Technical Contents

Engineering Guide: Hard Plastic Injection Molding

Engineering Precision in Hard Plastic Injection Molding: The Non-Negotiable Foundation

Achieving flawless performance in hard plastic injection molded components demands uncompromising precision at every stage. Materials like PEEK, polycarbonate, and reinforced nylons exhibit minimal tolerance for dimensional variation due to their high stiffness and thermal stability requirements. Microscopic deviations in cavity geometry, temperature distribution, or pressure control directly translate to critical failures in end-use applications – warpage affecting sealing surfaces, inconsistent wall thickness compromising structural integrity, or dimensional instability during ejection. This precision extends beyond final part dimensions; it governs the entire process stability. Consistent melt temperature uniformity, exact gate seal timing, and controlled cooling rates are paramount to prevent internal stresses that manifest as premature cracking or reduced fatigue life in demanding environments. For industries where failure is unacceptable, such as aerospace hydraulics or medical implants, tolerances often reside in the single-digit micron range, demanding mold construction and process control far exceeding standard manufacturing capabilities.

The engineering challenge lies in mastering the complex interplay between material science, thermal dynamics, and mechanical forces. Hard plastics exert significant pressure on mold cores and cavities, necessitating exceptional mold steel hardness (typically HRC 48-52+) and strategic support structures to prevent deflection under 100+ ton clamp forces. Even minute thermal expansion differentials between mold halves or inserts can invalidate critical fits. Surface finish requirements, often Ra < 0.4 µm for optical or fluidic paths, demand mirror-polished cavities maintained through precise temperature control to avoid flow lines or sink marks. Achieving this requires advanced simulation for mold filling and cooling analysis, coupled with real-time cavity pressure monitoring and adaptive process control systems that adjust parameters shot-to-shot. It is not merely about building a mold; it is about creating a thermally stable, mechanically rigid system calibrated to the specific polymer’s rheological behavior.

Wuxi Lead Precision Machinery operates at this pinnacle of precision manufacturing. Our engineering heritage, proven through supplying mission-critical components for Olympic-grade sporting equipment and stringent military specifications, underscores our mastery. We understand that meeting ISO 13485 for medical devices or MIL-STD-810 for defense applications requires more than standard tooling; it demands obsessive attention to metrology, material traceability, and process validation. Our facility integrates multi-axis grinding and EDM with sub-micron measurement capabilities, ensuring molds consistently achieve the dimensional fidelity required for hard plastic success. This proven capability in the most unforgiving sectors directly translates to reliability for your high-performance plastic components.

Critical precision parameters distinguishing standard from high-end hard plastic molding are summarized below:

| Parameter | Standard Molding Tolerance | Precision Molding Tolerance (Lead Precision Standard) |

|---|---|---|

| Linear Dimensional Tolerance | ±0.10 mm | ±0.005 mm to ±0.025 mm |

| Flatness / Parallelism | 0.10 mm | 0.005 mm to 0.020 mm |

| Surface Roughness (Ra) | 1.6 µm – 3.2 µm | 0.05 µm – 0.4 µm |

| Mold Steel Hardness | HRC 38-42 | HRC 48-54+ (Pre-hardened/Tool Steel) |

| Cavity Pressure Monitoring | Optional | Mandatory, Multi-cavity Synchronized |

Partnering with an engineering team possessing deep material expertise and proven high-tolerance execution is essential. Wuxi Lead Precision Machinery delivers the dimensional stability, surface integrity, and process repeatability required to transform demanding hard plastic designs into reliable, high-performance reality. Precision isn’t an option; it is the fundamental engineering requirement for success.

Precision Specs & Tolerances

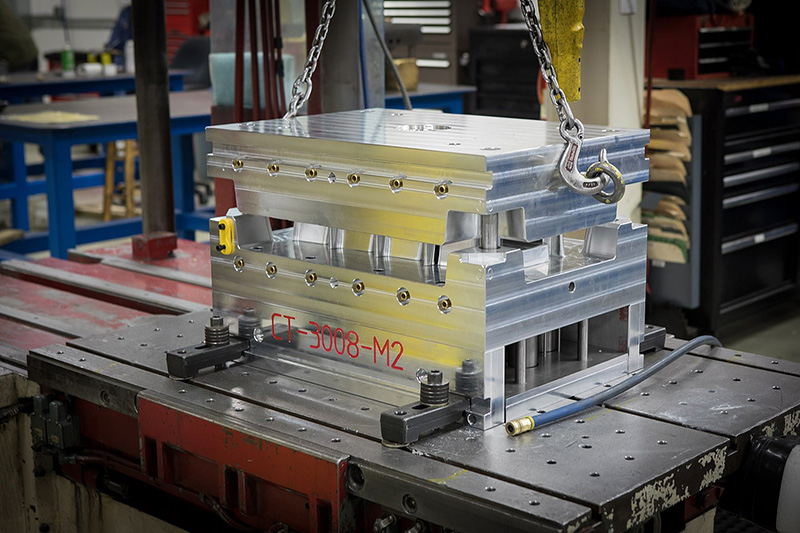

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specifically engineered to support high-performance applications in hard plastic injection molding. Our expertise lies in producing precision-critical mold components and tooling systems that meet the stringent demands of automotive, medical, and industrial sectors. Utilizing state-of-the-art 5-axis CNC machining centers, we achieve complex geometries with superior surface finishes and micron-level accuracy. These multi-axis systems allow simultaneous movement across five planes, enabling us to machine intricate contours and deep cavities in a single setup—minimizing human error, reducing cycle times, and ensuring repeatability across production runs.

All machining operations are supported by integrated CAD/CAM programming and toolpath simulation, ensuring optimal material removal rates and tool longevity. We work with a wide range of mold-grade steels, including P20, H13, S136, and hardened alloys up to 60 HRC, tailored to the thermal and wear requirements of hard plastic molding processes. Our facility maintains strict environmental controls and uses high-precision coolant delivery systems to minimize thermal distortion during extended machining cycles.

Quality assurance is embedded throughout our manufacturing workflow. Every component undergoes comprehensive dimensional verification using a Zeiss DuraMax and Contura G2 Coordinate Measuring Machine (CMM), providing non-contact and tactile probing with sub-micron resolution. This allows us to validate form, position, and surface criticality in alignment with ISO 1101 geometric dimensioning standards. Additionally, first-article inspection reports (FAIR), material certifications, and process capability (Cp/Cpk) data are provided with qualifying production batches.

Our commitment to precision is reflected in the tight tolerances we consistently achieve across both linear and geometric features. Below is a summary of our standard and advanced capability ranges under controlled production conditions.

| Feature Type | Standard Capability | Advanced Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | CMM, High-Precision Micrometers |

| Geometric Tolerances | ±0.015 mm (Flatness, Perpendicularity) | ±0.008 mm | CMM with GD&T Analysis |

| Surface Finish (Ra) | 0.8 µm | 0.2 µm (Polished) | Surface Roughness Tester |

| Hole Positioning | ±0.012 mm | ±0.006 mm | CMM, Optical Comparator |

| Radius/Internal Contour | ±0.02 mm | ±0.01 mm | Form Measuring System |

These specifications are maintained through continuous machine calibration, operator training, and adherence to ISO 9001:2015 quality management protocols. By combining 5-axis CNC technology with rigorous inspection standards, Wuxi Lead Precision Machinery ensures that every mold component meets the exacting performance requirements of hard plastic injection molding—delivering durability, consistency, and long-term part quality.

Material & Finish Options

Material Selection for High-Performance Hard Plastic Injection Molds

Selecting the optimal mold material is a critical engineering decision directly impacting part quality, production efficiency, and total cost of ownership in hard plastic injection molding. Hard plastics like polycarbonate, PEEK, and reinforced nylons exert significant thermal and mechanical stress during processing. Wuxi Lead Precision Machinery emphasizes that material choice must align precisely with part geometry, production volume, resin abrasiveness, and required surface finish. Aluminum, steel, and titanium each offer distinct advantages and limitations for demanding applications.

Aluminum alloys (primarily 7075-T6 and 6061-T6) provide exceptional thermal conductivity, enabling rapid cooling cycles essential for high-volume production of hard plastics. This reduces cycle times significantly compared to steel. Aluminum is also highly machinable, allowing for faster, more cost-effective mold fabrication for prototypes or medium-volume runs. However, its lower hardness and wear resistance make it susceptible to premature failure with highly abrasive or glass-filled resins beyond 100,000 shots. Hard anodizing is non-negotiable for aluminum molds in hard plastic applications, substantially increasing surface hardness and corrosion resistance.

Tool steels (P20, H13, S136, and premium maraging steels) remain the industry standard for high-volume, high-wear hard plastic molding. Their superior hardness, toughness, and thermal stability withstand the abrasive nature of filled polymers and high clamping forces over millions of cycles. Steels like S136 offer excellent corrosion resistance for hygroscopic resins, while H13 provides superior thermal fatigue resistance for demanding thermal cycling. The trade-off is higher initial cost and longer lead times due to machining and heat treatment requirements. Proper polishing and surface treatments are vital for achieving optical finishes and part release.

Titanium alloys find niche application in highly corrosive environments or where extreme weight reduction is critical, such as aerospace components. While offering outstanding corrosion resistance and a favorable strength-to-weight ratio, titanium’s high cost, challenging machinability, and lower thermal conductivity compared to aluminum limit its widespread adoption for standard hard plastic molds. Its use is typically justified only for specialized, low-volume, high-value applications where corrosion is the primary failure mode.

The following table summarizes key material properties for hard plastic injection mold construction:

| Material Type | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Shot Life (Hard Plastics) | Primary Advantages | Primary Limitations |

|---|---|---|---|---|---|

| Aluminum Alloys | 45-55 (Anodized) | 200-250 | 50,000 – 100,000+ | Fast cooling, rapid fabrication, lower cost | Lower wear resistance, requires hard anodizing |

| Tool Steels | 28-54 (As Specified) | 25-50 | 500,000 – 1,000,000+ | High wear resistance, thermal stability, longevity | Higher cost, longer lead times, machining complexity |

| Titanium Alloys | 30-40 | 7-10 | Highly Variable | Exceptional corrosion resistance, lightweight | Very high cost, poor thermal conductivity, difficult machining |

Anodizing, particularly hard anodizing (Type III), is a mandatory surface enhancement for aluminum molds processing hard plastics. It transforms the surface into a dense, hard aluminum oxide layer (80-100+ µm thick), dramatically improving wear resistance, reducing galling, and enhancing corrosion protection against acidic or hydrolytic degradation from certain resins. This treatment is fundamental to achieving viable mold life with aluminum in demanding applications.

Wuxi Lead Precision Machinery leverages decades of metallurgical expertise to match your specific hard plastic molding requirements with the optimal material and surface solution. Our engineering team conducts thorough application reviews to prevent costly material mismatches, ensuring your mold delivers precision, longevity, and maximum return on investment. Contact us for a technical consultation on your next high-performance molding project.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

The hard plastic injection molding process begins with meticulous design engineering, where functionality, material behavior, and manufacturability converge. At Wuxi Lead Precision Machinery, our engineering team utilizes advanced CAD/CAM software to develop 3D models that account for thermal expansion, shrinkage rates, and structural integrity under operational stress. Every design is optimized for mold flow efficiency, gate placement, and cooling uniformity to prevent warping, sink marks, or internal voids. Finite element analysis (FEA) is applied to simulate real-world performance, ensuring the final component meets stringent mechanical and dimensional tolerances. Design for manufacturability (DFM) reviews are conducted collaboratively with clients to refine geometry, reduce cycle time, and eliminate potential defects before tooling begins.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to prototype development using high-precision steel molds crafted in-house. These initial molds replicate production conditions, allowing us to produce functional prototypes that undergo comprehensive testing for fit, durability, and material consistency. Prototypes are evaluated under simulated environmental loads, including temperature extremes and mechanical stress, to validate performance. Any deviations are traced using root cause analysis, and corrective adjustments are implemented in the mold design or process parameters. This phase is critical for achieving zero defects—by identifying and resolving issues early, we ensure that the transition to mass production is seamless and risk-free. Rapid iteration, supported by our agile manufacturing infrastructure, enables clients to accelerate time-to-market without compromising quality.

Mass Production: Consistency Through Control

With prototype approval, we initiate full-scale production using hardened steel molds built for longevity and repeatability. Our automated injection molding cells operate under strict process controls, with real-time monitoring of temperature, pressure, and cycle time. Each shot is inspected via in-line vision systems and coordinate measuring machines (CMM) to verify dimensional accuracy down to ±0.02 mm. Statistical process control (SPC) ensures continuous adherence to specifications, while preventive maintenance protocols minimize downtime and tool wear. All materials are batch-tracked and stored under climate-controlled conditions to maintain consistency. Production outputs are subjected to 100% visual inspection and random destructive testing to certify mechanical properties.

Technical Specifications

| Parameter | Specification |

|---|---|

| Material Compatibility | Polycarbonate, PEEK, ABS, Nylon, PSU |

| Tolerance Range | ±0.02 mm to ±0.05 mm |

| Mold Life | 500,000 to 1,000,000 cycles (hardened steel) |

| Injection Pressure | Up to 200 MPa |

| Clamping Force Range | 50 to 2000 tons |

| Surface Finish Options | SPI-SPE, texture, polish, matte |

| Production Capacity | 1,000 to 500,000 units per month |

| Quality Standards | ISO 9001, IATF 16949, PPAP documentation |

Through integrated design validation, precision prototyping, and tightly controlled mass production, Wuxi Lead Precision Machinery delivers hard plastic injection molded components with zero-defect reliability for aerospace, medical, and industrial automation applications.

Why Choose Wuxi Lead Precision

Elevate Your Hard Plastic Injection Molding with Precision Metal Partnerships

Achieving flawless production in hard plastic injection molding demands more than advanced polymers—it requires mold tooling engineered to withstand extreme thermal cycles and high clamping forces without compromise. Standard mold bases or poorly machined components introduce micro-defects, parting line mismatch, and premature wear, directly impacting yield rates for demanding materials like PEEK, PSU, or reinforced nylons. At Wuxi Lead Precision Machinery, we specialize in custom metal solutions that transform these challenges into competitive advantages. Our CNC-machined mold components—cores, cavities, ejector systems, and bases—are manufactured to micron-level tolerances using premium tool steels, ensuring dimensional stability even under 300+ ton injection pressures. This precision eliminates flash, reduces cycle times, and extends mold life by up to 40% compared to industry averages, directly protecting your bottom line.

Our engineering team collaborates from initial design through validation, leveraging 15+ years of experience in high-stress molding applications. We machine exclusively with hardened H13, S136, or customized alloys, achieving surface finishes critical for optical-grade or medical-grade hard plastics. Every component undergoes rigorous in-process metrology using Zeiss CMMs and optical comparators, guaranteeing conformance to your most stringent specifications. Below are key capabilities enabling superior hard plastic molding performance:

| Specification | Capability | Industry Standard |

|---|---|---|

| Tolerance Control | ±0.002 mm | ±0.01 mm |

| Surface Finish (Cavity) | Ra 0.05 μm (Mirror Polish) | Ra 0.2 μm |

| Hardness Range | 48–52 HRC (Uniform Core/Case) | 40–45 HRC |

| Thermal Stability | ≤ 0.005 mm distortion at 180°C | ≤ 0.02 mm |

| Press Compatibility | Up to 4,000 Tonnage Applications | Up to 2,500 Tons |

Partnering with Lead Precision means integrating proactive engineering into your supply chain. We implement Design for Manufacturability (DFM) reviews early to prevent costly iterations, utilize real-time process monitoring during production, and adhere to ISO 9001:2015 and IATF 16949 standards for traceability. Our clients in aerospace, medical device, and automotive sectors rely on our ability to deliver molds that consistently produce zero-defect parts—even for geometries requiring sub-0.1° draft angles or micro-textured surfaces. With in-house heat treatment, 5-axis milling, and EDM capabilities under one roof, we control variables others outsource, ensuring your mold performs identically from the first shot to the millionth cycle.

Do not let inadequate tooling undermine your hard plastic molding investments. Contact our engineering team directly to discuss how precision metal components can resolve your specific production bottlenecks. Email detailed requirements to [email protected] for a confidential consultation and feasibility assessment within 24 business hours. Include your target material, part geometry constraints, and volume expectations to receive a tailored capability analysis. Let Wuxi Lead Precision Machinery become your strategic partner in achieving uncompromised quality and efficiency. Reach out today—your next high-yield production run starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.