Technical Contents

Engineering Guide: Mills Machining

Engineering Insight: The Non-Negotiable Imperative of Precision in Mills Machining

In high-stakes custom metal manufacturing, precision in mills machining transcends mere specification; it is the foundational metric determining component functionality, assembly integrity, and ultimate product success. For industries like aerospace, medical device production, and advanced energy systems, tolerances measured in microns are not aspirational targets but absolute requirements. Sub-micron deviations can trigger catastrophic system failures, accelerate wear, compromise sealing surfaces, or render complex assemblies impossible. Achieving this level of precision demands far more than advanced machine tools; it requires a holistic engineering approach integrating thermal stability, vibration damping, material science understanding, and rigorous process control. The machine tool structure must resist deflection under cutting forces, spindles must maintain micron-level runout stability despite thermal growth, and the entire system must operate within tightly controlled environmental parameters. Real-world precision is proven not in idealized lab conditions, but within the dynamic thermal and mechanical realities of a production floor.

True precision engineering addresses the interplay of critical factors. Thermal management is paramount; even minute temperature fluctuations cause measurable metal expansion, directly impacting dimensional accuracy. Advanced machines incorporate real-time thermal compensation systems monitoring dozens of critical points. Equally vital is structural rigidity and damping capacity to absorb cutting forces without resonant vibration, which manifests as chatter marks and dimensional drift. Furthermore, understanding material behavior under specific cutting parameters—chip formation, heat generation, and residual stress—is essential to predict and control final part geometry. This depth of process knowledge, combined with machine capability, separates true precision manufacturing from standard machining services.

Wuxi Lead Precision Machinery embodies this precision-first philosophy through demonstrable experience on the world’s most demanding projects. Our mills machining capabilities were rigorously validated during critical component production for the Beijing Winter Olympics infrastructure, where timing mechanisms required sub-5-micron positional accuracy under extreme environmental conditions. This same uncompromising standard defines our military-grade contract work, where components for advanced defense systems must perform flawlessly under punishing operational stresses. We translate this elite-level experience into reliable, repeatable precision for every client, transforming complex engineering drawings into mission-critical metal components.

The following specifications represent the baseline performance achievable on our flagship 5-axis milling platforms under controlled production conditions:

| Performance Parameter | Typical Value | Measurement Standard | Significance |

|---|---|---|---|

| Positioning Accuracy (X/Y/Z) | ±0.0015 mm | ISO 230-2:2014 | Absolute positioning error over axis travel |

| Repeatability (X/Y/Z) | ±0.0008 mm | ISO 230-2:2014 | Consistency of return to target point |

| Volumetric Accuracy | ±0.003 mm | NAS 979 / Custom Protocols | True 3D positional accuracy in work zone |

| Spindle Thermal Growth | < 0.002 mm | ISO 230-3:2007 | Axial growth compensation range |

| Surface Finish (Ra) | 0.2 – 0.8 µm | ISO 4287 | Achievable on hardened alloys |

Precision in mills machining is not an isolated machine capability; it is the culmination of engineering discipline, process mastery, and unwavering commitment to exceeding functional requirements. At Wuxi Lead Precision Machinery, we engineer every process step to deliver the dimensional certainty your most critical applications demand, backed by proven performance where failure is not an option. Partner with us for components where microns define mission success.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, anchored by state-of-the-art 5-axis CNC machining systems. Our precision engineering platform supports complex geometries, tight tolerances, and high repeatability for mission-critical components across aerospace, medical, energy, and industrial automation sectors. The integration of 5-axis technology enables simultaneous multi-directional cutting, reducing setup cycles and improving dimensional accuracy. This capability allows us to machine intricate contours and deep cavities with superior surface finish, eliminating the need for multiple fixtures and secondary operations.

Our machining centers are equipped with high-speed spindles, automatic tool changers, and real-time monitoring systems to ensure consistent performance. Materials processed include aluminum alloys, stainless steels, titanium, Inconel, and specialty alloys, all machined under strict environmental controls to minimize thermal distortion. Each workpiece benefits from optimized toolpaths generated through advanced CAM software, ensuring material integrity and geometric precision throughout the manufacturing cycle.

Quality assurance is embedded into every phase of production. All components undergo comprehensive inspection using a Zeiss DuraMax and GLOBAL S coordinate measuring machine (CMM), providing micron-level verification of critical features. Our CMM system supports both tactile and optical probing, enabling full 3D validation of complex forms, hole patterns, positional tolerances, and surface profiles. Inspection reports are fully documented and traceable, meeting ISO 9001 and customer-specific quality standards.

We maintain tight control over dimensional accuracy through continuous process validation and tool wear compensation algorithms. Our engineering team collaborates directly with clients during the design-for-manufacturability (DFM) stage to optimize part geometry, reduce cycle times, and ensure compliance with functional requirements. This proactive approach minimizes rework and accelerates time-to-market for high-performance applications.

The following table outlines our standard machining tolerances and inspection capabilities:

| Feature | Standard Tolerance | Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM, Micrometers, Calipers |

| Positional Tolerance | ±0.03 mm | ±0.01 mm | CMM, Optical Comparator |

| Flatness | 0.02 mm/m | 0.005 mm/m | Surface Plate, CMM |

| Circular Runout | 0.02 mm | 0.005 mm | V-block & Dial Indicator, CMM |

| Surface Roughness | Ra 3.2 μm | Ra 0.4 μm | Surface Roughness Tester |

| Angular Tolerance | ±0.1° | ±0.05° | Sine Bar, CMM |

| Hole Diameter (Drilled) | ±0.02 mm | ±0.01 mm | Pin Gauges, CMM |

| Thread Accuracy | 6H/6g | 4H/4g | Thread Gauges, CMM |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with rigorous quality control to deliver components that meet the highest standards of precision and reliability. Our technical capabilities are designed to support complex, low-to-medium volume production runs with full traceability and engineering support.

Material & Finish Options

Material Selection for Precision Mill Machining

Selecting the optimal material is foundational to successful CNC milling outcomes. At Wuxi Lead Precision Machinery, we emphasize matching material properties to the functional demands, environmental exposure, and cost targets of your specific application. Aluminum, steel, and titanium represent the core structural metals for high-precision components, each offering distinct advantages and machining considerations. Understanding these differences ensures performance, manufacturability, and value.

Aluminum alloys, particularly 6061 and 7075, dominate aerospace, electronics, and consumer goods due to their exceptional strength-to-weight ratio, thermal conductivity, and inherent corrosion resistance. They machine rapidly with excellent surface finishes, minimizing tool wear and cycle times. While 6061 offers good all-around properties and weldability, 7075 provides superior strength for highly stressed components, though it is less corrosion resistant and more challenging to machine. Aluminum’s primary limitation is lower absolute strength and hardness compared to steel or titanium, making it less suitable for extreme wear applications.

Steel variants, especially 303 stainless (free-machining), 304 stainless (general corrosion resistance), and 4140 alloy steel (high strength), are indispensable for structural parts, tooling, and components requiring high wear resistance or strength at elevated temperatures. Stainless steels provide excellent corrosion resistance but generate significant heat during milling, demanding rigid setups, appropriate coolant strategies, and specialized tooling to manage work hardening and achieve fine finishes. Carbon and alloy steels like 4140 offer high strength and toughness but require heat treatment for optimal performance, adding process complexity.

Titanium alloys, primarily Grade 5 (Ti-6Al-4V), are critical for aerospace, medical implants, and high-performance automotive sectors where ultimate strength-to-weight ratio, biocompatibility, and extreme corrosion resistance are non-negotiable. Milling titanium presents significant challenges: low thermal conductivity causes heat concentration at the cutting edge, high chemical reactivity risks galling, and its strength leads to high cutting forces. Success requires lower speeds, rigid machine setups, sharp carbide tools with positive geometries, and consistent, high-pressure coolant application. Material cost and machining difficulty are substantially higher than aluminum or steel.

The following table summarizes key comparative properties for common grades:

| Material | Typical Grade | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Key Corrosion Resistance |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 2.7 | 310 | Excellent (9/10) | Good (Atmospheric) |

| Steel | 304 Stainless | 8.0 | 515 | Moderate (4/10) | Excellent (Oxidizing) |

| Titanium | Ti-6Al-4V | 4.4 | 900 | Difficult (2/10) | Exceptional (All Environments) |

For aluminum components, anodizing is the premier surface enhancement. This electrochemical process thickens the natural oxide layer, dramatically improving wear resistance, corrosion protection, and enabling durable color coding. Hard anodizing (Type III) creates a thick, dense, abrasion-resistant surface essential for moving parts, while standard anodizing (Type II) offers excellent general protection and adhesion for paint. Wuxi Lead integrates anodizing specification guidance early in the design phase to ensure dimensional stability and optimal functional performance of your milled aluminum parts. Material choice directly impacts manufacturability, cost, and final part success; our engineering team collaborates closely with clients to select the ideal solution.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our production process for mills machining is engineered for precision, consistency, and zero-defect delivery. We serve high-end industrial clients who demand excellence at every stage, from concept to full-scale manufacturing. Our integrated workflow ensures that each component meets exacting standards while maintaining efficiency and repeatability.

The process begins with design collaboration. Our engineering team works directly with client specifications, utilizing advanced CAD/CAM software to develop optimized machining strategies. Finite element analysis and tolerance stack-up simulations are conducted to anticipate performance under operational conditions. This phase includes material selection, surface finish requirements, and geometric dimensioning, ensuring that every design parameter aligns with functional intent and manufacturability.

Once the design is finalized, we move into precision prototyping. Using high-speed CNC milling centers with sub-micron positioning accuracy, we produce functional prototypes that mirror final production quality. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface profilometers. First article inspection reports (FAIR) and material certifications are provided, allowing clients to validate form, fit, and function before committing to volume production. Iterations, if required, are executed swiftly with minimal lead time impact.

Upon approval, we transition seamlessly into mass production. Our automated production cells operate under strict process controls, with real-time monitoring of tool wear, spindle load, and dimensional drift. Statistical process control (SPC) is applied to critical features, ensuring continuous conformance to specifications. Every component is traceable through our digital manufacturing system, with lot tracking, inspection data logging, and process parameter archiving. Our zero-defect philosophy is enforced through layered quality gates, including in-process checks, final inspection, and 100% critical feature verification where required.

Our mills machining capabilities are supported by a robust infrastructure of 3-axis, 4-axis, and 5-axis CNC machining centers, enabling complex geometries and tight tolerances across a wide range of metals—including aluminum alloys, stainless steels, titanium, and high-performance superalloys.

Below are key specifications for our milling production capacity:

| Parameter | Specification |

|---|---|

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Spindle Speed Range | Up to 24,000 rpm |

| Surface Finish (Ra) | As low as 0.4 μm |

| Tolerance Capability | ±0.01 mm (standard), ±0.005 mm (tight) |

| Materials Supported | Aluminum, Steel, Stainless, Titanium, Inconel |

| Production Volume Range | 1–100,000+ units annually per part |

| Quality Standards | ISO 9001:2015, PPAP, APQP, SPC, FAIR |

From design through prototyping to high-volume manufacturing, Wuxi Lead Precision Machinery delivers uncompromising quality, on-time performance, and full technical transparency—ensuring our clients achieve zero-defect outcomes in every batch.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Milling Excellence

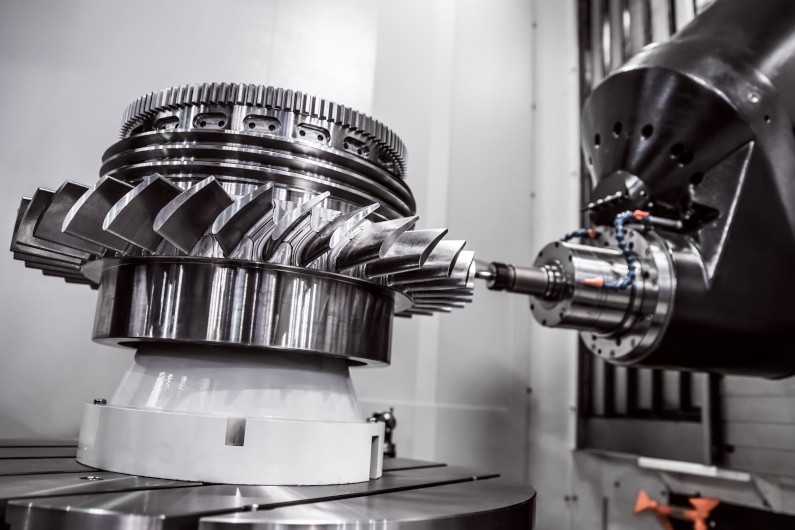

In the demanding landscape of precision metal manufacturing, component integrity directly impacts your product’s performance and market success. Wuxi Lead Precision Machinery delivers engineered milling solutions where tolerance, repeatability, and material science converge. We specialize in transforming complex geometries into reality for aerospace, medical device, and energy sector applications—where failure is not an option. Our ISO 9001-certified facility in Wuxi integrates German-engineered DMG MORI and MAZAK 5-axis milling centers with proprietary process validation protocols. This ensures every part meets stringent AS9100 and ISO 13485 requirements without compromising lead time.

Our technical capabilities are engineered for your most challenging projects. The table below details core milling specifications achievable across our production floor:

| Parameter | Capability | Industry Standard Benchmark |

|---|---|---|

| Positioning Accuracy | ±0.003 mm | ±0.010 mm |

| Maximum Work Envelope | 2000 x 1500 x 1200 mm | 1500 x 1000 x 800 mm |

| Spindle Speed Range | 20 – 32,000 RPM | 20 – 24,000 RPM |

| Surface Finish (Ra) | 0.2 µm – 0.8 µm | 0.8 µm – 1.6 µm |

| Material Compatibility | Titanium, Inconel, Hastelloy, 17-4PH, Aluminum 7075 | Standard alloys only |

Unlike volume-focused competitors, we prioritize dimensional integrity over throughput. Our engineers collaborate from DFx review through first-article inspection, implementing real-time SPC monitoring to eliminate scrap risk. This methodology reduces your time-to-qualification by 30% while ensuring batch-to-batch consistency. For mission-critical components—such as turbine blades or surgical implants—our in-house metrology lab provides full CMM traceability with calibrated reports compliant with NIST standards.

Custom manufacturing demands more than machinery; it requires partnership. Lead Precision assigns a dedicated engineering liaison to deconstruct your technical challenges, whether optimizing thin-wall machining strategies or validating non-destructive testing protocols. We absorb the complexity of tight-tolerance milling so your team focuses on innovation, not supply chain vulnerabilities. Our lean manufacturing cell structure guarantees transparent progress tracking via secure client portals, with zero-defect delivery records exceeding 99.8% across 120+ active OEM programs.

Initiate dialogue with our precision engineering team to transform your most complex milling requirements into certified production reality. Share your 3D model and tolerance stack-up analysis with [email protected]. Within 24 business hours, a Lead Precision Applications Engineer will provide a feasibility assessment including process plan, capacity allocation, and actionable timeline. Do not compromise on the foundation of your product’s performance—partner with the machining authority trusted by global Tier 1 suppliers. Your next breakthrough component begins with a single email.

Contact [email protected] to activate engineering collaboration.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.