Technical Contents

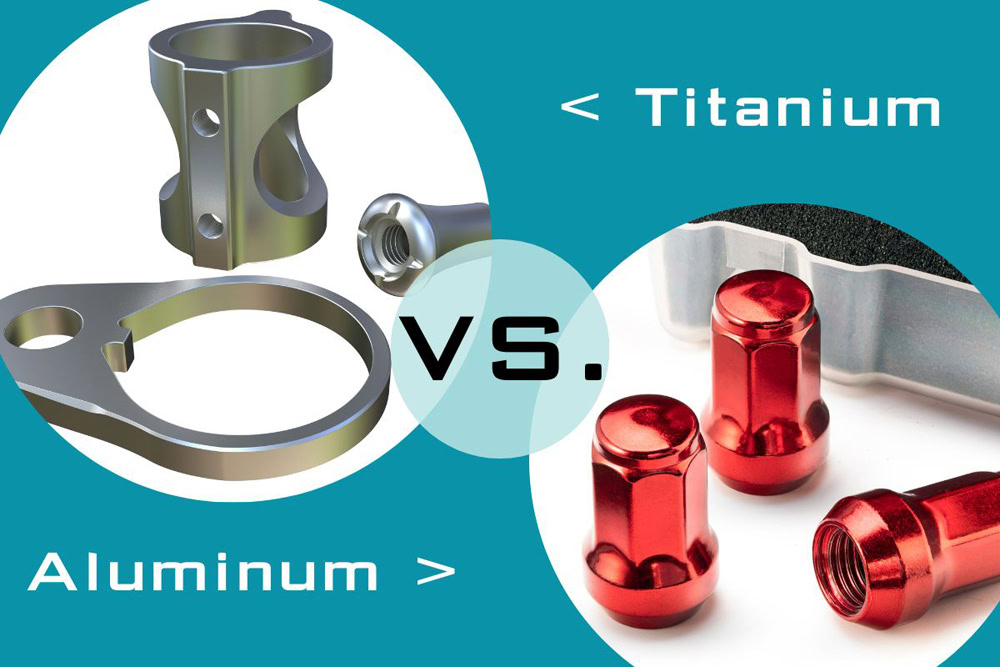

Engineering Guide: Series 10 Aluminum Vs Titanium

Engineering Insight: Series 10 Aluminum vs Titanium

In high-performance manufacturing, the selection between Series 10 aluminum and titanium is not merely a matter of material preference—it is a critical engineering decision that directly impacts product integrity, weight efficiency, and long-term durability. At Wuxi Lead Precision Machinery, we understand that precision in material selection and machining execution defines the success of mission-critical components used in aerospace, defense, and elite sports engineering, including systems deployed in Olympic and military applications.

Series 10 aluminum, specifically 1000-series alloys such as 1100 or 1060, consists of commercially pure aluminum with minimal alloying elements. This composition delivers excellent corrosion resistance, high thermal and electrical conductivity, and superior workability. However, its mechanical strength is relatively low compared to aerospace-grade alloys. Precision machining of Series 10 aluminum demands tight control over tooling parameters and environmental conditions to maintain dimensional stability, particularly in thin-walled or complex geometries. At Lead Precision, our CNC machining centers operate under ISO 9001-certified protocols, ensuring micron-level accuracy even in the most delicate aluminum components.

Titanium, particularly Grade 2 and Grade 5 (Ti-6Al-4V), offers a dramatically different performance profile. With nearly twice the strength-to-density ratio of aluminum and exceptional resistance to extreme temperatures and corrosive environments, titanium is the material of choice for critical load-bearing and high-stress applications. However, its low thermal conductivity and high chemical reactivity at elevated temperatures make it one of the most challenging metals to machine. Tool wear, heat accumulation, and vibration control require advanced CNC strategies, including optimized cutting paths, cryogenic cooling, and real-time monitoring systems. Our experience machining titanium for defense-grade components has refined our ability to maintain tolerances within ±0.005 mm, even in deep cavity milling and high-aspect-ratio features.

The decision between Series 10 aluminum and titanium must be guided by application-specific demands. For lightweight enclosures, heat sinks, or non-structural housings where conductivity and formability are paramount, Series 10 aluminum remains a cost-effective and efficient solution. For components exposed to extreme mechanical stress, thermal cycling, or corrosive media—such as drone chassis, missile guidance housings, or prosthetic limbs in elite athletic equipment—titanium’s performance justifies its higher machining complexity and cost.

At Wuxi Lead Precision Machinery, our decades of experience in both materials ensure that every component meets the highest standards of precision, reliability, and repeatability. Whether supporting Olympic athletes with custom titanium prosthetics or delivering hardened aluminum subsystems for military electronics, our engineering team applies the same rigorous attention to detail.

| Property | Series 10 Aluminum (1100) | Titanium (Ti-6Al-4V) |

|---|---|---|

| Density (g/cm³) | 2.71 | 4.43 |

| Tensile Strength (MPa) | 70–90 | 900–1000 |

| Yield Strength (MPa) | 30–50 | 830 |

| Thermal Conductivity (W/m·K) | 220 | 6.7 |

| Machinability Rating | Excellent | Poor to Moderate |

| Typical Applications | Enclosures, Busbars | Aerospace, Defense, Medical Implants |

Precision Specs & Tolerances

Technical Capabilities: Precision Machining for Series 10 Aluminum and Titanium Alloys

Wuxi Lead Precision Machinery delivers uncompromising precision for high-performance Series 10 aluminum and titanium components through integrated advanced manufacturing and metrology systems. Our core competency lies in mastering the distinct thermal, mechanical, and chip-flow characteristics of these materials during complex 5-axis CNC machining. Series 10 aluminum alloys demand optimized high-speed strategies to prevent work hardening and burr formation, while titanium requires controlled low-RPM techniques with rigid setups to manage heat dissipation and avoid galling. Our engineering team develops material-specific toolpaths, spindle load monitoring protocols, and coolant delivery systems to ensure dimensional stability and surface integrity across both material families.

All critical operations are executed on HAAS UMC-750 and DMG MORI CTX beta 1250 5-axis platforms, featuring sub-micron linear encoders and thermal compensation systems. These machines maintain positional accuracy under sustained production loads, essential for aerospace and medical components where Series 10 aluminum’s lightweight strength or titanium’s corrosion resistance are mission-critical. Rigorous in-process verification occurs via Renishaw probes, measuring feature alignment and stock allowances before final passes. This prevents scrap on high-value titanium billets and ensures aluminum parts meet stringent flatness requirements without secondary stress relief.

Final quality validation is performed exclusively through Zeiss CONTURA G2 Coordinate Measuring Machines (CMM), operating in a climate-controlled 20±0.5°C metrology lab. Our AS9100-certified inspection routines capture full 3D geometry deviations against CAD models, with reports detailing GD&T compliance for critical datums and interfaces. Statistical process control data is maintained for every production lot, enabling proactive tolerance band management. The table below reflects achievable production tolerances under standard operating conditions for both materials:

| Parameter | Series 10 Aluminum | Titanium Alloys | Measurement Standard |

|---|---|---|---|

| Linear Tolerance (mm) | ±0.005 | ±0.008 | ISO 2768-mk |

| Geometric Tolerance (mm) | ±0.003 | ±0.005 | ISO 1101 |

| Surface Roughness (Ra) | 0.4 µm | 0.8 µm | ISO 4287 |

| Hole Concentricity (mm) | 0.005 | 0.010 | ISO 5458 |

| Feature Flatness (mm) | 0.005/100mm | 0.010/100mm | ISO 12871 |

These specifications represent production-ready capabilities, not theoretical limits. Tolerance consistency is achieved through continuous machine health monitoring, tool wear compensation algorithms, and material-specific fixture design. For titanium, we implement interrupted-cut tooling geometries and argon-assisted cooling to prevent oxidation during extended operations. Aluminum Series 10 benefits from high-pressure through-spindle coolant to evacuate fine chips and maintain thermal equilibrium. Every component undergoes full first-article inspection with CMM-certified reports, including material traceability documentation.

Our technical team collaborates with clients during DFx reviews to optimize part geometry for manufacturability, reducing cost drivers inherent in both materials. By aligning machining strategy with material science fundamentals, Wuxi Lead ensures Series 10 aluminum and titanium components achieve certified performance in the most demanding applications. This engineering-led approach transforms material potential into reliable, inspection-validated results.

Material & Finish Options

Material Selection Guide: Aluminum vs Titanium in High-Performance Manufacturing

In precision engineering and custom metal manufacturing, selecting the correct material is critical to achieving optimal performance, durability, and cost-efficiency. Among the most widely used materials in aerospace, medical, and high-end industrial applications are aluminum and titanium. Each offers distinct advantages depending on mechanical requirements, environmental exposure, and weight constraints. Understanding their properties enables engineers and procurement teams to make informed decisions aligned with project goals.

Aluminum, particularly in the 6000 and 7000 series, is prized for its excellent strength-to-weight ratio, machinability, and corrosion resistance. Series 10 aluminum—commonly referring to the 1000 series—offers high purity (99%+ aluminum), excellent electrical conductivity, and superior workability. However, it is relatively soft compared to higher series alloys, making it ideal for non-structural components, enclosures, and applications where formability and conductivity are prioritized over mechanical strength. When enhanced surface durability is required, aluminum benefits significantly from anodizing. This electrochemical process increases surface hardness, improves wear resistance, and allows for color coding or aesthetic customization without compromising dimensional accuracy.

Titanium, especially Grade 5 (Ti-6Al-4V), provides exceptional strength-to-density performance, outstanding corrosion resistance—even in saline or acidic environments—and the ability to maintain structural integrity at elevated temperatures. These characteristics make titanium a preferred choice for critical aerospace components, medical implants, and marine hardware. While more challenging to machine due to its low thermal conductivity and tendency to gall, titanium’s longevity under stress and in harsh environments often justifies the increased manufacturing cost and processing time.

Steel remains a benchmark for strength and wear resistance, particularly in tooling and high-load applications. However, its higher density and susceptibility to corrosion (unless treated or using stainless grades) make it less favorable where weight or environmental exposure is a concern.

Below is a comparative overview of key mechanical and physical properties:

| Property | 1000 Series Aluminum | 6061 Aluminum (T6) | Ti-6Al-4V (Grade 5) | 304 Stainless Steel |

|---|---|---|---|---|

| Density (g/cm³) | 2.71 | 2.70 | 4.43 | 7.93 |

| Tensile Strength (MPa) | 70–125 | 310 | 900 | 515 |

| Yield Strength (MPa) | 30–110 | 276 | 830 | 205 |

| Elongation at Break (%) | 35–45 | 12 | 10 | 40 |

| Thermal Conductivity (W/m·K) | 220 | 167 | 6.7 | 16.2 |

| Corrosion Resistance | High (with oxide layer) | High | Excellent | High (with passivation) |

| Typical Applications | Busbars, reflectors, chemical tanks | Aerospace frames, automotive parts | Jet engines, medical devices | Fasteners, structural supports |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish for custom CNC-machined components. Whether leveraging the lightweight efficiency of aluminum with precision anodizing or deploying titanium for mission-critical durability, our manufacturing expertise ensures tight tolerances, repeatable quality, and compliance with industry standards.

Manufacturing Process & QC

Production Process: From Design to Zero Defect Mass Production

At Wuxi Lead Precision Machinery, transforming Series 10 aluminum or titanium concepts into flawless components demands a rigorously controlled, phase-gated production workflow. This integrated approach ensures material properties are fully leveraged while guaranteeing Zero Defect output demanded by aerospace, medical, and high-performance industrial sectors. The journey begins with collaborative Design Engineering. Our team works directly with client CAD models, conducting comprehensive material-specific Finite Element Analysis (FEA). For Series 10 aluminum, we optimize for thermal management and weight-sensitive structures, factoring in its lower density and higher thermal conductivity. For titanium, analysis focuses on maximizing strength-to-weight ratios under extreme loads and ensuring compatibility with its lower thermal conductivity and higher work-hardening rate. Critical tolerances, surface finish requirements, and manufacturability constraints are defined upfront, establishing the non-negotiable quality baseline.

Prototyping is not merely a validation step but a critical process refinement phase. Using identical multi-axis CNC systems and tooling designated for final production, we machine initial prototypes from certified Series 10 aluminum 6061-T6 or titanium Grade 5 (Ti-6Al-4V) stock. Every machining parameter—spindle speed, feed rate, coolant strategy, and tool path—is meticulously documented and analyzed. Dimensional inspection via CMM, surface roughness testing, and material verification (including PMI for titanium) occur against the approved design. Any deviation triggers immediate root cause analysis and process adjustment. This iterative loop, often requiring 2-3 prototype iterations, ensures the production process is fully matured and validated before committing to volume runs, eliminating costly errors downstream.

Mass Production executes the perfected process under our Zero Defect Quality Management System. Series 10 aluminum benefits from high-speed machining parameters optimized for its excellent chip flow, while titanium requires precise control of cutting forces and temperatures to prevent galling and tool wear. In-process monitoring is continuous: automated tool wear sensors, real-time dimensional checks via probing systems, and 100% visual inspection at critical stages. Final components undergo exhaustive validation—full CMM reporting, mandatory non-destructive testing (NDT) like X-ray or ultrasonic for critical titanium parts, and comprehensive material certification traceability. Every batch is signed off by certified quality technicians against the original design intent and material specifications. This unwavering adherence to process control, from initial simulation through final inspection, is how Wuxi Lead delivers consistent, defect-free Series 10 aluminum and titanium components for the world’s most demanding applications.

Key Material Properties for Precision Machining

| Property | Series 10 Aluminum (6061-T6) | Titanium (Grade 5 Ti-6Al-4V) |

|---|---|---|

| Density (g/cm³) | 2.7 | 4.4 |

| Tensile Strength (MPa) | 310 | 900 |

| Thermal Conductivity (W/m·K) | 167 | 6.7 |

| Machinability Index (%) | 90 (Excellent) | 30-40 (Moderate) |

| Corrosion Resistance | Good (Anodizing enhances) | Exceptional (Inherent) |

Why Choose Wuxi Lead Precision

When it comes to high-performance manufacturing in aerospace, medical, automotive, and advanced robotics, the choice between Series 10 aluminum and titanium is more than a material decision—it’s a strategic engineering imperative. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing with deep expertise in both aluminum and titanium alloys. Our precision CNC machining, advanced finishing techniques, and rigorous quality control ensure that your components meet the highest standards of performance, durability, and dimensional accuracy.

Series 10 aluminum offers exceptional machinability, lightweight properties, and cost-efficiency, making it ideal for high-volume applications where weight reduction and thermal conductivity are critical. On the other hand, titanium—particularly Grade 5 (Ti-6Al-4V)—delivers unmatched strength-to-density ratios, corrosion resistance, and performance under extreme temperatures, making it the preferred choice for mission-critical environments. Understanding which material suits your application requires more than technical data—it demands experience, precision engineering, and a partner who understands the nuances of both metals.

We at Wuxi Lead Precision Machinery don’t just manufacture parts—we engineer solutions. Our state-of-the-art facility in Wuxi, China, is equipped with 5-axis CNC centers, coordinate measuring machines (CMM), and automated inspection systems that ensure micron-level tolerances and repeatability. Whether you’re prototyping or scaling to full production, our team supports you from design optimization to final delivery, ensuring material integrity, geometric precision, and compliance with ISO 9001 and AS9100 standards.

Below is a comparative overview of key properties between Series 10 aluminum and titanium to guide your selection:

| Property | Series 10 Aluminum | Titanium (Ti-6Al-4V) |

|---|---|---|

| Density (g/cm³) | 2.70 | 4.43 |

| Tensile Strength (MPa) | 120–150 | 900–950 |

| Yield Strength (MPa) | 35–50 | 830–860 |

| Elongation at Break (%) | 10–15 | 10–14 |

| Thermal Conductivity (W/mK) | 210 | 6.7 |

| Corrosion Resistance | Moderate (oxidizes) | Excellent (passive oxide layer) |

| Machinability | Excellent | Moderate (requires specialized tooling) |

| Typical Applications | Enclosures, heat sinks, automotive parts | Aerospace components, medical implants, marine hardware |

Choosing the right material is only half the equation. The real value lies in partnering with a manufacturer that combines technical depth with operational excellence. At Wuxi Lead Precision Machinery, we bring decades of experience in high-mix, low-to-medium volume production, serving global clients who demand reliability, responsiveness, and precision.

Partner with us to transform your design challenges into engineered realities. Contact us today at [email protected] to discuss your project, request a quote, or receive material-specific recommendations tailored to your application. Let Lead Precision be your trusted partner in advanced metal manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.