Technical Contents

Engineering Guide: Metal Fabrication Solutions

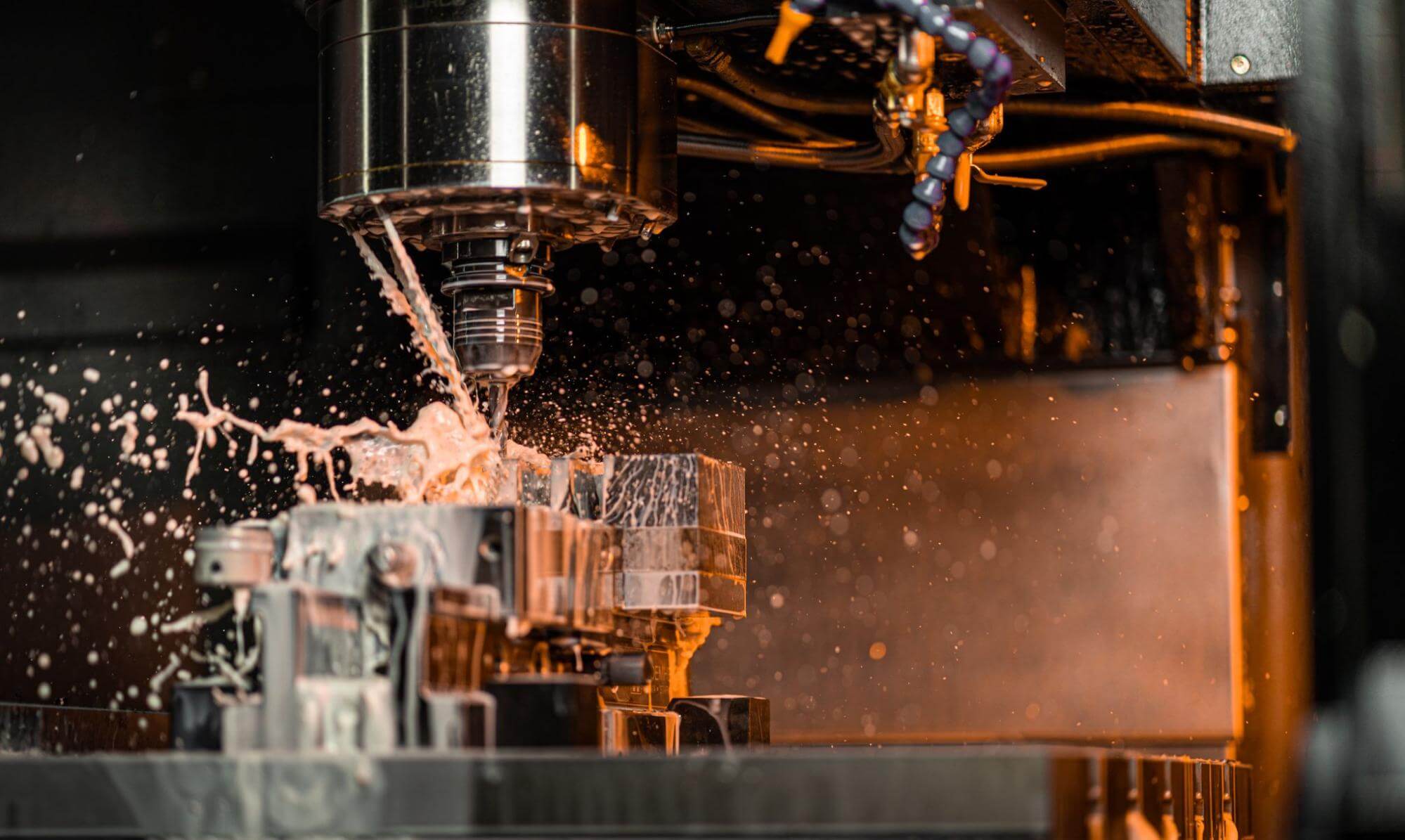

Engineering Insight: The Critical Role of Precision in Metal Fabrication Solutions

In the realm of advanced manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, safety, and innovation are built. For industries ranging from aerospace and defense to high-performance infrastructure, the margin for error in sheet metal fabrication is effectively zero. At Wuxi Lead Precision Machinery, we understand that the integrity of every component begins with exacting engineering standards and a relentless commitment to dimensional accuracy.

Precision in metal fabrication transcends the simple act of cutting or bending metal. It encompasses the entire production lifecycle: material selection, CAD/CAM programming, tooling calibration, real-time quality monitoring, and final inspection. Even a deviation of a few microns can compromise structural performance, especially in load-bearing or high-stress applications. This is why our processes are engineered to maintain tolerances within ±0.05 mm across complex geometries and multi-stage assemblies.

Our expertise has been rigorously tested in some of the most demanding environments. Wuxi Lead has contributed to projects aligned with Olympic-standard construction and military-grade equipment manufacturing, where failure is not an option. These engagements required not only precision but also full traceability, compliance with international standards, and the ability to scale production without sacrificing quality. Our role in such high-stakes initiatives underscores our technical capability and the trust placed in our engineering solutions.

We achieve this level of consistency through a combination of advanced CNC technology, in-house tooling design, and a skilled workforce trained in lean manufacturing principles. Every stage of fabrication—from laser cutting and CNC punching to robotic welding and automated bending—is monitored using coordinate measuring machines (CMM) and real-time feedback systems. This closed-loop quality control ensures that every part meets or exceeds customer specifications.

Below are key technical capabilities that define our precision metal fabrication solutions:

| Specification | Performance Standard |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm |

| Cutting Tolerance | ±0.05 mm |

| Bending Tolerance | ±0.1° angular, ±0.2 mm linear |

| Welding Standards | ISO 3834, AWS D1.1 |

| Surface Roughness (Ra) | Up to 0.8 µm (polished finishes) |

| Maximum Part Size | 4000 mm × 1500 mm (laser cutting) |

| Inspection Equipment | CMM, Vision Systems, Laser Scanners |

Precision is not an add-on—it is engineered into every process, every workflow, and every product we deliver. At Wuxi Lead Precision Machinery, we don’t just meet industry standards; we help define them. For global partners seeking metal fabrication solutions where accuracy determines performance, we offer proven expertise, cutting-edge technology, and a legacy of excellence forged in the most challenging applications.

Precision Specs & Tolerances

Technical Capabilities

Wuxi Lead Precision Machinery delivers uncompromising precision in sheet metal fabrication through integrated advanced manufacturing systems. Our core strength lies in multi-axis CNC machining, specifically 5-axis technology, which enables the production of geometrically complex components in a single setup. This eliminates cumulative errors from multiple repositioning stages, ensuring superior dimensional accuracy and surface integrity. Our 5-axis CNC centers feature simultaneous motion control across X, Y, Z linear axes and A, B rotational axes, accommodating intricate contours, undercuts, and compound angles typical in aerospace, medical, and energy sector components. Material efficiency is maximized through optimized toolpaths, reducing scrap rates by up to 25% compared to conventional 3-axis methods. All machining operations leverage high-rigidity spindles with micron-level positioning repeatability, supporting materials ranging from aluminum alloys and stainless steel to titanium and Inconel. This capability streamlines prototyping and low-volume production, accelerating time-to-market without sacrificing quality.

Quality assurance is rigorously maintained through a closed-loop inspection process anchored by Coordinate Measuring Machine (CMM) validation. Every critical feature undergoes 100% inspection against GD&T specifications using Zeiss CONTURA CMM systems, providing traceable metrology reports compliant with ISO 9001 and AS9100 standards. Our CMM workflow integrates directly with CAD/CAM data, enabling real-time deviation analysis and automatic process adjustments. This proactive approach ensures first-article conformity and sustained production stability, minimizing non-conformance risks for high-stakes applications. Statistical process control (SPC) methodologies are applied to all high-volume runs, with capability indices (Cp/Cpk) monitored per customer requirements.

The following table details achievable tolerance ranges across common sheet metal fabrication processes, reflecting our standard and precision-tier capabilities:

| Feature | Standard Tolerance | Precision Tolerance |

|---|---|---|

| Flatness (per 100mm) | ±0.10 mm | ±0.03 mm |

| Hole Diameter | ±0.10 mm | ±0.02 mm |

| Edge Bend Angle | ±1.0° | ±0.25° |

| Hole Position | ±0.15 mm | ±0.05 mm |

| Surface Roughness (Ra) | 3.2 μm | 0.8 μm |

| Critical Dimension (CMM) | ±0.05 mm | ±0.01 mm |

These tolerances are consistently achieved through our synchronized workflow: CAD model validation, adaptive CNC programming, in-process probing, and final CMM certification. We specialize in bridging design intent with manufacturability, offering DFM consultation to optimize part geometry for cost-effective precision. For mission-critical components demanding micron-level fidelity, our precision tier employs environmental temperature control and laser interferometer calibration to sustain tolerances at the upper limits of industry capability. Partner with Wuxi Lead to transform complex sheet metal designs into certified, high-integrity solutions with zero compromise on repeatability or compliance.

Material & Finish Options

Material Selection in Sheet Metal Fabrication: Aluminum, Steel, and Titanium

Selecting the appropriate material is a foundational step in precision sheet metal fabrication, directly influencing the performance, durability, and cost-efficiency of the final component. At Wuxi Lead Precision Machinery, we guide engineering teams through informed decisions based on mechanical requirements, environmental exposure, and finishing needs. Among the most widely used materials in industrial applications are aluminum, steel, and titanium—each offering distinct advantages depending on the operational context.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and electrical conductivity. It is particularly suitable for aerospace, transportation, and electronics enclosures where weight reduction is critical. Aluminum 5052 and 6061 are common grades, offering good formability and weldability. When exposed to harsh environments, aluminum benefits significantly from surface treatments such as anodizing, which enhances wear resistance and allows for color coding or branding.

Steel remains the backbone of heavy-duty industrial fabrication due to its high tensile strength, affordability, and broad availability. Mild steel (e.g., Q235, Q345) is ideal for structural components, enclosures, and machinery frames. While more prone to oxidation than aluminum, steel can be protected through galvanization, powder coating, or plating. For applications requiring enhanced corrosion resistance without the cost of titanium, stainless steel grades such as 304 and 316 offer a balanced solution with good formability and long-term durability in humid or chemically aggressive environments.

Titanium, though more expensive and challenging to process, delivers unmatched performance in extreme conditions. With exceptional strength-to-density ratio and resistance to high temperatures and corrosive media, titanium is the material of choice for aerospace, medical implants, and marine applications. Grade 2 (commercially pure) and Grade 5 (Ti-6Al-4V) are most commonly fabricated, requiring specialized tooling and slower machining parameters due to work hardening tendencies.

The choice of finish further defines the functional lifespan and aesthetic quality of fabricated parts. Anodizing, primarily applied to aluminum, creates a durable, non-conductive oxide layer that improves surface hardness and corrosion resistance. Type II (sulfuric acid) anodizing is standard for general protection and dyeing, while Type III (hard anodizing) is specified for high-wear components requiring thicker, more robust coatings.

Below is a comparative overview of key material properties to assist in selection:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Common Grades | Key Advantages | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 110–310 | 5052, 6061, 7075 | Lightweight, corrosion-resistant, conductive | Aerospace, electronics, transport |

| Steel | 7.8 | 370–550 | Q235, Q345, 304, 316 | High strength, cost-effective | Machinery, construction, enclosures |

| Titanium | 4.5 | 340–900 | Grade 2, Grade 5 | Extreme corrosion resistance, high strength-to-weight | Aviation, medical, marine |

At Wuxi Lead, we combine material expertise with advanced fabrication capabilities to deliver optimized metal fabrication solutions tailored to your engineering demands.

Manufacturing Process & QC

Precision Sheet Metal Fabrication: From Concept to Zero Defect Production

At Wuxi Lead Precision Machinery, our sheet metal fabrication process is engineered for uncompromising quality and efficiency, transforming client concepts into flawless end products. We rigorously execute three integrated phases—Design, Prototyping, and Mass Production—each governed by our Zero Defects philosophy. This systematic approach minimizes risk, accelerates time-to-market, and ensures absolute adherence to specifications for high-value industrial applications.

The Design phase begins with deep collaboration. Our engineering team leverages advanced CAD/CAM software and Design for Manufacturability (DFM) principles to optimize geometry, material selection, and process flow. Finite Element Analysis (FEA) simulates structural integrity and thermal behavior under operational loads, while Geometric Dimensioning and Tolerancing (GD&T) standards are embedded from inception. This proactive validation prevents costly downstream errors, ensuring the design is both functionally robust and inherently producible to micron-level accuracy. Client feedback is integrated iteratively, creating a shared blueprint for success before any material is cut.

Prototyping is not merely a sample step; it is a critical validation gate. Using our high-precision laser cutting, CNC turret punching, and automated bending cells, we produce functional prototypes mirroring final production conditions. Each prototype undergoes rigorous metrology via CMM (Coordinate Measuring Machine) and optical scanning against the approved CAD model, verifying dimensional conformity, assembly fit, and performance characteristics. Any deviation triggers immediate root cause analysis and design or process refinement. This phase statistically validates the manufacturing process capability, confirming it meets the stringent requirements for full-scale rollout. Only prototypes achieving 100% conformance advance.

Mass Production deploys the fully validated process within our controlled environment, where Zero Defects is operational reality. Real-time SPC (Statistical Process Control) monitors key parameters—laser power, bend angles, weld penetration—on every component. Automated in-process inspection stations, including vision systems and inline CMMs, provide continuous feedback, enabling instantaneous corrections. Our closed-loop feedback system integrates shop floor data with engineering databases, ensuring process stability. Material traceability is maintained from coil to finished part, and final inspection employs AQL 0.65 sampling per ISO 2859-1 standards. This relentless focus on process control and verification guarantees consistent output that meets aerospace, medical, and semiconductor industry demands.

Key Process Capabilities and Tolerances

| Process Stage | Key Technologies | Dimensional Tolerance | Critical Controls |

|---|---|---|---|

| Design | CAD/CAM, FEA, DFM, GD&T | ±0.1 mm (Initial Concept) | Simulation Validation, Client Sign-off |

| Prototyping | Fiber Laser Cutting, CNC Bending, Robotic Welding | ±0.05 mm (Verified) | CMM Scanning, Functional Testing, Process Capability (CpK ≥ 1.67) |

| Mass Production | Automated Laser Cells, Pneumatic Press Brakes, In-line Vision | ±0.02 mm (Sustained) | Real-time SPC, AQL 0.65 Final Inspection, Full Material Traceability |

This disciplined progression—from intelligent design through validated prototyping to tightly controlled mass production—eliminates waste and rework. Wuxi Lead delivers not just parts, but guaranteed performance and supply chain resilience, directly enhancing our partners’ total cost of ownership and market competitiveness. Zero Defects is our commitment, engineered into every process step.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Sheet Metal Fabrication Solutions

At Wuxi Lead Precision Machinery, we don’t just manufacture components—we engineer success for global manufacturers who demand precision, reliability, and scalability. As a leading provider of advanced sheet metal fabrication solutions in China, we specialize in delivering high-tolerance, custom-engineered parts across aerospace, medical, energy, and industrial automation sectors. Our state-of-the-art facility in Wuxi integrates cutting-edge CNC technology with rigorous quality assurance protocols, ensuring every component meets exacting international standards.

Choosing the right manufacturing partner is critical. Lead Precision stands apart through our commitment to engineering excellence, responsive communication, and end-to-end project ownership. From prototype development to high-volume production, we offer seamless scalability without compromising on quality or lead time. Our team of senior CNC engineers and project managers collaborates directly with your design and procurement teams to optimize manufacturability, reduce material waste, and lower total production costs.

We understand that precision is not just about tight tolerances—it’s about consistency, repeatability, and traceability. Our ISO 9001-certified processes, combined with in-house laser cutting, CNC bending, robotic welding, and surface treatment capabilities, allow us to handle complex geometries and exotic materials with confidence. Whether you require stainless steel enclosures for medical devices or aluminum structural components for renewable energy systems, our facility is equipped to deliver.

To ensure transparency and performance, we provide detailed production documentation, first-article inspection reports, and real-time project updates. Our clients benefit from reduced time-to-market, minimized supply chain risk, and a true engineering partnership built on trust and technical expertise.

Technical Capabilities Overview

| Capability | Specification Range | Tolerance |

|---|---|---|

| Laser Cutting | Up to 25 mm (steel), 20 mm (aluminum) | ±0.1 mm |

| CNC Punching | Up to 6 mm thickness | ±0.15 mm |

| CNC Bending | Up to 4 meters length, 25-ton capacity | ±0.25° angular |

| Welding | MIG, TIG, Spot Welding (steel, stainless, aluminum) | AWS D1.1/D1.6 compliant |

| Surface Finish | Powder coating, anodizing, passivation, plating | Custom Rz/Ra values |

| Max Part Size | 4000 x 2000 mm (fabricated assemblies) | N/A |

Partnering with Lead Precision means gaining a manufacturing ally deeply invested in your product’s success. We don’t outsource. We don’t compromise. Every process is controlled in-house, ensuring full accountability and consistent quality.

Contact us today to discuss your next fabrication challenge. Send your RFQ or design files to [email protected] and receive a detailed technical proposal within 24 hours. Let our engineers help you transform precision sheet metal concepts into reality—on time, to spec, and at competitive global rates.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.