Technical Contents

Engineering Guide: Pem Nuts For Stainless Steel

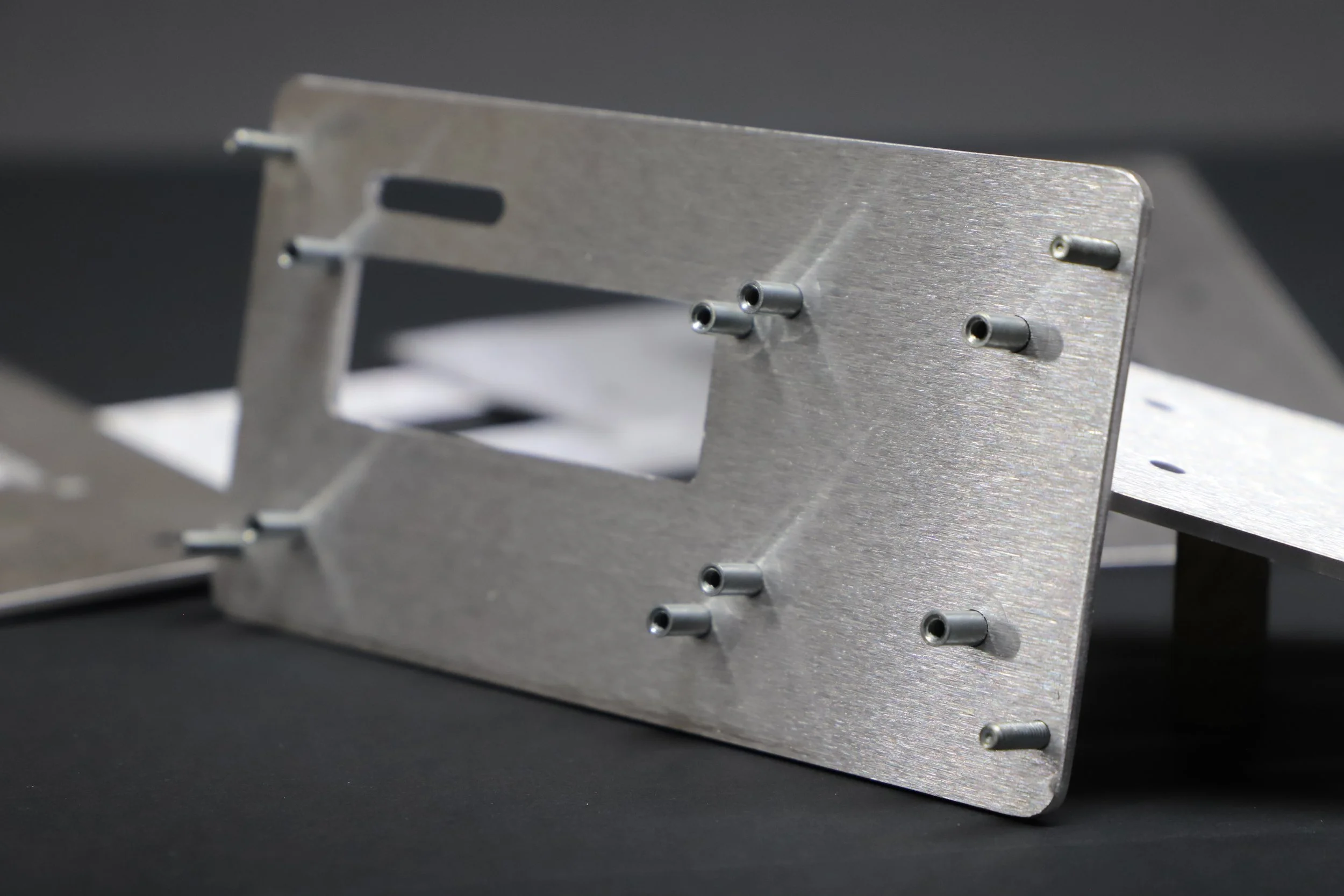

Engineering Insight: PEM Nuts for Stainless Steel – Precision That Defines Performance

In high-performance industries such as aerospace, defense, and advanced medical equipment, the integrity of every fastening point is critical. PEM nuts for stainless steel represent more than a mechanical solution—they are engineered junctions where strength, corrosion resistance, and dimensional accuracy converge. At Wuxi Lead Precision Machinery, we understand that precision in PEM nut integration is not optional; it is the foundation of structural reliability and long-term performance.

Stainless steel presents unique challenges in fastener integration due to its work-hardening characteristics and high tensile strength. When installing PEM nuts—especially self-clinching types—into stainless steel panels, even minor deviations in hole preparation, press-fit alignment, or insertion force can compromise the final assembly. Microscopic misalignment may lead to thread distortion, reduced load-bearing capacity, or premature failure under vibration and thermal cycling. This is why we emphasize a zero-tolerance approach to manufacturing tolerances, ensuring that each PEM nut installation maintains coaxial alignment within ±0.05 mm and achieves optimal surface flushness.

Our engineering team leverages decades of experience in custom metal manufacturing, with direct involvement in mission-critical applications including components for Olympic-standard sports infrastructure and military-grade enclosures. These projects demand uncompromising precision and traceable quality control—standards we apply uniformly across all PEM nut installations. Utilizing CNC-controlled punching, laser cutting, and hydraulic insertion systems, we maintain repeatability down to the micron level, ensuring every fastener performs as designed, every time.

Material compatibility is another cornerstone of successful PEM nut integration. We carefully match the alloy of the PEM nut—typically austenitic or precipitation-hardened stainless steel—to the base panel to prevent galvanic corrosion and ensure thermal expansion compatibility. All installations are verified through torque testing, push-out force analysis, and metallurgical inspection to validate performance under real-world conditions.

At Wuxi Lead, we do not simply install fasteners—we engineer load paths. Our process includes finite element analysis (FEA) for high-stress applications, allowing us to simulate performance under mechanical and environmental stress before production begins. This proactive engineering approach reduces field failures and enhances product lifecycle, particularly in outdoor, marine, or sterile environments where stainless steel is specified for its durability.

Below are representative specifications for our precision PEM nut installations in stainless steel:

| Parameter | Specification |

|---|---|

| Material Compatibility | SS304, SS316, 17-4PH, Custom Alloys |

| Hole Tolerance | ±0.05 mm |

| Insertion Force Control | ±2% accuracy via servo-hydraulic press |

| Thread Integrity | ISO 965 Class 6G |

| Torque Resistance (typical) | 8–12 Nm (M4), 18–25 Nm (M6) |

| Push-Out Strength | ≥4,500 N (for M4 in 2mm SS304) |

| Surface Flushness | ≤0.1 mm protrusion |

| Quality Standards | ISO 9001, MIL-STD-1312, ASTM F541 |

Precision in PEM nut application is not merely a manufacturing objective—it is a performance imperative. At Wuxi Lead Precision Machinery, we combine advanced technology with battle-tested engineering discipline to deliver fastening solutions that uphold the highest standards of safety, reliability, and longevity.

Precision Specs & Tolerances

Technical Capabilities for Stainless Steel PEM Nut Integration

Wuxi Lead Precision Machinery delivers precision-engineered solutions for integrating PEM nuts into demanding stainless steel applications. Our expertise centers on overcoming the inherent challenges of austenitic and martensitic stainless steels, including work hardening, galling tendencies, and stringent corrosion resistance requirements. We specialize in the precise formation, press-fitting, and secondary machining of PEM self-clinching nuts within thin-gauge and structural stainless components, ensuring reliable thread performance and structural integrity under load. Our process begins with rigorous material verification and extends through final inspection, guaranteeing every component meets the exacting standards of aerospace, medical, and high-end industrial sectors.

Our core manufacturing capability leverages advanced 5-axis CNC milling and turning centers. This technology is essential for the complex geometries often required around PEM nut mounting locations in stainless steel assemblies. Multi-axis simultaneous machining allows us to achieve critical features—such as counterbores, thread reliefs, and adjacent mounting surfaces—in a single setup. This eliminates cumulative errors from multiple handling operations, significantly enhancing positional accuracy relative to the PEM nut’s functional axis. Optimized toolpaths and specialized cutting strategies for stainless steel ensure superior surface finishes, controlled chip evacuation to prevent re-cutting and work hardening, and maintain the material’s passive layer integrity crucial for corrosion resistance. This capability directly supports the secure retention and optimal performance of the installed PEM fastener.

Quality assurance is non-negotiable in stainless steel PEM nut applications. Every production run undergoes comprehensive Coordinate Measuring Machine (CMM) inspection. Our Zeiss CONTURA CMM systems perform full 3D geometric dimensioning and tolerancing (GD&T) verification. We measure critical parameters including PEM nut positional accuracy relative to datums, hole concentricity, thread engagement depth, and the integrity of surrounding material features. This data-driven approach provides traceable evidence of conformance to client specifications and industry standards like ASME Y14.5. Statistical process control (SPC) methodologies are applied to monitor trends and ensure consistent output, preventing defects before they occur.

The following table details our standard achievable tolerances for stainless steel components featuring PEM nuts, verified through our CMM process:

| Feature Type | Tolerance Range | Measurement Method |

|---|---|---|

| Positional Accuracy | ±0.025 mm | CMM 3D Scanning |

| Hole Diameter (Fit) | H7 / -0.010 mm / 0 mm | CMM / Air Gaging |

| Thread Pitch Diameter | 6H | Thread CMM Probe |

| Surface Roughness (Ra) | 0.8 µm – 1.6 µm | Profilometer |

| Flatness (Seating) | 0.05 mm | CMM / Optical Flat |

This combination of 5-axis precision manufacturing and rigorous CMM-based quality control ensures that PEM nuts are integrated into stainless steel components with the highest levels of reliability and repeatability. We eliminate the risk of pull-out, rotation, or thread damage during assembly and service life. Partnering with Wuxi Lead provides OEMs with a guaranteed solution that reduces assembly costs, enhances product longevity in corrosive environments, and meets the most stringent global quality mandates for critical fastening applications. Our process delivers confidence in every press-fit installation.

Material & Finish Options

Material Selection Guide for PEM Nuts in Stainless Steel Applications

When integrating PEM nuts into stainless steel assemblies, selecting the appropriate base material and finish is critical to ensuring long-term performance, corrosion resistance, and mechanical integrity. Wuxi Lead Precision Machinery specializes in custom metal manufacturing solutions, providing engineered fastening components tailored to demanding industrial environments. The primary material choices—aluminum, steel, and titanium—each offer distinct advantages depending on the application’s load, weight, temperature, and exposure requirements.

Aluminum is frequently selected for its lightweight properties and excellent corrosion resistance, especially in aerospace and transportation sectors. While inherently softer than steel or titanium, high-strength aluminum alloys such as 6061-T6 and 7075-T73 can support moderate clamping forces when used with PEM nuts. However, due to galvanic compatibility concerns, direct pairing of aluminum components with stainless steel PEM nuts requires careful design consideration. Isolating coatings or insulating washers may be necessary to prevent electrochemical degradation in humid or saline environments.

Steel remains the most widely used material for PEM nut integration, particularly low-carbon and alloy steels such as 1008, 1010, and 4130. These materials provide high tensile and shear strength, making them ideal for structural and load-bearing applications in industrial machinery and automotive systems. When paired with stainless steel PEM nuts, carbon steel panels should be coated or plated to match the corrosion resistance of the fastener. Unprotected steel is prone to oxidation, which can compromise joint integrity over time.

Titanium offers the best strength-to-density ratio among the three materials and exhibits exceptional resistance to saltwater and high-temperature environments. It is commonly used in marine, defense, and aerospace applications where reliability under extreme conditions is non-negotiable. Titanium’s compatibility with stainless steel PEM nuts is generally favorable, though thermal expansion differences must be accounted for in precision assemblies.

Surface finishing plays a vital role in enhancing performance. Anodizing, particularly Type II (sulfuric acid) and Type III (hardcoat), significantly improves aluminum’s wear and corrosion resistance. While anodized layers are electrically insulating and reduce galvanic risk, they must be masked or removed at the PEM insertion point to ensure proper swaging and metal-to-metal bonding.

Below is a comparative overview of material properties relevant to PEM nut applications:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Typical Applications | Compatible PEM Nut Types |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | Moderate to High | Aerospace, Electronics | S, SO, SH, FHA |

| Low-Carbon Steel | 370–440 | 7.8 | Low (requires coating) | Industrial Equipment, Automotive | S, FHO, SO, FH |

| Titanium Grade 5 | 900 | 4.5 | Very High | Marine, Defense, Aviation | ST, SO, SH |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish combination based on environmental exposure, mechanical demands, and lifecycle expectations. Our engineering team ensures that every PEM nut integration meets stringent quality standards, providing reliable, permanent fastening in even the most challenging conditions.

Manufacturing Process & QC

PEM Nut Production Process: Precision Engineering for Stainless Steel Applications

At Wuxi Lead Precision Machinery, our PEM nut manufacturing for stainless steel integrates advanced engineering with uncompromising quality control. This three-phase process ensures zero defects while meeting the exacting demands of aerospace, medical, and industrial clients.

Design Phase: Material Science and Simulation

We begin with material-specific engineering, selecting ASTM F883-compliant stainless steel grades (304/316) based on corrosion resistance and strength requirements. Finite Element Analysis (FEA) validates thread engagement, torque tension, and pull-out force under operational stress. Critical parameters like chamfer angles and knurl geometry are optimized to prevent galling during installation. All designs adhere to ISO 13940 standards, with tolerances held to ±0.05mm for thread pitch and ±0.1° for angular features. Material certifications and traceability documentation are established prior to prototyping.

Prototyping: Validation Through Iterative Testing

Prototypes undergo rigorous validation in our ISO 17025-accredited lab. We perform torque-tension testing per ASTM F606, salt spray corrosion tests (ASTM B117), and micro-hardness verification (HV 200–300 for 316 SS). Dimensional accuracy is confirmed via CMM inspection against CAD models, with statistical process capability (CpK ≥1.67) required before scaling. Client feedback loops ensure functional compatibility with mating components. Only after 100% pass rates across 3 prototype batches do we approve tooling for mass production.

Mass Production: Zero-Defect Execution

Our automated CNC cold-forming lines use tungsten carbide tooling hardened to 60 HRC, ensuring consistent thread geometry across 500,000+ cycles. In-process controls include:

Real-time laser micrometry for diameter and length checks

100% automated vision inspection for thread integrity and surface defects

Statistical Process Control (SPC) charts monitoring torque values every 15 minutes

Batch-level material traceability via laser-etched lot codes

Final validation includes destructive testing of 0.5% of each lot for shear strength and non-destructive eddy current testing for subsurface flaws. All PEM nuts receive passivation per ASTM A967 to maximize corrosion resistance.

Critical PEM Nut Specifications for Stainless Steel

| Parameter | Specification | Standard |

|---|---|---|

| Material | AISI 304, 316 Stainless Steel | ASTM F883 |

| Thread Type | #4-40 to 1/2-13 UNC/UNF | ASME B1.1 |

| Tolerance (Dia.) | ±0.05 mm | ISO 2768-m |

| Torque Tension | 8–12 Nm (M6) | ASTM F606 |

| Corrosion Resistance | ≥500 hrs salt spray (316) | ASTM B117 |

| Surface Finish | Passivated, Ra ≤0.8 μm | ASTM A967 |

This closed-loop methodology—from computational design to SPC-monitored production—eliminates variability. Every PEM nut ships with full material test reports and dimensional certificates, guaranteeing reliability in mission-critical stainless steel assemblies.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Advanced PEM Nut Solutions in Stainless Steel

When it comes to high-performance fastening in demanding industrial environments, the integration of PEM nuts into stainless steel components is not just a convenience—it’s an engineering necessity. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing with a focus on precision-engineered PEM nut installations tailored to the mechanical, thermal, and corrosive requirements of your application. As a trusted partner in the global manufacturing supply chain, we combine advanced CNC technology, material science expertise, and rigorous quality control to deliver reliable, repeatable results—on time and to specification.

Our engineering team works closely with OEMs, aerospace contractors, medical device manufacturers, and industrial equipment designers to develop PEM nut solutions that enhance structural integrity while minimizing assembly time and long-term maintenance. Whether you are integrating flush-mounting nuts into thin-gauge stainless enclosures or embedding high-torque retention hardware into heavy-duty housings, our process ensures optimal thread engagement, minimal distortion, and maximum pull-out resistance.

We understand that every application presents unique challenges. That’s why we offer full customization—from selecting the appropriate PEM nut type and thread size to optimizing installation parameters such as hole preparation, insertion force, and post-installation verification. Our facility is equipped with precision presses, vision inspection systems, and in-house metallurgical testing to ensure every fastener performs to OEM standards.

Below are typical specifications we support for PEM nuts in stainless steel substrates. All parameters are adjustable based on project requirements.

| Specification | Details |

|---|---|

| Material Compatibility | 304, 316, and 316L Stainless Steel |

| PEM Nut Types | SO, SOO, SOZ, SOS, SMT, SB, HSO, FH, BF, K, KF, and custom variants |

| Thread Sizes | #2-56 up to 1/2-13 UNC, M3 to M12 metric |

| Panel Thickness | 0.5 mm to 3.0 mm (custom up to 4.0 mm) |

| Installation Method | Press-fit, self-clinching, or broaching |

| Tolerance Control | ±0.05 mm positional accuracy |

| Quality Standards | ISO 9001:2015, RoHS compliant, full traceability |

| Testing & Validation | Pull-out force, torque-out, head height, and visual inspection |

We don’t just manufacture—we collaborate. From initial design review to prototyping and full-scale production, Wuxi Lead Precision Machinery becomes an extension of your engineering team. Our clients rely on us not only for execution but for technical insight that improves manufacturability, reduces cost, and enhances product lifecycle performance.

If you are designing mission-critical equipment where fastener reliability cannot be compromised, it’s time to work with a partner who understands the science behind the fit. Contact us today at [email protected] to discuss your PEM nut integration project. Let’s build something precise, together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.