Technical Contents

Engineering Guide: 3D Printed Injection Molds

Engineering Insight: Precision Imperatives in 3D Printed Injection Molds

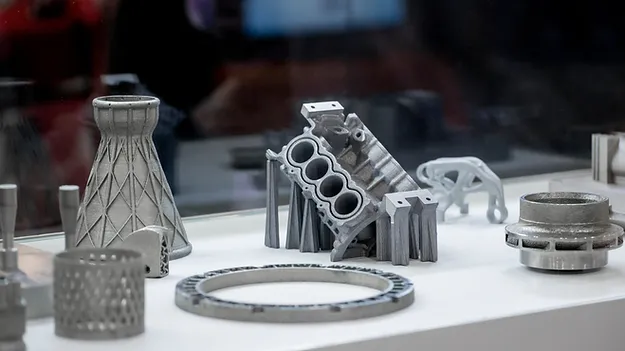

The emergence of metal additive manufacturing (AM) for injection molds represents a significant advancement in rapid tooling, offering complex geometries and accelerated lead times previously unattainable. However, the transition from prototype to functional, production-intent mold demands uncompromising precision. Surface finish, dimensional accuracy, and thermal management characteristics directly dictate part quality, cycle time stability, and mold longevity. Achieving consistent, high-fidelity results requires far more than the printing process alone; it necessitates integrated expertise in post-processing, metrology, and traditional mold-making principles. Neglecting these precision elements risks part defects, premature mold failure, and ultimately, negates the time-to-market advantages AM promises.

At Wuxi Lead Precision Machinery, we bridge the gap between additive innovation and industrial-grade reliability. Our approach integrates advanced metal AM systems with stringent CNC finishing, stress-relieving protocols, and comprehensive coordinate measuring machine (CMM) validation. This ensures printed mold cores, cavities, and conformal cooling channels meet the exacting tolerances required for demanding production environments. We treat every AM mold not as an isolated printed component, but as a precision-engineered system requiring holistic manufacturing control.

Critical performance parameters for production-viable metal 3D printed injection molds are non-negotiable. The table below outlines the baseline specifications achievable through our integrated process, reflecting the standards necessary for serious manufacturing applications.

| Parameter | Typical Range (Stainless Steel) | Lead Precision Standard | Significance for Production |

|---|---|---|---|

| Layer Thickness | 20 – 50 μm | ≤ 30 μm | Surface roughness, feature resolution |

| As-Printed Tolerance | ± 0.1 – 0.2 mm | ± 0.05 mm (post-CNC) | Core/cavity fit, part dimensions |

| Surface Roughness (Ra) | 10 – 25 μm | ≤ 1.6 μm (critical areas) | Part ejection, surface finish |

| Tensile Strength | ≥ 1100 MPa | ≥ 1200 MPa | Structural integrity under pressure |

| Hardness (HRC) | 35 – 45 | 40 – 48 (post-heat treat) | Wear resistance, longevity |

| Conformal Channel Accuracy | ± 0.15 mm | ± 0.05 mm | Predictable cooling, cycle time control |

Our commitment to precision is forged in the most demanding sectors. Lead Precision has successfully delivered mission-critical components requiring micron-level accuracy for aerospace applications and supplied precision timing systems integral to Olympic Games infrastructure. This experience operating under stringent military and elite event specifications directly informs our AM mold process. We understand that tolerances specified on a drawing are merely the starting point; true precision is validated through rigorous, repeatable measurement and proven performance under real-world production stress. When your application demands molds that consistently produce high-quality parts at scale, our integrated AM and precision machining expertise delivers the reliability your production floor requires. Partner with Lead Precision to transform additive potential into precision manufacturing reality.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions tailored for high-performance applications in the realm of 3D printed injection molds. As a leader in custom metal manufacturing, we integrate precision engineering with cutting-edge technology to produce tooling components that meet the exacting demands of modern production environments. Our technical capabilities are anchored in state-of-the-art equipment, rigorous quality control protocols, and a deep understanding of the interplay between additive manufacturing and traditional machining processes.

At the core of our machining operations is a fleet of 5-axis CNC machining centers, enabling us to achieve complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, providing unparalleled flexibility in contouring intricate mold features such as conformal cooling channels, undercuts, and organic internal structures—geometries often derived directly from 3D printed mold designs. The integration of 5-axis technology ensures minimal setup changes, reduced cycle times, and superior part consistency, all critical when producing high-precision mold components for low-volume or rapid prototyping injection applications.

Complementing our machining excellence is a comprehensive quality assurance system centered on CMM (Coordinate Measuring Machine) inspection. Every component undergoes full dimensional verification against CAD models, ensuring compliance with design specifications down to the micron level. Our CMM protocols include first-article inspection, in-process checks, and final batch validation, providing full traceability and documentation for every project. This metrology-driven approach guarantees that all 3D printed injection mold components meet the tight tolerances and geometric fidelity required for reliable mold performance and part repeatability.

To support the unique challenges of hybrid manufacturing—where 3D printed cores or inserts are integrated into precision metal molds—we maintain strict control over material compatibility, thermal stability, and mechanical alignment. Our engineers work closely with clients to optimize designs for manufacturability, ensuring that the transition from additive build to CNC finishing and final assembly is seamless and dimensionally robust.

The table below outlines the standard technical specifications and achievable tolerances for our 5-axis CNC machining and inspection processes:

| Parameter | Specification |

|---|---|

| Positional Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Surface Roughness (Ra) | As low as 0.4 μm (polished finishes available) |

| Maximum Work Envelope | 1200 × 800 × 600 mm |

| Tolerance for Critical Features | ±0.01 mm (standard), down to ±0.005 mm (tight) |

| Angular Tolerance | ±0.05° |

| CMM Measurement Uncertainty | < 0.0025 mm (at 95% confidence level) |

These capabilities position Wuxi Lead Precision Machinery as a trusted partner in the development of high-integrity, 3D printed injection mold systems. By combining advanced CNC technology with metrology-grade inspection, we ensure every component meets the highest standards of precision, durability, and functional performance.

Material & Finish Options

Material Selection Fundamentals for 3D Printed Injection Molds

Selecting the optimal material for 3D printed injection molds is critical for balancing production speed, part quality, mold longevity, and cost efficiency in low-to-mid volume manufacturing. Unlike traditional steel molds suited for high-volume runs, 3D printed metal molds excel in rapid prototyping and bridge production, where thermal management and rapid iteration are paramount. At Wuxi Lead Precision Machinery, we prioritize materials that maximize the inherent advantages of additive manufacturing while meeting stringent industrial requirements. Aluminum alloys, tool steels, and titanium each offer distinct performance profiles requiring careful evaluation against your specific application demands.

Aluminum alloys, particularly AlSi10Mg, are the dominant choice for 3D printed molds due to exceptional thermal conductivity. This property significantly reduces cycle times by up to 30% compared to steel molds, as heat transfers rapidly from the molten plastic to the cooling channels. Aluminum’s lower hardness makes it ideal for lower-clamp-force machines and abrasive-filled polymers where steel might gall. Its machinability also facilitates quick post-print modifications. While suitable for 1,000 to 10,000 parts depending on complexity and polymer, aluminum requires protective surface treatments like anodizing for extended life against wear and corrosion.

Tool steels, such as H13 or maraging steel, provide superior hardness and wear resistance for higher-volume bridge production or demanding engineering plastics. Steel molds withstand higher injection pressures and temperatures, supporting 10,000 to 50,000+ cycles in optimal conditions. However, their lower thermal conductivity increases cycle times and necessitates more complex conformal cooling channel designs to mitigate this drawback. Steel selection is essential when molding glass-filled nylons or high-temperature polymers like PEEK, where aluminum would erode prematurely. The trade-off is longer print times, higher material costs, and more intensive post-processing.

Titanium alloys (e.g., Ti6Al4V) are niche solutions primarily valued for extreme corrosion resistance in specific chemical environments or ultra-high-temperature applications near 600°C. Their thermal conductivity is poor, similar to steel, and the high material and processing costs generally make them impractical for standard injection molding. Titanium’s role remains limited to highly specialized medical or aerospace scenarios where its unique properties justify the expense.

Surface finishing, particularly hard anodizing for aluminum molds, is non-negotiable for durability. Anodizing creates a dense, wear-resistant ceramic layer (70-100µm thick) that dramatically improves release properties, reduces galling, and protects against chemical attack from polymers and release agents. Unanodized aluminum molds suffer rapid degradation. Steel molds typically utilize nitriding or specialized PVD coatings instead.

Material performance characteristics are summarized below for direct comparison.

| Material | Thermal Conductivity (W/m·K) | Hardness (HV) | Typical Use Cases | Cost Factor |

|---|---|---|---|---|

| Aluminum AlSi10Mg | 150-180 | 90-110 | Rapid prototyping, low-viscosity plastics, under 10k parts | Low |

| Tool Steel H13 | 25-35 | 450-500 | Engineering plastics, glass-filled resins, 10k-50k+ parts | High |

| Titanium Ti6Al4V | 7-10 | 300-350 | Extreme corrosion resistance, niche high-temp | Very High |

The optimal choice hinges on your production volume, polymer type, required surface finish, and thermal management needs. Wuxi Lead Precision Machinery leverages extensive metallurgical expertise and precision post-processing to ensure your 3D printed mold material selection delivers maximum ROI for your specific manufacturing challenge. Partner with us to navigate these critical decisions.

Manufacturing Process & QC

The production process for 3D printed injection molds at Wuxi Lead Precision Machinery follows a rigorously controlled sequence—Design, Prototyping, and Mass Production—engineered to achieve zero defects and uncompromised performance in high-volume manufacturing environments. Each phase integrates advanced simulation, precision metrology, and iterative validation to ensure functional reliability and dimensional accuracy.

Design begins with a comprehensive analysis of the customer’s part geometry, material requirements, and production volume. Our engineering team employs topology optimization and conformal cooling channel design using Siemens NX and Autodesk Moldflow, ensuring thermal efficiency and structural integrity. Finite Element Analysis (FEA) is conducted to predict stress distribution and deformation under injection cycles, allowing preemptive correction of potential failure points. All designs are reviewed against ISO 9001 and IATF 16949 standards, with full digital traceability from concept to completion.

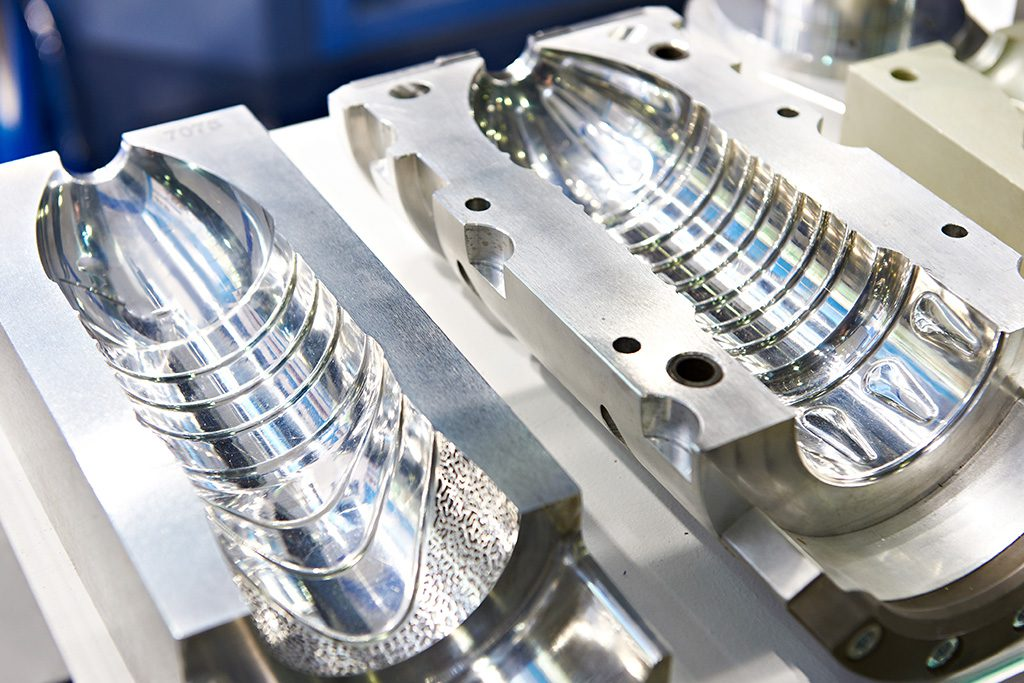

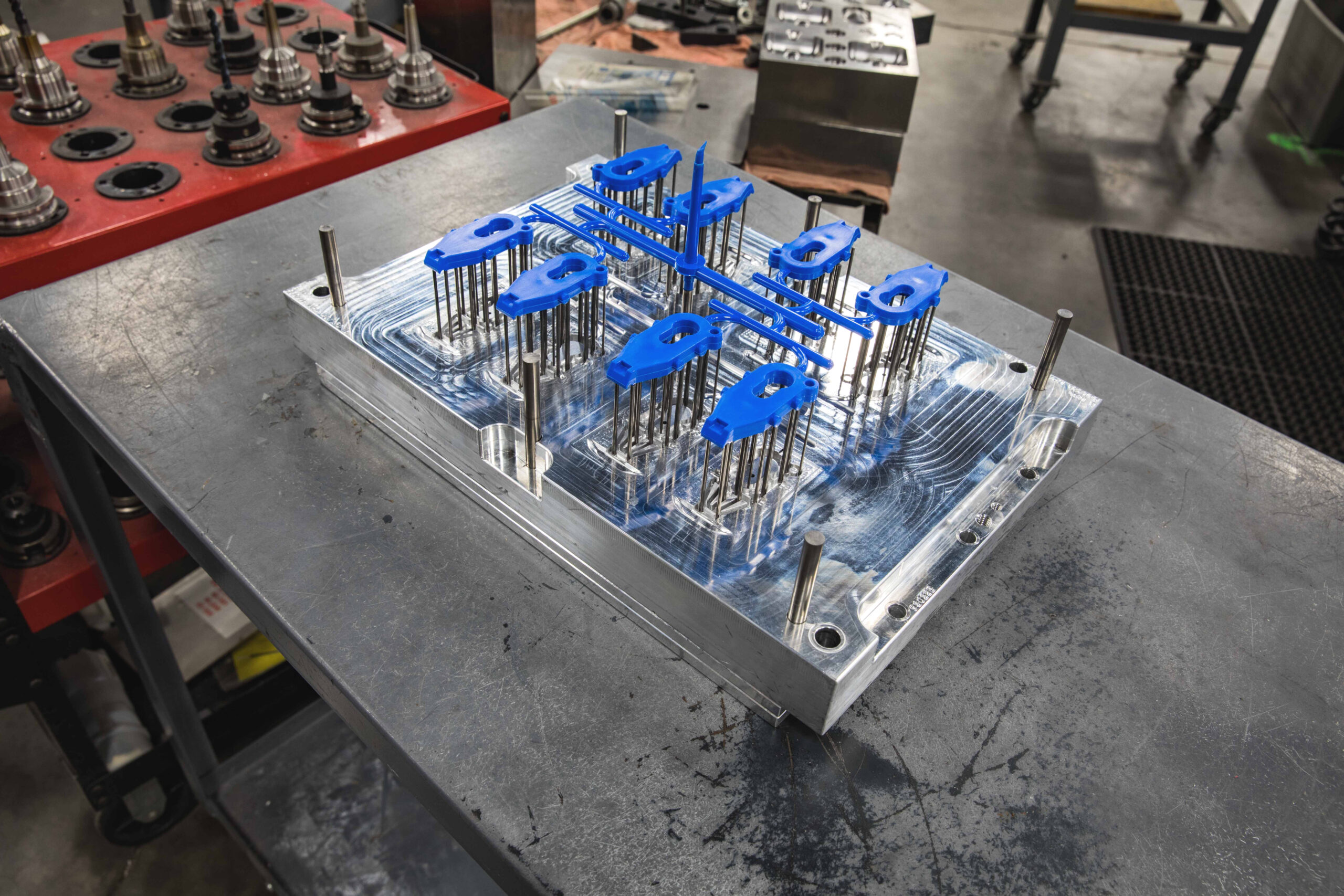

Prototyping follows a hybrid additive-subtractive methodology. Molds are fabricated using laser powder bed fusion (LPBF) with maraging steel (1.2709) or tool steel (H13), chosen for their high hardness, thermal fatigue resistance, and polishability. Layer resolution is maintained at 20–30 µm to ensure surface quality, followed by stress-relief annealing and hot isostatic pressing (HIP) to eliminate internal porosity. Critical surfaces undergo five-axis CNC machining and mirror polishing down to Ra 0.05 µm. Each prototype mold is subjected to a 100-cycle trial run under simulated production conditions, with real-time monitoring of cavity pressure, cooling efficiency, and ejection dynamics. Any deviation exceeding ±5 µm triggers automatic design revision.

Mass Production commences only after prototype validation and customer sign-off. Molds are replicated using identical build parameters and post-processing protocols to ensure batch consistency. Every unit undergoes Coordinate Measuring Machine (CMM) inspection at 15 critical points, with full 3D scanning for geometric deviation mapping. We implement Statistical Process Control (SPC) throughout production, with Cp/Cpk values monitored continuously to maintain process capability above 1.67. All molds are serialized and accompanied by a full quality dossier, including material certificates, heat treatment records, and first-article inspection reports.

Our zero-defect mandate is enforced through automated optical inspection (AOI) and in-line X-ray computed tomography (CT) for internal defect detection. Any non-conformance initiates an 8D root cause analysis, ensuring corrective actions are systemic, not symptomatic. This closed-loop quality system ensures every 3D printed injection mold meets the highest standards of repeatability, durability, and performance.

| Parameter | Specification |

|---|---|

| Build Material | Maraging Steel 1.2709, H13 Tool Steel |

| Layer Thickness | 20–30 µm |

| Surface Roughness (as-built) | Ra 10–15 µm |

| Post-Processing | HIP, Stress Relieving, 5-Axis CNC, Polishing (Ra 0.05 µm) |

| Dimensional Accuracy | ±5 µm over 100 mm |

| Cooling Channel Complexity | Conformal, Internal, Freeform |

| Inspection Method | CMM, 3D Scanning, AOI, X-ray CT |

| Production Cycle Validation | 100+ cycles under nominal load |

| Quality Standard | ISO 9001, IATF 16949, PPAP Level 3 |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised 3D Printed Injection Mold Excellence

When prototyping speed meets production-grade reliability, your choice of manufacturing partner becomes the critical variable. At Wuxi Lead Precision Machinery, we engineer 3D printed injection molds not as rapid prototypes, but as precision tooling assets capable of delivering consistent, high-integrity parts for low-to-mid volume production. Our integrated metal manufacturing ecosystem—spanning selective laser melting (SLM), precision CNC finishing, and rigorous metrology—ensures every mold meets the exacting demands of medical, aerospace, and automotive applications. We eliminate the traditional trade-off between accelerated time-to-market and dimensional stability, providing molds that withstand 10,000+ cycles with zero degradation in part quality.

Our technical capabilities are engineered for your most demanding specifications. The table below details core parameters achievable through our certified processes:

| Specification | Capability | Industry Standard Benchmark |

|---|---|---|

| Mold Base Material | Maraging Steel (1.2709), H13 Tool Steel | Typically Aluminum or Soft Steel |

| Cavity Complexity | Conformal Cooling Channels Integrated | Straight Drilled Channels Only |

| Surface Finish (As-Built) | Ra 4.5–6.0 µm | Ra 12–25 µm |

| Post-Processed Finish | Ra 0.4–0.8 µm (Mirror Polish) | Ra 0.8–1.6 µm |

| Dimensional Tolerance | ±0.005 mm (Critical Features) | ±0.025 mm |

| Max Build Volume | 500 x 500 x 400 mm | 250 x 250 x 250 mm |

This precision is non-negotiable. Every mold undergoes stringent validation against your CAD nominal using Zeiss CONTURA CMMs and 3D scanning, with full traceability from raw powder to final assembly. Our ISO 9001:2015 and IATF 16949-certified workflows enforce material batch tracking, in-process thermal monitoring during printing, and pressure-tested cooling circuits—ensuring zero surprises during your production ramp. Unlike generic service bureaus, we control the entire value stream under one roof, eliminating communication gaps between design, printing, and finishing teams.

The true cost of mold failure extends far beyond tooling expenses—it halts production lines, delays product launches, and risks regulatory non-compliance. Wuxi Lead mitigates these risks through proactive engineering collaboration. Share your part geometry and material requirements early, and our applications engineers will optimize mold architecture for ejection efficiency, thermal uniformity, and cycle time reduction. We deliver not just a mold, but a validated production system backed by lifetime technical support.

Your next high-stakes injection molding project demands a partner who treats additive tooling with the same rigor as traditional methods. Contact us today to discuss how Lead Precision’s certified metal manufacturing platform can accelerate your timeline without compromising quality. Email [email protected] with your project specifications. Our engineering team will respond within 24 business hours with a detailed capability assessment and timeline. Let us transform your design intent into precision-engineered reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.