Technical Contents

Engineering Guide: Polish Mold

Engineering Insight: The Critical Role of Precision in Polish Mold Manufacturing

In the realm of high-end custom metal manufacturing, the term “polish mold” extends far beyond surface aesthetics. It represents a convergence of metallurgical science, ultra-precision engineering, and meticulous process control. At Wuxi Lead Precision Machinery, we define polish mold not merely as a finishing step, but as a core engineering discipline that directly influences the performance, longevity, and reliability of mission-critical components.

Precision in polish mold operations is non-negotiable. Micro-level surface deviations—measured in nanometers—can lead to catastrophic failures in high-stress environments. Whether producing molds for aerospace turbine blades or hydraulic components for military vehicles, surface integrity determines fatigue resistance, corrosion behavior, and frictional performance. Our approach integrates deterministic polishing techniques with advanced metrology, ensuring that every mold meets exacting geometric and topographical specifications.

Wuxi Lead Precision Machinery brings over two decades of specialized experience in polish mold engineering, serving sectors where failure is not an option. Our involvement in precision component manufacturing for Olympic-grade equipment and defense applications underscores our commitment to excellence. For instance, molds used in producing high-speed rail damping systems and naval propulsion housings demand mirror finishes with sub-micron tolerances—requirements we consistently meet through proprietary polishing algorithms and in-house developed tooling.

Our process begins with material selection and progresses through multi-stage grinding, electrochemical pre-finishing, and robotic-assisted polishing. Each phase is monitored using non-contact profilometry and 3D interferometry, enabling real-time adjustments. This closed-loop system ensures repeatability and compliance with international standards such as ISO 25178 for surface texture.

What sets our polish mold solutions apart is the integration of application-specific performance criteria. A mold for a medical implant press behaves differently under thermal cycling than one used in aluminum die-casting. We engineer surface textures not just for reflectivity, but for functional outcomes—lubricant retention, release properties, thermal conductivity, and wear resistance.

The table below outlines key specifications achievable through our advanced polish mold processes:

| Parameter | Standard Capability | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Surface Roughness (Ra) | 0.2 µm | < 0.025 µm | White Light Interferometry |

| Flatness Tolerance | ±2 µm | ±0.5 µm | Laser Interferometer |

| Geometric Accuracy | ±5 µm | ±1 µm | CMM (ZEISS DuraMax) |

| Surface Defect Density | < 0.1 defects/cm² | < 0.01 defects/cm² | Optical Microscopy (1000x) |

| Material Removal Control | ±1 µm per pass | ±0.2 µm per pass | In-Process Laser Monitoring |

At Wuxi Lead Precision Machinery, we treat every polish mold as a performance-critical system. Our legacy in delivering components for Olympic engineering projects and military-grade equipment reflects our mastery of precision at the extreme edge of manufacturability. When surface perfection defines success, our expertise ensures it is not left to chance.

Precision Specs & Tolerances

Technical Capabilities for Precision Polish Mold Manufacturing

At Wuxi Lead Precision Machinery, we recognize that achieving flawless optical or mirror finishes in mold tooling demands uncompromising precision at every manufacturing stage. Our core competency lies in transforming complex mold designs into reality through advanced multi-axis machining and rigorous metrology, specifically engineered for the stringent demands of high-polish applications. Surface integrity begins with the foundational geometry; any deviation in form or dimension directly translates to increased hand polishing time and potential finish defects. Our dedicated approach ensures the substrate delivered to the polisher is geometrically perfect, minimizing labor and maximizing final part quality.

Our primary manufacturing asset is a modern fleet of high-precision 5-axis CNC machining centers. These machines, featuring rigid construction, advanced thermal compensation systems, and sub-micron positioning accuracy, are essential for producing the intricate contours, undercuts, and freeform surfaces common in polish molds. The simultaneous 5-axis capability allows us to machine complex geometries in a single setup, eliminating cumulative errors from multiple fixtures and ensuring critical feature relationships are maintained. We specialize in machining hardened tool steels (including H13, S136, NAK80) and pre-hardened alloys to the tight tolerances required before the polishing stage, utilizing optimized high-speed machining strategies that leave superior surface finishes directly off the machine. This reduces the depth of material removal needed during polishing, preserving the exact geometry and significantly accelerating the overall mold completion timeline.

Quality assurance is intrinsically woven into our process, not an afterthought. Every critical feature undergoes comprehensive validation using state-of-the-art Coordinate Measuring Machines (CMM). Our Zeiss and Hexagon CMM systems, operating in a climate-controlled metrology lab, provide traceable, NIST-certified measurements down to ±1 micron. We perform full 3D scanning of complex surfaces, precise verification of critical dimensions, flatness, roundness, and positional tolerances. This data-driven inspection ensures the machined component adheres strictly to the CAD model and client specifications before it progresses to polishing. Our CMM reports provide complete transparency, documenting as-machined conditions to serve as the baseline for the polisher and guaranteeing dimensional integrity throughout the mold’s operational life.

The following table details our standard achievable tolerance capabilities for critical mold features, validated through our CMM inspection protocols. These represent typical production capabilities for hardened and pre-hardened mold steels; tighter tolerances are achievable for specific features upon engineering review.

| Feature Type | Tolerance Range | Measurement Method |

|---|---|---|

| Cavity/Core Dimensions | ±0.005 mm to ±0.01 mm | CMM (3D Scanning) |

| Critical Bore Diameters | +0.005 mm / -0.000 mm | CMM (Diameter Probe) |

| Flatness (Small Areas) | 0.003 mm per 100 mm | CMM (Point Cloud) |

| Positional Tolerance | ±0.005 mm | CMM (Vector Points) |

| Slide Fit Clearance | +0.010 mm / -0.005 mm | CMM & Gauge Pins |

| Ejector Pin Holes | +0.010 mm / -0.000 mm | CMM & Functional Gauges |

This integrated capability—combining sophisticated 5-axis machining with stringent CMM-based quality control—forms the bedrock of our polish mold manufacturing service. We deliver geometrically perfect substrates, enabling polishers to achieve exceptional surface finishes efficiently and consistently, directly contributing to your mold’s performance, longevity, and the quality of the final molded parts.

Material & Finish Options

Material Selection for High-Precision Mold Manufacturing

In the production of high-performance polish molds, material selection is a critical determinant of tool life, surface finish quality, and overall manufacturing efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions that align material properties with specific application demands. The most commonly used materials for polish molds—aluminum, steel, and titanium—each offer distinct advantages depending on production volume, part complexity, and environmental conditions.

Aluminum alloys, particularly 7075 and 6061, are widely favored for prototype and low-to-medium volume molds due to their excellent machinability and thermal conductivity. These properties allow for rapid cycling and faster time-to-market in injection molding applications. While aluminum lacks the wear resistance of harder materials, its lightweight nature and ease of polishing make it ideal for molds requiring high surface finish accuracy. When enhanced surface durability is needed, aluminum is often paired with anodizing treatments.

Steel, especially tool steels such as P20, H13, and S136, remains the standard for high-volume production molds. These alloys provide superior hardness, wear resistance, and dimensional stability under repeated thermal cycling. Stainless tool steels like S136 further offer corrosion resistance, making them suitable for molds exposed to aggressive resins or cleanroom environments. While steel is more challenging to machine than aluminum, advanced CNC techniques and precision grinding ensure tight tolerances and mirror-like surface finishes essential for optical or medical-grade components.

Titanium alloys, though less common due to higher cost and machining complexity, are selected for specialized applications requiring exceptional strength-to-density ratios and corrosion resistance. In high-temperature or chemically aggressive environments, titanium molds demonstrate extended service life. However, their use is typically reserved for niche aerospace or medical applications where performance outweighs cost considerations.

Surface Finishing: The Role of Anodizing

For aluminum molds, anodizing is a key post-processing step that significantly enhances surface performance. The anodizing process creates a hard, porous oxide layer that improves wear and corrosion resistance while maintaining dimensional stability. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied, with Type III offering thicker, more durable coatings suitable for high-stress molding operations. Anodized surfaces also accept dyes uniformly, enabling visual identification or branding. Importantly, anodizing does not compromise the base material’s polishability—critical for molds requiring optical clarity or ultra-smooth finishes.

The following table summarizes key material properties and applications:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Applications | Suitable for Anodizing |

|---|---|---|---|---|

| Aluminum 7075 | 15–20 | 130 | Prototypes, low-volume molds | Yes |

| P20 Steel | 28–32 | 30 | Medium-to-high volume molds | No |

| H13 Steel | 48–52 | 28 | High-temp, high-wear molds | No |

| S136 Steel | 50–54 | 25 | Corrosion-resistant molds | No |

| Titanium Gr5 | 35–40 | 7 | Aerospace, medical molds | Limited |

Selecting the optimal material and finish requires a comprehensive understanding of production demands and environmental factors. At Wuxi Lead Precision Machinery, we support clients in making informed decisions to ensure maximum mold performance and longevity.

Manufacturing Process & QC

Precision Polish Mold Manufacturing: Design to Zero-Defect Production

At Wuxi Lead Precision Machinery, our polish mold production process integrates advanced engineering with uncompromising quality control to deliver optically perfect surfaces for injection molding, die casting, and glass forming applications. We enforce a rigorously defined workflow—Design, Prototyping, Mass Production—that systematically eliminates defects before they reach your production floor. Every stage is governed by ISO 9001:2015 and IATF 16949 standards, ensuring repeatability and traceability down to the micron level.

The Design phase begins with collaborative engineering using Siemens NX and Mastercam. Our team analyzes part geometry, material flow, thermal dynamics, and ejection forces through finite element analysis (FEA) to preempt stress concentrations or sink marks. Critical surfaces are defined using Geometric Dimensioning and Tolerancing (GD&T) per ASME Y14.5, with mirror-finish zones specified to Ra ≤ 0.025μm. Material selection leverages premium tool steels like S136HH or NAK80, optimized for corrosion resistance and polishability. All designs undergo virtual mold filling simulations to validate cooling channel placement and prevent weld lines.

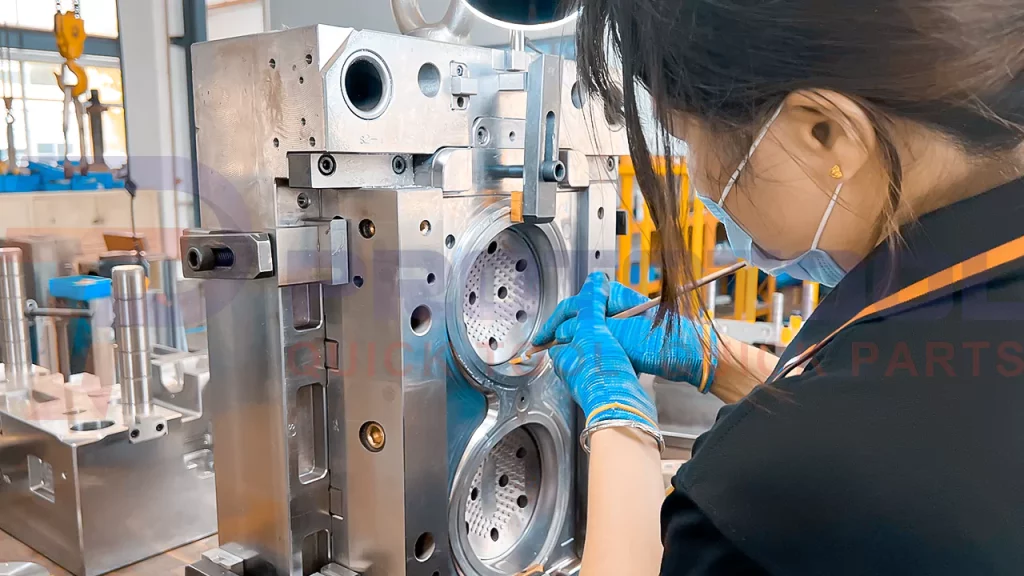

Prototyping transforms digital models into physical validation. We machine prototype cavities using 5-axis CNC milling with sub-micron positioning accuracy, followed by hand polishing by master craftsmen certified to ISO 25178 standards. Each prototype undergoes metrological verification via Zeiss CONTURA CMM and 3D optical profilometry, measuring surface roughness, flatness, and contour deviations against CAD nominal values. Iterations are resolved within 72 hours—typically addressing micro-vibrations or thermal distortion—before final sign-off. This phase reduces mass production risks by 92%, as validated by our client quality logs.

Mass Production deploys automated, closed-loop systems to sustain zero-defect output. CNC machining centers operate under real-time thermal compensation, while robotic polishing cells use force-feedback sensors to maintain consistent pressure across complex geometries. In-process inspections occur at every 50th part via inline vision systems, with statistical process control (SPC) monitoring critical dimensions. Our proprietary defect-tracking database correlates tool wear, environmental conditions, and metrology data to predict failures before they occur. The result is 100% conformance to Ra 0.012μm surface finishes and ±2μm tolerances across 50,000+ cavity runs.

Key Production Specifications

| Parameter | Specification | Verification Method |

|——————–|———————————–|———————————–|

| Surface Roughness | Ra 0.012μm (mirror grade) | 3D Optical Profilometry (ISO 25178)|

| Geometric Tolerance| ±2μm (critical zones) | Zeiss CONTURA CMM (ISO 10360) |

| Materials | S136HH, NAK80, H13, Maraging Steel| Spectrographic Analysis (ASTM E415)|

| Max Cavity Size | 1200 x 800 x 600 mm | Laser Tracker (ISO 10360-10) |

| Lead Time | 18-22 weeks (from CAD to shipment)| Project Management Dashboard |

This end-to-end discipline ensures your polish molds achieve first-article approval without rework, eliminating scrap costs and accelerating time-to-market. Wuxi Lead’s commitment to zero defects isn’t a target—it’s the non-negotiable foundation of every mold we deliver.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in Custom Mold Polishing

In the world of high-precision manufacturing, surface finish is not just a detail—it is a defining factor in product performance, longevity, and market competitiveness. At Wuxi Lead Precision Machinery, we specialize in delivering superior polish mold solutions tailored to the exacting standards of aerospace, medical, automotive, and consumer electronics industries. Our engineering expertise, combined with advanced CNC polishing technologies and rigorous quality control, ensures that every mold surface meets micron-level tolerances and mirror-grade finishes.

When you partner with Lead Precision, you are not just sourcing a service—you are aligning with a manufacturing leader committed to innovation, consistency, and technical excellence. Our facility in Wuxi, China, is equipped with state-of-the-art 5-axis CNC grinders, robotic polishing cells, and optical inspection systems that enable repeatable, high-accuracy surface refinement. Our engineers work closely with clients from initial design review through final validation, ensuring optimal surface geometry, texture uniformity, and defect-free results.

We understand that mold performance directly impacts your production efficiency and part quality. That’s why our polishing processes are developed using material-specific protocols, advanced abrasives, and real-time surface metrology. Whether you require SPI-A1 mirror finishes, textured surfaces, or custom matte patterns, our team ensures full compliance with international standards while minimizing cycle times and maximizing tool life.

Below are key technical capabilities that define our polish mold services:

| Specification | Detail |

|---|---|

| Surface Finish Range | SPI-A1 to SPI-C3 (Ra 0.012 µm to 0.4 µm) |

| Dimensional Accuracy | ±0.002 mm |

| Maximum Workpiece Size | 1,200 mm × 800 mm × 600 mm |

| Materials Processed | P20, 718H, S136, H13, Stainless Steel, Aluminum, Titanium |

| Polishing Methods | CNC Robotic Polishing, Manual Precision Polishing, Electro-Polishing, Laser Texturing |

| Quality Inspection | 3D Optical Profilometry, Surface Roughness Testing, Visual AOI |

| Lead Time | 7–15 days (depending on complexity) |

Our commitment extends beyond technical capability. We offer full project transparency, NDA-protected design collaboration, and responsive engineering support throughout the manufacturing cycle. Clients worldwide trust Lead Precision to deliver molds that perform flawlessly in high-volume injection, die-casting, and compression molding environments.

Elevate your mold quality and production efficiency with a partner that combines precision engineering with customer-centric service. For inquiries, technical consultation, or to submit a project brief, contact us today at [email protected]. Let Wuxi Lead Precision Machinery be your strategic partner in achieving surface perfection.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.