Technical Contents

Engineering Guide: Mill Cnc

Engineering Insight: The Critical Role of Precision in Mill CNC Operations

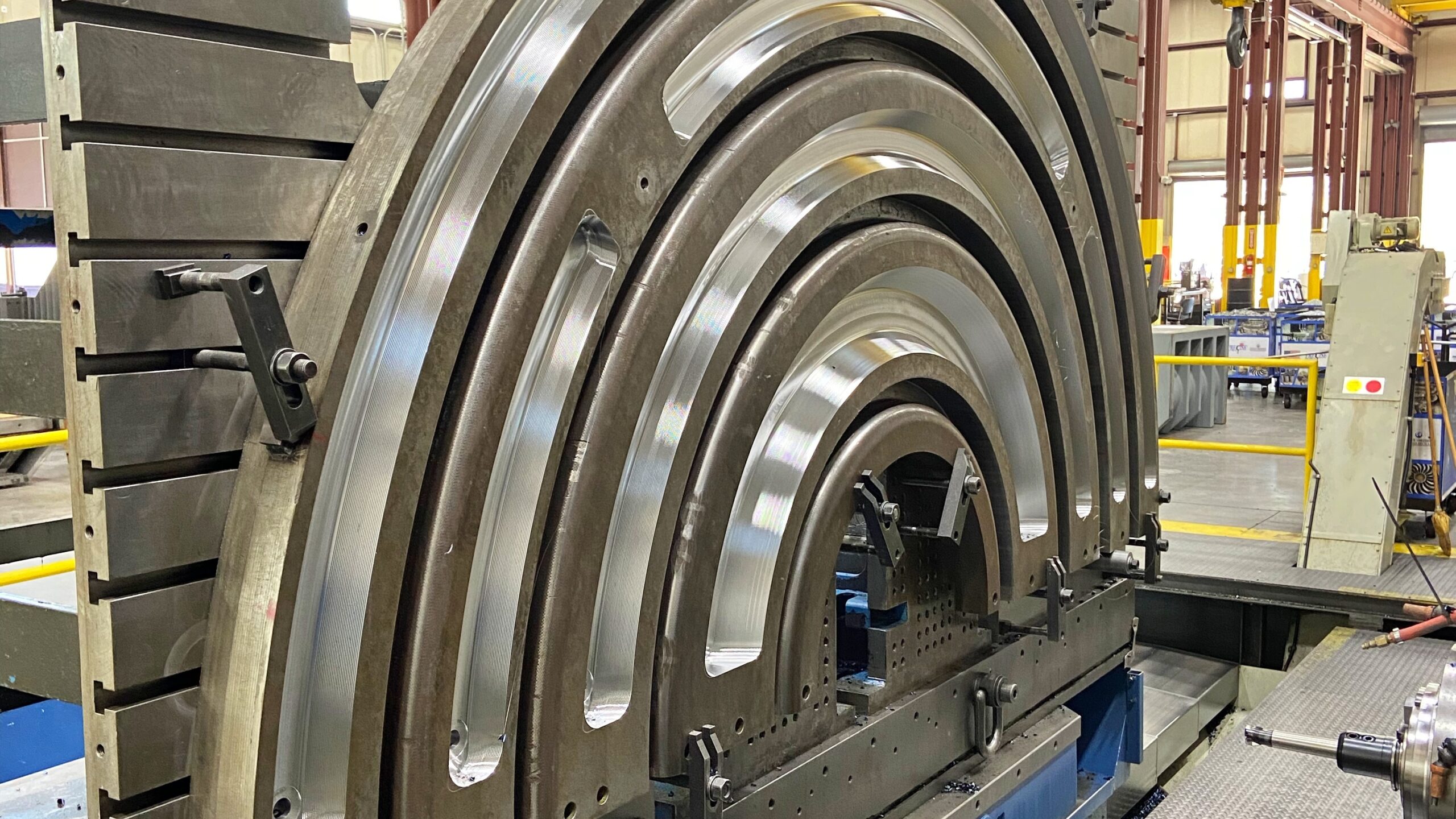

In high-end manufacturing, the term “precision” is not merely a performance metric—it is the foundation upon which reliability, repeatability, and performance are built. At Wuxi Lead Precision Machinery, we define precision in mill CNC systems as the consistent ability to achieve exact dimensional accuracy, surface finish, and geometric integrity across production cycles. This level of control is non-negotiable in industries where failure is not an option—such as aerospace, defense, and high-performance automotive engineering.

Our engineering philosophy centers on the integration of advanced kinematics, thermal stability, and real-time feedback systems to minimize deviation. Every mill CNC machine produced at our facility undergoes rigorous calibration and dynamic testing to ensure sub-micron accuracy under full load. This commitment to precision is validated through our involvement in mission-critical projects, including components for Olympic-standard sporting equipment and precision subsystems for military-grade applications. These projects demand not only tight tolerances—often within ±0.002 mm—but also long-term durability under extreme conditions.

The core of our mill CNC performance lies in the synergy between mechanical design and intelligent control. High-rigidity cast iron bases, preloaded linear guides, and direct-drive spindle technology reduce vibration and harmonic distortion. Simultaneously, our proprietary CNC interface enables adaptive machining strategies, allowing the system to adjust feed rates and tool paths in response to material variances and cutting forces. This closed-loop precision ensures optimal tool life and part consistency, even in complex multi-axis operations.

Material selection and machine build quality further reinforce precision longevity. Our frames are stress-relieved and aged to prevent deformation over time, while spindle units are balanced to ISO 1940 standards. These engineering choices reflect decades of refinement, rooted in our experience serving Tier 1 suppliers and government-certified manufacturers.

Below are key performance specifications representative of our flagship mill CNC models:

| Specification | Value |

|---|---|

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Spindle Speed Range | 8,000 – 24,000 rpm |

| Axis Configuration | 3 to 5-axis simultaneous |

| Control System | Fanuc 31i-B5 / Siemens 840D |

| Rapid Traverse Rate (X/Y/Z) | 60 / 60 / 50 m/min |

| Table Size (Standard) | 1,200 × 600 mm |

| Maximum Workpiece Weight | 1,200 kg |

| Tool Magazine Capacity | 30T / 60T (optional) |

| Positioning Precision (After Compensation) | ±0.001 mm |

Precision in mill CNC machining is not achieved through isolated components, but through holistic engineering. At Wuxi Lead Precision Machinery, our legacy in delivering systems for Olympic and military applications underscores our capability to meet the most stringent demands. Each machine is a testament to the principle that true precision is measured not in millimeters, but in microns—and in the confidence our clients place in every cut.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

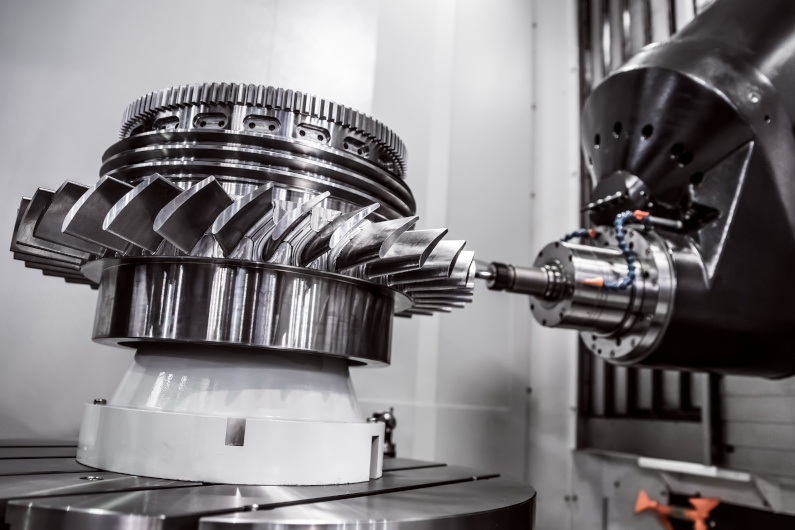

Wuxi Lead Precision Machinery delivers uncompromising precision and complexity management through our advanced CNC milling capabilities. Our core strength lies in high-performance 5-axis simultaneous machining centers, enabling the production of intricate geometries impossible with conventional 3-axis systems. This technology eliminates the need for multiple setups, significantly reducing cumulative error potential while enhancing part accuracy and surface integrity. We machine a comprehensive range of materials including aerospace-grade aluminum alloys, titanium, stainless steels, Inconel, and high-performance engineering plastics to exacting specifications. Our machining envelope accommodates components up to 1200 x 800 x 750 mm, supporting diverse project scales from miniature medical implants to substantial aerospace structural elements. The integration of high-torque spindles operating at speeds up to 24,000 RPM ensures optimal metal removal rates across diverse materials while maintaining stringent tolerances and superior finishes.

Quality assurance is rigorously embedded within our manufacturing process, not merely a final checkpoint. Every critical dimension and feature undergoes systematic verification using state-of-the-art Coordinate Measuring Machines (CMM) equipped with advanced tactile and optical probes. Our certified metrology technicians perform comprehensive inspections against original CAD models, validating geometric dimensioning and tolerancing (GD&T) compliance, complex surface profiles, and positional accuracy. This data-driven approach provides full traceability and generates detailed inspection reports, offering clients transparent verification of conformance to their engineering requirements. Our quality management system is ISO 9001 certified, ensuring consistent adherence to international standards throughout production.

The following table details our standard achievable tolerance capabilities under controlled production conditions. Actual tolerances for specific projects are confirmed during engineering review based on material, geometry complexity, and functional requirements.

| Specification Category | Standard Capability | High-Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensional Tolerance | ±0.010 mm | ±0.005 mm | Up to 150 mm feature size |

| Angular Tolerance | ±0.02° | ±0.01° | Verified via CMM |

| Geometric Tolerances (GD&T) | Full Capability | IT6 Level | Including profile, position, runout |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Machined finish; post-process available |

| Maximum Work Envelope (mm) | 1200 x 800 x 750 | N/A | XYZ travel on primary 5-axis platforms |

| Repeatability | ±0.003 mm | ±0.002 mm | Verified per ISO 230-2 |

Our technical team collaborates closely with client engineering departments during the Design for Manufacturability (DFM) phase to optimize part geometry for precision machining, ensuring cost-effective realization of the most challenging designs. Contact Wuxi Lead Precision Machinery to discuss how our technical capabilities align with your specific high-precision component requirements.

Material & Finish Options

Material selection is a critical phase in precision CNC milling, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in high-accuracy mill CNC operations tailored to the exacting demands of aerospace, medical, automotive, and industrial sectors. Our expertise ensures optimal pairing of materials and finishing processes to meet technical and functional requirements.

Aluminum stands as a preferred choice for applications requiring lightweight strength and excellent machinability. Grade 6061-T6 is widely used for structural components due to its balanced mechanical properties and corrosion resistance. For higher strength needs, 7075-T6 offers superior tensile strength, making it ideal for aerospace fittings and high-stress mechanical parts. Aluminum’s low density and high thermal conductivity also make it suitable for heat sinks and electronic enclosures.

Steel variants, particularly 4140 and 1018, deliver enhanced strength and wear resistance for heavy-duty applications. 4140 alloy steel, with its chromium and molybdenum content, provides excellent hardenability and toughness, frequently used in shafts, gears, and tooling. 1018 low-carbon steel is favored for its weldability and machinability, often selected for jigs, fixtures, and general-purpose components. Stainless steel 304 and 316 are chosen when corrosion resistance is paramount, especially in medical and marine environments.

Titanium, specifically Grade 5 (Ti-6Al-4V), offers an exceptional strength-to-density ratio and outstanding resistance to extreme temperatures and corrosion. It is the material of choice in aerospace, defense, and implantable medical devices. While more challenging to machine due to its low thermal conductivity and tendency to gall, our advanced mill CNC systems with optimized toolpaths and cooling strategies ensure precise, defect-free results.

Surface finishing significantly enhances both functionality and aesthetics. Anodizing is a key post-processing method for aluminum components. Type II (sulfuric acid) anodizing improves corrosion and wear resistance while allowing for color dyeing, commonly used in consumer and industrial products. Type III (hardcoat) anodizing produces a thicker, harder oxide layer, ideal for parts exposed to high abrasion or extreme environments.

Below is a comparative overview of key materials used in our mill CNC operations:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Applications | Machinability Rating |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.70 | Enclosures, brackets | Excellent |

| Aluminum 7075-T6 | 570 | 2.81 | Aerospace components | Good |

| Steel 4140 | 655 | 7.85 | Shafts, tooling | Moderate |

| Steel 1018 | 440 | 7.87 | Jigs, fixtures | Excellent |

| Stainless 304 | 505 | 8.00 | Medical, food processing | Fair |

| Titanium Ti-6Al-4V | 900 | 4.43 | Aerospace, medical implants | Poor |

At Wuxi Lead Precision Machinery, we combine deep material science knowledge with state-of-the-art CNC milling technology to deliver components that meet the highest standards of precision and reliability. Partner with us to ensure your next project leverages the right material and finish for optimal performance.

Manufacturing Process & QC

Precision CNC Milling Production Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our production process for high-end CNC milling is engineered for uncompromising quality and repeatability, ensuring Zero Defects from initial concept to final shipment. This rigorously controlled workflow integrates advanced technology with deep manufacturing expertise, specifically designed for demanding aerospace, medical, and industrial applications where failure is not an option.

The DESIGN PHASE begins with meticulous collaboration. Our engineering team works directly with client CAD models, performing comprehensive tolerance stack-up analysis and manufacturability reviews using Siemens NX and Mastercam. We identify potential stress points, material constraints, and critical GD&T callouts early, optimizing toolpaths virtually to prevent errors before metal is cut. This phase establishes the foundational blueprint for precision, ensuring every dimension and surface finish requirement is achievable within our process capabilities and aligned with AS9100 and ISO 13485 standards.

Prototyping is not merely a sample stage but a critical process validation step. Using the same HAAS and DMG MORI 5-axis machining centers designated for production, we manufacture initial parts under full production conditions. Each prototype undergoes exhaustive First Article Inspection (FAI) per AS9102 standards, utilizing Zeiss CONTURA CMMs and optical comparators to verify 100% of specified dimensions, material properties, and surface integrity. Any deviation triggers immediate root cause analysis and process refinement. This phase validates the entire manufacturing system – fixtures, tooling, programming, and inspection protocols – proving the process is capable of Zero Defects before scaling.

MASS PRODUCTION executes the validated process with relentless consistency. Our shop floor operates under real-time Statistical Process Control (SPC), with in-process gauging and automated tool wear compensation feeding data directly into our MES. Every operation is monitored; critical dimensions are verified at defined intervals using calibrated equipment traceable to NIST standards. The Zero Defects philosophy is embedded through poka-yoke fixtures, comprehensive operator training, and a culture of continuous improvement. Final inspection is non-negotiable, with full CMM reports and material certifications provided. This closed-loop system guarantees that every component in the production run meets the exact specifications validated during prototyping, delivering absolute reliability.

The following table summarizes our core production capabilities for precision CNC milling:

| Parameter | Capability | Standard Tolerance | Verification Method |

|---|---|---|---|

| Material Range | Aluminum, Titanium, Inconel, Stainless Steel, Plastics | N/A | Material Certificates (MTR) |

| Linear Tolerance | ±0.005 mm (±0.0002″) | ±0.0125 mm | Zeiss CMM, Optical Comparator |

| Geometric Tolerance | Position ±0.01 mm | Per Drawing GD&T | Zeiss CMM |

| Surface Finish | Ra 0.4 µm (16 µin) | Ra 1.6 µm | Profilometer |

| Max Work Envelope | 1000 x 600 x 500 mm | N/A | Laser Tracker Calibration |

This integrated approach – rigorous design validation, process-proven prototyping, and SPC-driven mass production – is the cornerstone of Wuxi Lead’s commitment to Zero Defects. We transform complex designs into flawless, high-performance components, ensuring your critical applications operate with absolute precision and reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Milling Excellence

At Wuxi Lead Precision Machinery, we understand that in high-stakes manufacturing environments, precision, reliability, and consistency are non-negotiable. As a leading provider of advanced CNC milling solutions in China, we specialize in delivering custom-engineered components and turnkey machining services that meet the exacting standards of aerospace, medical, automotive, and industrial equipment industries. Our commitment to innovation, quality control, and client collaboration sets us apart as a strategic partner in precision manufacturing.

When you choose to partner with Lead Precision, you gain access to state-of-the-art 3-axis, 4-axis, and 5-axis CNC milling capabilities, supported by a team of seasoned engineers and machinists with over 15 years of industry expertise. Our facility is equipped with cutting-edge HAAS, DMG MORI, and Fanuc-controlled machines, ensuring micron-level accuracy and repeatability across both prototyping and high-volume production runs. From complex geometries to tight-tolerance components, we deliver precision-machined parts that perform under the most demanding conditions.

Our integrated manufacturing approach combines advanced CAD/CAM programming, in-process inspection, and full traceability to ensure every component meets international quality benchmarks. We are ISO 9001:2015 certified and maintain rigorous quality assurance protocols, including first-article inspection reports (FAIR), PPAP documentation, and real-time process monitoring. Whether you require aluminum, stainless steel, titanium, or high-performance engineering plastics, our material expertise ensures optimal selection and machining parameters for your application.

We pride ourselves on being more than just a supplier—we are a solutions partner. From initial design consultation and DFM analysis to rapid prototyping and full-scale production, our team works closely with your engineering staff to streamline development, reduce lead times, and lower total cost of ownership. Our agile manufacturing model allows us to respond quickly to changing demands, ensuring on-time delivery without compromising quality.

Below are key technical specifications that define our CNC milling capabilities:

| Specification | Detail |

|---|---|

| Axis Configuration | 3-axis, 4-axis, 5-axis |

| Maximum Work Envelope | 1200 × 600 × 500 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Spindle Speed | Up to 24,000 RPM |

| Materials Processed | Aluminum, Steel, Stainless Steel, Titanium, Brass, PEEK, Delrin, and more |

| Tolerances Achieved | ±0.01 mm (standard), down to ±0.005 mm (precision) |

| Surface Finish | As low as Ra 0.4 µm |

| Quality Standards | ISO 9001:2015, FAIR, PPAP, SPC |

To elevate your manufacturing outcomes with precision-engineered CNC milling solutions, contact us today. Reach out to our team at [email protected] to discuss your project requirements, request a quote, or schedule a virtual factory audit. Let Wuxi Lead Precision Machinery be your trusted partner in advancing manufacturing excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.