Technical Contents

Engineering Guide: Plastic Printing Services

Engineering Insight Precision in Plastic Printing Services for Mission-Critical Applications

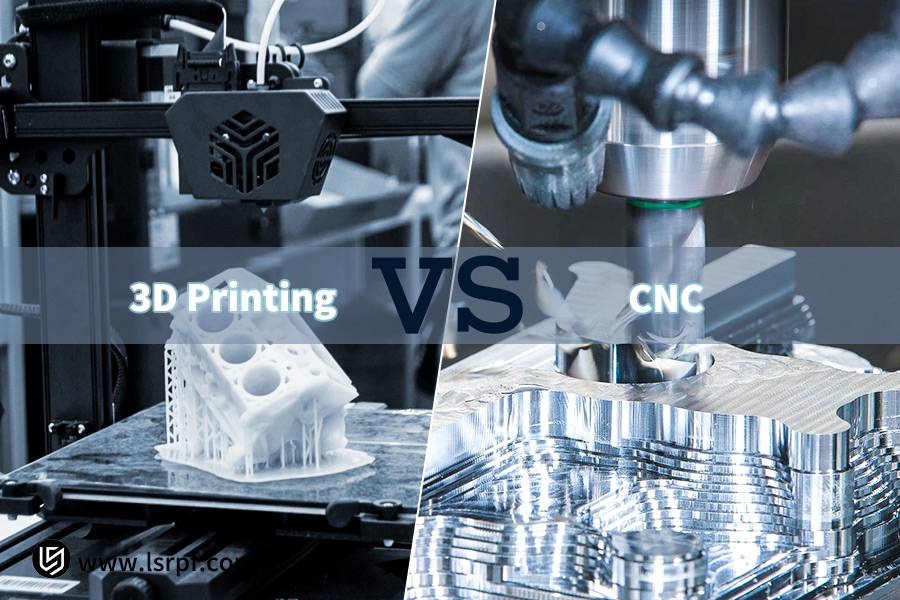

Precision in plastic printing services is non-negotiable for high-stakes industrial applications. Unlike consumer-grade prototyping, engineered polymer components must meet exacting dimensional stability, material integrity, and functional reliability standards. In aerospace, medical, and defense sectors, a tolerance deviation of ±0.05 mm can trigger catastrophic assembly failures or regulatory non-compliance. At Wuxi Lead Precision Machinery, we treat plastic additive manufacturing as an extension of precision metal engineering—where thermal management, layer adhesion, and post-processing calibration are scrutinized with the same rigor as CNC-machined titanium. Warpage during cooling or inconsistent layer bonding directly compromises part longevity, especially under thermal cycling or mechanical stress. This demands closed-loop environmental controls, certified material traceability, and metrology-grade validation at every production phase.

Our capabilities bridge the gap between rapid prototyping and certified end-use production. Below outlines the core specifications we enforce for industrial plastic printing services, exceeding typical bureau standards:

| Parameter | Wuxi Lead Capability | Typical Industry Standard |

|---|---|---|

| Layer Resolution | 20–30 microns | 50–100 microns |

| Dimensional Accuracy | ±0.03 mm | ±0.1–0.2 mm |

| Material Options | ULTEM 9085, PEEK, Carbon-Filled Nylon | PLA, ABS, Basic Resins |

| In-Process Monitoring | Real-time thermal imaging + AI correction | Basic chamber sensors |

| Post-Processing | Stress-relief annealing, CMM validation | Basic support removal |

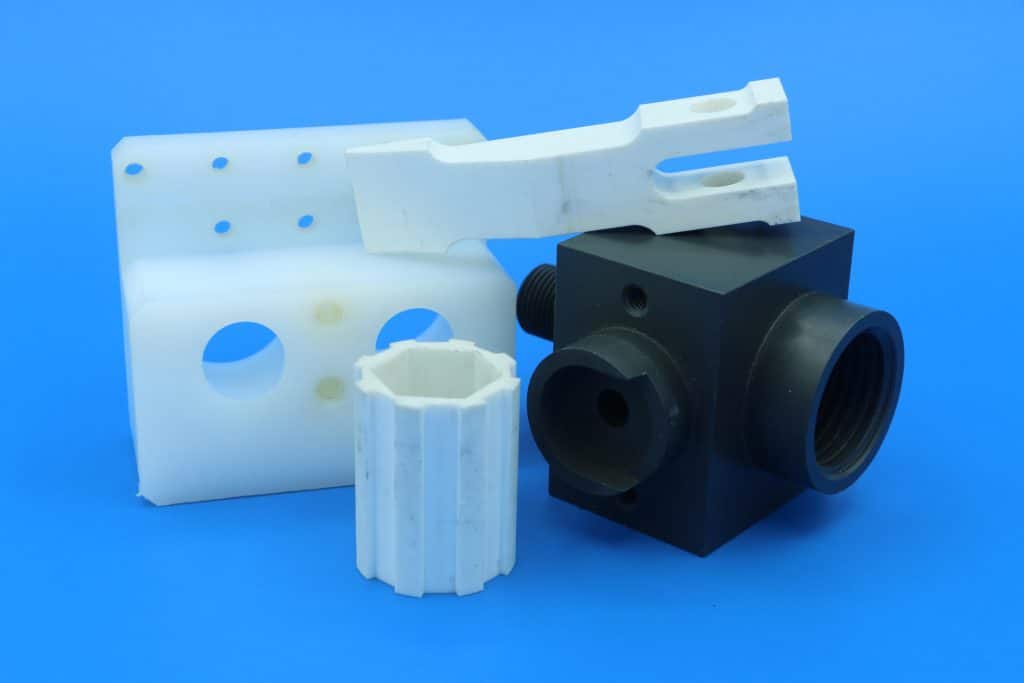

This precision discipline was forged through mission-critical projects. For the Tokyo 2020 Olympics, we produced polymer timing system housings requiring sub-0.04 mm alignment tolerances to interface with metal sensors—ensuring microsecond accuracy across 10,000+ race starts. Similarly, military drone components we manufactured demanded flame-retardant PEEK parts maintaining integrity from -55°C to 250°C, validated under MIL-STD-810G shock/vibration testing. These engagements taught us that plastic printing for engineered systems cannot operate in isolation; it must integrate seamlessly with metal subassemblies, electronics, and fluid dynamics. A misaligned polymer conduit in a hydraulic manifold or a warped sensor mount in a missile guidance system carries consequences far beyond cosmetic flaws.

At Wuxi Lead, we reject the notion that plastic printing is a standalone service. It is a precision engineering discipline requiring cross-functional expertise in materials science, thermal dynamics, and metrology. Our engineers collaborate with clients from DFM analysis through first-article inspection, ensuring polymer components meet the same zero-defect ethos as our aerospace-grade metal work. When your application demands that plastic parts perform under extreme conditions—whether in a satellite deployment mechanism or a surgical robot—precision isn’t optional. It’s the foundation of trust. Partner with a manufacturer that treats every printed layer as mission-critical.

Precision Specs & Tolerances

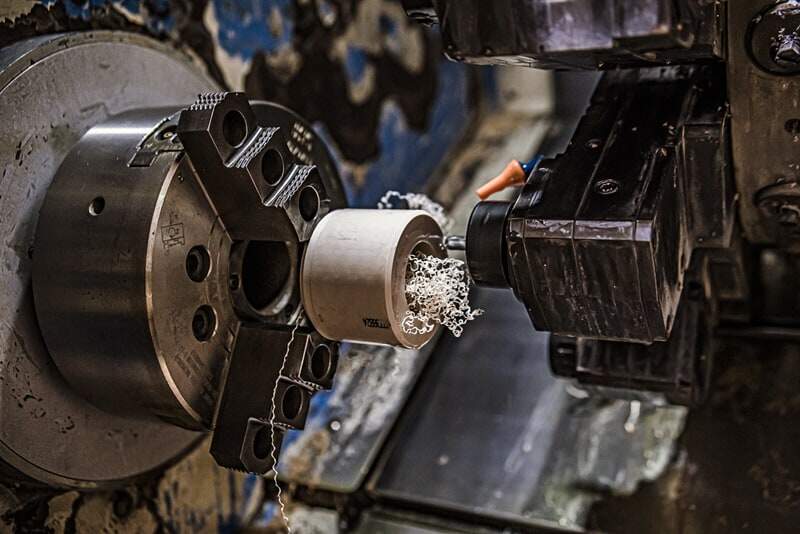

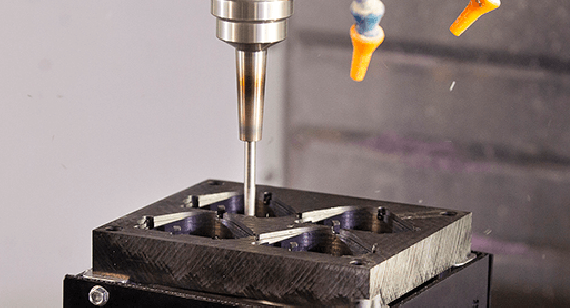

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for high-performance industrial applications, including precision components used in plastic printing services. Our technical capabilities are engineered to meet the stringent demands of modern production environments, where accuracy, repeatability, and material integrity are critical. At the core of our machining operations is our 5-axis CNC machining technology, which enables us to produce complex geometries with exceptional surface finishes and tight dimensional control. This advanced machining process allows for simultaneous movement across five axes, reducing setup times and eliminating the need for multiple fixtures, which in turn enhances part consistency and reduces potential error sources.

Our 5-axis CNC systems are operated by certified engineers with extensive experience in high-precision metal fabrication. These systems support a wide range of engineering-grade metals, including aluminum alloys, stainless steel, titanium, and brass—materials frequently required for durable components in plastic printing machinery such as nozzles, mounting brackets, heat sinks, and structural frames. The integration of high-speed cutting tools and real-time tool path optimization ensures minimal material waste and superior edge definition, critical for parts that interface directly with polymer feed systems and thermal management units.

To maintain the highest level of quality assurance, every component undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM). Our CMM system provides full 3D metrology validation, capturing thousands of data points to verify geometric dimensioning and tolerancing (GD&T) compliance. This non-contact and tactile measurement approach ensures that all critical features—such as bore diameters, flatness, angular alignment, and positional tolerances—are verified to meet or exceed customer specifications. Inspection reports are fully documented and traceable, supporting compliance with ISO 9001 standards and industry-specific regulatory requirements.

The following table outlines the standard tolerance capabilities achievable across typical production runs. These values reflect our commitment to precision and are maintained through continuous process monitoring, environmental controls, and preventive maintenance of all equipment.

| Feature Type | Standard Tolerance | Precision Tolerance (Optional) | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.010 mm | CMM, Micrometer |

| Hole Diameter | ±0.020 mm | ±0.008 mm | CMM, Air Gaging |

| Flatness | 0.02 mm | 0.005 mm | CMM, Surface Plate |

| Angular Tolerance | ±0.1° | ±0.05° | CMM, Optical Comparator |

| Positional Tolerance | ±0.025 mm | ±0.010 mm | CMM |

| Surface Finish (Ra) | 1.6 μm | 0.4 μm | Surface Roughness Tester |

All manufacturing and inspection processes are supported by integrated CAD/CAM software and digital workflow management, ensuring seamless transition from design to delivery. Wuxi Lead Precision Machinery remains committed to delivering technically superior, fully validated metal components that enhance the reliability and performance of plastic printing systems worldwide.

Material & Finish Options

Material Selection Guide for Precision Metal Components

Clarification: While the term plastic printing services may suggest additive manufacturing, Wuxi Lead Precision Machinery specializes in high-accuracy CNC machining of metal components for industrial applications. This guide addresses critical material and finish selection for custom metal parts where dimensional stability, strength, and surface integrity are paramount. Choosing correctly impacts performance, longevity, and total cost of ownership.

Aluminum alloys dominate aerospace, automotive, and electronics due to their exceptional strength-to-weight ratio and machinability. Grade 6061-T6 offers balanced mechanical properties and weldability for structural brackets, while 7075-T6 delivers superior strength for high-stress components like drone arms or aircraft fittings. Aluminum’s natural corrosion resistance is adequate for many environments, but anodizing is essential for enhanced wear protection and electrical insulation. Avoid aluminum in high-temperature or extreme abrasive applications where steel or titanium excel.

Steel remains indispensable for load-bearing parts requiring hardness and durability. Stainless steel 304 provides robust corrosion resistance for medical or food-grade housings, while 316L adds molybdenum for marine/saltwater exposure. For extreme wear resistance, hardened tool steels like D2 or 4140 are optimal for molds and cutting tools. Note that stainless grades 303 and 304 machine more efficiently than 316, reducing production costs. Always specify passivation post-machining for stainless to maximize corrosion resistance.

Titanium Grade 5 (Ti-6Al-4V) is the benchmark for critical applications demanding extreme strength, biocompatibility, and corrosion resistance at elevated temperatures. It is non-magnetic and ideal for aerospace actuators, medical implants, and chemical processing equipment. However, titanium’s low thermal conductivity complicates machining, requiring specialized toolpaths and coolant strategies to prevent work hardening. Its high material cost necessitates rigorous design validation to minimize waste.

Anodizing is the premier surface treatment for aluminum, creating a durable, non-conductive oxide layer. Type II (sulfuric acid) anodizing offers good corrosion resistance with color dyeing options for branding. Type III (hardcoat) anodizing achieves 50–75 µm thickness for severe wear environments, doubling surface hardness. Critical parameters include precise voltage control and sealing in hot deionized water to prevent staining. Never anodize steel or titanium—alternative finishes like electroless nickel plating or PVD coatings apply.

Material specifications must align with functional demands. Below are key properties for common grades:

| Material | Key Grades | Tensile Strength (MPa) | Primary Applications |

|---|---|---|---|

| Aluminum | 6061-T6 | 310 | Brackets, enclosures, automotive parts |

| 7075-T6 | 570 | Aerospace fittings, high-stress mounts | |

| Steel | 304 Stainless | 515 | Medical devices, food processing |

| 4140 Alloy | 655 | Shafts, gears, tooling | |

| Titanium | Ti-6Al-4V | 900 | Aircraft components, surgical implants |

Selecting the optimal material-finish combination requires analyzing load, environment, regulatory needs, and lifecycle costs. Wuxi Lead’s engineering team collaborates to validate material choices against your operational demands, ensuring machinability and finish integrity without over-engineering. Contact us for material datasheets or application-specific testing protocols.

Manufacturing Process & QC

The production process for high-precision plastic printing services at Wuxi Lead Precision Machinery follows a rigorously controlled sequence designed to ensure absolute consistency, dimensional accuracy, and zero defects. Rooted in advanced custom metal manufacturing principles, our approach integrates engineering excellence with real-time quality assurance at every phase: Design, Prototyping, and Mass Production.

The process begins with Design, where our engineering team collaborates closely with clients to translate conceptual requirements into manufacturable solutions. Utilizing CAD/CAM software and finite element analysis (FEA), we optimize part geometry, material selection, and thermal behavior to meet functional and environmental demands. This stage includes comprehensive tolerance stack-up analysis and mold flow simulation to predict and eliminate potential defects such as warping, sink marks, or voids before any physical prototype is created.

Following design validation, we proceed to Prototyping. Employing high-speed CNC machining and metal 3D printing, we fabricate prototype molds from premium-grade tool steels or aluminum alloys, depending on volume and cycle requirements. These molds are used to produce functional plastic components under actual processing conditions, enabling full performance testing. Each prototype undergoes dimensional inspection via coordinate measuring machines (CMM), surface roughness evaluation, and mechanical property verification. Feedback from this stage is systematically integrated into final design adjustments, ensuring that all variables are controlled prior to scale-up.

Mass Production is executed on fully automated, closed-loop injection molding systems housed in ISO 9001-certified facilities. Machines are equipped with in-cavity pressure and temperature sensors that feed real-time data to a central monitoring system, enabling predictive maintenance and immediate deviation detection. All production runs follow Statistical Process Control (SPC) protocols, with process capability (Cp/Cpk) monitored continuously. Each batch is subject to 100% visual inspection using machine vision systems and random sampling per ANSI/ASQ Z1.4 standards.

Our zero-defect philosophy is enforced through a multi-tiered quality management system that includes operator training, preventive maintenance schedules, and full traceability from raw material lot to finished part. Non-conforming products are quarantined and subjected to root cause analysis using 8D methodology, ensuring continuous improvement.

The following table outlines key process specifications and capabilities:

| Parameter | Specification |

|---|---|

| Material Compatibility | ABS, PC, POM, PA6/66, PBT, PPS, LCP, PEEK |

| Tolerance Range | ±0.02 mm (standard), ±0.005 mm (precision) |

| Mold Steel Types | NAK80, S136, 2738, H13, 420 Stainless |

| Injection Press Capacity | 50–1,200 tons |

| Surface Finishes | SPI A1–B2, texture, matte, high-gloss |

| Production Capacity | Up to 5 million parts/year per line |

| Quality Standards | ISO 9001, IATF 16949, RoHS, REACH |

Through disciplined execution and technological integration, Wuxi Lead Precision Machinery delivers plastic printing services that meet the most demanding industrial requirements with uncompromised quality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Engineered Precision for Demanding Plastic Printing Systems

Wuxi Lead Precision Machinery operates at the critical intersection of advanced manufacturing and industrial innovation. While our core expertise lies in custom metal component production, we recognize the foundational role precision-engineered metal parts play in enabling high-performance plastic printing systems. The reliability, thermal stability, and micron-level accuracy demanded by industrial 3D printers, injection molding equipment, and extrusion systems depend entirely on the quality of their metal sub-assemblies. As your strategic manufacturing partner, we deliver the mission-critical metal components that form the backbone of these technologies – from hardened steel nozzles and aluminum heat-break assemblies to vibration-dampened gantry frames and corrosion-resistant build plates. We do not provide plastic printing services; we engineer the metal infrastructure that makes elite plastic printing possible.

Our CNC machining capabilities are calibrated to the exacting tolerances required by the additive and injection molding industries. Every component undergoes rigorous in-process and final inspection using calibrated CMMs and optical comparators, ensuring dimensional integrity that directly impacts print fidelity and machine longevity. The table below details our certified production parameters for materials commonly specified in plastic printing hardware:

| Specification | Capability Range | Industry Standard Compliance |

|---|---|---|

| Material Types | Aluminum 6061/7075, Stainless 303/316, Tool Steels, Brass | ASTM, ISO, EN |

| Tolerance Control | ±0.005 mm (±0.0002″) | ISO 2768-mK, GD&T |

| Surface Finish | Ra 0.4 µm to 3.2 µm (16 to 125 µin) | ISO 1302 |

| Max Work Envelope | 1200 x 800 x 650 mm (47 x 31.5 x 25.6″) | – |

| Quality Certifications | ISO 9001:2015, AS9100D | Full traceability with PPAP |

Choosing Lead Precision means integrating a partner who understands the thermal dynamics, mechanical stresses, and contamination risks inherent in plastic printing environments. Our engineering team collaborates early in your design phase to optimize part geometry for manufacturability, material performance, and cost efficiency – preventing costly iterations downstream. We implement controlled clean-room protocols for critical components to eliminate particulate interference, and our thermal stress-relieving processes ensure dimensional stability across operational temperature ranges from -40°C to 300°C. This level of control is non-negotiable when producing elements like heated bed mounting plates or laser sintering chamber components where even micron-scale warpage causes system failure.

The plastic printing sector demands unwavering consistency in its foundational hardware. Substandard metal components lead to print failures, accelerated wear, and unplanned downtime – directly impacting your operational costs and reputation. Lead Precision’s commitment to process discipline, material science expertise, and transparent communication mitigates these risks at the source. We provide comprehensive documentation including first-article inspection reports, material certifications, and SPC data, giving your engineering and quality teams absolute confidence in every shipment.

Elevate the performance and reliability of your plastic printing systems by partnering with a manufacturer that treats precision as a non-negotiable standard. Contact our engineering sales team to discuss how our metal fabrication excellence can solve your most complex component challenges. Submit your RFQ or technical specifications to [email protected] for a detailed capability assessment and timeline within 24 business hours. Let Lead Precision become the unseen force behind your visible innovation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.