to support your next project with technical expertise and responsive service.

For inquiries, project specifications, or quotations, email us at [email protected]. Let Wuxi Lead Precision Machinery be your strategic manufacturing partner in delivering excellence—on time, every time.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.