Technical Contents

Engineering Guide: Injection Mold Training

Engineering Insight: Precision as the Non-Negotiable Foundation of Injection Mold Training

In high-stakes injection molding, precision transcends mere specification; it is the absolute determinant of part functionality, production efficiency, and ultimate product success. For B2B manufacturers serving aerospace, medical, and advanced automotive sectors, tolerances measured in microns directly impact safety, regulatory compliance, and brand reputation. A deviation of 0.005mm in a critical mold cavity can cascade into catastrophic part failure, costly scrap, and production line halts. This reality underscores why comprehensive injection mold training must prioritize precision engineering principles above all else. Training cannot be confined to machine operation; it must instill a deep, systemic understanding of how material behavior, thermal dynamics, cavity pressure, and machine kinematics converge to define dimensional accuracy and surface integrity. Without this foundation, even the most advanced molding equipment operates at a fraction of its potential.

Wuxi Lead Precision Machinery embodies this precision imperative through rigorous engineering discipline and real-world validation. Our core competency lies in manufacturing molds where micron-level accuracy is non-negotiable, proven through demanding projects including components for Olympic-standard sporting equipment requiring flawless aerodynamics and structural integrity under extreme stress, and mission-critical defense applications where failure is inconceivable. These engagements demanded adherence to AS9100 aerospace standards and military-grade material certifications, pushing our engineering teams to master the intricate interplay of mold design, material selection, and process control. This hard-won expertise directly informs our approach to injection mold training. We translate complex theoretical principles into actionable, field-tested methodologies, emphasizing predictive tolerance analysis, robust process validation, and real-time correction techniques essential for zero-defect manufacturing.

The tangible outcome of precision-focused training manifests in quantifiable performance metrics. Consider the critical specifications governing high-performance mold manufacturing and operation:

| Specification Category | Standard Requirement | Wuxi Lead Precision Target | Impact on Production |

|---|---|---|---|

| Cavity Dimensional Tolerance | ±0.025mm | ±0.005mm | Reduces part rejection rates by 35-50% |

| Surface Finish (Cavity) | Ra 0.8µm | Ra 0.2µm | Eliminates secondary polishing, cuts cycle time |

| Mold Alignment Tolerance | 0.05mm | 0.01mm | Prevents flash, ensures consistent part geometry |

| Thermal Uniformity | ±5°C | ±1.5°C | Minimizes warpage, improves material consistency |

| Process Capability (Cpk) | Cpk ≥ 1.33 | Cpk ≥ 1.67 | Achieves near-zero defect rates at scale |

This relentless pursuit of precision is not theoretical. It is forged in the crucible of projects where global reputations and human safety depend on flawless execution. When engineers and technicians undergo training grounded in these exacting standards, they gain the foresight to anticipate failure points and the skills to execute processes capable of meeting the most stringent global manufacturing demands. At Wuxi Lead, we equip your team with the precision mindset and technical mastery required to transform injection molding from a production step into a strategic competitive advantage. The cost of imprecision is measured in scrap, delays, and lost trust; the investment in true precision engineering expertise delivers measurable ROI through yield, reliability, and market leadership.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to meet the stringent demands of high-performance injection mold production. Our facility integrates cutting-edge 5 Axis CNC machining systems with comprehensive quality control protocols, ensuring precision, repeatability, and consistency across all components. This advanced infrastructure supports complex geometries, tight tolerances, and superior surface finishes—critical for mold components used in automotive, medical, and consumer electronics industries.

At the core of our manufacturing process is our 5 Axis CNC machining platform. This technology enables continuous machining from multiple angles in a single setup, reducing cycle times and minimizing human error. Unlike conventional 3 Axis systems, 5 Axis CNC allows for undercuts, deep cavities, and contoured surfaces to be machined with exceptional accuracy. The simultaneous movement across five axes ensures optimal tool positioning, enhancing both efficiency and part integrity. Our machines are operated by certified CNC programmers and machinists with extensive experience in mold steel and hardened alloys, including P20, 718H, H13, and S136.

To maintain the highest standards of dimensional accuracy, every component undergoes rigorous inspection using a Coordinate Measuring Machine (CMM). Our CMM system provides full 3D metrology validation, capturing critical data points across complex surfaces and internal features. This non-contact and tactile probing technology ensures that each part conforms precisely to CAD specifications. All inspection reports are documented and archived for full traceability, supporting compliance with ISO 9001 and customer-specific quality requirements.

Our commitment to precision is reflected in the tolerances we consistently achieve across various machining parameters. These specifications are maintained through environmental controls, tool wear monitoring, and real-time process feedback systems. Whether producing core inserts, cavity plates, or ejector systems, Wuxi Lead ensures every component meets or exceeds industry benchmarks.

The following table outlines our standard achievable tolerances under controlled conditions:

| Feature Type | Standard Tolerance | High-Precision Capability | Material Compatibility |

|---|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm | Steel, Stainless, Aluminum |

| Hole Diameter | ±0.01 mm | ±0.003 mm | Hardened Steel, Pre-Hard |

| Positional Accuracy | ±0.008 mm | ±0.005 mm | All mold-grade alloys |

| Surface Flatness | 0.01 mm/m² | 0.005 mm/m² | Cavity Blocks, Base Plates |

| Surface Finish (Ra) | 0.8 μm | 0.2 μm | Mirror Polishing Applications |

These capabilities are further enhanced by in-house heat treatment monitoring and stress-relief cycles, ensuring dimensional stability post-machining. Wuxi Lead Precision Machinery combines technological sophistication with engineering expertise to deliver injection mold components that perform reliably in high-cycle production environments.

Material & Finish Options

Material Selection for High-Performance Injection Molds

Selecting the optimal material for injection molds is critical for achieving dimensional stability, extended service life, and cost efficiency in production. At Wuxi Lead Precision Machinery, our engineering team prioritizes material properties aligned with your specific resin, part geometry, and volume requirements. This foundational choice directly impacts thermal management, wear resistance, and ultimately, part quality consistency. Misalignment here leads to premature mold failure, increased downtime, and compromised surface finishes.

Aluminum alloys, particularly 7075-T6, offer exceptional thermal conductivity and machinability. This makes them ideal for rapid prototyping, low-volume production runs under 10,000 cycles, and molds requiring intricate cooling channels. While cost-effective for initial iterations, aluminum lacks the hardness for abrasive resins or high-volume applications. Its susceptibility to wear necessitates careful resin selection and limits long-term use with glass-filled polymers.

Tool steels remain the industry standard for high-volume production. P20 (1.2311) provides a balanced combination of toughness, polishability, and moderate wear resistance for general-purpose molds exceeding 100,000 cycles. For demanding applications involving corrosive resins or elevated temperatures, H13 (1.2344) hot-work steel is essential. Its superior thermal fatigue resistance and hardenability to 48-52 HRC ensure longevity in molds running engineering plastics like PEEK or nylon 6/6 with high glass content. Pre-hardened steels offer reduced lead times versus fully hardened alternatives.

Titanium alloys present a specialized solution where extreme weight reduction is paramount, such as large mold bases for automotive components. Grade 5 (Ti-6Al-4V) offers excellent strength-to-weight ratio and corrosion resistance. However, its high cost, challenging machinability, and potential for galling during ejection limit widespread adoption. Titanium is typically reserved for niche applications where its specific advantages outweigh significant investment and processing complexities.

Surface finishing, particularly anodizing for aluminum molds, is non-negotiable for performance. Hard anodizing (Type III) creates a dense, wear-resistant aluminum oxide layer typically 25-50μm thick. This significantly enhances surface hardness (up to 60-70 HRC equivalent), reduces galling, improves release properties, and provides crucial corrosion resistance against acidic or hygroscopic resins. Standard decorative anodizing lacks the necessary thickness and hardness for functional mold surfaces. Proper sealing post-anodizing is vital to maximize corrosion protection.

The following table summarizes key material properties and applications for informed decision-making:

| Material | Hardness (HRC) | Typical Use Case | Cost Factor |

|---|---|---|---|

| Aluminum 7075-T6 | 15-20 | Prototyping, Low-volume (<10k cycles) | 0.6 |

| P20 Steel | 28-32 | Medium-volume (100k+ cycles), General use | 1.0 |

| H13 Steel | 48-52 | High-temp resins, High-volume (>500k) | 1.8 |

| Titanium Ti-6Al-4V | 32-36 | Weight-critical applications, Corrosive | 4.0+ |

Material selection is not a one-size-fits-all proposition. Wuxi Lead Precision Machinery leverages decades of mold manufacturing expertise to analyze your specific production demands. We recommend comprehensive consultation with our engineering team to evaluate resin characteristics, cycle expectations, and budget constraints, ensuring the optimal material and finish selection for your injection molding success. Contact us for a detailed technical assessment.

Manufacturing Process & QC

The production process for high-precision injection molds at Wuxi Lead Precision Machinery follows a disciplined, phase-gated approach that ensures zero-defect outcomes across Design, Prototyping, and Mass Production stages. This methodology is engineered to meet the exacting standards of global automotive, medical, and consumer electronics industries, where consistency, repeatability, and precision are non-negotiable.

The process begins with Design, where our engineering team collaborates closely with clients to translate product concepts into manufacturable mold architectures. Utilizing advanced CAD/CAM software—such as Siemens NX, SolidWorks, and Moldflow—we conduct comprehensive mold flow analysis, thermal simulation, and structural integrity checks. This phase includes precise wall thickness optimization, gate positioning, and cooling channel design to prevent warpage, sink marks, and cycle time inefficiencies. All designs are validated through Design for Manufacturing and Assembly (DFMA) principles and undergo rigorous internal review before moving forward.

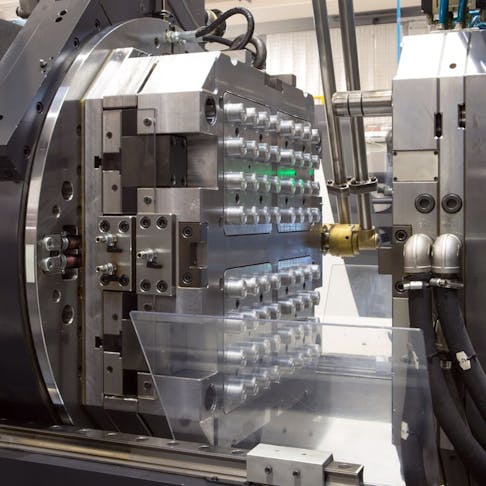

Prototyping follows design finalization, serving as a physical validation step. At Wuxi Lead, we employ high-speed CNC machining, wire EDM, and surface grinding on materials such as P20, H13, and S136 hardened steels to produce functional prototype molds. These prototypes are used to produce initial sample runs under simulated production conditions. Each prototype undergoes dimensional inspection via CMM (Coordinate Measuring Machine), surface finish evaluation, and performance testing for ejection, venting, and cycle stability. Feedback from this stage is systematically integrated to refine mold geometry and process parameters, ensuring readiness for full-scale production.

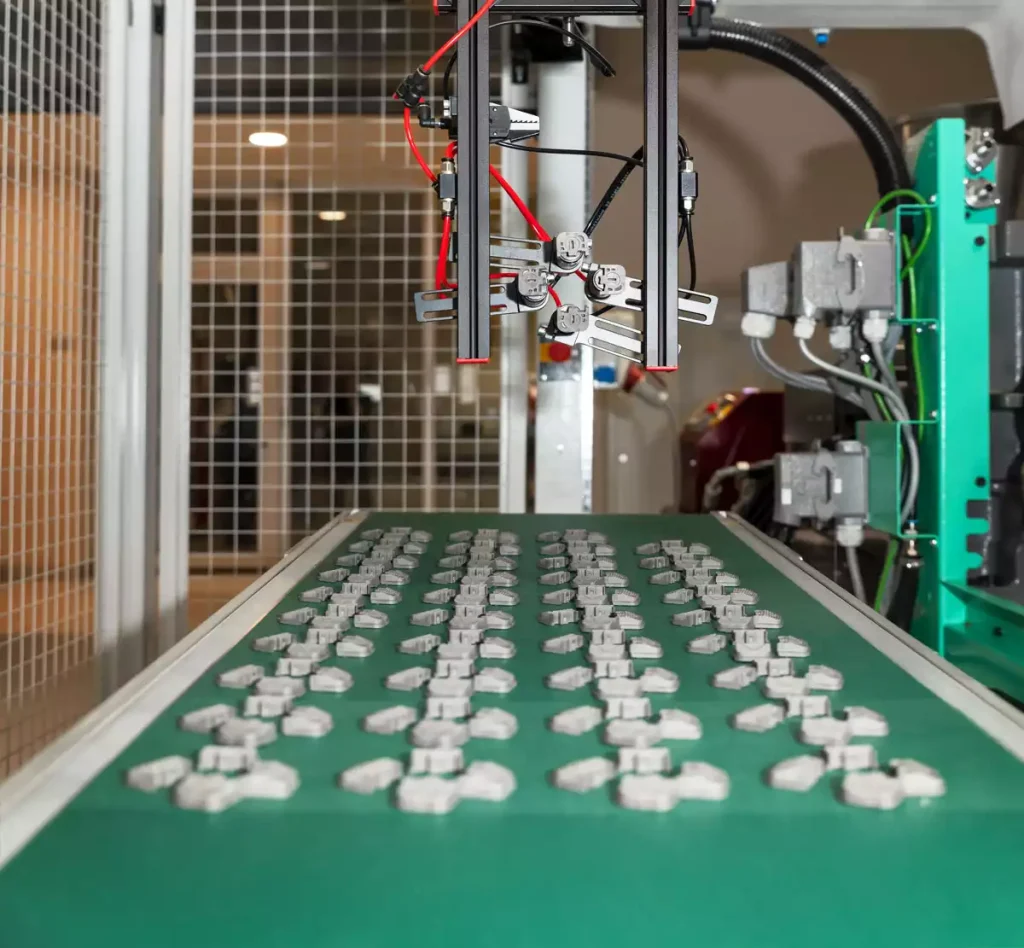

Mass Production is executed on automated, monitored lines with real-time quality control. Our facility uses 80–2,500-ton hydraulic and electric injection molding machines equipped with cavity pressure sensors, mold protection systems, and robotic part handling. Every production cycle is logged, and statistical process control (SPC) monitors key variables including melt temperature, injection speed, and clamping force. In-process inspections occur at defined intervals, supported by first-article inspection reports (FAIR) and production part approval processes (PPAP) compliant with IATF 16949 standards.

To ensure zero defects, Wuxi Lead implements a closed-loop quality system. Any deviation triggers immediate root cause analysis and corrective action. Preventive maintenance schedules, tool wear tracking, and operator certification programs further reinforce process stability.

The table below outlines key process capabilities and tolerances maintained throughout production:

| Parameter | Capability |

|---|---|

| Mold Accuracy | ±0.002 mm |

| Surface Finish | Ra 0.05 µm (mirror polish) to Ra 3.2 µm (textured) |

| Material Compatibility | P20, 718, H13, S136, 2344, 2738, Aluminum 7075 |

| Machine Tonnage Range | 80–2,500 tons |

| Lead Time (Prototype) | 4–6 weeks |

| Lead Time (Production Mold) | 8–12 weeks |

| Production Tolerance | ±0.02 mm (standard), ±0.005 mm (tight) |

| Quality Standards | ISO 9001, IATF 16949, PPAP Level 3 |

This end-to-end control framework enables Wuxi Lead Precision Machinery to deliver injection molds that perform reliably over millions of cycles, with zero compromise on quality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Injection Mold Manufacturing Excellence

Wuxi Lead Precision Machinery stands as your definitive engineering partner for mission-critical injection mold components. We bridge advanced CNC manufacturing with deep industry expertise to solve the precision challenges that stall production and compromise part integrity. Our facility in Wuxi, China, operates under ISO 9001-certified protocols, ensuring every mold base, cavity, core, and ejector system meets the exacting tolerances demanded by aerospace, medical, and automotive sectors. When dimensional stability, surface finish, and thermal management dictate mold longevity, our processes deliver repeatability where others falter.

Why Partner with Lead Precision for Injection Mold Training Support

We engineer partnerships, not transactions. Our technical team collaborates directly with your engineers during training phases to translate theoretical mold design principles into actionable manufacturing insights. We identify potential machining constraints early—such as undercuts, thin walls, or complex cooling channels—and provide optimized solutions before steel is cut. This proactive approach minimizes costly redesigns and accelerates time-to-market. Our facility houses 45+ CNC machining centers, including 5-axis DMG MORI and Makino systems, dedicated solely to mold component production. We prioritize material science understanding, routinely processing P20, H13, S136, and beryllium-copper alloys with thermal stability protocols that prevent warpage during heat treatment.

Technical Capabilities for Injection Mold Fabrication

| Specification | Capability Detail | Relevance to Mold Performance |

|---|---|---|

| Machining Accuracy | ±0.002 mm (0.00008″) over 500 mm | Ensures cavity/core alignment for zero flash |

| Surface Finish | Ra 0.05 µm (mirror polish achievable) | Reduces part ejection force, extends mold life |

| Max Work Envelope | 1,200 x 800 x 650 mm | Accommodates large, multi-cavity molds |

| Lead Time (Typical) | 15-25 days for complex mold sets | Accelerates production validation cycles |

| Material Certification | Full traceability with mill test reports | Guarantees hardness consistency for wear resistance |

Your injection mold training initiative gains tangible value when theoretical knowledge integrates with real-world manufacturing constraints. We provide detailed process documentation—cutting parameters, fixture setups, and inspection reports—that enriches your training curriculum with actionable data. This transparency builds operator confidence in mold maintenance and troubleshooting. Our engineers also conduct virtual or on-site sessions to demonstrate how precision machining choices directly impact cycle times, part quality, and ROI.

Initiate a precision-focused collaboration today. Contact our technical sales team at [email protected] to schedule a dedicated consultation. Specify “Injection Mold Training Inquiry” in your subject line to receive our Mold Fabrication Technical Dossier—a 22-page guide detailing material selection criteria, tolerance stacking analysis, and case studies from medical device mold projects. Let Wuxi Lead Precision Machinery transform your training outcomes through engineered reliability. We respond to all inquiries within 4 business hours.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.