Technical Contents

Engineering Guide: Machining Montreal

Engineering Insight: The Critical Role of Precision in Modern Metal Manufacturing

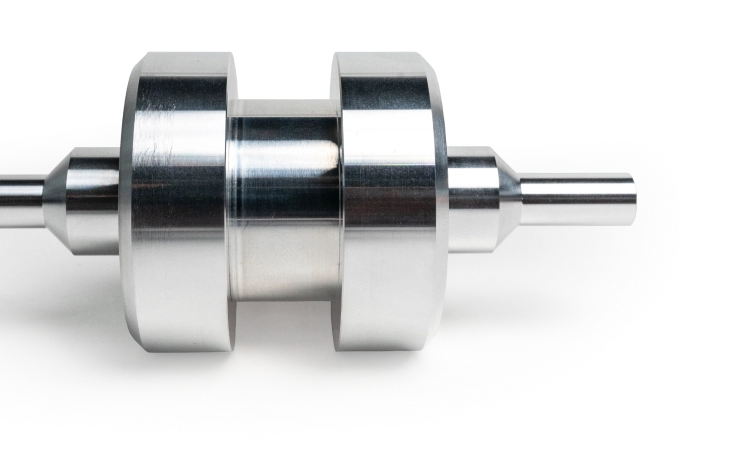

In the world of custom metal manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, safety, and innovation are built. For industries operating at the highest standards—such as aerospace, defense, medical, and advanced automation—micron-level accuracy can determine the success or failure of a mission-critical component. At Wuxi Lead Precision Machinery, we understand that precision engineering transcends machinery and processes; it reflects a culture of excellence honed through decades of delivering components for some of the most demanding applications globally.

Our engineering heritage includes contributions to Olympic-grade equipment and military-grade systems, where failure is not an option. These projects demanded not only the tightest tolerances but also rigorous material integrity, dimensional stability, and repeatable consistency across production runs. The experience gained from such high-stakes environments has shaped our approach: every part we manufacture is treated as mission-critical, regardless of industry.

Precision begins at the design phase. Our engineering team collaborates closely with clients to optimize part geometry, material selection, and manufacturability, ensuring that theoretical designs translate into real-world performance. Utilizing advanced CAD/CAM systems and 5-axis CNC machining platforms, we achieve tolerances as tight as ±0.002 mm. This level of control is sustained through continuous in-process inspection using coordinate measuring machines (CMM) and laser probing systems, enabling real-time adjustments and zero-defect output.

Material science plays an equally vital role. Whether working with titanium alloys for aerospace applications or hardened steels for defense mechanisms, our team applies deep metallurgical knowledge to manage thermal deformation, residual stress, and surface integrity. This ensures that components not only meet dimensional specs but also perform under extreme operational conditions.

The result is a manufacturing process where precision is not an outcome—it is engineered into every step.

Below are key performance specifications achieved across our precision machining operations:

| Specification | Capability |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.2 µm |

| Maximum Work Envelope | 2000 x 1000 x 800 mm |

| Materials Processed | Aluminum Alloys, Stainless Steels, Titanium, Inconel, Tool Steels, Brass |

| CNC Equipment | 5-Axis Machining Centers, High-Speed Milling, Precision Lathes |

| Quality Standards | ISO 9001:2015, Full Inspection Reporting, PPAP Documentation |

At Wuxi Lead Precision Machinery, our experience with Olympic and military-grade projects has instilled a relentless pursuit of perfection. When industries in Montreal and beyond require custom metal components where precision defines performance, we stand ready to deliver engineered excellence—on time, to spec, every time.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery: Advanced Technical Capabilities for Demanding Montreal Applications

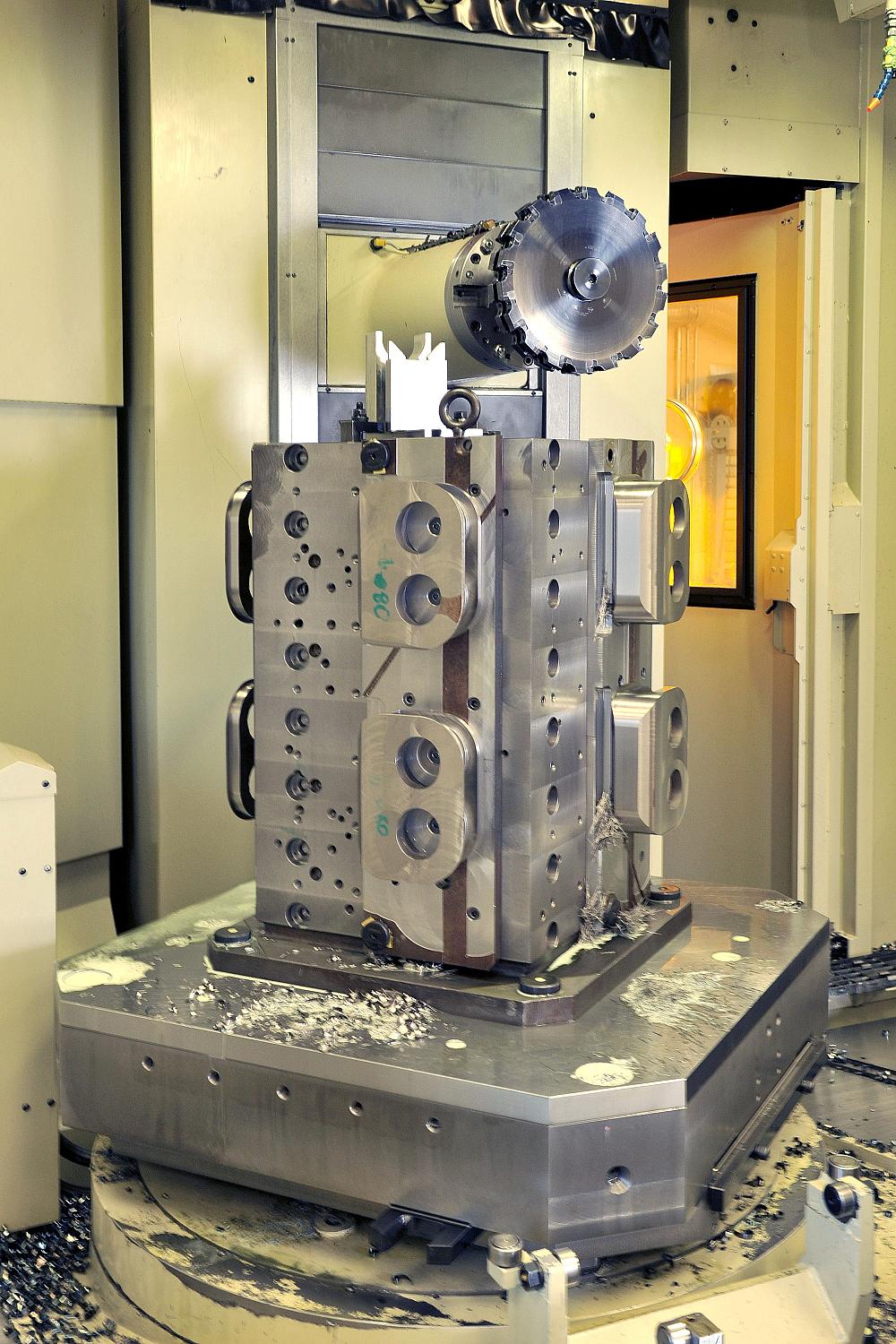

Wuxi Lead Precision Machinery delivers uncompromising precision for Montreal’s high-value manufacturing sectors, including aerospace, medical device, and energy. Our technical foundation rests on German-engineered 5-axis CNC machining centers, specifically configured for complex geometries and stringent tolerances demanded by Montreal’s engineering community. These DMG MORI and Hermle platforms feature sub-micron repeatability, integrated probing, and high-speed spindles capable of maintaining accuracy across extended production runs on challenging materials like Inconel 718, Ti-6Al-4V, and high-performance composites. We eliminate costly secondary operations through single-setup machining of intricate contours, deep cavities, and undercuts, directly addressing Montreal manufacturers’ needs for reduced lead times and enhanced part integrity.

Our commitment to dimensional certainty is enforced through a rigorous, multi-stage quality control protocol centered on Zeiss CONTURA and GLOBAL S coordinate measuring machines (CMM). Every critical feature undergoes 100% inspection against CAD models using calibrated touch probes and optical sensors, generating comprehensive AS9100-compliant inspection reports traceable to NIST standards. This process extends beyond final part verification; in-process gauging on our CNC machines ensures deviations are corrected in real-time, preventing scrap and guaranteeing consistency batch after batch. Material certifications, first-article inspections, and full FAI documentation are standard deliverables, providing Montreal clients with complete supply chain transparency and audit readiness.

The precision achievable across our facility is quantifiable and consistently exceeds typical industry standards. The following table details representative tolerance capabilities for common feature types under controlled production conditions:

| Material Category | Feature Type | Standard Industry Tolerance | Wuxi Lead Precision Capability |

|---|---|---|---|

| Metals (Steel, Al) | Linear Dimension | ±0.025 mm (±0.001″) | ±0.005 mm (±0.0002″) |

| Metals (Steel, Al) | Hole Diameter (Ø10) | ±0.013 mm (±0.0005″) | ±0.003 mm (±0.0001″) |

| Titanium/Inconel | Profile Contour | ±0.050 mm (±0.002″) | ±0.010 mm (±0.0004″) |

| Plastics/Composites | Flatness (100x100mm) | ±0.050 mm (±0.002″) | ±0.015 mm (±0.0006″) |

| All Materials | Positional (Ø) | ±0.025 mm (±0.001″) | ±0.008 mm (±0.0003″) |

This documented capability ensures Montreal design engineers can confidently specify tighter tolerances without incurring prohibitive costs or extended schedules. Our technical team collaborates directly with Montreal clients during the Design for Manufacturability (DFM) phase, providing actionable feedback to optimize part geometry for precision machining while meeting functional requirements. By integrating advanced 5-axis technology with metrology-grade verification, Wuxi Lead provides Montreal manufacturers a reliable offshore partner capable of executing the most demanding precision metal components to exacting specifications. Contact our engineering team to discuss your specific tolerance requirements and receive a detailed capability analysis.

Material & Finish Options

Material Selection for High-Precision Custom Metal Manufacturing

Selecting the appropriate material is a foundational step in custom metal manufacturing, directly influencing performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision CNC machining for demanding industrial applications, and our expertise guides clients toward optimal material choices based on mechanical requirements, environmental exposure, and functional intent. The most widely used materials in our production—aluminum, steel, and titanium—each offer distinct advantages tailored to specific engineering challenges.

Aluminum stands out for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is ideal for aerospace, automotive, and consumer electronics components where weight reduction is critical without sacrificing structural integrity. The most common grade used in precision machining is 6061-T6, known for its weldability and response to heat treatment. When combined with surface finishing such as anodizing, aluminum gains enhanced wear resistance and aesthetic versatility.

Steel, particularly in its stainless and alloy forms, provides superior strength, hardness, and thermal stability. Stainless steel grades like 304 and 17-4 PH are frequently selected for medical devices, industrial machinery, and marine applications due to their resistance to oxidation and ability to withstand high stress. While heavier than aluminum, steel’s durability and cost-effectiveness make it a preferred choice for high-load and high-wear environments.

Titanium, though more challenging to machine, delivers exceptional performance in extreme conditions. Its high strength-to-density ratio, biocompatibility, and resistance to corrosion—even in saline or acidic environments—make it indispensable in aerospace, defense, and medical implant manufacturing. Grade 5 titanium (Ti-6Al-4V) is the most commonly machined alloy, offering an optimal balance of toughness and temperature resistance.

Surface finishing plays a critical role in enhancing material performance. Anodizing, primarily applied to aluminum, is an electrochemical process that thickens the natural oxide layer, significantly improving corrosion and abrasion resistance. Type II (sulfuric acid) anodizing is standard for decorative and protective finishes, while Type III (hardcoat anodizing) provides a denser, thicker layer suitable for industrial components subject to high wear. Anodized surfaces also accept dyes, allowing for color-coding or branding without compromising integrity.

Below is a comparative overview of key mechanical properties for common materials used in precision machining.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Key Applications |

|---|---|---|---|---|

| Aluminum | 310 | 2.7 | 6061-T6, 7075-T6 | Aerospace, Electronics, Automotive |

| Stainless Steel | 515–1300 | 7.9 | 304, 316, 17-4 PH | Medical, Marine, Industrial |

| Titanium | 900–1100 | 4.5 | Ti-6Al-4V (Grade 5) | Aerospace, Defense, Medical |

Material and finish selection must align with both functional demands and production feasibility. At Wuxi Lead, we support clients through this decision process with engineering consultation and prototyping services, ensuring every component meets exacting standards. For precision manufacturing in Montreal and beyond, partnering with a technically capable supplier ensures optimal performance and long-term reliability.

Manufacturing Process & QC

Wuxi Lead Precision Machinery: Zero Defects Production Process for Custom Metal Components

At Wuxi Lead Precision Machinery, our production process for custom metal manufacturing is engineered to deliver uncompromising quality from concept to volume delivery. Serving high-precision industries including aerospace and medical device manufacturing, we integrate rigorous process control at every stage to achieve true Zero Defects outcomes. This methodology ensures Montreal-based partners receive components that meet exacting global standards while minimizing project risk and cost.

The process begins with collaborative Design for Manufacturability (DFM) analysis. Our engineering team reviews client CAD models using Siemens NX software, identifying potential stress points, material inefficiencies, or geometric constraints early. We simulate machining sequences, thermal dynamics, and toolpath optimization to preempt errors before metal is cut. Critical tolerances, surface finishes, and material certifications are validated against AS9100D and ISO 13485 requirements, ensuring designs are both feasible and compliant. This phase reduces downstream revisions by up to 70% compared to conventional workflows.

Prototyping transitions validated designs into physical validation. Using 5-axis CNC machining centers with sub-micron repeatability, we produce functional prototypes in the exact production alloy. Each prototype undergoes comprehensive metrology: CMM inspection verifies dimensional accuracy against nominal CAD data, while surface profilometry confirms finish specifications. Material test reports (MTRs) and hardness validation are provided. Clients receive a full dimensional report with deviation analysis, enabling data-driven sign-off. This iterative stage catches 98% of potential production flaws, eliminating costly errors during scale-up.

Mass production leverages our Zero Defects framework through real-time process control. Every component is manufactured on dedicated cells with automated tool wear compensation and in-process probing. Statistical Process Control (SPC) monitors critical dimensions continuously, triggering immediate corrective action if trends approach tolerance limits. Final inspection employs multi-sensor CMMs, optical comparators, and leak testing where applicable. Crucially, full material traceability—from raw billet heat number to finished part—is digitally recorded, satisfying stringent aerospace and medical audits. This closed-loop system ensures batch-to-batch consistency with a historical defect rate below 50 PPM.

Our process control specifications guarantee precision across all production phases:

| Phase | Tolerance Range | Key Verification Method | Compliance Standard |

|---|---|---|---|

| Design | ±0.005mm simulation | FEA & Machining Simulation | ISO 10303 (STEP) |

| Prototyping | ±0.010mm | CMM + Surface Profilometry | AS9102 Form 1-3 |

| Mass Production | ±0.002mm (critical) | SPC + Multi-Sensor CMM | AS9100D / ISO 13485 |

Wuxi Lead’s integrated approach transforms design intent into flawless physical reality. By embedding quality at each step—from virtual validation through to serialized production—we eliminate rework cycles and ensure Montreal clients receive mission-critical components on time, every time. Partner with us to convert engineering ambition into defect-free deliverables.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

When your business demands precision, reliability, and scalability in custom metal manufacturing, partnering with Wuxi Lead Precision Machinery sets you apart. As a leading manufacturer based in Wuxi, China, we specialize in delivering high-performance CNC machining, milling, turning, and fabrication solutions tailored to the exacting standards of global industries. From aerospace and medical devices to energy and automation, our engineering expertise ensures your components meet the highest benchmarks for quality, consistency, and performance.

At Lead Precision, we understand that every project is unique. That’s why we offer fully customized manufacturing services supported by advanced CNC technology, a rigorous quality control system, and a team of experienced engineers who collaborate with you from prototype to full-scale production. Our ISO 9001-certified facility is equipped with state-of-the-art machinery, enabling us to work with a wide range of materials—including aluminum, stainless steel, titanium, brass, and specialty alloys—delivering tight tolerances down to ±0.005 mm.

We are committed to seamless international collaboration, ensuring that clients in Montreal and across North America receive responsive communication, on-time delivery, and full project transparency. Our logistics network supports efficient shipping with customs documentation handled professionally, minimizing delays and maximizing supply chain reliability. Whether you require low-volume prototypes or high-volume production runs, Lead Precision scales with your needs without compromising precision or lead time.

Our clients choose us not only for technical excellence but for our partnership-driven approach. We invest time to understand your application, design requirements, and performance goals—ensuring the final product performs flawlessly in real-world conditions. With in-house capabilities spanning CNC machining, surface finishing, heat treatment, and assembly, we reduce dependency on third parties and maintain full control over quality and delivery.

Explore how we can support your next manufacturing challenge with precision-engineered solutions built to your exact specifications.

Technical Capabilities Overview

| Specification | Detail |

|---|---|

| Machining Processes | CNC Milling, CNC Turning, 4 & 5-Axis Machining, Wire EDM, Grinding |

| Materials | Aluminum, Stainless Steel, Titanium, Brass, Copper, PEEK, Delrin, Carbon Steel |

| Tolerances | ±0.005 mm (standard), up to ±0.001 mm (precision) |

| Max Work Envelope | 1200 x 800 x 600 mm (5-axis), larger upon request |

| Surface Finishes | As-machined, Anodizing (Type II & III), Powder Coating, Passivation, Polishing, Plating |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP, CMM Reporting |

| Lead Times | Prototypes: 7–10 days; Production: 15–25 days (varies by complexity) |

| Industries Served | Aerospace, Medical, Robotics, Automotive, Industrial Automation, Energy |

Contact us today to discuss your custom manufacturing needs. Send your drawings, specifications, or project inquiries to [email protected] and receive a detailed quote within 24 hours. Let Wuxi Lead Precision Machinery become your trusted partner in precision manufacturing—where engineering excellence meets global reliability.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.