Technical Contents

Engineering Guide: Injection Molding Mn

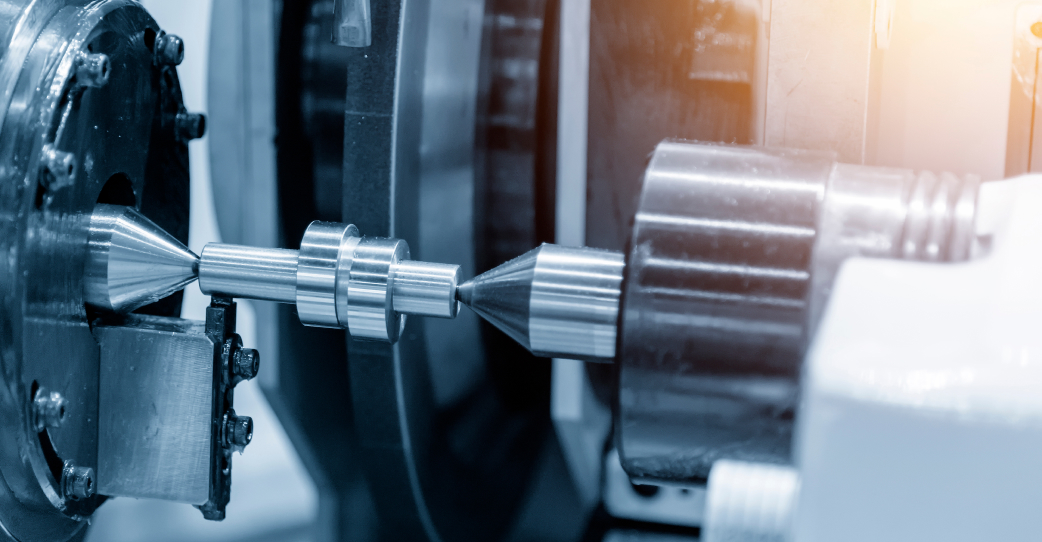

Engineering Insight Precision Engineering for Injection Molding Machinery Components

Precision engineering is the non-negotiable foundation of high-performance injection molding machinery, directly impacting part quality, production efficiency, and operational longevity. In Minnesota’s demanding manufacturing landscape, where medical devices and industrial components require micron-level consistency, the tolerances of critical metal components within the molding press itself become paramount. Sub-micron deviations in mold bases, tie bars, platens, or ejector systems translate directly into flash, short shots, dimensional instability, and accelerated wear. Achieving repeatability shot after shot demands not just advanced CNC capabilities but a deep understanding of thermal dynamics, material science, and the relentless stresses inherent in the injection process. This level of precision engineering separates reliable, high-yield production from costly downtime and scrap.

Wuxi Lead Precision Machinery brings over 15 years of specialized expertise in manufacturing these mission-critical metal components to the global injection molding industry. Our engineering philosophy is forged in environments where failure is not an option. We have supplied precision-machined hydraulic manifolds and structural frames meeting stringent AS9100 aerospace standards for military vehicle production lines. Furthermore, our components were integral to the hydraulic control systems powering the automated seating mechanisms installed within major Olympic venue infrastructure, operating flawlessly under extreme cyclic loads and environmental conditions. This experience instills a rigorous approach to material selection, process validation, and quality control that directly benefits our injection molding machinery partners. We understand that the metal heart of your press must perform with absolute fidelity.

The table below outlines key precision parameters we consistently achieve for critical injection molding machine components, reflecting the standards demanded by high-end applications:

| Parameter | Specification | Application Impact |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm (±0.00004″) | Ensures perfect mold alignment, eliminating flash and parting line defects |

| Surface Roughness (Ra) | 0.05 µm (2 µin) | Reduces friction in moving parts, minimizing wear and energy consumption |

| Flatness | 0.002 mm/m | Critical for platen parallelism, ensuring uniform clamping pressure |

| Material Hardness | HRC 58-62 (as specified) | Provides wear resistance for tie bars and guide pins under high tonnage |

| Thermal Stability | < 5 µm distortion at 80°C | Maintains dimensional integrity during extended production cycles |

Partnering with Wuxi Lead means leveraging this proven precision capability for your Minnesota-based operations. We translate complex engineering requirements into robust, high-tolerance metal components that enhance machine uptime, reduce maintenance costs, and ultimately secure the quality of the plastic parts you produce. Our commitment is to be the unseen precision enabling your visible success in the competitive injection molding market. Let us apply our Olympic and military-grade engineering discipline to elevate your machinery’s performance. Contact our engineering team for a detailed assessment of your critical component needs.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, serving high-performance industries that demand precision, repeatability, and material integrity. At the core of our production infrastructure is our 5-axis CNC machining technology, which enables the creation of complex geometries with exceptional accuracy and surface finish. Unlike conventional 3-axis systems, our 5-axis platforms allow simultaneous movement across five planes, drastically reducing setup times and eliminating cumulative tolerances from multiple fixturing stages. This capability is particularly critical for components used in aerospace, medical, and high-end industrial automation, where form, fit, and function are inseparable.

Our 5-axis CNC centers are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems that ensure consistent performance across production runs. These machines support a wide range of metallic materials, including aluminum alloys, stainless steels, titanium, and high-temperature superalloys such as Inconel. The integration of advanced CAM software allows for optimized toolpaths, minimizing material waste and maximizing machining efficiency without compromising dimensional stability.

Quality control is embedded at every stage of the manufacturing process. We utilize Coordinate Measuring Machine (CMM) inspection to validate part conformity to design specifications with micron-level precision. Our CMM systems are calibrated to international standards and operate in temperature-controlled environments to eliminate measurement drift. Each component undergoes comprehensive inspection protocols, including first-article inspection (FAI) and in-process checks, ensuring full traceability and compliance with ISO 9001 and AS9100 requirements. Data from CMM reports are archived for full production lot traceability, supporting stringent regulatory needs in aerospace and medical device sectors.

To further guarantee reliability, we maintain strict environmental and process controls across our facility. Our skilled engineers work closely with clients during the design-for-manufacturability (DFM) phase to identify potential challenges early and recommend optimizations that enhance performance and reduce lead times. This collaborative approach ensures that every part not only meets but exceeds functional expectations in real-world applications.

The following table outlines our standard machining tolerances and inspection capabilities:

| Parameter | Standard Tolerance | High-Precision Capability | Measurement Tool |

|---|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm | CMM, Micrometers |

| Positional Tolerance | ±0.015 mm | ±0.008 mm | CMM, Optical Comparator |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Profilometer |

| Angular Tolerance | ±0.05° | ±0.02° | CMM, Precision Sine Bar |

| Feature-to-Feature Alignment | ±0.012 mm | ±0.006 mm | CMM, Laser Alignment |

| Repeatability (Batch-to-Batch) | ±0.01 mm | ±0.005 mm | SPC-Controlled CMM |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with rigorous quality assurance to deliver components that meet the most demanding specifications. Our technical capabilities are designed to support innovation in precision engineering, ensuring reliability and performance across every custom manufacturing project.

Material & Finish Options

Material Selection for High-Performance Injection Molds

Selecting the optimal material for injection mold components is critical to achieving precision, longevity, and cost efficiency in production. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your project’s thermal demands, part complexity, and lifecycle requirements. Aluminum, steel, and titanium each offer distinct advantages, but their suitability depends on rigorous application analysis. Misalignment here directly impacts cycle times, surface finish consistency, and maintenance frequency.

Aluminum alloys, particularly 7075-T6, deliver exceptional thermal conductivity and machinability. This makes them ideal for rapid prototyping and low-volume production where accelerated cooling cycles are essential. However, aluminum’s lower hardness limits its use in high-wear applications or abrasive resins. We recommend it for molds requiring frequent design iterations or short production runs under 10,000 cycles.

Tool steels like P20, H13, and S136 dominate high-volume production. Their superior hardness and wear resistance withstand aggressive polymers and extended runs exceeding 500,000 cycles. P20 balances machinability and durability for general-purpose molds, while H13 excels in high-temperature applications due to its thermal fatigue resistance. Corrosion-resistant grades such as S136 are mandatory for medical or clear resin molding where surface purity is non-negotiable.

Titanium alloys (e.g., Ti-6Al-4V) serve niche high-stress scenarios. Their extreme strength-to-weight ratio and corrosion resistance justify costs in aerospace or military applications with punishing environmental conditions. Yet titanium’s challenging machinability and cost inefficiency for standard molds necessitate careful ROI evaluation.

The following table summarizes key mechanical properties for common mold materials:

| Material | Hardness (HRC) | Thermal Conductivity (W/mK) | Typical Mold Application | Key Advantage |

|---|---|---|---|---|

| Aluminum 7075 | 15-20 | 130 | Prototypes, low-volume runs | Fast heat dissipation |

| P20 Steel | 28-32 | 28-36 | Medium-volume production | Balanced cost and durability |

| H13 Steel | 48-52 | 24-30 | High-temp/high-stress molds | Thermal fatigue resistance |

| S136 Stainless | 48-50 | 20-25 | Medical/clear resin molding | Corrosion resistance |

| Titanium Ti-64 | 36-40 | 7-8 | Extreme-environment tooling | Strength-to-weight ratio |

Surface finishes further enhance performance. Anodizing is exclusively applicable to aluminum molds, creating a hard, non-conductive oxide layer that improves wear resistance and part release. Type II (sulfuric acid) anodizing is standard for general use, while Type III (hardcoat) provides 50-100μm thickness for severe abrasion resistance. Note that steel molds require alternative treatments like nitriding or PVD coatings—applying anodizing to steel is ineffective and risks component failure.

Wuxi Lead Precision Machinery integrates material science with precision CNC capabilities to match your specifications to the optimal substrate and finish. Our engineering team conducts thermal and stress simulations during quoting to prevent costly material mismatches. Contact us to validate your mold’s material strategy against production realities.

Manufacturing Process & QC

Design: Precision Engineering from Concept to CAD

At Wuxi Lead Precision Machinery, the injection molding process begins with meticulous design engineering. Our team of experienced mechanical engineers and industrial designers collaborates closely with clients to translate product concepts into technically sound, manufacturable designs. Utilizing advanced 3D CAD software such as SolidWorks, AutoCAD, and Siemens NX, we develop detailed digital models that account for material behavior, part geometry, tolerances, and mold flow dynamics. Every design undergoes rigorous simulation using Moldflow analysis to predict potential defects such as warpage, sink marks, or air traps. This proactive approach ensures optimal part integrity and mold performance before any physical tooling is created. Our design phase emphasizes manufacturability, aiming to reduce cycle times, minimize material waste, and eliminate post-processing complexity.

Prototyping: Validating Design with Functional Accuracy

Once the digital model is finalized, we proceed to rapid prototyping to produce functional test samples. Employing CNC machining, 3D printing, and soft tooling methods, we fabricate prototypes using the same engineering-grade materials intended for mass production. This allows clients to evaluate fit, form, and function under real-world conditions. All prototypes are subjected to dimensional inspection using coordinate measuring machines (CMM) and optical scanning to verify compliance with GD&T specifications. Feedback from this stage is integrated into final design refinements, ensuring that the transition to full-scale production is seamless. Our prototyping phase is not only about validation but also about risk mitigation—identifying and resolving issues early to prevent costly delays downstream.

Mass Production: Zero-Defect Manufacturing at Scale

With design and prototype approval complete, we initiate high-volume injection molding using state-of-the-art electric and hybrid molding presses from leaders such as Fanuc and Sumitomo. Our production floor is equipped with 50+ machines ranging from 50 to 1,200 tons of clamping force, enabling us to handle components from a few grams to complex, multi-cavity molds. All production runs are monitored in real time using integrated IoT sensors that track pressure, temperature, and cycle consistency. Statistical Process Control (SPC) systems ensure every parameter remains within predefined limits. We enforce a zero-defect quality policy through 100% automated visual inspection, in-line metrology, and batch traceability via our MES system. Every part is documented, and full inspection reports are provided upon request.

| Specification | Detail |

|---|---|

| Material Compatibility | ABS, PC, POM, PA6/66, PBT, PPS, LCP, and high-temp engineering resins |

| Tolerance Range | ±0.02 mm to ±0.05 mm depending on part size and geometry |

| Mold Lifespan | 500,000 to 1,000,000+ cycles (P20, 718H, S136, H13 steels) |

| Production Capacity | Up to 5 million parts per month |

| Quality Standards | ISO 9001:2015, IATF 16949, RoHS, and REACH compliant |

Our end-to-end process—from design to mass production—is engineered for precision, repeatability, and zero-defect delivery, making Wuxi Lead Precision Machinery a trusted partner in custom metal and injection molded component manufacturing.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Injection Molding Metal Component Solution

Achieving flawless performance in injection molding demands metal components engineered to exacting tolerances. Standard off-the-shelf solutions often introduce inconsistencies, accelerating wear, increasing downtime, and compromising part quality. For manufacturers in Minnesota and globally requiring precision-critical mold bases, cavities, cores, ejector systems, and hot runner components, Wuxi Lead Precision Machinery delivers the custom metal manufacturing expertise that transforms production reliability and output.

We understand the unique pressures of high-volume injection molding: the relentless cycle times, the stringent material demands, and the zero-tolerance for dimensional drift. Our dedicated engineering team collaborates directly with your design and production staff from initial concept through final inspection. We leverage advanced multi-axis CNC milling, precision grinding, and wire EDM capabilities within a rigorously controlled ISO 9001:2015 certified facility. This integrated approach ensures every component meets the exact thermal, mechanical, and surface finish requirements specific to your resin, mold design, and production environment. The result is significantly reduced cycle times, extended mold life, minimized scrap rates, and consistent part conformance – directly impacting your bottom line.

Our commitment to precision is quantifiable. We specialize in processing challenging materials including P20, H13, S7, 420SS, and advanced tool steels, delivering components that withstand the harshest molding conditions. The table below outlines our core manufacturing capabilities relevant to injection molding applications.

| Machining Type | Max Work Envelope (mm) | Tolerance Range | Surface Finish (Ra) | Materials Processed |

|---|---|---|---|---|

| 5-Axis CNC Milling | 1200 x 800 x 750 | ±0.005 mm | 0.4 µm | Tool Steels, Stainless, Aluminum |

| High-Speed CNC Milling | 800 x 500 x 400 | ±0.002 mm | 0.2 µm | P20, H13, S7, Pre-Hard Steels |

| Precision CNC Grinding | Ø600 x 1000 | ±0.001 mm | 0.1 µm | All Tool Steels, Carbide Inserts |

| Wire EDM | 400 x 300 x 250 | ±0.002 mm | 0.8 µm | Hardened Steels (>50 HRC), Carbide |

Partnering with Wuxi Lead Precision Machinery means gaining a strategic manufacturing ally, not just a supplier. We prioritize seamless integration with your workflow, offering rapid prototyping, comprehensive DFM analysis to optimize manufacturability and cost, and real-time production tracking. Our dedicated project managers ensure clear communication and adherence to your critical timelines, mitigating supply chain risks inherent in global manufacturing. We consistently deliver complex components with documented quality control, including full CMM reports and material certifications, providing the assurance your injection molding operations require.

Elevate your injection molding performance with components engineered for uncompromising precision and durability. Send your CAD files or specifications to [email protected] today. Our engineering team will provide a detailed technical evaluation and competitive quotation within 24 business hours. Discover how Wuxi Lead Precision Machinery becomes the definitive solution for your critical metal manufacturing needs, driving efficiency and quality from Minnesota to global production floors. Your next step towards superior mold performance starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.