Technical Contents

Engineering Guide: 3D Printed Parts Online

Engineering Insight Precision in Online 3D Printed Metal Parts

The convenience of ordering 3D printed metal parts online often masks a critical industrial reality: dimensional accuracy and material integrity are non-negotiable for mission-critical applications. While many providers emphasize speed and accessibility, true precision engineering demands rigorous process control far beyond standard additive manufacturing tolerances. At Wuxi Lead Precision Machinery, we define precision not by theoretical machine capabilities alone, but by consistent, verifiable outcomes across full production runs. This requires deep integration of material science, thermal management, and post-processing expertise—elements frequently overlooked in purely transactional online platforms. For aerospace actuators or medical implant interfaces, a variance of ±0.05mm can trigger catastrophic system failure. Online ordering must therefore be anchored to engineering oversight, not merely automated quoting.

Our approach begins with material certification traceability and proprietary parameter optimization for each alloy. We implement in-situ monitoring during printing to detect microstructural anomalies, followed by mandatory stress-relief cycles and precision CNC machining of critical interfaces. This hybrid methodology ensures geometric fidelity and mechanical properties meet stringent industry standards. Unlike vendors relying solely on as-printed surfaces, we treat additive manufacturing as the first step in a tightly controlled finishing sequence. Surface roughness, internal porosity, and residual stress must be actively managed—not accepted as inherent limitations.

The following specifications reflect our certified production capabilities for online-ordered metal components, validated through third-party testing:

| Parameter | Capability | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.025mm after finishing | CMM with ISO 10360-2 calibration |

| Surface Roughness (Ra) | 0.8µm (as-machined) | Profilometer per ISO 4287 |

| Material Density | >99.95% (Ti6Al4V, Inconel 718) | Archimedes’ principle testing |

| Build Volume | Ø350mm x 500mm | Laser-tracked build chamber |

| Post-Processing Lead Time | +3-5 days (vs. base print) | Integrated CNC workflow |

This level of control is why Lead Precision was selected to manufacture components for Olympic Games timing systems and military-grade drone subsystems. In these applications, zero-defect performance is mandatory—online convenience cannot compromise engineering integrity. Our Olympic project required sub-0.01mm repeatability across 200+ titanium housings operating under extreme vibration; military contracts demanded certified fatigue resistance in printed aluminum structures subjected to supersonic stress cycles. These projects proved that online ordering must be backed by offline expertise: metallurgists reviewing every build file, CNC engineers programming final features, and QA teams validating every lot against MIL-STD-883.

When sourcing 3D printed metal parts online, prioritize partners who treat precision as a system—not a specification sheet. At Lead Precision, we deliver the reliability of traditional precision manufacturing fused with additive flexibility. Your application’s success depends on it.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions for global industries requiring high-precision 3D printed metal parts produced through hybrid manufacturing workflows. Our technical capabilities integrate additive manufacturing with precision CNC machining, enabling the production of complex, mission-critical components that meet stringent performance and quality standards. At the core of our machining operations is a fleet of 5-axis CNC machining centers, which provide exceptional flexibility and accuracy for post-processing 3D printed metal components. These machines allow for simultaneous multi-axis movement, enabling intricate geometries, tight tolerances, and superior surface finishes that are unattainable with conventional 3- or 4-axis systems.

Our 5-axis CNC systems are optimized for a wide range of aerospace, medical, automotive, and industrial applications where precision, repeatability, and material integrity are paramount. By combining additive techniques with subtractive finishing, we eliminate dimensional inaccuracies introduced during the printing process and achieve final part specifications with micron-level consistency. This hybrid approach ensures that components meet functional requirements while reducing material waste and lead times compared to fully subtractive methods.

Quality is embedded into every phase of production at Wuxi Lead. All machined and 3D printed components undergo rigorous inspection using state-of-the-art Coordinate Measuring Machine (CMM) technology. Our CMM systems provide full 3D metrology validation, ensuring geometric accuracy, dimensional compliance, and traceability. Each inspection report is documented and archived, providing full quality traceability for every production batch. This level of scrutiny is essential for clients in regulated industries where certification and compliance are mandatory.

We maintain strict environmental and operational controls within our facility to ensure consistent machining performance, including temperature-stabilized environments and calibrated tooling systems. Our engineering team collaborates closely with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, material selection, and process sequencing—maximizing performance while minimizing cost and cycle time.

The following table outlines the standard technical specifications and achievable tolerances for our 5-axis CNC machining services when applied to 3D printed metal components:

| Specification | Standard Capability | High-Precision Capability |

|---|---|---|

| Positional Tolerance | ±0.025 mm | ±0.010 mm |

| Dimensional Tolerance | ±0.05 mm | ±0.012 mm |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm |

| Geometric Tolerance (GD&T) | ±0.02 mm | ±0.005 mm |

| Feature Size (Minimum) | 0.5 mm | 0.3 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm | 1200 x 800 x 600 mm |

These capabilities are supported by advanced CAD/CAM software and real-time process monitoring, ensuring that every component meets or exceeds client expectations. Wuxi Lead Precision Machinery is committed to delivering precision, reliability, and technical excellence in every custom metal part produced through our integrated 3D printing and CNC manufacturing platform.

Material & Finish Options

Material Selection for High-Performance Metal 3D Printed Parts

Selecting the optimal material for metal additive manufacturing is critical to achieving component performance, durability, and cost efficiency. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your application’s mechanical, thermal, and environmental demands. Aluminum alloys excel in weight-sensitive applications like aerospace and automotive components due to their high strength-to-weight ratio and thermal conductivity. Steel variants, including stainless and tool steels, deliver exceptional strength, wear resistance, and corrosion tolerance for industrial tooling, medical devices, and high-stress machinery parts. Titanium, particularly Grade 5 (Ti-6Al-4V), offers unparalleled strength, biocompatibility, and resistance to extreme temperatures and corrosive environments, making it ideal for aerospace, medical implants, and marine engineering.

Material choice directly impacts printability, post-processing requirements, and final part integrity. Aluminum’s lower density reduces build time and material costs but may require thermal management during printing to prevent warping. Steel provides excellent dimensional stability and supports complex geometries but often necessitates stress-relief annealing. Titanium’s biocompatibility and fatigue resistance come with higher raw material costs and stringent inert atmosphere printing requirements to avoid oxidation. Understanding these trade-offs ensures your design leverages additive manufacturing’s full potential without compromising functionality.

Surface finish selection further enhances performance and longevity. Anodizing is a critical post-processing step for aluminum parts, creating a durable, corrosion-resistant oxide layer that also accepts dyes for identification. Type II (sulfuric acid) anodizing offers standard protection for general industrial use, while Type III (hardcoat) anodizing delivers superior abrasion resistance for high-wear applications like hydraulic components or aerospace brackets. Anodizing thickness must align with functional requirements—excessive thickness can induce microcracking, while insufficient coating compromises longevity.

Below is a comparative overview of key material properties for common metal 3D printing alloys:

| Material | Key Alloys | Tensile Strength (MPa) | Density (g/cm³) | Primary Applications |

|---|---|---|---|---|

| Aluminum | AlSi10Mg, AlSi7Mg | 280–350 | 2.67 | Lightweight brackets, heat sinks |

| Stainless Steel | 316L, 17-4PH | 550–1300 | 7.9–8.0 | Medical instruments, fluid systems |

| Titanium | Ti-6Al-4V (Gr5) | 900–1100 | 4.43 | Aircraft fittings, surgical implants |

Wuxi Lead Precision Machinery combines deep material science expertise with advanced metal 3D printing capabilities to guide your selection process. We analyze operational stresses, environmental exposure, and lifecycle costs to recommend the precise alloy and finish—ensuring your parts meet or exceed performance benchmarks. Consult our engineering team early in the design phase to optimize material choice, minimize post-processing, and accelerate time-to-market for your mission-critical components. Partner with us to transform material potential into manufacturing excellence.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

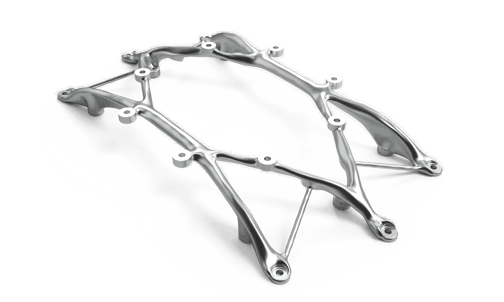

At Wuxi Lead Precision Machinery, the production process for custom 3D printed metal parts begins with meticulous design engineering. Every component is developed using advanced CAD software, ensuring dimensional accuracy, structural integrity, and manufacturability. Our engineering team collaborates directly with clients to analyze functional requirements, load conditions, and environmental factors. Finite element analysis (FEA) and computational fluid dynamics (CFD) simulations are applied to optimize part performance and reduce material waste. Design for Additive Manufacturing (DfAM) principles guide geometry refinement, enabling complex internal channels, lattice structures, and topology-optimized forms unachievable through traditional methods. This phase culminates in a validated digital model ready for prototyping, ensuring alignment with both performance goals and production feasibility.

Prototyping: Validating Performance Before Scale

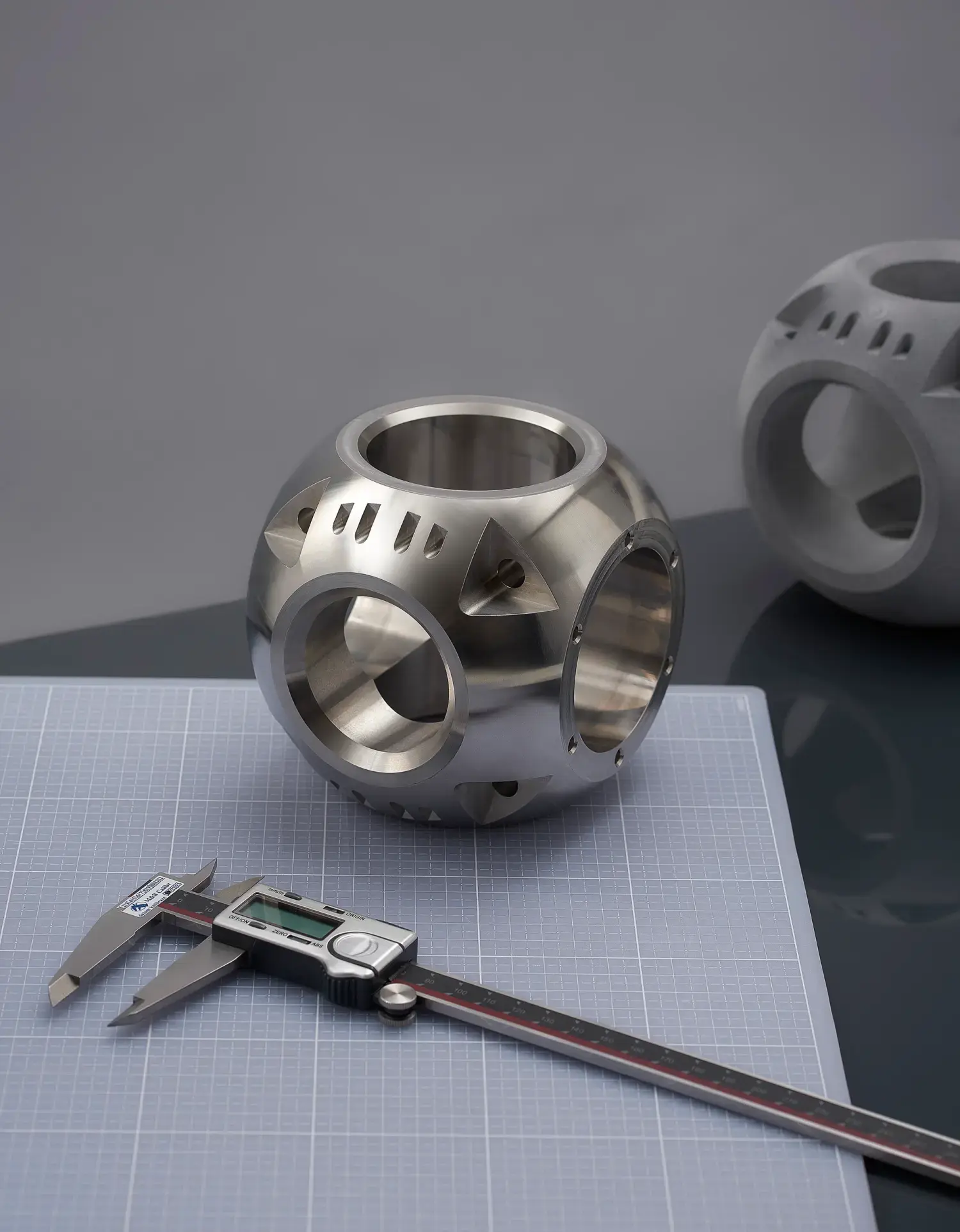

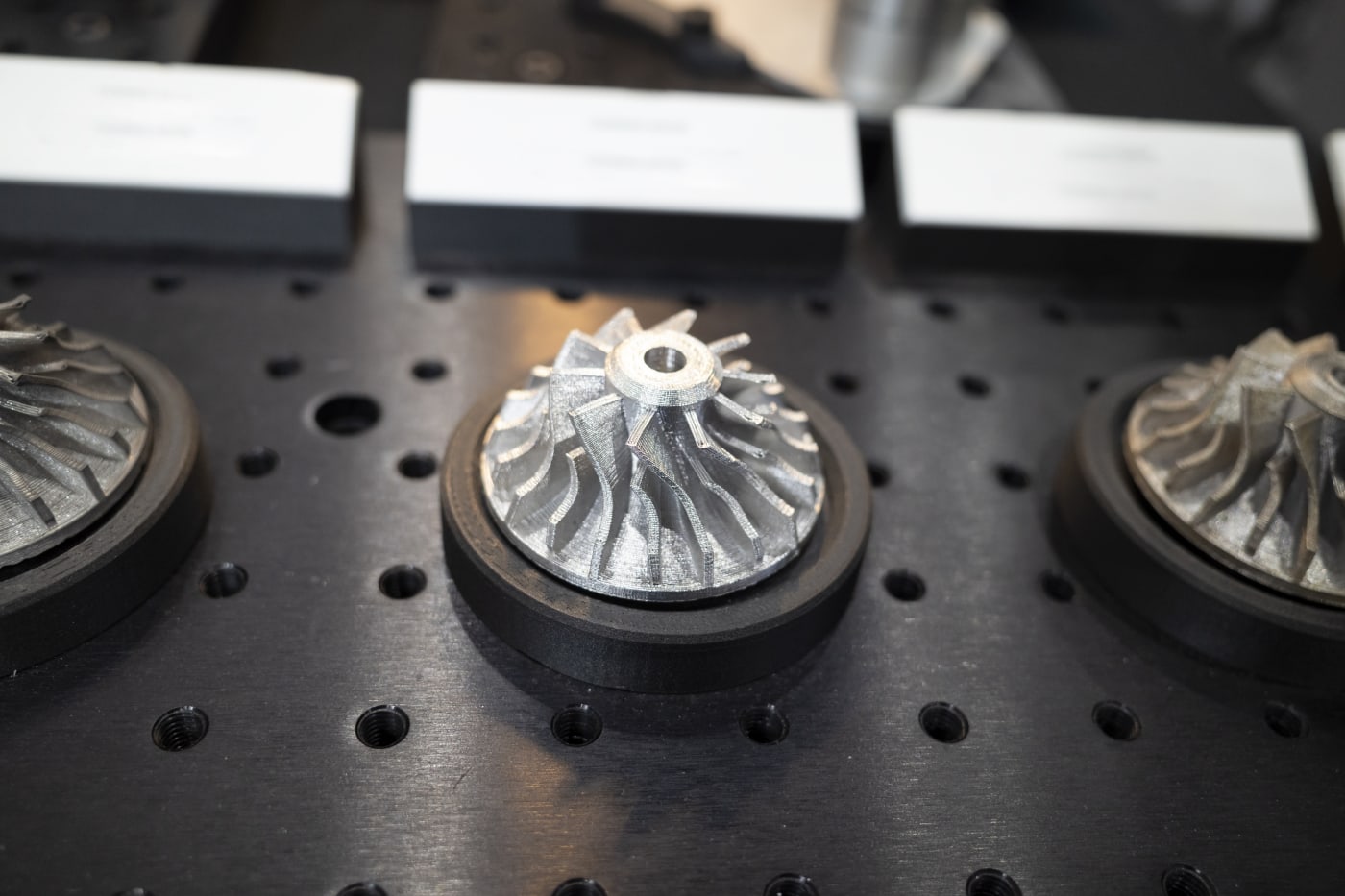

Prototyping serves as a critical validation step in our zero-defect philosophy. Using selective laser melting (SLM) or electron beam melting (EBM) technologies, we produce functional prototypes from high-grade metal alloys such as Inconel 718, Ti-6Al-4V, stainless steel 316L, and AlSi10Mg. These prototypes undergo rigorous mechanical testing, dimensional inspection via coordinate measuring machines (CMM), and non-destructive testing (NDT) including X-ray and ultrasonic analysis. Surface finish, porosity levels, and microstructure are evaluated to confirm material consistency. Any deviations trigger immediate design or parameter adjustments. This iterative process ensures that only fully qualified designs advance to mass production, minimizing risk and accelerating time-to-market.

Mass Production: Consistency Through Controlled Processes

Once prototype approval is secured, we transition to high-precision mass production. Our automated SLM production cells operate under tightly controlled environments with real-time monitoring of laser power, scan speed, layer thickness, and inert gas composition. Each build is tracked through a digital twin system, enabling full traceability of process parameters and material batches. Post-processing—including stress relief, hot isostatic pressing (HIP), precision CNC machining, and surface treatments such as shot peening or electropolishing—is performed in-house to maintain quality control. Every finished component undergoes final inspection against AS9100 and ISO 13485 standards, with certification documentation provided upon request.

Material and Process Specifications

| Parameter | Specification |

|---|---|

| Layer Thickness | 20–60 µm |

| Build Envelope | Up to 500 x 500 x 400 mm |

| Positional Accuracy | ±0.05 mm |

| Surface Roughness (as-built) | Ra 8–15 µm |

| Post-Processing Options | CNC Machining, HIP, Heat Treatment, Polishing, Passivation |

| Supported Materials | Ti-6Al-4V, Inconel 718, 316L Stainless Steel, AlSi10Mg, Maraging Steel, CoCr |

| Quality Standards | ISO 9001, AS9100, ISO 13485, NDT (RT, UT), CMM, Material Certification |

Through integrated design validation, prototyping rigor, and controlled mass production, Wuxi Lead ensures every 3D printed metal part meets the highest standards of reliability and performance—delivering zero-defect outcomes for aerospace, medical, and high-end industrial applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Metal Components

When your application demands uncompromising precision, structural integrity, and repeatability beyond the limitations of additive manufacturing, Wuxi Lead Precision Machinery delivers engineered metal solutions that perform. While 3D printing serves specific prototyping or low-stress applications, high-performance end-use metal components require the rigor of subtractive manufacturing. Our CNC machining expertise ensures your parts meet aerospace, medical, and energy sector standards where failure is not an option. We transform complex geometries into certified, high-tolerance components using aerospace-grade alloys, hardened steels, and exotic materials—guaranteeing dimensional stability, fatigue resistance, and longevity that printed parts cannot achieve.

Our integrated manufacturing ecosystem combines 5-axis milling, multi-turn Swiss machining, and wire EDM with rigorous in-process metrology. Every component undergoes stringent first-article inspection and batch validation against your GD&T specifications. We eliminate supply chain vulnerabilities by managing material traceability, heat treatment, and surface finishing internally—reducing lead times while ensuring full compliance with AS9100, ISO 13485, and NADCAP standards.

| Capability | Specification | Application Impact |

|---|---|---|

| Tolerance Range | ±0.005 mm to ±0.001 mm | Critical sealing surfaces, bearing fits |

| Materials | Ti-6Al-4V, Inconel 718, 17-4 PH, Waspaloy, Tungsten | Extreme temp/corrosion resistance |

| Max Part Size | Ø650 mm x 1,200 mm | Large structural housings, manifolds |

| Surface Finish | Ra 0.2 µm to Ra 0.8 µm (as-machined) | Fluid dynamics, fatigue life extension |

| Certifications | AS9100D, ISO 13485, NADCAP AC7102 | Regulatory approval assurance |

Partnering with Lead Precision means engaging engineering collaborators, not just a vendor. Our technical team reviews your DFM early in the design phase, identifying cost-saving optimizations without sacrificing performance—reducing your time-to-market by up to 30%. We implement real-time SPC monitoring across 47 CNC workcells, providing digital quality dossiers with every shipment. For urgent requirements, our dedicated rapid-response cell delivers qualified parts in 15 days without expedited fees.

Your project demands more than online quoting algorithms. It requires metallurgical expertise, process validation, and accountability for every micron. Contact our engineering team directly to discuss material selection, tolerance stack-up analysis, or production scalability. Submit your RFQ with 3D model and specifications to [email protected]. We respond within 24 business hours with a detailed manufacturing plan—including process flow, fixture strategy, and delivery timeline. Let Lead Precision become your trusted partner for mission-critical metal components where precision defines performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.