Technical Contents

Engineering Guide: Polycarbonate Injection Molding

Engineering Insight: Precision in Polycarbonate Injection Molding

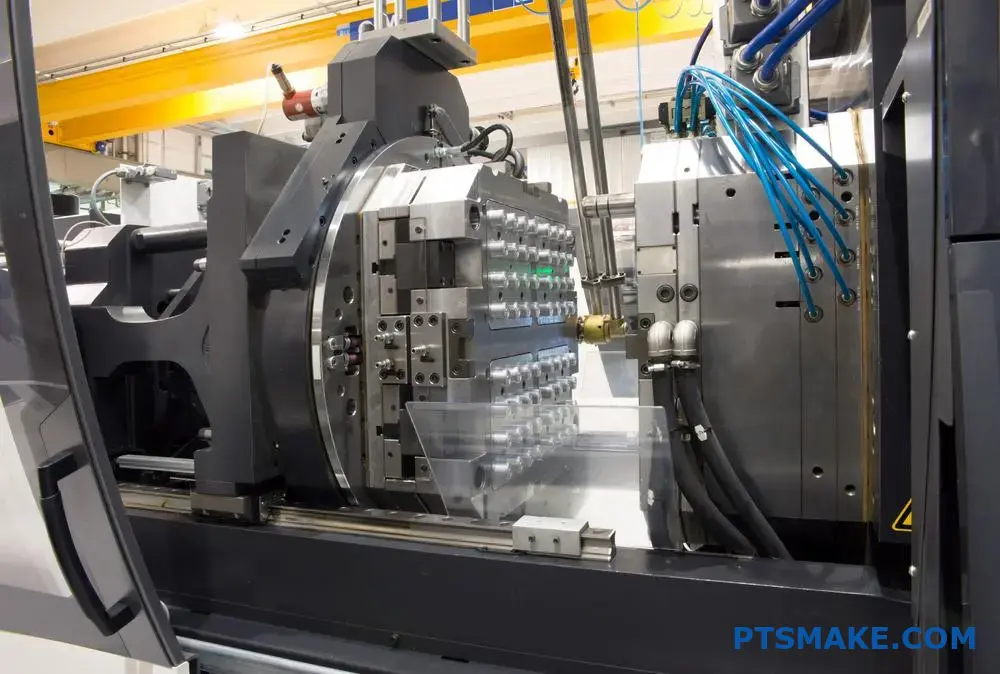

Polycarbonate injection molding is a critical process in high-performance manufacturing, where material properties and dimensional accuracy must align with exacting engineering standards. As a thermoplastic known for its exceptional impact resistance, optical clarity, and thermal stability, polycarbonate is widely used in aerospace, defense, medical, and automotive applications. However, its processing demands a level of precision that only advanced machinery and expert engineering can deliver. At Wuxi Lead Precision Machinery, we understand that success in polycarbonate molding is not just about material selection—it’s about control, consistency, and the ability to maintain tolerances under dynamic thermal and mechanical conditions.

One of the primary challenges in polycarbonate injection molding is managing its high melt viscosity and sensitivity to shear. Without precise control over injection speed, pressure, and temperature, defects such as flow lines, internal stresses, and warpage can compromise part integrity. This is where precision-engineered molding systems become indispensable. Our custom metal manufacturing solutions are designed to deliver uniform melt homogeneity and repeatable shot-to-shot accuracy, ensuring that every component meets the tightest tolerances. Our machines feature closed-loop control systems, high-response servo valves, and real-time monitoring capabilities that allow for micro-adjustments during the molding cycle.

Temperature control is another key factor. Polycarbonate typically requires melt temperatures between 280°C and 320°C, with mold temperatures maintained around 80°C to 110°C to minimize residual stress and optimize surface finish. Our proprietary thermal management systems ensure uniform heating and cooling across the mold surface, reducing cycle times while enhancing part quality. This level of control is essential when producing components for mission-critical applications—such as those supplied for Olympic-grade equipment and military-grade enclosures—where failure is not an option.

Wuxi Lead Precision Machinery has a proven track record in delivering custom solutions for technically demanding sectors. Our engineering team has supported projects requiring compliance with ISO 13485, MIL-STD-810, and other rigorous international standards. This experience informs every machine we build, integrating robust construction with intelligent design to handle the unique demands of polycarbonate processing.

The following table outlines key specifications for our precision injection molding systems optimized for polycarbonate:

| Parameter | Specification |

|---|---|

| Clamping Force Range | 800 kN – 6,500 kN |

| Injection Pressure | Up to 2,200 bar |

| Screw Diameter | 30 mm – 70 mm |

| Shot Weight (PS) | 120 g – 2,800 g |

| Melt Temperature Control | ±1°C accuracy |

| Mold Temperature Range | 20°C – 150°C (with oil-based regulation) |

| Repeatability (Shot Weight) | ±0.15% |

| Control System | Siemens S7-1500 with HMI interface |

| Cycle Time Optimization | Adaptive process learning with AI feedback |

At Wuxi Lead Precision Machinery, we combine decades of metallurgical expertise with cutting-edge automation to deliver systems that excel in the most demanding polycarbonate molding applications. Precision is not a feature—it is the foundation.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Components for Demanding Applications

Wuxi Lead Precision Machinery specializes in the advanced manufacturing of critical metal components, leveraging cutting-edge technology to meet the exacting demands of high-performance industries. While our core expertise lies in precision metal fabrication, we recognize the importance of understanding adjacent processes like injection molding. Crucially, our capabilities directly support the production of the ultra-precise metal tooling – molds and inserts – essential for high-integrity applications, including those utilizing engineered polymers like polycarbonate where metal component integration or mold construction is paramount. We do not manufacture plastic parts; we engineer the metal foundations that enable their precise formation.

Our production floor is anchored by state-of-the-art 5-axis CNC machining centers. This technology provides unparalleled geometric flexibility, allowing us to machine complex, high-tolerance features in a single setup. This eliminates cumulative errors inherent in multi-setup processes, ensuring exceptional part accuracy and surface integrity critical for mold cavities, cores, electrodes, and structural components interacting with injection molding systems. Materials processed include hardened tool steels (e.g., H13, S136), stainless steels, aluminum alloys, and exotic superalloys, all machined to stringent specifications required for durability and precision in demanding molding environments.

Rigorous quality control is non-negotiable. Every critical dimension and feature undergoes comprehensive validation using Coordinate Measuring Machines (CMM) with sub-micron resolution. Our metrology lab operates under strict environmental controls, ensuring measurement repeatability and traceability to international standards. This systematic CMM inspection process verifies geometric dimensioning and tolerancing (GD&T), surface profiles, and critical form features against the original CAD model, providing documented proof of conformance before components leave our facility. This level of metrological assurance is vital for mold performance, directly impacting the dimensional stability and quality of any molded part, whether plastic or metal.

The table below outlines the precision capabilities achievable on critical metal components and mold elements for high-end applications:

| Feature Category | Typical Capability Range | Measurement Method | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm to ±0.010 mm | CMM | For features < 100 mm; scales with size |

| Geometric Tolerances | 0.008 mm to 0.020 mm | CMM | Includes flatness, perpendicularity, true position |

| Surface Roughness (Ra) | 0.2 µm to 0.8 µm | Profilometer | As-machined; polishable to finer finishes |

| Critical Mold Features | ±0.003 mm to ±0.008 mm | CMM / Optical Comparator | Cavities, cores, shut-offs, alignment features |

| Hole Position Accuracy | ±0.005 mm | CMM | Relative to datums; critical for pins/cores |

This precision foundation, built on advanced 5-axis CNC machining and uncompromising CMM validation, ensures that the metal components and tooling we produce meet the rigorous demands of aerospace, medical device, and high-tech industrial sectors. We deliver not just parts, but certified dimensional integrity essential for the successful performance of integrated systems, including those interfacing with polymer processing technologies. Partner with Wuxi Lead for metal solutions where tolerance is not a target, but a guaranteed outcome.

Material & Finish Options

Material Selection for Polycarbonate Injection Molding Tooling

Selecting the appropriate tooling material is critical in polycarbonate injection molding, where high precision, thermal stability, and durability directly impact part quality and production efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for high-performance molds, leveraging advanced metallurgy and finishing techniques to meet the demanding requirements of polycarbonate processing. The most commonly used materials for mold construction in this application are aluminum, steel, and titanium, each offering distinct advantages depending on production volume, part complexity, and cost targets.

Aluminum alloys are favored for low- to medium-volume production due to their excellent machinability and thermal conductivity. They allow for faster cooling cycles, reducing overall cycle time and increasing throughput during prototyping or short runs. While softer than steel or titanium, modern high-strength aluminum grades such as 7075-T6 provide sufficient wear resistance for thousands of cycles when properly treated. Aluminum molds are also significantly lighter, simplifying handling and integration into automated systems.

Tool steels, particularly P20, H13, and S136, remain the standard for high-volume polycarbonate molding. These materials offer superior hardness, wear resistance, and dimensional stability under prolonged thermal cycling. P20 steel is commonly used for pre-hardened molds requiring moderate polishability, while H13 excels in applications involving high thermal stress due to its excellent resistance to heat checking. For optical-grade or medical polycarbonate parts requiring mirror finishes, stainless tool steels like S136 are preferred for their corrosion resistance and ability to achieve ultra-smooth surfaces.

Titanium and its alloys are emerging in specialized molding applications where extreme durability and corrosion resistance are paramount. Though more expensive and challenging to machine, titanium molds offer exceptional longevity in aggressive environments and are ideal for highly corrosive additives or flame-retardant polycarbonate formulations. Their high strength-to-density ratio also contributes to long-term dimensional stability.

Surface finishing plays a complementary role in mold performance. Anodizing, particularly hard anodizing, enhances aluminum’s surface hardness and wear resistance, extending mold life significantly. It also improves release characteristics, reducing the need for mold release agents that could contaminate polycarbonate parts. For steel molds, polishing and chrome plating are more common, though anodizing remains exclusive to aluminum substrates.

The following table summarizes key properties of the primary mold materials used in polycarbonate injection molding:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Mold Life (cycles) | Best Use Case |

|---|---|---|---|---|

| Aluminum 7075 | 40–45 | 130 | 10,000 – 50,000 | Prototyping, low-volume runs |

| P20 Steel | 28–32 | 30 | 100,000 – 500,000 | Medium to high-volume production |

| H13 Steel | 48–52 | 36 | 500,000+ | High-heat, high-stress molding |

| S136 Steel | 50–54 | 25 | 1M+ | Optical, medical-grade parts |

| Titanium Grade 5 | 35–40 | 7 | 1M+ | Corrosive or specialty resins |

At Wuxi Lead Precision Machinery, we guide clients through this selection process based on application-specific demands, ensuring optimal balance between performance, cost, and production efficiency.

Manufacturing Process & QC

Polycarbonate Injection Molding: Precision Engineering from Concept to Zero-Defect Production

Achieving flawless polycarbonate components demands a rigorously controlled process, integrating advanced material science with uncompromising precision engineering. At Wuxi Lead Precision Machinery, our Zero Defects philosophy is embedded within every phase, leveraging our core expertise in custom metal manufacturing to ensure mold integrity and process stability from initial concept through high-volume output.

The Design phase transcends basic CAD modeling. Our engineers conduct in-depth material flow analysis specific to polycarbonate’s high viscosity and thermal sensitivity. We meticulously optimize gate locations, runner systems, and cooling channel geometry within the mold cavity – a critical metal component fabricated to micron-level tolerances in our facility. This upfront precision prevents common defects like sink marks, weld lines, or internal stresses, establishing the foundation for dimensional stability and optical clarity. Material selection is validated against application requirements, considering factors like UV resistance, impact strength, and flame ratings, ensuring the chosen polycarbonate grade performs under real-world conditions.

Prototyping utilizes rapid tooling techniques with hardened steel inserts, mirroring production conditions far more accurately than soft tooling. Each prototype undergoes rigorous metrological validation against CAD data using CMM and optical scanning, alongside functional testing for critical properties. This phase is not merely a form check; it is a vital process window qualification. We fine-tune parameters like melt temperature, injection speed profiles, and packing pressure to eliminate cosmetic flaws and ensure mechanical integrity, capturing data essential for seamless scale-up. Defect root cause analysis begins here, preventing recurrence in mass production.

Mass Production executes the validated process within our climate-controlled facility using state-of-the-art all-electric and hybrid hydraulic presses. Real-time monitoring systems track over 20 critical parameters per cycle, including melt temperature consistency, cavity pressure curves, and cooling time. Our proprietary SmartMold™ technology integrates with press controls for instantaneous micro-adjustments, maintaining process stability despite minor material batch variations. Automated vision inspection systems perform 100% surface defect checks, while statistical process control (SPC) ensures dimensional conformity remains within tight tolerance bands. Every component is traceable, linking process data to the final part, enabling immediate corrective action should any parameter drift occur. This closed-loop system, powered by precision-engineered tooling, is the cornerstone of our Zero Defects commitment.

Critical process parameters are meticulously maintained within optimized ranges, as demonstrated below:

| Parameter | Optimal Range (Polycarbonate) | Unit | Critical Impact if Out of Range |

|---|---|---|---|

| Melt Temperature | 280 – 320 | °C | Degradation (yellowing), poor flow |

| Mold Temperature | 80 – 110 | °C | Stresses, poor surface finish, warpage |

| Injection Pressure | 80 – 150 | MPa | Short shots, sink, flash |

| Holding Pressure | 40 – 80 | MPa | Voids, sink, dimensional instability |

| Drying Temperature | 120 – 130 | °C | Moisture bubbles, hydrolysis, weakness |

| Drying Time | ≥ 4 | Hours | Moisture-related defects |

Wuxi Lead’s mastery in precision metal manufacturing directly enables this level of plastic part perfection. Our ability to fabricate and maintain complex, high-precision molds ensures consistent replication of geometry and surface finish, transforming the demanding properties of polycarbonate into reliable, high-performance components meeting the most stringent industrial and medical standards.

Why Choose Wuxi Lead Precision

When it comes to high-performance polycarbonate injection molding, precision, material integrity, and process consistency are non-negotiable. At Wuxi Lead Precision Machinery, we specialize in delivering custom metal manufacturing solutions engineered specifically for the rigorous demands of polycarbonate processing. Our expertise spans mold design, hardened tool steel fabrication, thermal management systems, and automated production integration—all tailored to ensure dimensional accuracy, optical clarity, and long-term durability in every molded component.

Polycarbonate presents unique challenges due to its high melt viscosity, sensitivity to shear stress, and hygroscopic nature. Standard molding practices often result in internal stresses, warpage, or surface defects. That’s where our engineering-driven approach makes the difference. We design molds with optimized gate placement, balanced runner systems, and precise cooling channels to maintain uniform flow and minimize residual stress. Our in-house CNC machining, wire EDM, and surface finishing capabilities ensure micron-level tolerances and mirror-polished cavities essential for optical-grade parts.

We understand that your success depends on reliability, repeatability, and speed to market. That’s why every project at Lead Precision begins with a collaborative design review. Our engineers work directly with your team to analyze part geometry, material selection, and production volume, ensuring the mold architecture aligns perfectly with your performance and cost targets. From prototype development to full-scale production, we maintain strict quality control using CMM inspection, mold flow analysis, and first-article reporting.

Our clients span industries where failure is not an option—medical devices, automotive lighting, aerospace components, and consumer electronics. Whether you require micro-molding for intricate connectors or large-format molds for structural enclosures, our facility is equipped to handle insert molding, overmolding, and multi-cavity configurations with zero compromise on precision.

Partner with Wuxi Lead Precision Machinery and gain more than a supplier—you gain a technical extension of your engineering team. We don’t just build molds; we engineer manufacturing solutions that enhance part quality, reduce cycle times, and extend tool life.

Below are key technical specifications that define our polycarbonate injection molding capabilities:

| Specification | Detail |

|---|---|

| Maximum Clamping Force | 2,500 Tons |

| Shot Weight (Maximum) | 6,000 g |

| Mold Tolerance | ±0.005 mm |

| Surface Finish Options | SPI A1 (Mirror Polish), Texture, EDM Finish |

| Tooling Materials | H13, S136, 2738H, Custom Alloys |

| Cooling System Design | Conformal Cooling, Baffles, Thermal Simulation |

| Production Monitoring | Real-time Data Logging, SPC Integration |

| Secondary Operations | Ultrasonic Welding, Laser Marking, Assembly |

Your next breakthrough in polycarbonate component manufacturing starts with the right partner. Contact us today at [email protected] to schedule a technical consultation. Let Wuxi Lead Precision Machinery bring your most demanding injection molding projects to life—with precision, performance, and proven results.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.