Technical Contents

Engineering Guide: Sheet Metal Material Types

Engineering Insight Sheet Metal Material Types Precision as the Core Differentiator

Material selection in sheet metal fabrication transcends basic mechanical properties; it is the foundational decision dictating precision outcomes, long-term performance, and total project value. At Wuxi Lead Precision Machinery, we understand that the optimal material choice directly impacts dimensional stability during complex CNC forming, laser cutting accuracy, and the final component’s ability to meet stringent functional tolerances. Generic material specifications are insufficient for high-stakes applications. True precision engineering demands a deep understanding of how specific alloys behave under thermal stress, during multi-axis machining, and within the final operational environment. This expertise is non-negotiable when fabricating components for sectors where failure is not an option.

Our decades of experience delivering mission-critical components for Olympic infrastructure projects and demanding military applications have rigorously tested this principle. The structural frameworks of Olympic venues required materials with exceptional thermal expansion characteristics to maintain precise alignment under intense sunlight and varying weather, demanding tolerances held to within microns over vast spans. Similarly, defense applications necessitate materials that maintain dimensional integrity under extreme vibration and temperature fluctuations, where even microscopic deviations compromise system functionality. These projects ingrained in our engineering team the absolute necessity of matching material science to the exact precision requirements of the end-use scenario. It is not merely about strength or cost; it is about how the material enables or hinders the achievement of the specified geometric and surface finish tolerances throughout the entire fabrication process.

Selecting the right grade requires analyzing factors beyond yield strength: grain structure uniformity affects edge quality during shearing, thermal conductivity influences laser cut kerf width and heat-affected zones, and work-hardening rates dictate bend allowances in precision forming. Wuxi Lead leverages this granular understanding to guide clients towards optimal material choices, ensuring the fabrication process inherently supports the required precision rather than fighting against inherent material limitations. We translate complex material science into actionable fabrication strategies.

The following table outlines key precision considerations for common high-performance sheet metal alloys:

| Material | Key Properties for Precision | Typical Precision Applications | Critical Tolerance Range (mm) |

|---|---|---|---|

| Aluminum 5052-H32 | Excellent formability low thermal expansion | Enclosures aerospace brackets fluid systems | ±0.05 – ±0.10 |

| Stainless 304/316 | High corrosion resistance moderate work hardening | Medical equipment food processing marine hardware | ±0.03 – ±0.08 |

| Cold Rolled Steel | High strength consistent grain structure | Structural chassis automotive components | ±0.05 – ±0.15 |

| Aluminum 6061-T6 | High strength good machinability anodizing | Aerospace structural defense components | ±0.02 – ±0.05 |

Material selection is the first critical engineering decision on the path to precision. At Wuxi Lead Precision Machinery, our Olympic and military project heritage provides the proven framework to navigate this complexity. We partner with clients not just to cut and form metal, but to engineer solutions where the material itself becomes an enabler of uncompromising dimensional accuracy and reliability, directly contributing to the success and longevity of your most demanding products. Precision begins with the right sheet.

Precision Specs & Tolerances

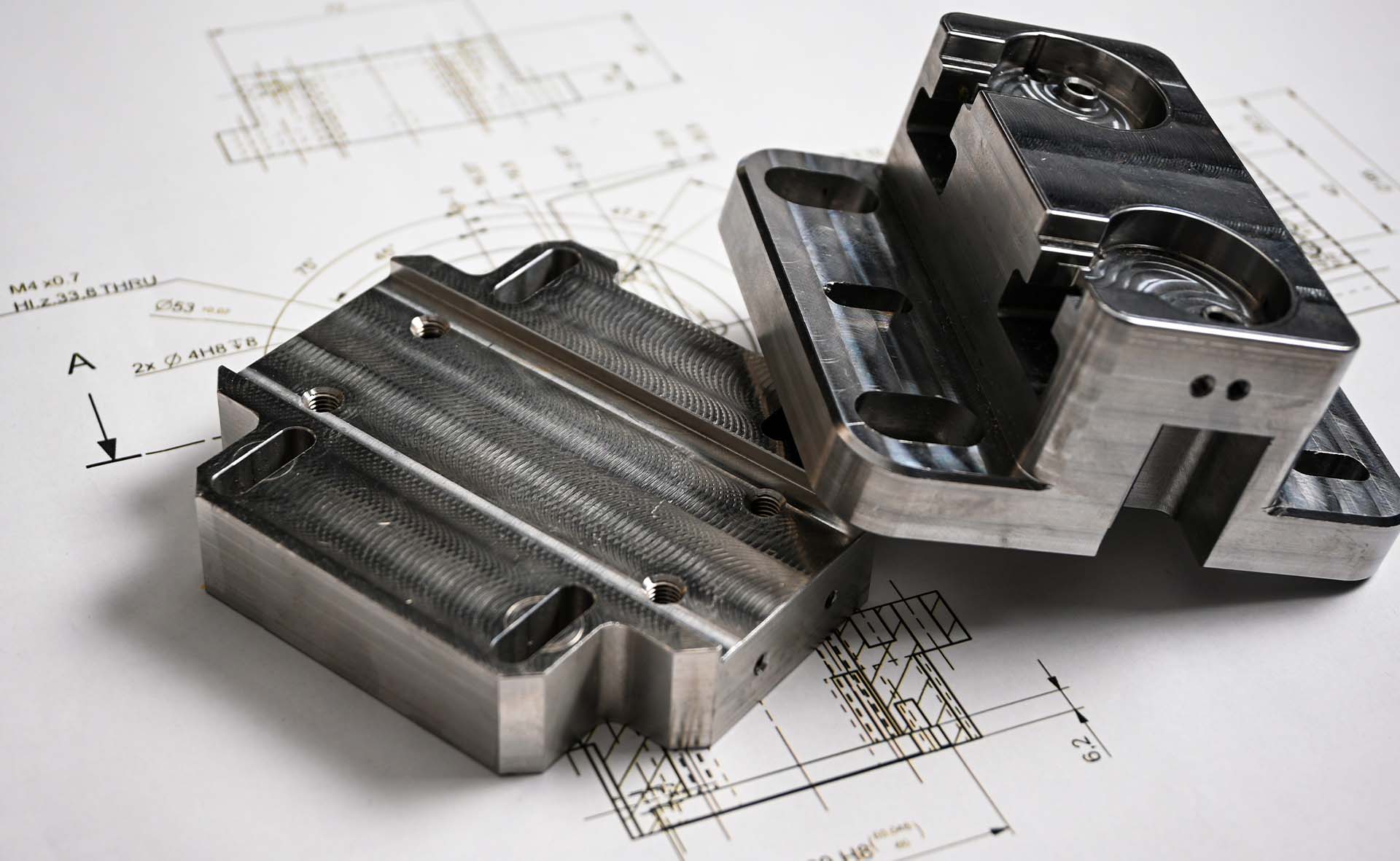

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions tailored for high-precision industrial applications. Our technical capabilities integrate state-of-the-art machinery, rigorous quality control, and deep engineering expertise to ensure every component meets exacting standards. At the core of our production capacity is our 5-axis CNC machining system, which enables complex geometries, tight tolerances, and superior surface finishes on a wide range of sheet metal materials.

Our 5-axis CNC technology allows simultaneous multi-directional cutting, significantly enhancing accuracy and efficiency, particularly for intricate parts requiring minimal setup changes. This capability is essential for industries such as aerospace, medical devices, and high-end automation, where precision and repeatability are non-negotiable. The integration of 5-axis machining with sheet metal processing expands design possibilities, allowing for seamless transitions between formed and milled features on a single platform.

Material versatility is a cornerstone of our service offering. We process a comprehensive range of sheet metal types, including cold-rolled steel (CRS), stainless steel (grades 304, 316, 430), aluminum alloys (5052, 6061, 7075), brass, and copper. Each material is selected based on mechanical properties, corrosion resistance, formability, and end-use requirements. Our engineering team collaborates closely with clients during material selection to ensure optimal performance and cost-efficiency.

Quality assurance is embedded throughout our fabrication workflow. Every component undergoes rigorous inspection using a Coordinate Measuring Machine (CMM), ensuring dimensional accuracy and compliance with ISO and customer-specific standards. Our CMM system provides full traceability and detailed inspection reports, supporting certification needs for regulated industries. In addition to CMM, we employ laser scanning and optical comparators for critical features, ensuring consistency across production runs.

We maintain strict control over environmental conditions and machine calibration to minimize thermal and mechanical drift, further enhancing repeatability. Our facility operates under ISO 9001-certified processes, and all technicians are trained in lean manufacturing and precision handling techniques.

The following table outlines our standard machining tolerances for sheet metal components processed on 5-axis CNC systems:

| Feature Type | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.02 mm | Up to 500 mm |

| Hole Diameter | ±0.03 mm | ±0.01 mm | Reamed or CNC drilled |

| Positional Tolerance | ±0.03 mm | ±0.01 mm | Relative to datum |

| Angular Features | ±0.1° | ±0.05° | 5-axis interpolated |

| Surface Roughness | Ra 1.6 µm | Ra 0.4 µm | As machined or polished |

These capabilities reflect Wuxi Lead Precision Machinery’s commitment to delivering high-integrity sheet metal components that meet the most demanding technical specifications.

Material & Finish Options

Precision Material Selection for Sheet Metal Fabrication

Material selection fundamentally dictates the performance, cost, and manufacturability of sheet metal components. At Wuxi Lead Precision Machinery, our engineering team prioritizes matching material properties precisely to your application’s functional requirements, environmental exposure, and production constraints. Understanding the core characteristics of aluminum, steel, and titanium is critical for optimal part integrity and lifecycle value. Each material offers distinct advantages and limitations that must be evaluated within the context of CNC machining, forming, welding, and finishing processes.

Aluminum alloys, particularly 5052-H32 and 6061-T6, dominate applications demanding a high strength-to-weight ratio, excellent corrosion resistance, and superior machinability. These grades are ideal for aerospace components, enclosures, and heat sinks where weight savings and thermal conductivity are paramount. Mild steel (e.g., A36) provides high strength and cost-effectiveness for structural frames, brackets, and industrial housings, though it requires protective finishes like powder coating to prevent rust. Stainless steel grades 304 and 316 offer exceptional corrosion and heat resistance for medical devices, food processing equipment, and marine environments, with 316 providing superior performance in chloride-rich settings. Titanium, primarily Grade 2 and 5 (Ti-6Al-4V), delivers unmatched strength-to-weight ratio and extreme corrosion resistance for critical aerospace, defense, and biomedical implants, though its high cost and challenging machinability necessitate specialized CNC expertise.

Key mechanical and fabrication properties are summarized below for rapid comparison:

| Material | Typical Density (g/cm³) | Tensile Strength (MPa) | Key Advantages | Primary Fabrication Considerations |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Lightweight, corrosion resistant, weldable, excellent machinability | Minimal burring, low cutting forces |

| Stainless 304 | 8.0 | 515 | High corrosion/heat resistance, strong | Work hardening requires sharp tools, higher cutting forces |

| Mild Steel A36 | 7.8 | 400 | Low cost, high strength, readily formable | Prone to rust, requires post-fab finishing |

| Titanium Grade 5 | 4.4 | 900 | Extreme strength/weight, biocompatible, corrosion proof | Very slow machining, heat sensitivity, high tool wear |

Surface finishing, particularly anodizing, is integral to aluminum component performance. Type II (Sulfuric Acid) anodizing provides robust corrosion resistance and a porous surface for dyeing, suitable for consumer electronics and architectural elements. Type III (Hardcoat) anodizing creates a significantly thicker, harder, and more wear-resistant ceramic layer essential for aerospace hydraulic components, military hardware, and high-abrasion industrial parts. Proper pre-treatment and process control are non-negotiable for achieving consistent, high-integrity anodized finishes that meet aerospace (AMS 2469) or military specifications.

Selecting the optimal sheet metal requires balancing performance needs against manufacturability and total cost of ownership. Wuxi Lead Precision Machinery provides comprehensive material consultation, leveraging our CNC fabrication expertise and material science knowledge to ensure your chosen alloy and finish deliver maximum value and reliability. Contact our engineering team for a detailed analysis of your specific application requirements.

Manufacturing Process & QC

Sheet Metal Fabrication: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our sheet metal fabrication process is engineered for precision, consistency, and zero-defect delivery. We follow a disciplined workflow that spans three critical phases: Design, Prototyping, and Mass Production. This structured approach ensures every component meets stringent quality standards while optimizing cost and lead time for high-volume manufacturing.

The process begins with Design, where engineering excellence sets the foundation. Our team collaborates closely with clients to analyze technical drawings, material requirements, and functional specifications. Utilizing advanced CAD/CAM software such as SolidWorks, AutoCAD, and Siemens NX, we model each component with micron-level accuracy. Design for Manufacturability (DFM) principles are applied rigorously to eliminate potential production issues—such as excessive tolerances or complex bending sequences—before any material is cut. Material selection is optimized based on mechanical properties, environmental resistance, and cost-efficiency, ensuring compatibility with the final application.

Once the design is finalized, we move to Prototyping. This phase is critical for validating form, fit, and function. Using the same CNC-controlled machinery employed in mass production—laser cutters, turret presses, press brakes, and robotic welding cells—we produce a limited batch of functional prototypes. This ensures that the prototype behavior accurately reflects mass-produced output. Each prototype undergoes comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and surface finish testers. Any deviations are traced back to root causes, and design or process adjustments are implemented before progression.

The final phase, Mass Production, is executed under a zero-defect manufacturing philosophy. Our production floor integrates real-time monitoring systems, statistical process control (SPC), and automated in-process inspections. Every sheet metal part is tracked through our ERP system, enabling full traceability from raw material to finished product. We deploy poka-yoke (error-proofing) mechanisms at critical workstations to prevent defects before they occur. Continuous operator training, preventive maintenance schedules, and ISO 9001-certified quality management systems ensure stable, repeatable output.

Material selection plays a pivotal role in achieving zero defects. The table below outlines common sheet metal materials we fabricate, along with key mechanical and fabrication properties.

| Material | Thickness Range (mm) | Tensile Strength (MPa) | Common Applications | Key Advantages |

|---|---|---|---|---|

| Cold Rolled Steel (SPCC) | 0.5 – 4.0 | 340 – 450 | Enclosures, brackets, chassis | High formability, cost-effective |

| Stainless Steel 304 | 0.8 – 6.0 | 515 – 620 | Medical devices, food processing | Corrosion resistance, hygienic |

| Aluminum 5052 | 0.8 – 5.0 | 290 – 340 | Aerospace, transportation | Lightweight, excellent fatigue resistance |

| Galvanized Steel (SGCC) | 0.6 – 3.2 | 350 – 450 | Outdoor enclosures, construction | Enhanced corrosion protection |

| Brass H62 | 0.5 – 3.0 | 370 – 500 | Electrical components, decorative parts | Good conductivity, aesthetic finish |

Through seamless integration of design validation, precision prototyping, and tightly controlled mass production, Wuxi Lead ensures every sheet metal component meets the highest standards of quality and reliability.

Why Choose Wuxi Lead Precision

Strategic Material Selection for Precision Sheet Metal Fabrication

Material choice fundamentally dictates the performance, longevity, and cost-efficiency of your sheet metal components. At Wuxi Lead Precision Machinery, we engineer solutions where material properties align precisely with your functional requirements, environmental conditions, and production scalability. Generic supplier catalogs often overlook critical nuances like grain directionality in aluminum alloys or thermal expansion variances in high-temperature applications. Our 15-year specialization in tight-tolerance fabrication ensures optimal material pairing through rigorous ASTM and ISO 9001-certified testing protocols. We analyze your project’s stress points, corrosion exposure, and secondary processing needs to eliminate costly rework or premature failure.

Below is a distilled reference of core materials we deploy with precision-engineered process parameters:

| Material Grade | Tensile Strength (MPa) | Formability Rating | Corrosion Resistance | Key Applications |

|---|---|---|---|---|

| ASTM A36 Carbon Steel | 400-510 | Moderate | Low (requires coating) | Structural frames, brackets |

| AISI 304 Stainless Steel | 515-1000 | Good | Excellent | Food processing, medical enclosures |

| 5052-H32 Aluminum | 228 | High | Very Good | Aerospace panels, marine hardware |

| SPCC Cold Rolled Steel | 270-380 | Excellent | Low | Consumer electronics chassis |

| Titanium Gr 2 | 345-483 | Moderate | Exceptional | Defense, chemical processing |

This table reflects real-world production data from our CNC press brakes, laser cutters, and robotic welding cells. Note how 5052-H32 aluminum’s superior formability reduces springback in complex bends versus 6061-T6—critical for repeatability at ±0.05mm tolerances. Similarly, our stainless steel protocols account for intergranular corrosion risks during welding, a detail often missed by standard fabricators.

Wuxi Lead Precision Machinery integrates material science with precision manufacturing. Our engineers collaborate from design inception to validate material suitability against your lifecycle demands. We prevent hidden costs like excessive tool wear from abrasive materials or yield loss due to improper bend allowances. Every project undergoes finite element analysis (FEA) to simulate material behavior under load, ensuring your components perform identically in production as in prototype.

When your project demands materials expertise beyond basic supplier datasheets, partner with a manufacturer who treats material selection as a scientific discipline. Contact our engineering team directly at [email protected] to discuss your specific requirements. Include your target tolerances, environmental exposure, and annual volume—we will provide a material optimization report within 48 hours. Let us transform your sheet metal challenges into competitive advantages through precision-engineered solutions.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.