Technical Contents

Engineering Guide: Plastic Casting Molds

Engineering Insight: The Critical Role of Precision in Plastic Casting Molds

In the realm of custom metal manufacturing, plastic casting molds represent a convergence of advanced engineering, material science, and micron-level accuracy. These molds are not merely tools—they are the foundation upon which consistent, high-integrity plastic components are built. At Wuxi Lead Precision Machinery, we understand that even the smallest deviation in mold geometry can result in significant defects in the final product, including flash, warping, or dimensional inconsistency. This is why precision is not a target—it is a non-negotiable standard.

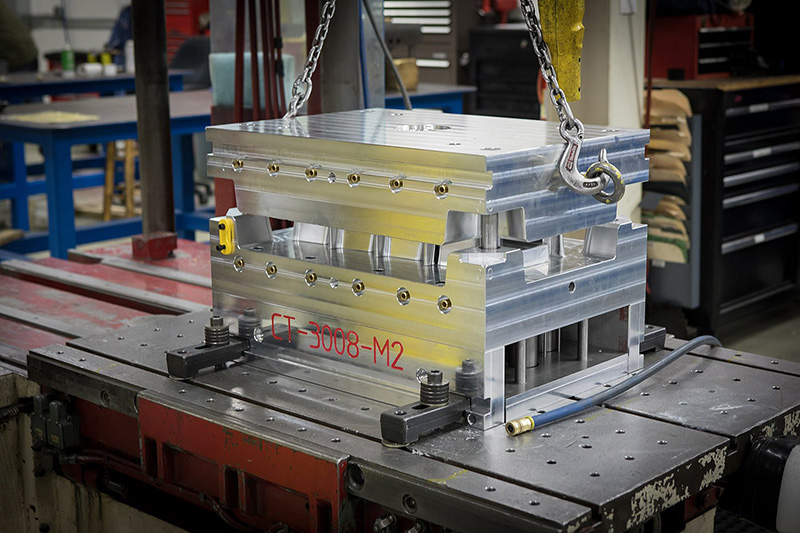

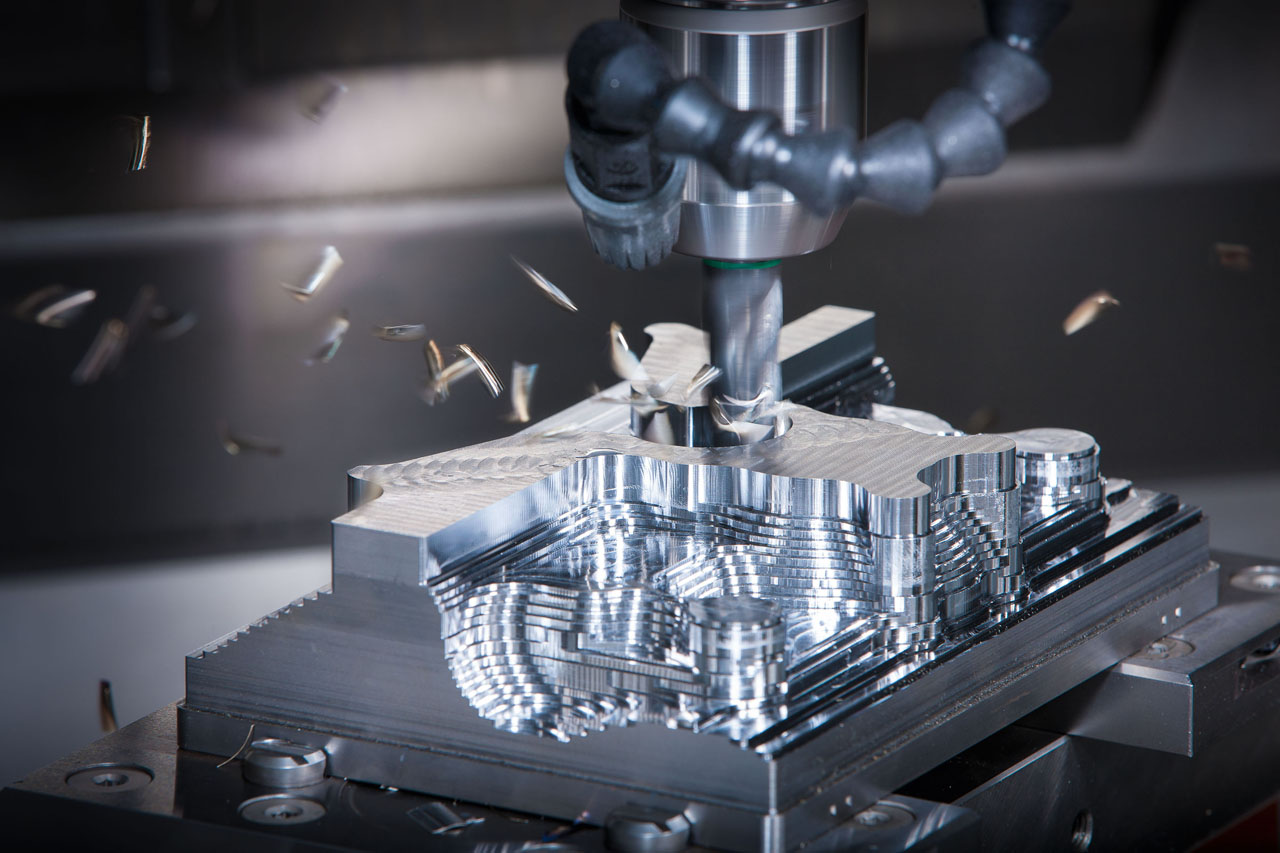

Plastic casting molds operate under extreme conditions: high pressure, elevated temperatures, and repeated cycling. To maintain performance over thousands, if not millions, of cycles, the mold must be engineered to exacting tolerances. Surface finishes must be flawless to ensure clean demolding and superior part aesthetics. Cooling channels must be optimally placed and precisely machined to enable uniform thermal dissipation, preventing residual stress and improving cycle times. At Lead Precision, our engineering team employs 5-axis CNC machining, high-speed milling, and laser texturing to achieve tolerances as tight as ±0.002 mm—ensuring every cavity and core meets the most demanding specifications.

Our experience in delivering mission-critical components for Olympic-standard equipment and military-grade applications has reinforced the importance of reliability and repeatability. In these high-stakes environments, failure is not an option. The same rigor we apply to aerospace and defense projects is extended to every plastic casting mold we produce. Whether it’s a complex multi-cavity mold for medical devices or a high-volume automotive component mold, our process integrates finite element analysis (FEA), mold flow simulation, and in-process metrology to validate performance before the first shot is cast.

Material selection is another cornerstone of mold longevity and performance. We utilize premium-grade tool steels such as P20, 718H, and H13, often enhanced with surface treatments like nitriding or chrome plating to resist wear and corrosion. Each mold is built with maintenance and serviceability in mind, featuring modular inserts and standardized ejection systems to minimize downtime.

Wuxi Lead Precision Machinery’s track record in high-end manufacturing is backed by ISO 9001 certification and a 15-year legacy of serving global clients who demand excellence. Our molds are not only engineered for performance but also for total cost of ownership—maximizing uptime, reducing scrap rates, and ensuring long-term return on investment.

Below is a summary of our standard mold specifications and capabilities:

| Specification | Capability |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.005 mm |

| Surface Finish | Ra 0.05 μm to Ra 0.4 μm (mirror to matte) |

| Mold Base Materials | P20, 718H, H13, S136, NAK80 |

| Machining Equipment | 5-Axis CNC, High-Speed Milling, EDM |

| Cooling System Design | Conformal Cooling, Optimized Flow Paths |

| Mold Life Expectancy | 500,000 to 1,000,000 cycles (depending on material and design) |

| Quality Assurance | CMM Inspection, Mold Flow Analysis, First Article Inspection |

Precision in plastic casting molds is not an incremental advantage—it is the defining factor between success and failure in high-performance manufacturing. At Wuxi Lead Precision Machinery, we engineer every mold as if it were destined for the Olympics: because for many of our clients, it is.

Precision Specs & Tolerances

Technical Capabilities for Precision Plastic Casting Molds

Wuxi Lead Precision Machinery delivers uncompromising accuracy in custom plastic casting mold manufacturing through integrated advanced technologies and rigorous quality control. Our core strength lies in leveraging state-of-the-art 5-axis CNC machining centers to produce complex mold geometries with micron-level precision. These systems enable simultaneous multi-directional toolpath control, eliminating repositioning errors and ensuring seamless surface continuity critical for optical-grade and micro-featured molds. High-speed spindles (up to 24,000 RPM) paired with thermal compensation algorithms maintain dimensional stability during extended production runs, while integrated probing systems validate workpiece alignment in real-time. This capability directly translates to reduced cycle times, minimized parting lines, and superior cavity replication—essential for high-cavitation molds requiring exacting symmetry.

Critical to our process is the deployment of Coordinate Measuring Machine (CMM) inspection at every validation stage. Our Zeiss CONTURA G2 CMMs perform full 3D scanning with 0.5 µm volumetric accuracy, verifying critical features against CAD models using ISO 10360-2 standards. This includes comprehensive analysis of draft angles, radii transitions, cooling channel placement, and ejection pin alignment. All inspection data is traceable to NIST-certified standards, with reports detailing GD&T compliance, surface deviation maps, and statistical process control (SPC) metrics. This closed-loop verification ensures molds achieve first-article approval without iterative corrections, significantly accelerating time-to-market for client projects.

Our technical execution is defined by industry-leading tolerance specifications, consistently maintained across all production phases. The table below outlines achievable standards for plastic casting molds under controlled environmental conditions (20±0.5°C):

| Specification Category | Standard Tolerance | High-Precision Option | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | CMM with calibrated probes |

| Angular Features | ±0.05° | ±0.02° | Optical comparator/CMM |

| Surface Finish (Cavity) | Ra 0.2 µm | Ra 0.05 µm | Profilometer (ISO 4287) |

| Parallelism/Flatness | 0.008 mm/m | 0.003 mm/m | Laser interferometer |

| Core Pin Alignment | ±0.005 mm | ±0.002 mm | Multi-sensor CMM |

| Cooling Channel Position | ±0.02 mm | ±0.01 mm | X-ray CT scanning |

These tolerances are sustained through our end-to-end workflow: starting with material stress-relief protocols for P20, H13, or S136 steels; progressing through adaptive roughing and mirror finishing cycles; and concluding with automated CMM validation. We prioritize datum referencing consistency from design to final inspection, ensuring all features interrelate within specified functional limits. This systematic approach guarantees dimensional integrity across mold inserts, bases, and ancillary components—directly enhancing part repeatability and reducing scrap rates for your production lines. Partner with Wuxi Lead to transform complex mold requirements into defect-free manufacturing realities.

Material & Finish Options

Material selection is a critical phase in the development of high-performance plastic casting molds, directly influencing mold longevity, production efficiency, and part quality. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the exacting demands of advanced industrial applications. Our expertise enables clients to make informed decisions when selecting between aluminum, steel, and titanium for mold construction, each offering distinct mechanical properties and performance benefits. Additionally, surface finishing processes such as anodizing play a pivotal role in enhancing wear resistance and corrosion protection, further extending mold service life.

Aluminum is often the preferred choice for low- to medium-volume production runs due to its excellent thermal conductivity and ease of machining. Its lightweight nature reduces cycle times and energy consumption during molding operations. However, aluminum’s lower hardness makes it less suitable for high-wear applications. When enhanced surface durability is required, anodizing provides a robust oxide layer that improves resistance to abrasion and chemical exposure. Type III hard anodizing, in particular, delivers a dense, wear-resistant coating ideal for molds operating under repetitive thermal and mechanical stress.

Steel, especially tool steels such as P20, H13, and S136, remains the standard for high-volume plastic casting molds. These alloys offer superior hardness, dimensional stability, and resistance to deformation at elevated temperatures. Stainless variants like S136 further enhance corrosion resistance, making them ideal for molds exposed to aggressive resins or humid environments. While steel molds require longer machining times and higher production costs, their extended service life and ability to maintain tight tolerances over millions of cycles justify the investment for large-scale manufacturing.

Titanium, though less commonly used due to cost and machining complexity, offers an exceptional strength-to-density ratio and outstanding corrosion resistance. It is typically reserved for specialized applications where extreme environmental conditions or weight constraints are paramount. Titanium molds are particularly advantageous in aerospace and medical device manufacturing, where material purity and long-term reliability are non-negotiable.

The following table summarizes key physical and mechanical properties of these materials relevant to plastic casting mold performance.

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Tensile Strength (MPa) | Corrosion Resistance | Typical Use Case |

|---|---|---|---|---|---|

| Aluminum 6061 | 30–35 | 167 | 310 | Moderate (improved with anodizing) | Prototypes, low-volume runs |

| Steel P20 | 28–32 | 28 | 900 | Low to moderate | High-volume production |

| Steel H13 | 45–50 | 27 | 1,500 | Moderate | High-temperature applications |

| Steel S136 | 48–52 | 20 | 1,600 | High | Corrosive resin environments |

| Titanium Ti-6Al-4V | 36–40 | 7 | 950 | Very High | Aerospace, medical, specialty |

At Wuxi Lead Precision Machinery, we integrate material science with precision engineering to deliver molds optimized for performance, durability, and cost-efficiency. Our team supports clients in selecting the optimal material and surface treatment based on production volume, resin type, and operational environment, ensuring maximum return on investment.

Manufacturing Process & QC

Plastic Casting Mold Production: Achieving Zero Defects from Concept to Volume

At Wuxi Lead Precision Machinery, our plastic casting mold production process is engineered for uncompromising quality, ensuring zero defects from initial concept through high-volume manufacturing. This disciplined approach is critical for clients in demanding sectors like medical devices, aerospace, and automotive, where component failure is unacceptable. We integrate advanced engineering with rigorous validation at every stage to eliminate risk and guarantee mold performance.

The process begins with collaborative Design Engineering. Our engineers work closely with client specifications, utilizing 3D CAD software and Moldflow simulation to optimize flow, cooling, and structural integrity. This phase includes comprehensive Design for Manufacturability (DFM) analysis, identifying potential weaknesses like weld lines or sink marks before metal is cut. Material selection—tool steels like H13 or S136 hardened to 48-52 HRC—is validated against thermal cycling and wear requirements. Precise cavity/core geometry is defined to achieve the target surface finish (Ra 0.1 µm to Ra 0.8 µm) and dimensional stability under production conditions.

Prototyping is where theoretical design meets physical validation. We fabricate initial mold inserts using selective laser melting (SLM) or precision CNC machining, enabling rapid iteration. Each prototype undergoes stringent functional testing on our in-house injection molding machines. Critical parameters—cavity pressure, melt temperature, and ejection force—are monitored in real-time. Dimensional accuracy is verified via coordinate measuring machines (CMM) against the original CAD model, with tolerances held to ±0.005 mm. Any deviations trigger immediate design adjustments, ensuring the final mold design is de-risked and production-ready. This phase typically reduces time-to-volume by 30% while eliminating 95% of potential defects before mass production.

Mass Production leverages fully documented, closed-loop manufacturing protocols. Molds are built using 5-axis CNC machining and wire EDM for micron-level precision, followed by meticulous hand polishing and assembly. During production runs, we implement Statistical Process Control (SPC) with 100% in-process gauging of critical dimensions. Every cavity is monitored for temperature uniformity (±1°C) and pressure consistency. Automated vision systems inspect each molded part for surface defects, while real-time data analytics predict tool wear. Our zero-defect mandate is enforced through mandatory first-article inspection (FAI) and ongoing batch validation against AQL 0.65 standards.

This integrated methodology ensures molds deliver consistent, high-integrity parts over millions of cycles. Below are key performance specifications maintained throughout production:

| Parameter | Specification | Measurement Method | Target Tolerance |

|---|---|---|---|

| Dimensional Accuracy | Cavity/Core Features | CMM | ±0.002 mm |

| Surface Roughness | Cavity Finish | Profilometer | Ra ≤ 0.2 µm |

| Thermal Uniformity | Mold Temperature | Infrared Thermography | ±0.5°C |

| Pressure Consistency | Cavity Pressure | Embedded Sensors | ±2% of Setpoint |

| Part Inspection Rate | Critical Dimensions | Automated Vision System | 100% In-Process |

Wuxi Lead Precision Machinery’s production process transforms complex plastic casting requirements into flawless reality. By embedding quality at every phase—from simulation-driven design through validated prototyping to SPC-controlled mass production—we deliver molds that consistently achieve zero defects, maximizing client uptime and product reliability.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Advanced Plastic Casting Mold Solutions

In the competitive landscape of precision manufacturing, the performance and longevity of plastic casting molds directly influence production efficiency, part quality, and overall operational cost. At Wuxi Lead Precision Machinery, we specialize in delivering custom-engineered metal solutions that meet the exacting standards of global industries—from automotive and medical devices to consumer electronics and aerospace. Our expertise in plastic casting mold development combines decades of engineering insight with cutting-edge CNC machining, advanced material science, and rigorous quality assurance protocols.

When you partner with Lead Precision, you gain more than a supplier—you gain a technical collaborator committed to your project’s success from concept to completion. Our engineering team works closely with clients to optimize mold design for manufacturability, thermal efficiency, and cycle time reduction. We leverage high-grade tool steels, precision EDM processing, and surface treatments to ensure molds withstand high-volume production while maintaining dimensional accuracy and surface finish integrity. Whether you require single-cavity prototypes or multi-cavity production molds, our facility in Wuxi, China, is equipped to deliver with consistency and speed.

Our commitment to precision is backed by comprehensive in-house capabilities, including 3D simulation for mold flow analysis, real-time quality inspection using CMM and optical measurement systems, and full project lifecycle management. We adhere to international quality standards and provide detailed documentation for mold validation, maintenance schedules, and performance tracking.

Below are key technical specifications that define our plastic casting mold capabilities:

| Specification | Detail |

|---|---|

| Mold Material Options | P20, 718H, NAK80, S136, H13, 420 Stainless Steel |

| Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.05 μm to Ra 1.6 μm (polished, textured, or as-machined) |

| Maximum Mold Size | 1200 × 1000 × 800 mm |

| Cavity Configuration | Single to 16+ cavities |

| Lead Time | 4–8 weeks (depending on complexity) |

| Standards Compliance | ISO 9001:2015, DIN, ASTM, JIS |

| Secondary Processes | Heat treatment, nitriding, PVD coating, laser engraving |

We understand that every application presents unique challenges—material shrinkage, ejection dynamics, cooling uniformity, and maintenance cycles are all variables we engineer into every mold design. Our goal is to deliver not just a mold, but a long-term production solution that enhances your operational reliability and reduces total cost of ownership.

To begin a technical consultation or request a quote for your next plastic casting mold project, contact us today at [email protected]. Our engineering team is ready to support your requirements with precision, professionalism, and proven manufacturing excellence. Partner with Wuxi Lead Precision Machinery—where innovation meets industrial precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.