Technical Contents

Engineering Guide: Custom Fabrication Services

Engineering Insight Custom Fabrication Services

Precision in custom fabrication transcends mere measurement; it is the foundational element determining product functionality, assembly integrity, and long-term reliability within complex manufacturing ecosystems. In high-stakes industries such as aerospace, defense, and advanced medical equipment, deviations measured in microns can cascade into catastrophic system failures or costly field recalls. The true value of a fabrication partner lies not just in executing drawings, but in proactively engineering solutions that anticipate real-world stresses, thermal dynamics, and assembly sequences. This requires deep material science understanding, rigorous process validation, and an unwavering commitment to dimensional stability from raw material through final finishing. At Wuxi Lead Precision Machinery, we recognize that precision is not a singular checkpoint but an integrated philosophy embedded within every stage of production – from initial design consultation to final quality assurance documentation.

Our commitment to exceptional precision is validated through demanding applications where failure is not an option. We have successfully delivered mission-critical sheet metal components for infrastructure supporting Olympic Games venues, requiring absolute dimensional consistency across thousands of parts for seamless integration under intense global scrutiny. Furthermore, our facility maintains stringent protocols meeting specific military-grade specifications, producing enclosures and structural elements where environmental resilience and exacting tolerances are non-negotiable for operational safety and performance. These projects demanded not only technical capability but also robust traceability systems, advanced metrology, and a zero-defect culture – capabilities we now apply universally to every client engagement, regardless of sector.

The technical execution of this precision is quantifiable through our controlled manufacturing parameters. The following table outlines core capabilities defining our sheet metal fabrication accuracy for custom projects:

| Specification Category | Capability Range | Industry Relevance |

|---|---|---|

| Geometric Dimensioning & Tolerancing (GD&T) | ±0.05 mm to ±0.1 mm | Ensures critical fit for multi-part assemblies in aerospace and automation |

| Material Thickness Range | 0.5 mm to 6.0 mm | Supports diverse applications from delicate electronics enclosures to structural frames |

| Flatness Tolerance | ≤ 0.1 mm per 300 mm | Critical for sealing surfaces and optical mounting platforms |

| Hole Positional Accuracy | ±0.03 mm | Essential for precision bolt patterns in machinery and robotics |

| Repeatability (CpK) | ≥ 1.67 | Guarantees consistent output batch after batch for high-volume production |

Achieving these standards requires more than advanced machinery; it necessitates experienced engineers who understand how material grain direction, tool wear compensation, and residual stress management impact final part geometry. Our team leverages decades of collective experience to optimize nest layouts, select appropriate tooling strategies, and implement in-process inspection points that prevent deviations before they occur. This proactive engineering approach minimizes scrap, accelerates time-to-market, and delivers components that perform flawlessly within the client’s final assembly. For global manufacturers demanding reliability in their supply chain, precision in custom fabrication is not merely a specification – it is the cornerstone of operational excellence and competitive advantage. Partnering with a provider rigorously validated in the most exacting environments ensures your project inherits a legacy of proven accuracy.

Precision Specs & Tolerances

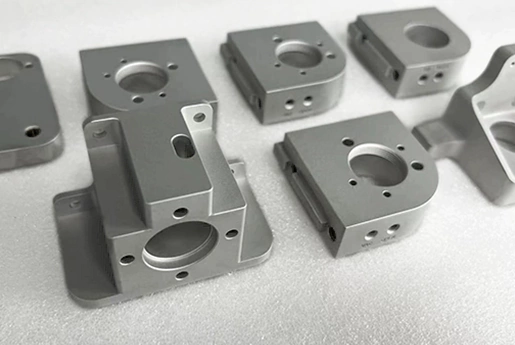

Wuxi Lead Precision Machinery delivers advanced custom fabrication services with a core focus on precision, repeatability, and technical excellence in sheet metal manufacturing. Our technical capabilities are built around state-of-the-art equipment, highly trained engineering personnel, and a rigorous quality assurance framework designed to meet the demanding requirements of aerospace, medical, automation, and high-tech industrial sectors. At the heart of our production floor is a fleet of 5-axis CNC machining centers, enabling us to execute complex geometries and tight-tolerance components with exceptional accuracy and efficiency.

The integration of 5-axis CNC technology allows for simultaneous multi-directional tool movement, reducing the need for multiple setups and minimizing cumulative error. This capability is particularly critical when fabricating intricate sheet metal enclosures, brackets, and structural components that require precise hole patterns, beveled edges, and compound angles. Our machining centers support a wide range of materials, including stainless steel, aluminum alloys, carbon steel, and specialty metals, ensuring compatibility with diverse application requirements. Advanced CAD/CAM software drives toolpath optimization, ensuring minimal material waste and consistent surface finish across production runs.

Complementing our machining capabilities is a full suite of sheet metal forming and cutting technologies, including high-precision laser cutting, CNC punching, and automated bending systems. These processes are seamlessly coordinated through digital workflows to maintain dimensional integrity from raw blank to finished part. All operations are supported by in-house design for manufacturability (DFM) analysis, allowing us to collaborate with clients early in the product development cycle to enhance performance, reduce cost, and accelerate time to market.

Quality is embedded into every stage of production. Our dedicated metrology laboratory is equipped with a Zeiss coordinate measuring machine (CMM), enabling full 3D inspection of critical features with micron-level accuracy. Each component undergoes comprehensive dimensional verification against first-article inspection (FAI) standards, with detailed inspection reports provided upon request. Statistical process control (SPC) methodologies are applied to monitor process stability and ensure batch-to-batch consistency.

The following table outlines our standard tolerance capabilities across key fabrication processes:

| Process | Typical Tolerance | Material Thickness Range | Maximum Work Envelope (mm) |

|---|---|---|---|

| 5-Axis CNC Machining | ±0.005 mm | N/A (machined from block or plate) | 1200 x 800 x 600 |

| Laser Cutting | ±0.05 mm | 0.5 – 25 mm | 3000 x 1500 |

| CNC Punching | ±0.1 mm | 0.8 – 6.0 mm | 2500 x 1250 |

| CNC Bending | ±0.2° angular, ±0.1 mm | 0.5 – 12 mm | 3000 mm length |

| CMM Inspection | Measurement accuracy ±0.003 mm | N/A | 1000 x 700 x 600 |

These technical capabilities, combined with our commitment to continuous improvement and customer collaboration, position Wuxi Lead Precision Machinery as a trusted partner for high-precision custom fabrication services in global manufacturing supply chains.

Material & Finish Options

Material Selection for Precision Sheet Metal Fabrication

Selecting the optimal material is foundational to achieving performance, durability, and cost efficiency in custom sheet metal fabrication. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your application’s mechanical demands, environmental exposure, and lifecycle requirements. Below, we detail critical considerations for aluminum, steel, and titanium—three pillars of high-end fabrication—alongside anodizing as a premier finish for aluminum components.

Aluminum

Aluminum alloys like 6061-T6 dominate aerospace, electronics, and transportation sectors due to their exceptional strength-to-weight ratio and natural corrosion resistance. Its machinability allows for complex geometries with tight tolerances, while low density reduces component weight without compromising structural integrity. However, aluminum requires protective finishes like anodizing for harsh environments or aesthetic applications. We recommend aluminum for projects demanding lightweight solutions with moderate strength and excellent thermal/electrical conductivity.

Steel

Carbon and stainless steel variants serve heavy-industry applications requiring high tensile strength and wear resistance. Stainless 304 offers balanced corrosion resistance for medical or food-processing equipment, while 316 stainless excels in marine or chemical environments due to molybdenum-enhanced pitting resistance. Carbon steel provides superior hardness for structural frames but necessitates coatings like powder painting to prevent oxidation. Steel is ideal for load-bearing components where weight is secondary to durability and cost-effectiveness.

Titanium

Titanium Grade 5 (Ti-6Al-4V) is the benchmark for extreme-performance scenarios, including aerospace and biomedical implants. Its unparalleled corrosion resistance, biocompatibility, and strength-to-weight ratio surpass aluminum and steel, though at a higher material cost. Titanium’s low thermal conductivity complicates machining, requiring specialized tooling and slower feed rates. We reserve titanium for mission-critical applications where failure is not an option, such as jet engine components or surgical instruments.

Anodizing: Elevating Aluminum Performance

Anodizing transforms aluminum’s surface into a durable, corrosion-resistant oxide layer while enabling color customization. Type II (sulfuric acid) anodizing offers standard protection and dye compatibility for consumer goods, while Type III (hardcoat) anodizing delivers superior abrasion resistance for industrial machinery. At Wuxi Lead, our anodizing process adheres to MIL-A-8625 standards, ensuring uniform thickness (5–25 μm for Type II; 25–50 μm for Type III) and adhesion for extended service life.

Material Comparison for Critical Applications

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Key Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Moderate (enhanced with anodizing) | Enclosures, heat sinks, drone frames |

| Stainless 316 | 8.0 | 570 | Excellent | Marine hardware, chemical tanks |

| Titanium Grade 5 | 4.4 | 900 | Exceptional | Aircraft fittings, medical implants |

Material choice directly impacts manufacturability, longevity, and total cost of ownership. Wuxi Lead Precision Machinery combines metallurgical expertise with advanced CNC capabilities to guide your selection—from prototyping to volume production. Contact our engineering team to validate material suitability against your operational parameters and leverage our integrated finishing solutions for peak component performance.

Manufacturing Process & QC

The production process at Wuxi Lead Precision Machinery is engineered for precision, consistency, and zero-defect outcomes in custom sheet metal fabrication. Our integrated workflow spans from initial design to prototyping and full-scale mass production, ensuring every component meets the highest standards of quality and performance.

Design is the foundation of every successful fabrication project. Our engineering team collaborates closely with clients to translate conceptual requirements into detailed 3D models and technical drawings using advanced CAD software. This phase includes material selection, tolerance analysis, and manufacturability assessment to ensure optimal performance and cost-efficiency. Finite element analysis (FEA) and design for assembly (DFA) principles are applied to identify potential issues before production begins, minimizing downstream risks.

Once the design is finalized, we proceed to prototyping. This critical stage allows us to validate form, fit, and function under real-world conditions. Utilizing high-precision CNC punching, laser cutting, bending, and welding equipment, we produce functional prototypes that mirror the final product. Prototypes undergo rigorous in-house testing, including dimensional inspection via coordinate measuring machines (CMM), surface finish evaluation, and structural integrity checks. Client feedback is incorporated at this stage to ensure complete alignment with expectations before moving forward.

Mass production follows strict process controls and standardized work instructions to maintain consistency across high-volume runs. Our automated production lines are monitored in real time using IoT-enabled systems that track machine performance, tool wear, and environmental conditions. Each stage—from cutting and forming to welding, surface treatment, and assembly—is subject to inline quality checks. Our zero-defect philosophy is enforced through statistical process control (SPC), first-article inspection (FAI), and 100% visual inspection for critical features.

Traceability is maintained throughout the production cycle using barcode tracking and digital work orders, ensuring full visibility from raw material to finished part. All processes are compliant with ISO 9001:2015 and adhere to international standards for dimensional accuracy, material certification, and surface protection.

Below are key production specifications that define our capabilities:

| Parameter | Specification |

|---|---|

| Material Thickness | 0.5 mm – 25 mm |

| Tolerance (Standard) | ±0.1 mm (tighter upon request) |

| Max Part Size | 3000 mm × 1500 mm |

| Cutting Methods | Laser, CNC Punching, Plasma |

| Forming | CNC Press Brake (up to 1000 tons) |

| Welding Processes | MIG, TIG, Spot, Robotic Welding |

| Surface Treatments | Powder Coating, Anodizing, Zinc Plating, Passivation |

| Quality Standards | ISO 9001:2015, ISO 14001, IATF 16949 (automotive) |

At Wuxi Lead Precision Machinery, we combine engineering excellence with disciplined manufacturing to deliver custom sheet metal solutions that perform reliably in demanding industrial applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Sheet Metal Excellence

Wuxi Lead Precision Machinery stands as your definitive engineering partner for mission-critical sheet metal fabrication. We transcend conventional manufacturing by integrating aerospace-grade precision with scalable production rigor, ensuring your components meet the most stringent functional and dimensional requirements. Our facility operates under ISO 9001:2015 certification, with processes validated for industries where failure is not an option—medical devices, semiconductor equipment, and advanced energy systems. When you select Lead Precision, you gain a collaborative extension of your engineering team, not merely a supplier. We engage early in your design phase to optimize manufacturability, reduce waste, and accelerate time-to-market without sacrificing quality.

Our technical capabilities are engineered for complexity. We handle materials from ultra-thin 0.5mm aluminum to robust 25mm mild steel, with tolerances held to ±0.05mm across multi-stage fabrication sequences. Below are key specifications defining our operational envelope:

| Parameter | Specification | Application Impact |

|---|---|---|

| Laser Cutting Accuracy | ±0.03mm | Critical for micro-fluidic and sensor housings |

| Punching Tolerance | ±0.08mm (up to 6mm thickness) | Ensures seamless assembly of high-mix panels |

| CNC Bending Precision | ±0.2° angular tolerance | Guarantees repeatability in structural frames |

| Welding Standards | ISO 15614-1; ASME IX certified | Validates integrity for pressure vessels |

| Max. Press Brake Force | 300 tons | Supports heavy-gauge defense components |

| Surface Finish Range | Ra 0.4μm to Ra 3.2μm | Meets medical-grade cleanability demands |

This precision is sustained through our 24/7 monitored production ecosystem. All equipment—including Bystronic laser cutters, Amada press brakes, and Fronius welding cells—undergoes daily calibration against NIST-traceable standards. Real-time SPC data is shared via secure client portals, providing full transparency into first-pass yield rates and process stability. For projects requiring rapid iteration, our in-house prototyping cell delivers functional samples within 72 hours of CAD approval, using production-intent tooling to eliminate scale-up risks.

Initiate your precision fabrication project by contacting our engineering team directly at Contact [email protected]. Specify your component’s critical-to-quality parameters, annual volume, and target launch timeline in your inquiry. Our applications engineers will respond within 24 business hours with a tailored process plan—including DFM feedback, capacity allocation, and logistics strategy for global shipment. For urgent RFQs, reference project code “LEAD-URGENT” in your subject line to trigger expedited review.

Wuxi Lead Precision Machinery operates at the intersection of Chinese manufacturing scale and German engineering discipline. We do not merely fulfill drawings; we safeguard your product’s performance through metallurgical expertise, relentless process control, and unwavering accountability. Connect with us to transform your sheet metal challenges into competitive advantage. Your next breakthrough component begins with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.