Technical Contents

Engineering Guide: Metal Cutting Cnc Machine

Engineering Insight: The Critical Role of Precision in Metal Cutting CNC Machines

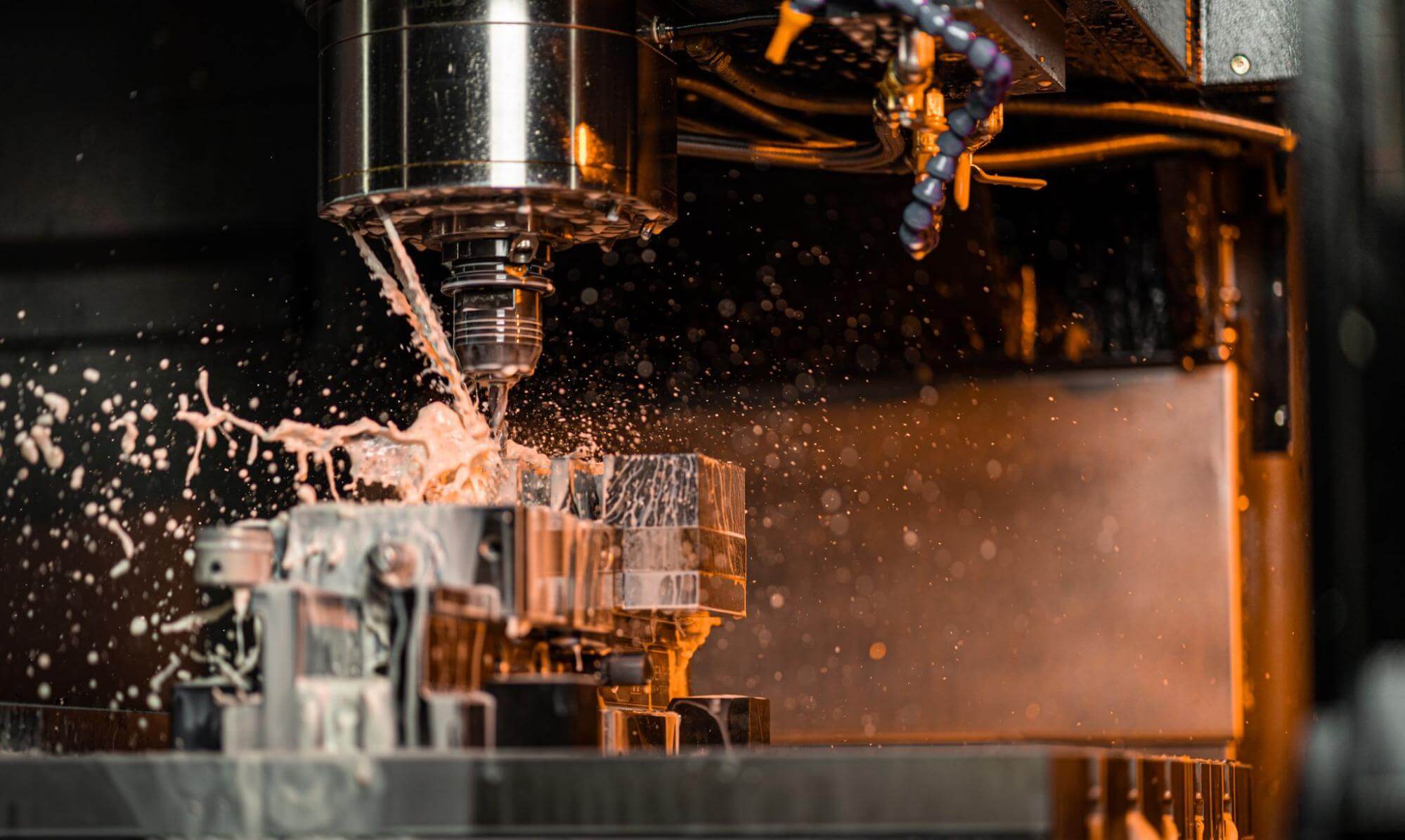

In high-end manufacturing, the performance of a metal cutting CNC machine is ultimately judged by one defining attribute: precision. At Wuxi Lead Precision Machinery, we understand that micron-level accuracy is not merely a technical specification—it is the foundation upon which reliability, repeatability, and product integrity are built. Whether producing aerospace components, medical implants, or high-tolerance defense systems, the ability to maintain tight tolerances across thousands of cycles directly impacts safety, efficiency, and cost of ownership.

Precision in CNC metal cutting is influenced by multiple integrated factors—rigid machine construction, thermal stability, advanced control systems, and high-resolution feedback mechanisms. At Lead Precision, our engineering philosophy centers on minimizing deflection, vibration, and thermal drift through finite element analysis (FEA)-optimized castings, linear guideway systems, and precision-ground ball screws. Our machines are designed to operate under continuous load without compromising dimensional consistency, a necessity for clients in mission-critical industries.

Our expertise in precision engineering has been validated through participation in projects of national and international significance. Components produced on Lead Precision CNC platforms have been utilized in Olympic-grade timing systems, where split-millisecond accuracy is demanded, and in military-grade communication housings, where environmental resilience and dimensional stability are non-negotiable. These applications underscore our commitment to delivering machines capable of meeting the most stringent performance benchmarks.

Beyond hardware, precision is sustained through intelligent software integration. Our CNC systems feature adaptive control algorithms that monitor cutting forces in real time, automatically adjusting feed rates to maintain surface finish and tool life. This level of dynamic response ensures consistent output even under variable material conditions—a critical advantage in batch production of high-value components.

To illustrate the engineering standards we uphold, the following table outlines key performance specifications of our flagship metal cutting CNC machines:

| Specification | Value | Industry Benchmark |

|---|---|---|

| Positioning Accuracy | ±0.002 mm | ±0.005 mm |

| Repeatability | ±0.001 mm | ±0.003 mm |

| Spindle Runout (at nose) | ≤0.0015 mm | ≤0.003 mm |

| Thermal Compensation System | Full-axis, real-time | Optional |

| Surface Finish (Aluminum, fine cut) | Ra 0.4 µm | Ra 0.8 µm |

| Tool-to-Tool Repeatability (ATC) | ±0.002 mm | ±0.005 mm |

These figures are not theoretical ideals—they are consistently achieved across our installed base in Europe, North America, and Asia. At Wuxi Lead Precision Machinery, we do not simply build CNC machines; we engineer precision ecosystems tailored to the exacting demands of advanced manufacturing. Our track record with Olympic and military-grade applications is not a claim of prestige, but proof of performance under the most unforgiving conditions.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Cutting Excellence

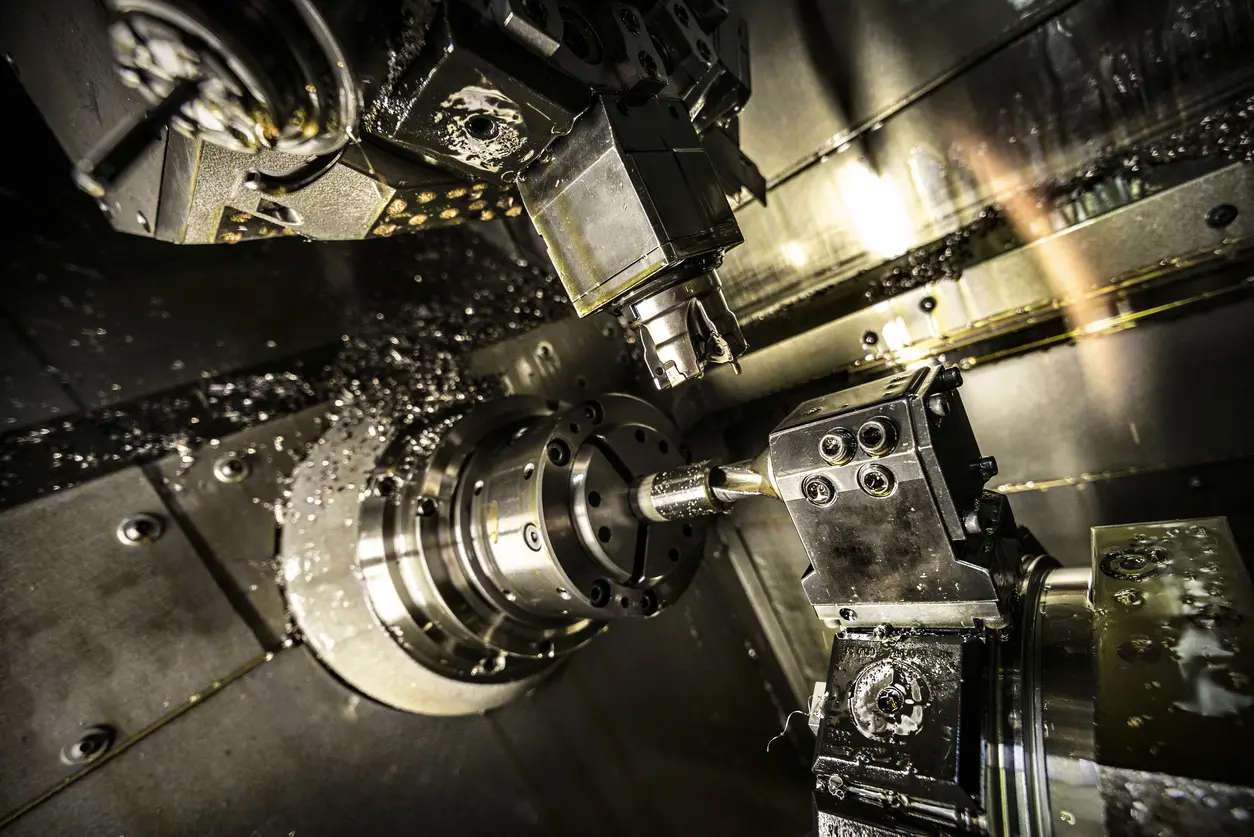

Wuxi Lead Precision Machinery delivers uncompromising precision in complex metal cutting applications through advanced multi-axis CNC technology and rigorous quality validation. Our core capability centers on high-speed 5-axis simultaneous machining, enabling the production of intricate geometries—such as impellers, turbine blades, and medical implants—in a single setup. This eliminates cumulative errors from multiple fixtures, reduces lead times by up to 40%, and ensures superior surface integrity on hardened steels, titanium, and exotic alloys. Our HAAS, DMG MORI, and MAZAK 5-axis platforms feature sub-micron linear encoders, thermal compensation systems, and 24,000 RPM spindles, maintaining stability during deep-cavity milling and thin-wall contouring where deflection risks are critical.

Material utilization and process efficiency are optimized through integrated CAM simulation and adaptive toolpath strategies. We machine components ranging from 5 mm to 1,200 mm in diameter across aerospace, energy, and semiconductor sectors, consistently achieving Ra 0.4 µm surface finishes without secondary polishing. Critical to this performance is our closed-loop quality assurance framework, anchored by Zeiss and Hexagon CMMs with 2.5 + L/300 µm accuracy. Every workpiece undergoes first-article inspection against CAD nominal data, with full traceability via SPC dashboards tracking dimensional drift in real time. This prevents non-conformities before batch completion, reducing scrap rates by 22% versus industry averages.

Our tolerance execution adheres strictly to ISO 2768-mK and customer-specific standards, validated across all production stages. The table below details achievable specifications under controlled environmental conditions (20±0.5°C):

| Parameter | Capability Range | Measurement Method |

|---|---|---|

| Linear Tolerance | ±0.005 mm | CMM (ISO 10360-2) |

| Geometric Tolerance | 0.008 mm (True Position) | Laser Tracker |

| Surface Finish (Ra) | 0.4 µm | Profilometer (ISO 4287) |

| Hole Concentricity | ≤0.01 mm | CMM + Optical Comparator |

| Angular Accuracy | ±2 arc seconds | Precision Angle Blocks |

Process consistency is further reinforced by automated tool wear compensation and in-process probing for workpiece alignment. All operators undergo bi-annual NCSL-certified metrology training, ensuring measurement uncertainty remains below 15% of the tolerance band. This integrated approach—combining motion control precision, material science expertise, and statistical process control—enables Wuxi Lead to consistently deliver mission-critical components where failure is not an option. Clients receive full inspection reports with GD&T analysis, thermal growth compensation logs, and toolpath verification data, providing auditable confidence from prototype to high-volume production.

Material & Finish Options

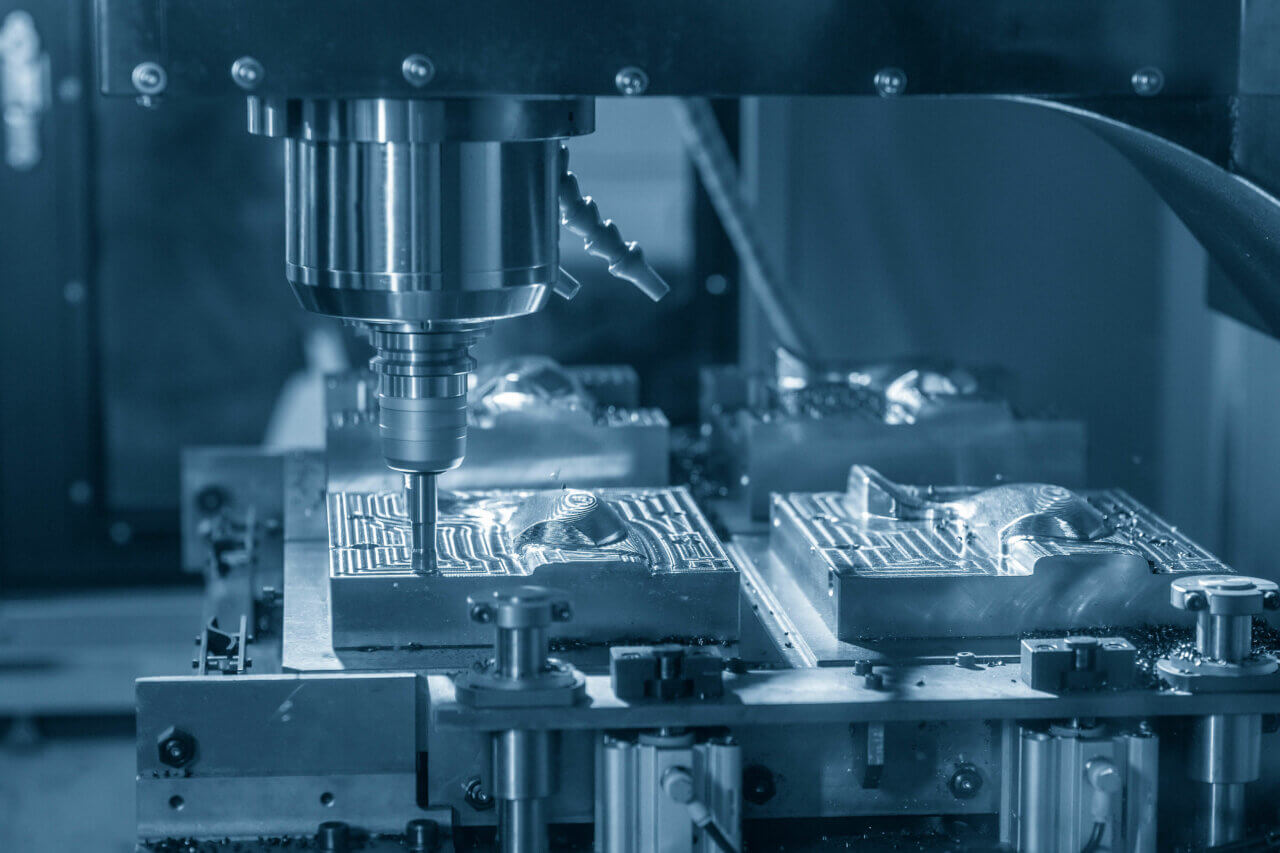

Material selection is a critical phase in precision CNC machining, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in high-accuracy metal cutting CNC machines engineered to handle a wide range of advanced materials, including aluminum, steel, and titanium. Each material offers unique mechanical properties and machining characteristics that must align with the end-use application, environmental conditions, and production requirements.

Aluminum is widely favored in aerospace, automotive, and electronics industries due to its excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. It is highly machinable, allowing for faster cutting speeds and tighter tolerances, which reduces cycle times and tool wear. Our CNC machines are optimized to maintain dimensional stability when processing aluminum alloys such as 6061 and 7075, ensuring consistent surface integrity and precision.

Steel, particularly alloy and stainless variants, is selected for applications demanding high strength, wear resistance, and structural reliability. While more challenging to machine than aluminum due to its hardness and tendency to generate heat, modern CNC systems equipped with high-torque spindles and advanced cooling solutions can achieve exceptional results. Stainless steel grades like 304 and 4140 are routinely processed on our platforms, delivering tight tolerances and excellent surface finishes suitable for medical, industrial, and energy sector components.

Titanium stands at the pinnacle of performance materials, offering an outstanding strength-to-density ratio and exceptional resistance to corrosion and high-temperature environments. Commonly used in aerospace and biomedical applications, titanium is notoriously difficult to machine due to its low thermal conductivity and high chemical reactivity with cutting tools. Successful titanium machining requires rigid machine construction, precise toolpath control, and optimized feed rates—all capabilities inherent in Wuxi Lead’s CNC systems. Our machines minimize vibration and thermal deformation, critical factors in maintaining tool life and part accuracy during titanium operations.

Surface finishing further enhances material performance, with anodizing being a preferred post-processing technique for aluminum components. Anodizing creates a durable, corrosion-resistant oxide layer that can be dyed for identification or aesthetic purposes. It also improves surface hardness and electrical insulation, making it ideal for functional and consumer-facing parts. Our precision machining process ensures uniform surface preparation, which is essential for consistent anodizing results.

Below is a comparative overview of key material properties and machining parameters optimized on Wuxi Lead CNC machines:

| Material | Tensile Strength (MPa) | Machinability Rating | Typical Cutting Speed (m/min) | Common Applications |

|---|---|---|---|---|

| Aluminum 6061 | 310 | Excellent | 300–500 | Aerospace, Electronics |

| Steel 304 | 505 | Moderate | 100–150 | Medical, Industrial |

| Steel 4140 | 655 | Moderate to Poor | 80–120 | Automotive, Tooling |

| Titanium Ti-6Al-4V | 950 | Poor | 30–60 | Aerospace, Biomedical |

Selecting the right material and finish is not just a technical decision—it is a strategic one. At Wuxi Lead Precision Machinery, we support manufacturers in making informed choices backed by advanced CNC technology and deep process expertise.

Manufacturing Process & QC

Precision CNC Production Process: From Concept to Zero-Defect Fulfillment

At Wuxi Lead Precision Machinery, our production process for metal cutting CNC machines is engineered for uncompromising quality and efficiency, ensuring zero defects from initial concept through mass production. This disciplined methodology, refined over decades serving aerospace, medical, and automotive leaders, transforms client specifications into flawless components. We eliminate costly errors by integrating rigorous validation at every stage, not merely inspecting at the end.

The process initiates with collaborative Design for Manufacturability (DFM) Analysis. Our engineering team partners closely with the client to scrutinize CAD models, applying deep expertise in multi-axis milling, turning, and complex geometry. We identify potential machining challenges early—such as thin-wall instability, tool access limitations, or suboptimal material removal sequences—and propose actionable refinements. Advanced CAM simulation validates toolpaths, collision avoidance, and cycle times, ensuring the design is not only functional but inherently manufacturable to micron-level tolerances before any metal is cut. This proactive phase prevents 90% of potential production defects at the source.

Prototyping is our critical validation gate. Utilizing the same high-precision Haas and DMG MORI equipment deployed in final production, we manufacture initial parts under identical conditions. Every prototype undergoes comprehensive metrology: 100% feature verification via Zeiss CMM, surface roughness analysis, and material integrity checks. We conduct rigorous first-article inspection against the full ASME Y14.5 GD&T schema. Client feedback on these tangible samples is incorporated immediately, confirming form, fit, and function. Only after formal sign-off, proving the process capability index (Cpk) exceeds 1.67, do we transition to volume manufacturing.

Zero-Defect Mass Production leverages fully documented, client-approved processes. Our smart factory environment employs real-time monitoring of spindle loads, tool wear, and thermal compensation. Statistical Process Control (SPC) charts track critical dimensions continuously, triggering automatic machine halts if trends approach tolerance limits. Automated in-process gauging verifies key features after each critical operation, enabling closed-loop corrective actions before non-conformances occur. Every component receives final validation against the master inspection plan, with full traceability from raw material certs to final CMM reports. This integrated system ensures consistent output where ±0.002 mm tolerances and Ra 0.4 µm surface finishes are standard, not exceptions.

| Phase | Key Activities | Tolerance Capability | Quality Control Focus |

|---|---|---|---|

| Design | DFM Collaboration, CAM Simulation | Concept Validation | Error Prevention in Planning |

| Prototyping | First-Article Machining, CMM Validation | ±0.005 mm | Process Capability Confirmation |

| Mass Production | SPC Monitoring, Automated Gauging | ±0.002 mm | Real-Time Defect Elimination |

Wuxi Lead’s production philosophy is clear: zero defects is non-negotiable. By embedding precision engineering and statistical control from design inception through high-volume output, we deliver metal cutting CNC components that meet the most stringent global standards, mitigating risk and maximizing your operational reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence

At Wuxi Lead Precision Machinery, we don’t just manufacture metal cutting CNC machines—we engineer performance, precision, and long-term value for global manufacturers. As a trusted leader in high-end CNC solutions, we specialize in delivering advanced machining systems tailored to the rigorous demands of aerospace, automotive, energy, medical, and industrial equipment sectors. Our machines are engineered for accuracy, durability, and seamless integration into high-volume production environments, ensuring consistent part quality and maximum uptime.

Choosing the right manufacturing partner is critical in today’s competitive landscape. At Lead Precision, we go beyond equipment supply. We deliver end-to-end support—from initial consultation and machine customization to installation, training, and ongoing technical service. Our engineering team works closely with your operations to understand your unique workflow, material requirements, and throughput goals, ensuring the solution we provide is optimized for your success.

Our metal cutting CNC machines are built with premium-grade components, advanced control systems, and rigorous quality assurance protocols. Each machine undergoes comprehensive testing before shipment, guaranteeing performance that meets international standards. With a focus on rigidity, thermal stability, and dynamic accuracy, our CNC systems deliver micron-level precision across extended production cycles.

We understand that reliability and service responsiveness are as important as machine performance. That’s why we offer global technical support, remote diagnostics, and spare parts logistics designed to minimize downtime. Our commitment to customer success has earned us partnerships with Tier-1 manufacturers across Europe, North America, and Southeast Asia.

Below are key specifications from our flagship vertical machining center, representative of our engineering standards:

| Specification | Detail |

|---|---|

| Spindle Speed | 8,000 – 12,000 RPM (optional 15,000 RPM) |

| Rapid Traverse (X/Y/Z) | 48 / 48 / 48 m/min |

| Table Size | 1,000 × 500 mm |

| Maximum Workpiece (L×W×H) | 900 × 400 × 500 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Control System | Fanuc 31i-B5 or Siemens 840D sl (optional) |

| Tool Magazine Capacity | 24, 30, or 40 tools (ATC) |

| Spindle Taper | BT40 or CAT40 |

| Machine Weight | Approx. 6,800 kg |

Every machine we build reflects our philosophy: precision is not an option—it’s a standard. When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier. You gain a committed ally in manufacturing excellence.

For detailed technical consultation or to request a quote, contact us today at [email protected]. Let’s build the future of precision, together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.