Technical Contents

Engineering Guide: Brass Inserts For Plastic Injection Molding

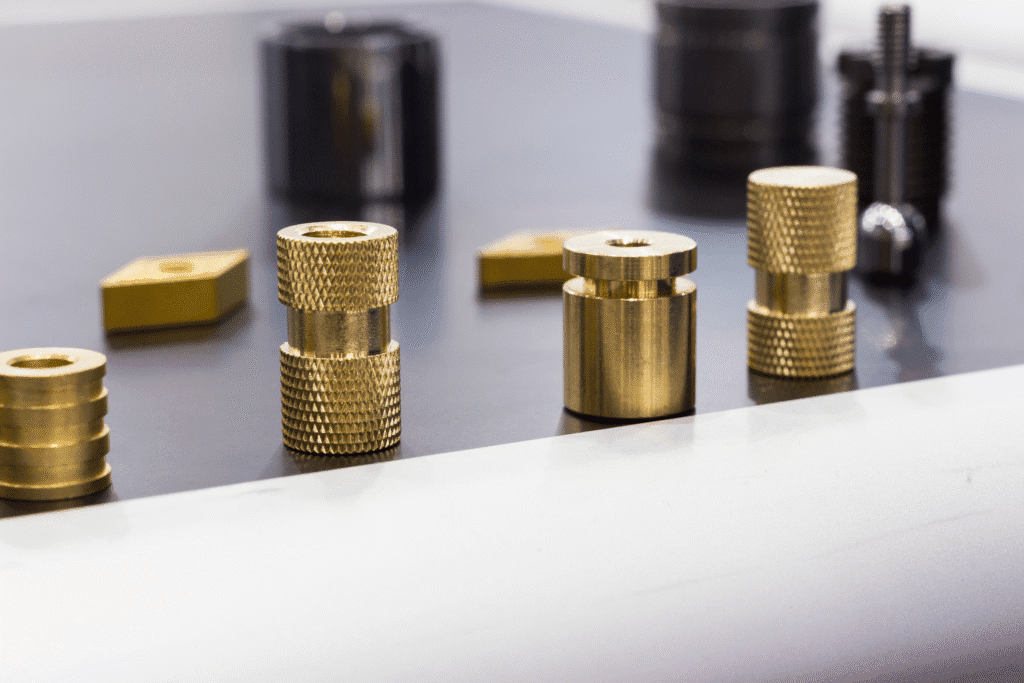

Engineering Insight Precision Brass Inserts for Plastic Injection Molding

Achieving flawless integration of brass inserts within plastic injection molded components demands uncompromising dimensional accuracy. These seemingly small elements serve as critical structural and functional anchors, transferring load, enabling assembly, or providing electrical pathways. Any deviation in thread geometry, outer diameter concentricity, or insertion depth tolerance directly compromises the final product’s integrity, assembly speed, and long-term reliability. Microscopic variations cause thread stripping during fastening, uneven stress distribution leading to plastic cracking under load, or misalignment preventing proper mating of components. In high-cycle applications or safety-critical assemblies, such failures are unacceptable. Precision machining is not merely desirable; it is the non-negotiable foundation for performance.

At Wuxi Lead Precision Machinery, we engineer brass inserts to exacting micro-tolerance standards, recognizing that ±0.02mm deviations translate directly to field failures. Our CNC Swiss-type turning and multi-axis milling processes, coupled with rigorous in-process metrology using coordinate measuring machines (CMMs) and optical comparators, ensure every insert meets the stringent requirements of advanced molding. We control critical parameters including thread pitch diameter consistency, lead-in chamfer geometry for smooth mold insertion, and surface finish to optimize plastic adhesion without causing flash. Material selection—primarily C3604 free-cutting brass for its machinability and strength—is verified to international standards, with optional plating like nickel or tin applied under controlled conditions for corrosion resistance or conductivity.

Our commitment to precision is validated through demanding real-world applications. We supplied mission-critical brass threaded inserts for seating systems within the Beijing National Stadium infrastructure, where thermal cycling and structural loads demanded absolute reliability over decades. Similarly, inserts for military-grade communication equipment housings required zero-defect performance under extreme vibration and environmental exposure, meeting stringent MIL-STD specifications. These projects underscore our capability to deliver components where failure is not an option.

The following table outlines key precision parameters we consistently achieve for custom brass inserts:

| Parameter | Typical Capability | Critical Impact |

|---|---|---|

| Thread Pitch Diameter | ±0.01 mm | Ensures proper torque-tension, prevents stripping |

| Outer Diameter Tolerance | ±0.015 mm | Controls press-fit force, prevents mold damage |

| Concentricity (OD to ID) | ≤ 0.02 mm | Eliminates uneven stress in plastic matrix |

| Insertion Depth Tolerance | ±0.05 mm | Guarantees consistent thread engagement |

| Surface Roughness (Ra) | 0.8 µm max | Optimizes plastic adhesion, minimizes flash |

| Plating Thickness | ±2 µm | Ensures corrosion protection without fit issues |

Precision brass inserts are the silent enablers of complex molded assemblies. Wuxi Lead Precision Machinery leverages decades of advanced CNC expertise and proven success in Olympic and defense-tier projects to deliver inserts that perform flawlessly within the most challenging injection molding processes. We partner with engineers to transform design intent into reliable, high-performance reality—where every micron matters. Contact our engineering team to discuss your specific application requirements and tolerance-critical challenges.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in the production of brass inserts for plastic injection molding, leveraging state-of-the-art infrastructure and precision engineering to meet the stringent demands of high-performance applications. Our specialization in custom metal manufacturing enables us to produce complex brass insert geometries with exceptional accuracy, consistency, and material integrity. Central to our manufacturing excellence is our investment in 5-axis CNC machining technology, which allows for simultaneous multi-directional cutting and the ability to machine intricate features in a single setup. This minimizes human intervention, reduces cumulative tolerances, and significantly enhances part repeatability—critical factors when producing inserts that must integrate seamlessly into injection-molded plastic components.

Our 5-axis CNC machining centers are operated by experienced engineers who utilize advanced CAM software to optimize toolpaths, manage material removal rates, and ensure surface finish consistency. This digital integration enables us to handle small batch prototypes as well as high-volume production runs with equal precision. Materials are carefully selected based on application requirements, with common choices including high-strength brass alloys such as C3604 and C38500, known for their excellent machinability, corrosion resistance, and thermal conductivity. Each brass insert is machined to exact client specifications, accommodating features such as knurls, undercuts, threading, and precision chamfers that promote strong mechanical bonding within the plastic housing.

Quality assurance is embedded throughout our production workflow. Every batch undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM), ensuring dimensional compliance with design intent. Our CMM systems are calibrated to international standards and capable of verifying complex geometries with micron-level accuracy. In addition to dimensional checks, we perform material verification, surface finish analysis, and visual inspections to eliminate defects. This systematic approach to quality control ensures that every brass insert meets or exceeds industry standards for fit, function, and durability.

The following table outlines the typical technical specifications achievable for brass inserts produced at Wuxi Lead Precision Machinery:

| Parameter | Specification |

|---|---|

| Machining Process | 5-Axis CNC Milling and Turning |

| Typical Materials | C3604, C38500, CZ121, Custom Brass Alloys |

| Dimensional Tolerance | ±0.005 mm (standard), down to ±0.002 mm (tight-tolerance) |

| Positional Tolerance | ±0.01 mm |

| Surface Roughness (Ra) | 0.4 μm to 1.6 μm (adjustable per requirement) |

| Minimum Feature Size | 0.3 mm (e.g., slot width, thread pitch) |

| Maximum Part Size | Ø150 mm × 100 mm height |

| Inspection Equipment | Zeiss DuraMax CMM, Optical Comparators, Micrometers, Ring Gauges |

| Lead Time (Prototype) | 7–12 days |

| Lead Time (Production) | 15–25 days, scalable |

Our technical capabilities are designed to support industries such as automotive, medical devices, consumer electronics, and industrial automation—where reliability and precision are non-negotiable. By combining advanced machinery, rigorous quality control, and engineering expertise, Wuxi Lead Precision Machinery ensures that every brass insert performs reliably in its intended injection molding application.

Material & Finish Options

Material Selection for Brass Threaded Inserts in Injection Molding

Selecting the optimal material for brass threaded inserts is critical for mold longevity, part integrity, and production efficiency. The insert must withstand high cyclic loads, thermal stress from the molten polymer, and maintain precise dimensional stability during ejection. While brass forms the core threaded component, the housing or carrier material significantly impacts performance. Aluminum, steel, and titanium each offer distinct advantages and limitations based on application demands. Understanding these differences prevents premature insert failure, reduces downtime, and ensures consistent part quality in high-volume production.

Aluminum alloys, particularly 6061-T6 and 7075-T6, provide an excellent strength-to-weight ratio and superior thermal conductivity. This facilitates faster heat dissipation from the insert interface, minimizing thermal distortion in the surrounding plastic part. Aluminum is ideal for prototypes, low-to-medium volume production, and applications where weight reduction is paramount. However, its lower hardness compared to steel makes it less suitable for high-cycle molds exceeding 500,000 shots or abrasive engineering plastics, as wear on the insert seat can lead to flash or part ejection issues.

Steel, especially hardened tool steels like H13 or P20, delivers exceptional wear resistance and compressive strength. This makes it the standard choice for high-volume, high-pressure molding cycles, often exceeding 1 million shots. Steel maintains dimensional stability under extreme thermal cycling and resists deformation when molding glass-filled or mineral-reinforced polymers. The trade-off is higher weight and lower thermal conductivity than aluminum, potentially requiring longer cooling cycles. Proper surface treatment is essential to prevent galling during insert installation and part ejection.

Titanium alloys, primarily Ti-6Al-4V, offer a unique combination of high strength, exceptional corrosion resistance, and a very low coefficient of thermal expansion. While significantly more expensive, titanium is reserved for highly specialized applications involving aggressive chemical environments or extreme thermal stability requirements where even minute dimensional shifts are unacceptable. Its use in standard brass insert housings is uncommon due to cost and machining complexity, but it solves critical failure modes in niche aerospace or medical molding.

Anodizing is the predominant surface finish for aluminum insert housings. This electrochemical process creates a hard, wear-resistant oxide layer that significantly improves surface hardness and corrosion resistance. Type II (sulfuric acid) anodizing provides good general protection, while harder Type III (hardcoat) anodizing is essential for high-wear zones. Anodizing also allows for color coding for identification. Crucially, it prevents galvanic corrosion between the aluminum housing and the brass insert or steel mold base. Steel housings typically utilize nitriding, chrome plating, or PVD coatings for similar wear and corrosion protection objectives.

Material properties directly dictate insert performance. Key specifications are summarized below.

| Material | Tensile Strength (MPa) | Hardness (HRC) | CTE (10⁻⁶/°C) | Key Applications |

|---|---|---|---|---|

| Aluminum 6061 | 310 | 15 | 23.0 | Prototypes, low/medium volume, weight-sensitive |

| Steel H13 | 1650 | 48 | 10.8 | High-volume, abrasive plastics, high pressure |

| Titanium Ti-64 | 950 | 36 | 8.6 | Extreme corrosion, ultra-stable thermal environments |

Material selection must align precisely with your molding parameters, polymer type, and production volume. Wuxi Lead Precision Machinery leverages advanced CNC machining and stringent metrology to ensure inserts meet exact dimensional and material specifications, guaranteeing seamless integration and maximum service life within your mold system. Consult our engineering team for application-specific validation.

Manufacturing Process & QC

Design: Precision Engineering for Optimal Integration

The foundation of flawless brass insert integration into plastic injection molding begins with precision-driven design. At Wuxi Lead Precision Machinery, our engineering team collaborates closely with clients to analyze the functional requirements, load conditions, thermal exposure, and mating components of the final assembly. Utilizing advanced 3D CAD software and finite element analysis (FEA), we simulate stress distribution, thermal expansion, and insert retention to ensure mechanical integrity. Thread profiles, knurling geometry, and overall dimensions are optimized for both the molding process and end-use performance. Special attention is given to draft angles, wall thickness transitions, and interference fits to prevent stress concentration and ensure reliable overmolding. Design for manufacturability (DFM) reviews are conducted to preempt potential defects such as sink marks, warpage, or insert misalignment, ensuring seamless compatibility with the client’s injection molding parameters.

Prototyping: Validation Before Scale

Once the design is finalized, we proceed to rapid prototyping using high-precision CNC turning and micro-machining techniques. These prototypes are manufactured from the same brass alloy—typically C3604 or C3771—as the final production inserts, ensuring material consistency. Each prototype undergoes rigorous metrological inspection using coordinate measuring machines (CMM) and optical comparators to verify dimensional accuracy within ±0.005 mm. We then support mold trials with our clients, inserting prototypes into actual molding tools to evaluate performance under real processing conditions. This phase validates insert placement, bonding strength, and ejection behavior. Any necessary design refinements are implemented swiftly, minimizing downstream risk. The prototyping stage is critical to our zero-defect philosophy, serving as a functional checkpoint before committing to full-scale production.

Mass Production: Consistency Through Automation and Control

With design and fitment confirmed, we transition to high-volume manufacturing under a fully controlled production environment. Our automated CNC Swiss lathes and multi-spindle machines operate with tight process parameters, monitored in real time via SPC (Statistical Process Control). Each batch is produced under ISO 9001-certified workflows, with 100% in-process inspections at critical stages. Final inserts are subjected to comprehensive quality checks including thread gauging, visual inspection under magnification, and adhesion testing post-molding simulation. Cleanliness is strictly maintained to avoid contamination, with ultrasonic cleaning and anti-corrosion packaging applied as required. Traceability is ensured through batch coding and material certifications.

The following table outlines key specifications and tolerances achievable in our production process:

| Parameter | Typical Value / Tolerance | Material Options | Surface Finish (Ra) |

|---|---|---|---|

| Diameter Range | 2 mm – 25 mm | C3604, C3771, H59 | 0.8 – 3.2 µm |

| Length Tolerance | ±0.05 mm | Lead-free on request | As per drawing |

| Thread Accuracy | 6g (metric), 2A (imperial) | Custom alloys available | – |

| Knurling Pitch | 0.5 mm – 1.5 mm (straight/diag) | – | – |

| Production Capacity | Up to 500,000 pcs/month | – | – |

| Quality Standard | ISO 9001:2015, 100% inspection | – | – |

Through this disciplined progression—from intelligent design to validated prototyping and tightly controlled mass production—Wuxi Lead ensures brass inserts that deliver zero-defect performance in even the most demanding injection molding applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Brass Insert Solutions

Precision brass inserts are non-negotiable components in high-performance plastic injection molding applications. Failures due to poor thread integrity, dimensional inaccuracy, or material incompatibility lead directly to costly production downtime, rejected parts, and compromised product lifespan. Generic off-the-shelf inserts rarely meet the stringent demands of aerospace, medical device, or automotive sectors where thermal stability, corrosion resistance, and absolute mechanical reliability are paramount. Wuxi Lead Precision Machinery exists to eliminate these risks through engineered-to-order brass insert manufacturing.

We operate at the intersection of advanced CNC machining expertise and deep material science understanding. Our dedicated production lines utilize state-of-the-art Swiss-type lathes and multi-axis milling centers, all operating under strict ISO 9001:2015 protocols. This ensures every brass insert achieves micron-level tolerances consistently, batch after batch. We specialize in complex geometries including custom thread profiles, precision knurls, undercuts, and flange designs tailored to your specific molding process parameters and plastic resin characteristics. Material selection is critical; we rigorously source high-quality free-machining brass alloys like C36000 and C37700, verified for optimal zinc content and grain structure to prevent galling and ensure seamless integration within the polymer matrix during the injection cycle.

Our engineering collaboration starts at the design phase. We review your CAD models and molding data to proactively identify potential stress points, ejection challenges, or thermal mismatch issues. This upstream engagement prevents costly redesigns and tooling modifications later. Rigorous in-process inspection using calibrated CMMs, optical comparators, and thread gauges guarantees conformance before shipment. We understand that lead time predictability is as vital as quality for your production scheduling. Our streamlined workflow and dedicated project management deliver complex custom inserts with remarkable consistency.

Critical Brass Insert Specifications We Guarantee

| Parameter | Standard Capability | Precision Capability | Material Options |

|---|---|---|---|

| Thread Standards | M, UNC, UNF, NPT, PG | Custom profiles | C36000, C37700, CZ121 |

| Outer Diameter | 1.0 mm – 25.0 mm | ±0.005 mm tolerance | Lead-free variants |

| Length | 1.5 mm – 50.0 mm | ±0.01 mm tolerance | Custom alloys |

| Thread Accuracy | 6g/6H | 4g/4H (precision) | Verified chemistry |

| Surface Finish | Ra 0.8 µm standard | Ra 0.4 µm achievable | Nickel, Tin plating |

| Knurl Patterns | Standard diamond/side | Custom pitch/depth | Passivated options |

Do not compromise your molding integrity or final product performance with substandard inserts. Partner with Wuxi Lead Precision Machinery for brass components engineered for zero-failure operation in the most demanding environments. Our technical team is prepared to analyze your specific application requirements, provide actionable design for manufacturability feedback, and establish a reliable supply chain for your critical components. Contact us today to discuss your project timeline, material specifications, and precision requirements. Initiate the conversation that secures your production quality and efficiency.

Email [email protected] with your design files and molding parameters to receive a detailed engineering assessment and quotation within 24 business hours. Let Lead Precision become your trusted partner for uncompromising brass insert performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.