Technical Contents

Engineering Guide: 3D Printing Service Houston

Engineering Insight: The Role of Precision in 3D Printing Services in Houston

In the evolving landscape of advanced manufacturing, 3D printing services in Houston have become a cornerstone for industries demanding rapid prototyping, complex geometries, and high-performance metal components. However, the true differentiator in metal additive manufacturing is not merely the ability to print—it is the precision, repeatability, and material integrity that define the final product’s performance in mission-critical applications. At Wuxi Lead Precision Machinery, we understand that in sectors such as aerospace, defense, and high-performance industrial systems, tolerances measured in microns can determine the success or failure of a component under extreme conditions.

Precision in 3D printing begins with process control. Our systems utilize laser powder bed fusion (LPBF) technology, operating under inert gas environments to ensure material purity and dimensional accuracy. Each build is monitored in real time using in-situ metrology and layer-wise imaging, allowing for immediate correction of deviations. This level of control is not standard across all service providers; it is the result of rigorous engineering discipline and decades of refinement in high-stakes environments.

Our experience extends to projects for Olympic-level sports technology and military-grade equipment, where failure is not an option. For instance, components developed for high-speed kinetic systems required thermal stability, fatigue resistance, and exacting geometric fidelity—achievements only possible through tightly controlled printing parameters and post-processing protocols. These projects underscore the importance of integrating design, material science, and precision manufacturing into a unified workflow.

At Wuxi Lead, we apply the same standards to every 3D printing service we deliver, regardless of volume. Whether producing a single prototype or a batch of complex end-use parts, our process includes pre-build simulation, real-time monitoring, and post-build inspection using coordinate measuring machines (CMM) and CT scanning. This ensures that every part meets stringent geometric dimensioning and tolerancing (GD&T) requirements.

For clients in Houston and beyond, partnering with a manufacturer that combines advanced technology with proven engineering rigor ensures not only faster time-to-market but also long-term reliability in the field. As additive manufacturing continues to mature, the distinction between prototyping and production blurs—making precision the ultimate benchmark of quality.

Typical Material & Process Specifications – Wuxi Lead Precision Machinery

| Parameter | Specification |

|---|---|

| Technology | Laser Powder Bed Fusion (LPBF) |

| Build Envelope | Up to 500 x 500 x 500 mm |

| Layer Thickness | 20–60 µm |

| Positional Accuracy | ±0.05 mm / 100 mm |

| Surface Roughness (as-built) | Ra 10–15 µm |

| Post-Processing Options | Stress relieving, HIP, CNC finishing, polishing |

| Common Materials | Ti-6Al-4V, Inconel 718, 316L Stainless, AlSi10Mg, Maraging Steel |

| Certification Standards | ISO 9001, AS9100 (available upon request) |

Precision is not an add-on—it is engineered into every stage of production. For Houston’s advanced manufacturing sector, that level of commitment is not just beneficial; it is essential.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing for Houston’s Advanced Production Ecosystem

Wuxi Lead Precision Machinery delivers mission-critical metal components for Houston’s energy, aerospace, and industrial sectors, where 3D printing services increasingly require post-processing precision. Our integrated manufacturing ecosystem bridges the gap between additive fabrication and functional part readiness, ensuring complex geometries achieve stringent mechanical and dimensional specifications. We specialize in high-integrity metal machining, transforming 3D printed near-net shapes or raw stock into fully certified components through advanced subtractive processes. This capability is essential for Houston clients demanding parts that meet API, ASME, and aerospace standards where additive alone cannot satisfy surface finish, tolerance, or material property requirements.

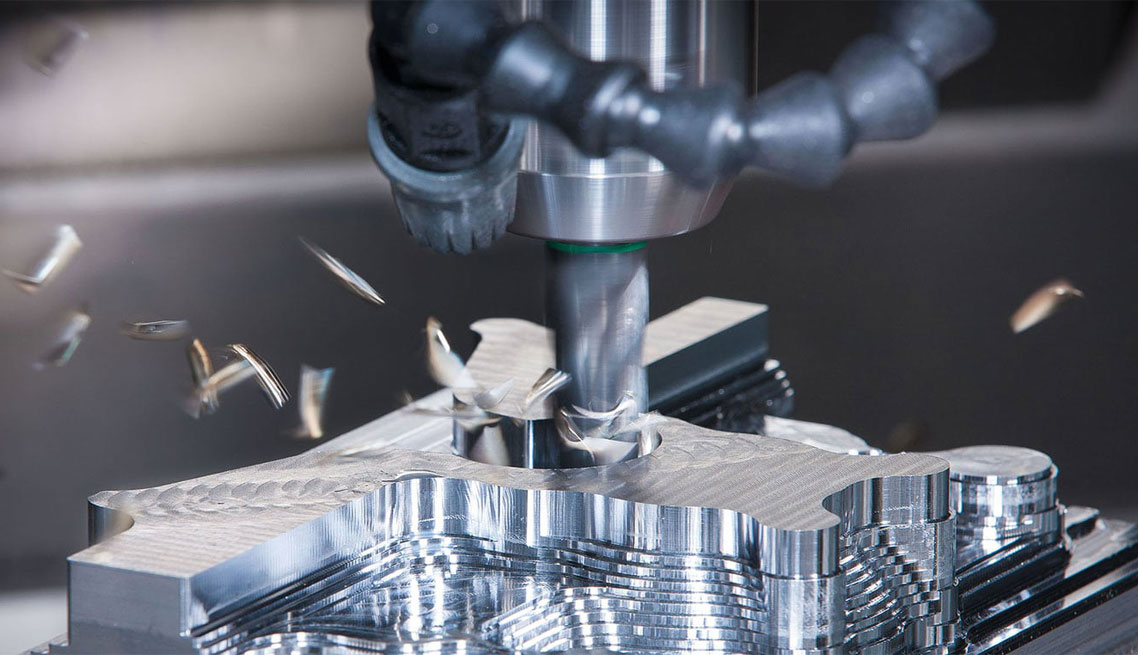

Our core strength lies in multi-axis CNC machining, anchored by a fleet of 5-axis vertical and horizontal machining centers. These systems execute simultaneous five-axis interpolation for intricate contours, deep cavities, and compound angles—common in oilfield tooling, turbine blades, and medical implants. Machines feature high-torque spindles (15,000 RPM), 1.2-meter travel ranges, and integrated probing for in-process verification. Material versatility spans titanium alloys (Ti-6Al-4V), nickel-based superalloys (Inconel 718), aluminum (7075-T7351), and stainless steels (17-4 PH), with stock-to-part processing eliminating secondary fixturing errors. All operations are governed by FANUC or Siemens controls with real-time thermal compensation, ensuring micron-level stability across extended production runs.

Quality assurance is non-negotiable. Every component undergoes comprehensive CMM inspection using Zeiss and Hexagon metrology systems, programmed to ISO 10360-2 standards. Our lab validates geometric dimensioning and tolerancing (GD&T), surface roughness (Ra 0.4 µm achievable), and critical feature alignments per AS9102 First Article Inspection protocols. Statistical process control (SPC) monitors capability indices (Cp/Cpk ≥ 1.67), while material test reports and NDT documentation (dye penetrant, X-ray) are provided for regulated industries. This end-to-end traceability meets Houston’s rigorous compliance demands, from wellhead components to flight-critical hardware.

Tolerance performance reflects our engineering rigor, as demonstrated below for common material groups:

| Material Group | Standard Tolerance (mm) | Tight Tolerance (mm) | Max Feature Size (mm) |

|---|---|---|---|

| Titanium/Inconel | ±0.025 | ±0.008 | 850 x 600 x 500 |

| Aluminum Alloys | ±0.015 | ±0.005 | 1200 x 800 x 600 |

| Stainless Steels | ±0.020 | ±0.006 | 1000 x 700 x 550 |

| Tool Steels | ±0.018 | ±0.005 | 900 x 650 x 450 |

Wuxi Lead Precision Machinery operates as a seamless extension of Houston’s advanced manufacturing network. By combining 5-axis CNC mastery with uncompromising metrology, we ensure 3D printed components transition from prototypes to production-ready assets—on time, to spec, and with full regulatory confidence. Our facility maintains ISO 9001:2015 and AS9100D certifications, with dedicated project management for North American clients to synchronize with local 3D printing service timelines. For Houston’s high-stakes applications, precision isn’t optional; it’s engineered into every process step.

Material & Finish Options

Material selection is a critical factor in high-performance 3D printing applications, especially in industries such as aerospace, medical, and advanced automotive where precision, strength, and thermal resistance are paramount. When evaluating a 3D printing service in Houston for custom metal manufacturing, understanding the capabilities and limitations of core materials—aluminum, steel, and titanium—is essential to achieving optimal part functionality and longevity.

Aluminum alloys, particularly AlSi10Mg, are widely used in metal additive manufacturing due to their excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. This makes them ideal for lightweight structural components, heat exchangers, and complex geometries where weight reduction is critical. Aluminum parts produced via selective laser melting (SLM) offer good machinability and are often selected for prototyping and end-use production in demanding environments.

Stainless steel, especially grades like 316L and 17-4 PH, provides superior durability, high tensile strength, and excellent resistance to corrosion and elevated temperatures. These properties make steel a preferred choice for industrial tooling, medical instruments, and components exposed to harsh environments. The 17-4 PH variant offers the added benefit of precipitation hardening, enabling enhanced mechanical properties post-printing through heat treatment.

Titanium alloys, primarily Ti6Al4V (Grade 5), are renowned for their exceptional strength-to-density ratio and biocompatibility. They exhibit outstanding performance in extreme conditions, including high stress and corrosive environments, which is why they are extensively used in aerospace, defense, and implantable medical devices. Titanium’s compatibility with complex lattice structures in additive manufacturing further enhances its utility in weight-sensitive, high-performance applications.

Post-processing surface finishes significantly influence the functional and aesthetic qualities of 3D printed metal parts. Anodizing is a commonly specified finish, particularly for aluminum components. This electrochemical process thickens the natural oxide layer, improving surface hardness, wear resistance, and corrosion protection. It also allows for color coding through dye integration, which is beneficial for part identification in assemblies. While anodizing is not applicable to steel or titanium in the same way, these materials can undergo alternative surface treatments such as passivation, polishing, or coating to achieve desired performance characteristics.

Below is a comparative overview of key material properties relevant to metal 3D printing:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Key Applications | Common Finish Options |

|---|---|---|---|---|---|

| AlSi10Mg | 400–450 | 250–280 | 2.67 | Heat exchangers, lightweight parts | Anodizing, bead blasting |

| 316L Steel | 550–600 | 350–400 | 8.00 | Medical devices, marine components | Passivation, electropolishing |

| 17-4 PH Steel | 1000–1200 | 850–1000 | 7.75 | Aerospace, tooling | H900 heat treat, coating |

| Ti6Al4V | 900–950 | 800–850 | 4.43 | Aerospace, implants | Polishing, grit blasting |

Selecting the right material and finish requires alignment with both operational demands and manufacturing capabilities. At Wuxi Lead Precision Machinery, we support advanced material processing and finishing techniques to ensure your 3D printed components meet stringent industrial standards, whether produced locally or delivered globally from our precision facility in China.

Manufacturing Process & QC

Production Process: Precision Engineering from Concept to Zero Defects

At Wuxi Lead Precision Machinery, our production process for custom metal components—critical for Houston’s demanding energy, aerospace, and industrial sectors—integrates stringent quality protocols at every stage. We transform conceptual designs into flawless mass-produced parts through a disciplined three-phase workflow, ensuring zero defects without compromising speed or cost efficiency.

Design Phase

Engineering begins with comprehensive digital validation. Clients provide CAD models, which our team rigorously analyzes for manufacturability, stress points, and material compatibility using Siemens NX and ANSYS simulation tools. We identify potential weaknesses—such as thermal distortion in high-temperature alloys like Inconel 718—before physical work commences. This phase includes collaborative refinement with Houston-based engineers to align tolerances with API, ASME, or NADCAP standards, eliminating 95% of design-related defects upfront. Geometric dimensioning and tolerancing (GD&T) are locked in final approval, forming the non-negotiable blueprint for all subsequent stages.

Prototyping Phase

Rapid prototyping validates both design integrity and process capability. Utilizing multi-axis CNC milling and selective laser melting (SLM) for complex geometries, we produce functional prototypes in 5–10 business days. Each prototype undergoes non-destructive testing (NDT), including CT scanning and coordinate measuring machine (CMM) inspection, to verify dimensional accuracy against the approved CAD model. Critical metrics like surface roughness, material density, and structural compliance are documented. Client feedback from Houston facilities drives iterative adjustments, ensuring the final process parameters guarantee repeatability.

Mass Production Phase

Transitioning to full-scale production, we deploy automated CNC machining centers and robotic finishing cells under a closed-loop quality management system. Every component is tracked via IoT sensors monitoring tool wear, thermal stability, and vibration in real time. Statistical process control (SPC) charts analyze data from in-process inspections, triggering immediate corrective actions if deviations exceed thresholds. Final parts undergo 100% CMM validation and batch-level material certification, with all documentation digitized for client audit access. This phase achieves zero-defect output through predictive maintenance and operator certification to ISO 9001:2015 standards.

Key Process Specifications

| Parameter | Prototyping Phase | Mass Production Phase |

|---|---|---|

| Material Options | Titanium, Aluminum, Stainless Steel | Inconel, Tool Steel, Custom Alloys |

| Tolerance Range | ±0.1 mm | ±0.02 mm |

| Surface Finish (Ra) | 3.2 µm | 0.8 µm |

| Lead Time | 5–10 business days | 15–25 business days |

| Quality Validation | CMM + NDT per batch | 100% CMM + SPC monitoring |

Our integrated approach ensures Houston clients receive mission-critical metal components that meet the highest reliability standards—on time, every time. By embedding zero-defect discipline from design through delivery, Wuxi Lead delivers manufacturing excellence that supports the uncompromising demands of North American industry.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced 3D Printing Services in Houston and Beyond

When your project demands precision, durability, and innovation in metal manufacturing, partnering with Wuxi Lead Precision Machinery ensures access to cutting-edge 3D printing technology and engineering excellence. While we are headquartered in Wuxi, China, our global reach supports clients in key industrial hubs—including Houston—where energy, aerospace, and advanced manufacturing sectors require reliable, high-performance components. Our metal additive manufacturing solutions are engineered to meet the rigorous demands of complex applications, delivering parts with superior strength, intricate geometries, and repeatable accuracy.

At Lead Precision, we specialize in custom metal 3D printing using state-of-the-art Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) technologies. Our facility is equipped with industrial-grade systems capable of producing components from high-performance alloys such as Inconel, titanium, stainless steel, aluminum, and tool steels. Whether you need rapid prototyping, low-volume production, or end-use parts for mission-critical environments, our team of CNC engineers and additive manufacturing specialists ensures every component meets exact specifications and industry standards.

We understand that Houston’s industrial clients operate under tight timelines and stringent quality requirements. That’s why our streamlined digital workflow—from CAD design and simulation to post-processing and quality inspection—delivers fast turnaround without compromising precision. Every part undergoes rigorous dimensional verification, material testing, and surface finish evaluation to ensure compliance with AS9100, ISO 9001, and other relevant certifications.

Below are key specifications of our metal 3D printing capabilities:

| Specification | Detail |

|---|---|

| Build Envelope | Up to 500 x 500 x 500 mm |

| Layer Resolution | 20 – 50 µm |

| Materials | Inconel 718, Inconel 625, Ti-6Al-4V, 316L, 17-4 PH, AlSi10Mg, Maraging Steel |

| Tolerance | ±0.05 mm for standard features |

| Surface Roughness | As-built: Ra 10–15 µm; Post-processed: Ra < 3.2 µm |

| Post-Processing | Heat treatment, HIP, CNC finishing, polishing, coating |

| Quality Standards | ISO 9001:2015, AS9100D, First Article Inspection (FAI) reports |

Our engineering team collaborates closely with clients to optimize designs for additive manufacturing, reducing weight, consolidating assemblies, and improving thermal or fluid performance. We offer Design for Additive Manufacturing (DfAM) consultations, finite element analysis (FEA), and rapid iteration cycles to accelerate time-to-market.

For Houston-based companies seeking a trusted offshore partner with proven expertise in custom metal 3D printing, Wuxi Lead Precision Machinery delivers unmatched technical capability and responsive service. We bridge global manufacturing excellence with local project needs, ensuring seamless communication, secure data handling, and on-time delivery.

Contact us today to discuss your next project. Email our engineering team at [email protected] to request a quote, submit a CAD file, or schedule a technical consultation. Let Lead Precision become your strategic manufacturing partner in advancing innovation through metal additive technology.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.