Technical Contents

Engineering Guide: Sheet Steel Material

Engineering Insight Precision in Sheet Steel Fabrication

Precision in sheet steel fabrication is non-negotiable for mission-critical applications. Minor deviations in flatness, thickness tolerance, or edge quality directly impact structural integrity, assembly efficiency, and end-product performance. At Wuxi Lead Precision Machinery, we treat sheet steel not merely as raw material but as the foundational element of engineered reliability. Variations exceeding ±0.05mm in flatness can cause misalignment in automated assembly lines, while inconsistent thickness tolerances lead to weld failures or compromised load-bearing capacity. Our CNC-driven processes eliminate these risks through real-time material monitoring and adaptive toolpath compensation, ensuring every sheet meets exacting dimensional and geometric specifications before cutting or forming begins.

Our expertise extends beyond standard commercial requirements to sectors where failure is not an option. We engineered structural components for the Beijing 2022 Winter Olympics venue network, where sub-zero operational temperatures demanded steel with zero residual stress and micron-level flatness to prevent thermal deformation. Similarly, military-grade enclosures we produce for defense systems adhere to MIL-DTL-32169 standards, requiring surface finishes under 0.8μm Ra to ensure electromagnetic shielding integrity. This level of precision stems from 18 years of refining material science protocols, including proprietary stress-relief annealing cycles and laser-guided flatness calibration unique to Chinese-manufactured steel grades.

Material selection must align with both functional demands and manufacturability. Below are critical specifications we validate for every sheet steel order:

| Material Grade | Thickness Range (mm) | Thickness Tolerance (mm) | Flatness (mm/m) | Surface Finish (Ra μm) |

|---|---|---|---|---|

| Q235B | 0.5 – 12.0 | ±0.03 to ±0.08 | ≤1.0 | 3.2 |

| SUS304 | 0.3 – 10.0 | ±0.02 to ±0.05 | ≤0.5 | 0.8 |

| Q355B | 2.0 – 25.0 | ±0.05 to ±0.12 | ≤1.5 | 6.3 |

| Military Spec | 1.0 – 8.0 | ±0.015 to ±0.03 | ≤0.3 | ≤0.4 |

These parameters are not theoretical ideals but rigorously enforced checkpoints. Our facility’s ISO 17025-accredited metrology lab conducts pre-production material certification, including ultrasonic thickness mapping and spectral analysis for trace elements that affect weldability. For instance, Olympic project steel required phosphorus content below 0.015% to prevent cold cracking in arctic conditions—a detail overlooked in generic fabrication.

Wuxi Lead’s integration of material science and precision engineering transforms sheet steel from a commodity into a performance asset. When your application demands zero-defect consistency under extreme operational stress, our validated processes and sector-specific expertise deliver certainty. Contact us to discuss how our precision protocols can be tailored to your sheet steel requirements.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for high-performance industries including aerospace, medical, automation, and precision instrumentation. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to process sheet steel materials with exceptional accuracy, complexity, and efficiency. Unlike conventional 3-axis systems, our 5-axis CNC centers allow simultaneous multi-directional cutting, minimizing setup changes and supporting the production of intricate geometries from a single workholding position. This results in improved part consistency, reduced lead times, and superior surface finishes—critical for mission-critical sheet steel components.

We specialize in machining a wide range of sheet steel materials, including low-carbon steels, high-strength low-alloy (HSLA) steels, and stainless steel grades such as 304, 316, and 410. Our equipment is optimized for thin-gauge and mid-thickness sheet steel, with adaptive fixturing and high-speed spindles that prevent warping and maintain dimensional stability during precision milling, drilling, and contouring operations. Advanced toolpath simulation and in-process probing ensure material integrity and minimize tool deflection, particularly important when working with large or thin sheet formats prone to vibration and thermal expansion.

Quality assurance is integrated at every stage of production. All sheet steel components undergo comprehensive inspection using our Coordinate Measuring Machine (CMM) systems, which provide micron-level verification of geometric dimensions, positional tolerances, and surface profiles. Our CMM inspection routines are fully programmable and aligned with ISO 10360 standards, ensuring traceable and repeatable measurement results. In addition to first-article inspection, we perform in-process and final QA checks to maintain compliance with AS9100, ISO 9001, and customer-specific quality requirements.

The following table outlines our standard machining tolerances for sheet steel components processed on 5-axis CNC systems:

| Feature | Standard Tolerance | Tight Tolerance Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.025 mm | Up to 600 mm length |

| Angular Tolerances | ±0.1° | ±0.05° | Measured via CMM |

| Positional Tolerance | ±0.05 mm | ±0.02 mm | Relative to datum |

| Flatness | 0.1 mm per 100 mm | 0.05 mm per 100 mm | For sheet thickness ≥1 mm |

| Hole Diameter | +0.03 / -0.00 mm | +0.01 / -0.00 mm | Reamed or precision bored |

| Surface Roughness | Ra 3.2 µm | Ra 0.8 µm | As machined or polished |

Our technical team collaborates closely with engineering partners to optimize designs for manufacturability, ensuring that sheet steel components meet exact functional and regulatory demands. With full in-house control from CNC programming to final inspection, Wuxi Lead Precision Machinery guarantees precision, repeatability, and on-time delivery for every custom sheet steel project.

Material & Finish Options

Material Selection for Precision Sheet Metal Fabrication

Selecting the optimal sheet material is foundational to achieving performance, cost efficiency, and longevity in custom metal components. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your functional requirements, environmental exposure, and manufacturing complexity. Steel remains a dominant choice for structural applications due to its strength-to-cost ratio, though aluminum and titanium serve critical niches where weight savings or extreme corrosion resistance are paramount. Understanding these distinctions ensures your design translates into a reliable, manufacturable product.

Steel variants offer tiered solutions. Mild steel (e.g., A36) provides excellent weldability and formability for non-critical structural frames but requires protective finishes against rust. Stainless steel grades like 304 or 316 deliver inherent corrosion resistance through chromium content, making them ideal for medical, food processing, or marine environments. Tool steels (e.g., D2) suit high-wear tooling but demand specialized machining. Aluminum alloys, particularly 5052 and 6061, excel where weight reduction is critical—such as aerospace brackets—without sacrificing moderate strength. Titanium Gr5 (Ti-6Al-4V) is reserved for extreme scenarios like aerospace or biomedical implants, offering exceptional strength-to-weight and biocompatibility at a premium cost.

Anodizing is frequently specified but applies almost exclusively to aluminum. This electrochemical process thickens the natural oxide layer, enhancing surface hardness, corrosion resistance, and adhesion for paints. While steel cannot be anodized, equivalent protection comes from galvanization, powder coating, or passivation for stainless grades. Selecting the wrong finish for steel—such as anodizing—leads to process failure and wasted investment.

Below is a comparative overview of key material properties for common sheet stock:

| Material | Yield Strength (MPa) | Density (g/cm³) | Machinability Rating | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 276 | 2.7 | Excellent (A7) | Moderate | Aircraft panels, heat sinks |

| Mild Steel A36 | 250 | 7.8 | Good (B) | Low (requires finish) | Structural frames, brackets |

| Stainless 304 | 215 | 8.0 | Fair (C) | High | Medical devices, food equipment |

| Titanium Gr5 | 880 | 4.5 | Poor (D) | Exceptional | Aerospace fittings, implants |

Steel’s versatility makes it our most requested material for industrial enclosures, machinery guards, and load-bearing components. However, over-specifying stainless or titanium inflates costs unnecessarily. Conversely, under-specifying mild steel in corrosive settings risks premature failure. At Wuxi Lead, we conduct rigorous material validation during prototyping, including tensile testing and bend analysis, to confirm suitability. Our CNC fabrication processes—from laser cutting to precision forming—are calibrated for each material’s thermal and mechanical behavior, minimizing waste and ensuring dimensional accuracy.

Consult our engineering team early in your design phase. We provide material certification, mill test reports, and finish compatibility guidance to eliminate guesswork. Precision begins with the right substrate.

Manufacturing Process & QC

The production process for sheet steel components at Wuxi Lead Precision Machinery follows a disciplined, three-phase approach: Design, Prototyping, and Mass Production. This structured workflow ensures precision, repeatability, and zero-defect outcomes for high-end industrial clients across aerospace, automotive, and advanced equipment sectors.

Design begins with a detailed engineering review, where our team collaborates with client specifications to optimize geometry, material selection, and manufacturability. Finite element analysis (FEA) and 3D modeling in SolidWorks and Siemens NX ensure stress points, thermal behavior, and fitment are validated before any physical work begins. Material compatibility, corrosion resistance, and surface finish requirements are evaluated against international standards, including ASTM A1008 and EN 10142. Our engineers apply Design for Manufacturing and Assembly (DFM) principles to eliminate inefficiencies and reduce lead times without compromising integrity.

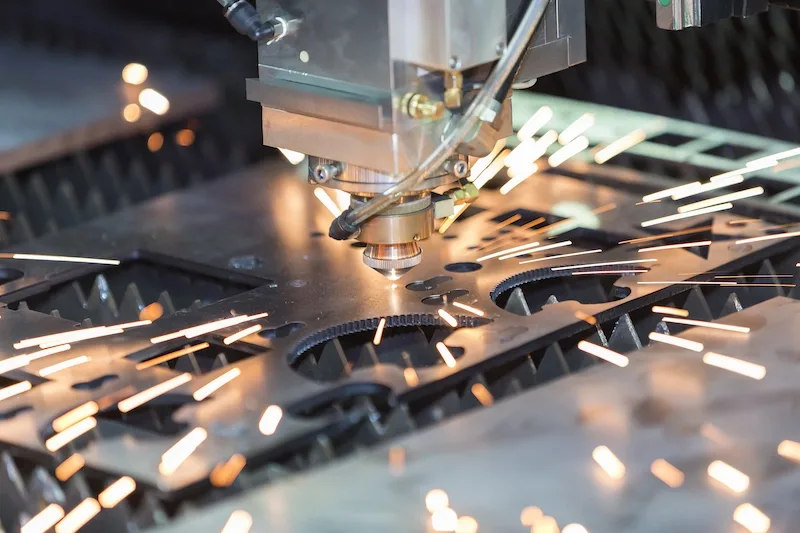

Prototyping follows design finalization, utilizing high-precision CNC laser cutting, press braking, and robotic welding stations. Each prototype is produced on the same class of equipment used in mass production to ensure process consistency. Dimensional inspection is performed using Zeiss coordinate measuring machines (CMM), with results mapped against the original CAD model via GD&T analysis. First article inspection reports (FAIR) and material test certificates (MTC) are provided for full traceability. This phase allows clients to validate form, fit, and function under real-world conditions, minimizing risk during scale-up.

Mass production is initiated only after formal client approval of the prototype. Our automated production cells integrate real-time monitoring systems that track tool wear, positional accuracy, and material flow. Each sheet steel component undergoes in-process inspection at critical control points, supported by statistical process control (SPC) methodologies. Final inspection includes 100% visual checks and random sampling per ANSI/ASQ Z1.4 standards. Non-conforming parts are automatically quarantined through our digital quality management system, ensuring zero-defect delivery.

Throughout all phases, Wuxi Lead maintains full material traceability from coil lot to finished part. Our ISO 9001 and IATF 16949 certifications underscore our commitment to quality, while lean manufacturing principles drive efficiency and on-time delivery.

Typical Sheet Steel Material Specifications

| Property | Value | Standard |

|---|---|---|

| Material Grade | SPCC, SPHC, Q195, Q235, DC01, DX51D | JIS G 3141, GB/T 3274, EN 10327 |

| Thickness Range | 0.5 – 6.0 mm | ISO 9001 |

| Tensile Strength | 270 – 500 MPa | ASTM A370 |

| Yield Strength | 140 – 420 MPa | ASTM A370 |

| Elongation | 25% – 45% | ISO 6892-1 |

| Surface Finish | Mill, Galvanized (Zinc 60–180 g/m²), or Powder Coated | ASTM B633, ISO 1461 |

| Tolerance (Cutting) | ±0.1 mm | ISO 2768-m |

| Tolerance (Bending) | ±0.2°, ±0.2 mm | ISO 2768-f |

This end-to-end control from digital design to defect-free delivery positions Wuxi Lead as a trusted partner in custom sheet steel manufacturing for mission-critical applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Sheet Steel Manufacturing Excellence

In high-stakes industrial applications, the integrity of your sheet steel components directly impacts system performance, longevity, and safety. Generic suppliers often treat material as a commodity, overlooking critical nuances in metallurgy, tolerances, and process control. At Wuxi Lead Precision Machinery, we engineer sheet steel solutions where material science converges with precision manufacturing. Our approach eliminates the guesswork in sourcing, ensuring every part meets exacting functional and regulatory demands—from aerospace structural elements to medical device housings.

We specialize in transforming raw sheet steel into mission-critical components through tightly integrated processes. Our facility combines advanced CNC laser cutting, precision bending, and robotic welding under one roof, all governed by ISO 9001:2015 and IATF 16949 certified systems. Unlike fragmented supply chains, we maintain full traceability from material certification to final inspection, providing documented proof of compliance for every batch. This end-to-end control minimizes risk, reduces lead times, and guarantees consistency across production runs—whether prototyping or high-volume manufacturing.

Material selection is foundational to performance. Our engineering team collaborates with clients to specify optimal grades, coatings, and thicknesses aligned with operational stresses, environmental exposure, and lifecycle requirements. We rigorously validate all incoming sheet steel against chemical composition, mechanical properties, and surface integrity standards before processing begins. The result is components that perform reliably in extreme conditions, avoiding costly field failures or rework.

Critical Sheet Steel Capabilities at a Glance

| Parameter | Specification Range | Quality Assurance Method |

|————————-|———————————|—————————————-|

| Material Thickness | 0.5 mm – 25 mm | Ultrasonic thickness mapping |

| Dimensional Tolerance | ±0.05 mm (standard) | CMM inspection per ASME Y14.5 |

| Surface Finish | Ra 0.4 µm – Ra 3.2 µm | Profilometer testing & visual grading |

| Material Certifications | Mill test reports (MTRs) | Full traceability to heat number |

| Max. Part Dimensions | 3000 mm x 1500 mm | Laser alignment verification |

Choosing Lead Precision means partnering with engineers who speak your technical language and prioritize your operational success. We invest in understanding your application’s failure modes—not just meeting drawings, but anticipating real-world stresses. Our agile manufacturing ecosystem adapts to your schedule, with rapid prototyping cycles and scalable production that aligns with your ramp-up demands.

Initiate your precision workflow with a partner committed to material integrity and process excellence. Contact our engineering team directly to discuss your sheet steel requirements, request material certification protocols, or schedule a facility audit. We respond to all technical inquiries within 4 business hours.

Email [email protected] to secure your dedicated project engineer and receive a customized material processing roadmap. Let us demonstrate how precision manufacturing elevates component reliability and reduces total cost of ownership. Your next-generation product deserves nothing less.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.