Technical Contents

Engineering Guide: Pc Moulding

Engineering Insight: Precision in PC Moulding for Demanding Industrial Applications

In the realm of custom metal manufacturing, polycarbonate (PC) moulding stands as a critical process for producing high-strength, thermally stable, and dimensionally accurate components. While PC is inherently a resilient engineering plastic, its performance in end-use applications—particularly in aerospace, defense, and high-performance industrial systems—is entirely dependent on the precision of the moulding process. At Wuxi Lead Precision Machinery, we recognize that tolerances measured in microns can determine the success or failure of a mission-critical component.

Precision in PC moulding begins with tooling design. Even minor deviations in cavity geometry or cooling channel placement can lead to warpage, internal stresses, or inconsistent wall thickness—defects that are unacceptable in applications where optical clarity, impact resistance, and thermal stability are non-negotiable. Our engineering team employs advanced simulation software to model flow dynamics, shrinkage behavior, and thermal gradients before a single pellet is melted. This predictive approach ensures that every mould we produce is optimized for repeatability and long-term stability.

Material handling is another cornerstone of precision. PC resin is hygroscopic and must be dried to exact specifications prior to processing. At Lead Precision, we maintain controlled environments for material storage and conditioning, ensuring that moisture content remains below 0.02%—a threshold essential for preventing hydrolysis and maintaining mechanical integrity. Our all-electric and hybrid injection systems offer superior control over injection speed, pressure, and temperature, allowing for consistent filling and packing with minimal variation across production runs.

Our commitment to precision is validated through rigorous in-process inspection and final quality assurance. Every component undergoes dimensional verification using coordinate measuring machines (CMM), and critical parts are subjected to environmental stress testing, including thermal cycling and impact evaluation. This level of scrutiny is not merely procedural—it is demanded by our clients in Olympic-grade sports technology and military-grade optical systems, where failure is not an option.

Wuxi Lead Precision Machinery has supported projects requiring compliance with ISO 9001, MIL-STD-810, and GB/T standards. Our experience in delivering PC-moulded components for high-visibility, high-reliability applications underscores our technical capability and operational discipline.

Below are key specifications we maintain for precision PC moulding:

| Parameter | Standard Tolerance | High-Precision Tolerance |

|---|---|---|

| Dimensional Accuracy | ±0.1 mm | ±0.025 mm |

| Surface Finish (Ra) | 0.8 μm | 0.2 μm |

| Warpage Control | < 0.3% | < 0.1% |

| Material Moisture Content | ≤ 0.02% | ≤ 0.015% |

| Mould Temperature Control | ±2°C | ±0.5°C |

| Shot-to-Shot Weight Variation | ≤ 0.5% | ≤ 0.2% |

Precision in PC moulding is not an incremental advantage—it is the foundation of performance. At Wuxi Lead Precision Machinery, we engineer every detail to meet the uncompromising demands of advanced manufacturing.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Component Manufacturing

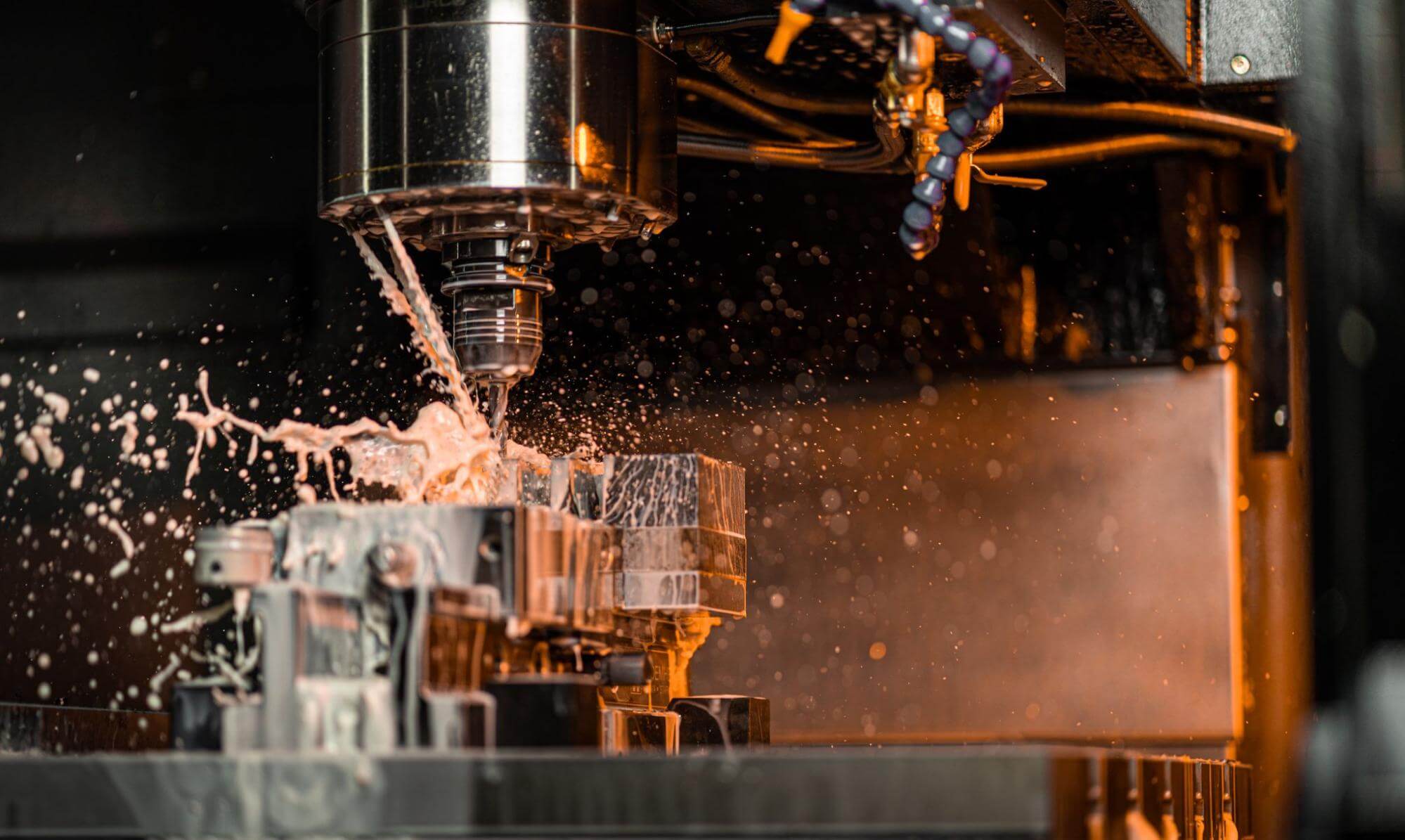

Wuxi Lead Precision Machinery delivers uncompromising precision for high-complexity metal components, leveraging advanced 5-axis CNC machining centers as the cornerstone of our production ecosystem. Our HAAS and DMG MORI systems execute simultaneous multi-axis movements, enabling single-setup fabrication of intricate geometries that would otherwise require costly secondary operations or specialized tooling. This capability eliminates cumulative error from multiple fixturing stages, ensuring geometric integrity for parts with deep cavities, undercuts, or organic contours common in aerospace, medical, and semiconductor applications. All machining processes adhere to ISO 130-1:2011 standards, with real-time tool wear compensation and thermal stability protocols maintaining micron-level consistency across production runs.

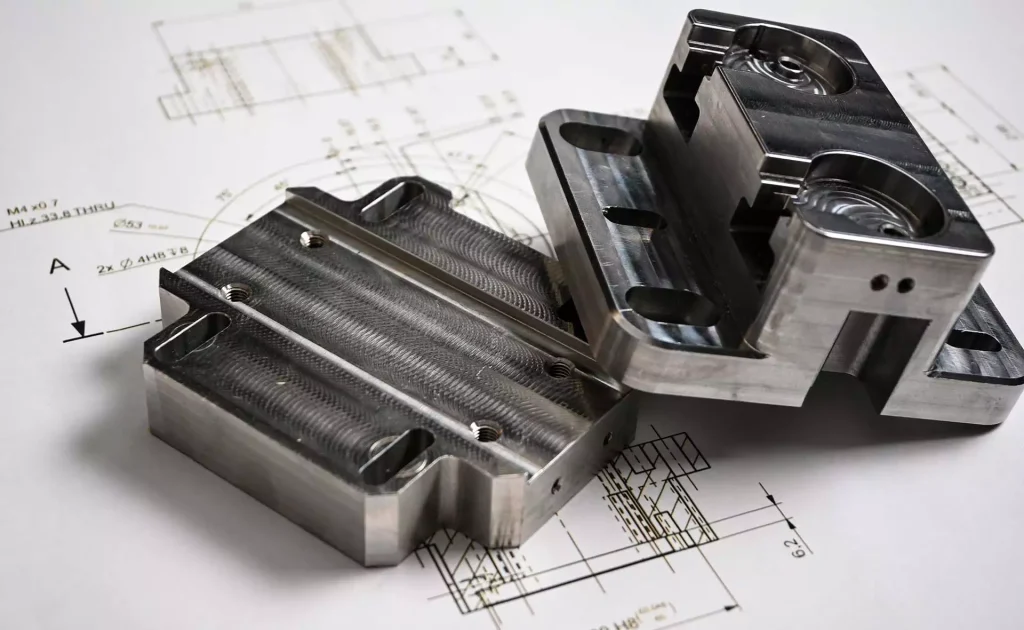

Integral to our quality assurance framework is Zeiss CONTURA G2 Coordinate Measuring Machine (CMM) inspection. Every critical dimension undergoes 100% verification against CAD nominal values, with GD&T analysis performed to ASME Y14.5-2018 standards. Our CMM cell operates in a temperature-controlled environment (20°C ±0.5°C), utilizing calibrated ruby-tipped probes and advanced software for point-cloud analysis of freeform surfaces. This rigorous metrology process validates not only dimensional accuracy but also surface continuity and positional tolerances, providing clients with full traceability through digital inspection reports.

Our tolerance capabilities reflect the synergy between cutting-edge equipment and master machinist expertise. The table below specifies achievable precision levels for common materials including aluminum 7075-T6, titanium Ti-6Al-4V, and stainless steel 17-4PH:

| Feature Type | Standard Tolerance | Precision Tolerance | Measurement Conditions |

|---|---|---|---|

| Linear Dimensions | ±0.02 mm | ±0.005 mm | 25 mm to 300 mm range |

| Hole Diameter | ±0.015 mm | ±0.003 mm | H7 fit or tighter |

| Positional Tolerance | ±0.025 mm | ±0.008 mm | Relative to primary datum |

| Surface Roughness | Ra 0.8 µm | Ra 0.2 µm | Machined surfaces only |

| Flatness | 0.02 mm/m | 0.005 mm/m | Over 100 mm span |

Material selection and part geometry influence final achievable tolerances. For critical features requiring nanometer-scale precision, we implement in-process air-gauging and laser interferometry validation. Our engineers collaborate with clients during Design for Manufacturing (DFM) reviews to optimize part geometry, ensuring tolerances align with functional requirements while minimizing production costs. This proactive approach reduces scrap rates by up to 35% compared to conventional manufacturing workflows.

Wuxi Lead’s technical infrastructure transforms complex design challenges into production realities. By integrating 5-axis machining with closed-loop CMM verification, we deliver components where dimensional stability and repeatability are non-negotiable. Clients receive not just parts, but certified precision engineered to perform under extreme operational conditions. Contact our applications engineering team to discuss tolerance validation protocols for your next high-mix, low-volume metal component project.

Material & Finish Options

Material Selection for High-Precision PC Moulding Applications

In the field of custom metal manufacturing for PC moulding, material selection is a critical determinant of performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in delivering precision-engineered components tailored to the rigorous demands of industrial and high-end consumer applications. The most commonly used materials in PC moulding tooling and structural components are aluminum, steel, and titanium. Each offers distinct mechanical properties, thermal behaviors, and compatibility with finishing processes such as anodizing.

Aluminum is widely favored for prototype tooling and low-to-medium volume production due to its excellent machinability, lightweight nature, and good thermal conductivity. It enables faster cycle times in moulding operations and reduces overall equipment weight. However, aluminum’s lower hardness makes it less suitable for high-wear environments. When enhanced surface resistance is required, aluminum is often treated with anodizing, which increases corrosion resistance and surface hardness.

Steel, particularly tool steel variants such as H13 or P20, is the standard for high-volume PC moulding applications. Its superior hardness, wear resistance, and thermal stability ensure long service life under repeated thermal cycling. While heavier and more challenging to machine than aluminum, steel’s durability justifies its use in large-scale production. Surface treatments such as nitriding or chrome plating are common, though anodizing is not applicable to steel.

Titanium is selected for highly specialized applications where extreme strength-to-weight ratio, corrosion resistance, and performance at elevated temperatures are paramount. While significantly more expensive and difficult to machine, titanium offers unmatched longevity in aggressive environments. It is typically used in aerospace or medical-grade PC moulding systems. Like aluminum, titanium can be anodized to enhance surface properties and provide aesthetic customization.

Anodizing is a key electrochemical finishing process, primarily applied to aluminum and titanium. It creates a controlled oxide layer on the surface, improving wear and corrosion resistance while allowing for color coding through dye integration. The thickness and hardness of the anodized layer can be precisely controlled, making it ideal for components requiring both functional durability and visual consistency.

Below is a comparative overview of the three materials in the context of PC moulding applications.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Hardness (HB) | Anodizing Compatible |

|---|---|---|---|---|---|

| Aluminum (6061-T6) | 2.7 | 310 | 167 | 95 | Yes |

| Steel (H13) | 7.8 | 1,560 | 36 | 230 | No |

| Titanium (Grade 5) | 4.5 | 1,000 | 7.2 | 330 | Yes |

Selecting the optimal material requires a balance between operational requirements, production volume, and lifecycle costs. At Wuxi Lead Precision Machinery, our engineering team collaborates closely with clients to match material and finish specifications to application-specific challenges, ensuring peak performance and reliability in every component we produce.

Manufacturing Process & QC

Precision Casting Production Process: Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our PC (Precision Casting) molding process is engineered for uncompromising quality in custom metal components. We integrate advanced metallurgy with rigorous process control to deliver zero-defect outcomes, essential for aerospace, medical, and high-performance industrial applications. Our methodology spans three disciplined phases, each validated against stringent international standards including ISO 9001 and AS9100.

The design phase begins with collaborative engineering. Our team works directly with client CAD models to optimize geometry for castability, ensuring dimensional stability and material integrity. Finite element analysis (FEA) simulates thermal gradients and solidification behavior, preempting shrinkage or porosity risks. Material selection is critical; we specify aerospace-grade alloys like Inconel 718 or Ti-6Al-4V based on operational stress, temperature, and corrosion requirements. Design for Manufacturing (DFM) reviews finalize gating systems and mold configurations, locking in tolerances achievable at scale.

Prototyping transitions design into physical validation. Using rapid tooling and vacuum induction melting, we produce functional prototypes mirroring production intent. Each prototype undergoes comprehensive metrology-grade CMM inspection against GD&T callouts, alongside destructive testing for microstructure homogeneity and mechanical properties. This phase confirms process capability indices (Cp/Cpk > 1.67) and refines thermal parameters. Client sign-off on first-article inspection (FAI) reports is mandatory before progression, eliminating downstream rework.

Mass production executes with closed-loop precision. Automated molding lines maintain consistent sand compaction density and binder ratios, while real-time spectrometry monitors molten metal chemistry within ±0.05% tolerance. Every casting undergoes 100% in-process inspection: laser scanners verify critical dimensions, and digital radiography detects sub-surface anomalies. Statistical process control (SPC) dashboards track key variables like pouring temperature and cooling rates, triggering immediate corrective actions if deviations exceed control limits. Final assembly includes stress-relief annealing per AMS 2750 and non-destructive testing (NDT) via MPI or fluorescent penetrant inspection.

Our commitment to zero defects is operationalized through traceability and continuous improvement. Each component’s lifecycle data—from raw material certs to final test logs—is digitally archived for full追溯性. This integrated approach ensures consistent delivery of complex geometries with minimal post-cast machining. Below are key process specifications distinguishing prototyping from production:

| Parameter | Prototyping Phase | Mass Production Phase |

|---|---|---|

| Tolerance Capability | ±0.10 mm | ±0.025 mm |

| Material Verification | Batch-level chemistry | Real-time melt analysis |

| Inspection Coverage | Critical features only | 100% dimensional + NDT |

| Process Control | Manual SPC checks | Automated SPC with AI alerts |

| Lead Time per Unit | 7-10 days | 48-72 hours |

| Yield Target | 85% | 99.5% |

Wuxi Lead transforms precision casting from a manufacturing step into a quality guarantee. By embedding defect prevention at every stage—from virtual simulation to automated production—we deliver metal components where failure is never an option. Partner with us to convert your most demanding designs into flawless reality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in PC Moulding Manufacturing

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and consistency are non-negotiable in the world of custom metal manufacturing—especially when it comes to high-performance PC moulding applications. As a leading provider of CNC-machined components and precision-engineered solutions based in Wuxi, China, we specialize in delivering tailored manufacturing services that meet the exacting standards of global industries including automotive, electronics, medical devices, and industrial automation.

Our expertise in PC moulding support structures, precision frames, cooling plates, and custom inserts ensures that every component we produce is engineered for optimal performance, dimensional accuracy, and long-term durability. We combine advanced CNC machining capabilities with rigorous quality control protocols to deliver parts that integrate seamlessly into your moulding systems, reducing downtime and enhancing production efficiency.

When you partner with Wuxi Lead Precision Machinery, you’re not just sourcing components—you’re gaining a strategic manufacturing ally. Our engineering team works closely with clients from concept through to production, offering DFM analysis, rapid prototyping, and scalable batch manufacturing. With in-house 3-, 4-, and 5-axis machining centers, wire EDM, and surface grinding, we maintain full control over lead times, tolerances, and material integrity. Whether you require aluminum 7075 for lightweight mould frames or hardened steel inserts with micron-level precision, we have the equipment and expertise to deliver.

We serve multinational OEMs and tier-one suppliers who demand more than just parts—they demand performance, traceability, and partnership. Our ISO 9001-certified processes, comprehensive inspection reports (including CMM and 3D scanning), and dedicated project management ensure that every order meets the highest standards of quality and consistency.

Below are the key technical specifications we support for PC moulding-related components:

| Specification | Capability |

|---|---|

| Machining Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.2 – 1.6 μm (custom finishes available) |

| Maximum Work Envelope | 1200 × 800 × 600 mm (5-axis) |

| Materials | Aluminum (6061, 7075), Stainless Steel (304, 316), Tool Steel (SKD61, H13), Brass, Copper |

| Secondary Processes | Anodizing, Hard Coating, Passivation, Nickel Plating, Laser Marking |

| Quality Standards | ISO 9001:2015, Full First Article Inspection, CMM Reporting |

Your success in PC moulding depends on the precision of every supporting component. Let us help you achieve tighter cycles, higher yields, and superior product quality through engineered manufacturing excellence.

Contact us today at [email protected] to discuss your next project. Our engineering team is ready to collaborate on design optimization, material selection, and production planning—ensuring your PC moulding systems perform at their peak. Partner with Wuxi Lead Precision Machinery and experience the difference that true precision engineering makes.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.