Technical Contents

Engineering Guide: Clear Plastic Molding

Engineering Insight: The Critical Role of Precision in Clear Plastic Molding

In high-end manufacturing, clear plastic molding is far more than a simple replication process—it is an exacting science where precision dictates optical clarity, structural integrity, and functional performance. At Wuxi Lead Precision Machinery, we approach clear plastic molding with the same rigor applied to aerospace and defense-grade metal components, ensuring every molded part meets the highest standards of dimensional accuracy and surface finish.

Transparency in plastic components amplifies the visibility of even the slightest imperfection. Flow lines, sink marks, or microscopic surface deviations become glaring defects under scrutiny. This makes precision not merely a manufacturing goal but a non-negotiable requirement. Achieving flawless clarity demands meticulous control over mold design, temperature regulation, injection speed, and material consistency. Any deviation in cavity alignment or thermal distribution can result in birefringence, warping, or hazing—rendering high-cost components unusable.

Our engineering team leverages decades of experience in custom metal manufacturing to design and produce molds with micron-level tolerances. This expertise, refined through projects for Olympic-standard equipment and military applications, ensures that our molds deliver repeatable, defect-free results. The synergy between advanced CNC machining, real-time process monitoring, and material science allows us to master the delicate balance required in molding optically clear polymers such as PMMA, PC, and COP.

Precision also extends to mold maintenance and longevity. A mold designed with high-grade tool steels, polished to optical-grade finishes, and equipped with precise venting and cooling channels, maintains performance over thousands of cycles. At Lead Precision, we integrate modular cooling systems and hardened surface treatments to minimize thermal distortion and prolong service life—critical factors in high-volume production of clear components.

Beyond tooling, our process validation includes rigorous in-cavity pressure and temperature sensing, coupled with automated optical inspection. This closed-loop quality control ensures that every part conforms to specification, batch after batch. Whether producing medical lenses, automotive light guides, or consumer electronics housings, our clients rely on our ability to merge optical perfection with industrial scalability.

The demand for clear plastic components in advanced industries continues to grow, driven by needs in imaging, sensing, and human-machine interfaces. At Wuxi Lead Precision Machinery, we stand at the intersection of optical excellence and precision engineering—delivering solutions where clarity is not just visual, but a measure of quality.

Typical Clear Plastic Molding Specifications at Wuxi Lead Precision Machinery

| Parameter | Specification Range |

|---|---|

| Mold Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | 0.01 – 0.05 µm (optical grade polish) |

| Material Compatibility | PMMA, PC, COP, COC, PS |

| Injection Pressure | Up to 200 MPa |

| Clamp Tonnage Range | 50 – 2000 tons |

| Cycle Time Optimization | ±0.5 sec repeatability |

| Optical Defect Rate | < 0.1% (measured by AOI) |

| Mold Lifespan | 1,000,000+ cycles (with maintenance) |

Precision Specs & Tolerances

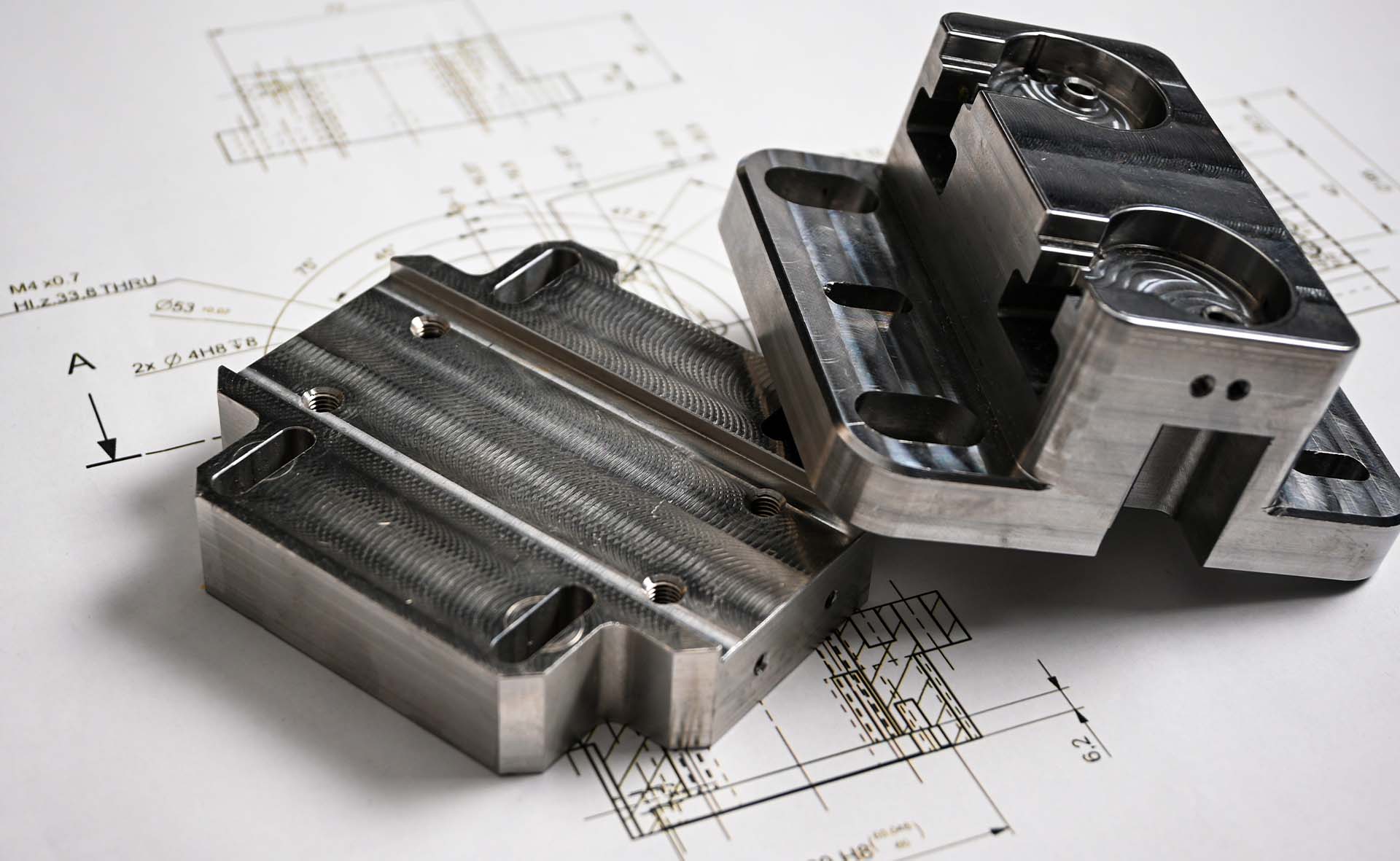

Precision Metal Components for Optical Clarity Applications

Wuxi Lead Precision Machinery delivers mission-critical metal components engineered specifically for high-fidelity clear plastic molding systems. Our expertise bridges advanced CNC manufacturing and the stringent demands of optical-grade polymer processing, where microscopic deviations directly impact light transmission, surface finish, and part integrity. We specialize in producing mold cores, cavities, inserts, and precision alignment hardware from premium tool steels (including H13, S136, and P20) and aluminum alloys, ensuring thermal stability and longevity under repeated molding cycles.

Our 5-axis CNC machining centers form the backbone of this capability, enabling the production of complex, undercut-free geometries essential for seamless optical surfaces. Simultaneous 5-axis motion eliminates manual repositioning errors, critical for maintaining micron-level consistency across multi-faceted mold features. This capability directly addresses the core challenge in clear plastic molding: eliminating knit lines, sink marks, and surface imperfections that scatter light. Materials are machined under strict thermal control to prevent residual stress, while proprietary toolpath strategies minimize micro-vibrations that could propagate into the final plastic part’s surface. All operations adhere to ISO 13090 standards for mold manufacturing, with real-time in-process monitoring of spindle load and tool wear.

Quality assurance is non-negotiable for optical applications. Every component undergoes comprehensive Coordinate Measuring Machine (CMM) inspection using Zeiss CONTURA systems, calibrated to NIST-traceable standards. Our inspection protocol validates not only dimensional accuracy but also geometric tolerances (flatness, roundness, profile) across the entire part envelope. Full first-article reports (FAIR) include 3D deviation maps, with data points correlated to the original CAD model. Critical surfaces receive additional optical profilometry scans to verify sub-micron roughness compliance. This rigorous QC ensures mold components consistently achieve the surface perfection required for zero-defect clear plastic molding—no speckles, haze, or distortion.

The following table details achievable tolerances for optical mold components, reflecting our standard production capability under controlled clean-room conditions:

| Feature Type | Standard Tolerance | Tight Tolerance | Surface Roughness (Ra) |

|---|---|---|---|

| Critical Mold Cavities | ±0.010 mm | ±0.005 mm | 0.05 µm |

| Core Pins & Ejectors | ±0.008 mm | ±0.003 mm | 0.08 µm |

| Alignment Features (Bushings/Pins) | ±0.005 mm | ±0.002 mm | 0.10 µm |

| General Mold Bases | ±0.020 mm | ±0.010 mm | 0.40 µm |

These specifications are validated through our integrated CMM workflow, with inspection data digitally archived for full traceability. By combining 5-axis precision, material science expertise, and uncompromising metrology, Wuxi Lead ensures your clear plastic molding operations achieve the optical clarity and dimensional stability demanded by medical, lighting, and consumer electronics applications. We transform design intent into flawless production reality—where every micron matters.

Material & Finish Options

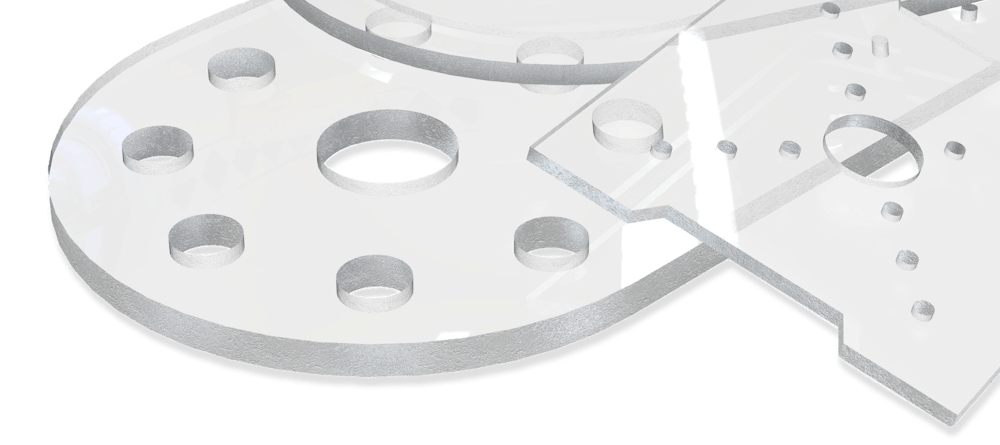

Material Selection for High-Precision Clear Plastic Molding Tools

In the production of high-clarity plastic components, the performance and longevity of molding tools are directly influenced by the choice of base material and surface treatment. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for precision molding applications, where material integrity and surface finish are critical to optical clarity, dimensional accuracy, and cycle efficiency. Aluminum, steel, and titanium each offer distinct advantages depending on production volume, part complexity, and environmental conditions.

Aluminum alloys, particularly 7075 and 6061, are widely used for prototyping and low-to-medium volume runs. Their excellent machinability allows for rapid tool fabrication, reducing time-to-market. Aluminum also exhibits good thermal conductivity, promoting uniform cooling and minimizing warpage in clear plastic parts. However, its lower hardness makes it less suitable for abrasive resins or extended production cycles.

Tool steels such as P20, H13, and S136 are preferred for high-volume molding. These materials provide superior hardness, wear resistance, and dimensional stability under repeated thermal cycling. Stainless variants like S136 further enhance corrosion resistance—essential when processing hygroscopic or chlorine-containing polymers such as polycarbonate or PVC. The increased durability of steel extends tool life significantly, making it cost-effective for large-scale manufacturing despite higher initial machining costs.

Titanium alloys, while less common, are selected for niche applications requiring extreme corrosion resistance and lightweight tooling. Their biocompatibility and inertness make them suitable for medical-grade optical components, though high material and machining costs limit widespread use.

Surface finish plays a decisive role in achieving optical clarity. For aluminum tools, hard anodizing is a critical process. This electrochemical treatment creates a dense, wear-resistant aluminum oxide layer that enhances surface hardness up to 60 HRC while maintaining dimensional stability. Hard anodizing also improves release properties, reducing the need for mold release agents that can contaminate transparent parts. The resulting surface can achieve a mirror finish (Ra < 0.05 µm), essential for lenses, light guides, and display covers.

For steel molds, polishing to optical grade (SPI A1 or finer) is standard, often followed by coatings such as PVD chrome or diamond-like carbon (DLC) for enhanced release and abrasion resistance. Titanium naturally forms a passive oxide layer, but additional passivation may be applied for maximum purity.

The following table summarizes key mechanical and thermal properties of common mold materials used in clear plastic molding:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Use Case |

|---|---|---|---|---|

| Aluminum 7075 | 15–20 | 130 | Low | Prototype, low-volume molds |

| P20 Steel | 28–32 | 30 | Moderate | Medium-volume production |

| H13 Steel | 48–52 | 35 | Moderate | High-temperature molding |

| S136 Steel | 50–54 | 25 | High | Corrosive resin processing |

| Titanium Ti-6Al-4V | 36 | 7 | Very High | Medical, aerospace applications |

Selecting the optimal material and finish requires balancing performance, cost, and application requirements. At Wuxi Lead Precision Machinery, we support clients in this decision with material testing, thermal analysis, and surface engineering expertise tailored to clear plastic molding challenges.

Manufacturing Process & QC

Clear Plastic Molding: Precision Engineering from Concept to Zero-Defect Production

Achieving optical clarity in plastic components demands an uncompromising, integrated manufacturing process. At Wuxi Lead Precision Machinery, we treat clear plastic molding as a high-stakes discipline where microscopic imperfections are unacceptable. Our end-to-end methodology, rigorously applied across Design, Prototyping, and Mass Production phases, ensures every part meets the exacting standards required for medical, optical, and premium consumer applications. This systematic approach is the foundation of our Zero Defects commitment.

The process begins with meticulous Design engineering. We collaborate closely with clients to select the optimal optical-grade resin—typically PMMA, PC, or COP—considering refractive index, thermal stability, and chemical resistance. Our engineers perform advanced mold flow analysis using Moldex3D, simulating filling, packing, and cooling to eliminate knit lines, sink marks, and internal stresses that compromise clarity. Critical parameters like gate location, venting strategy, and thermal management are optimized virtually before any steel is cut, ensuring the mold design inherently supports defect-free production.

Prototyping transitions theory into validated reality. We utilize high-precision CNC-machined aluminum or steel prototype molds, replicating final production conditions. Each prototype undergoes rigorous metrological inspection far beyond visual checks. We employ automated optical comparators for dimensional accuracy, haze meters per ASTM D1003 to quantify clarity, and birefringence analysis to detect internal stress. Any deviation triggers immediate design or process refinement. This phase isn’t merely validation; it’s the critical stress test where our Zero Defects protocol proves its efficacy through data-driven iteration.

Mass Production leverages the validated parameters within our climate-controlled facility. Process stability is non-negotiable. We implement closed-loop control systems monitoring melt temperature, injection speed, pack pressure, and cooling time to ±0.5°C and ±0.1MPa tolerances. In-mold pressure sensors provide real-time feedback, while 100% automated vision inspection systems scan for micro-scratches, inclusions, or surface distortions invisible to the human eye. Every shift commences with First Article Inspection against the prototype baseline, and statistical process control (SPC) tracks critical dimensions continuously. Material handling follows strict protocols—desiccant drying, nitrogen purging—to eliminate moisture-induced splay.

Our production capability for clear plastic molding is defined by measurable precision. Key specifications consistently achieved include:

| Parameter | Specification | Measurement Standard |

|---|---|---|

| Dimensional Tolerance | ±0.025 mm (±0.001″) | ISO 2768-m |

| Surface Roughness (Ra) | 0.012 µm (SPI-A1) | ISO 4287 |

| Haze | < 0.5% | ASTM D1003 |

| Mold Steel | Mirror-Polished NAK80 / S136H | VDI 3400 Grade A1 |

| Cycle Time Stability | ±0.3 seconds (3 Sigma) | In-Process SPC Monitoring |

This integrated workflow—where Design foresight, Prototyping validation, and Mass Production control converge—eliminates defects at their source. Wuxi Lead Precision Machinery delivers not just components, but guaranteed optical perfection, backed by our Zero Defects mandate and deep expertise in high-integrity clear plastic molding.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Clear Plastic Molding and Custom Metal Manufacturing

When precision, clarity, and performance define your product requirements, partnering with Wuxi Lead Precision Machinery ensures you achieve manufacturing excellence. As a leading provider of custom metal manufacturing solutions in China, we specialize in high-accuracy components and integrated systems tailored for advanced clear plastic molding applications. Our engineering-driven approach combines state-of-the-art CNC machining, tooling design, and quality assurance to deliver parts and molds that meet the most stringent optical and mechanical standards.

Clear plastic molding demands exceptional surface finish, dimensional stability, and thermal control—requirements that begin with precision metal tooling. At Lead Precision, we design and manufacture custom molds, inserts, and support components using premium-grade tool steels and advanced finishing techniques. Our in-house capabilities include 5-axis CNC milling, wire EDM, grinding, and mirror polishing to SPI A1 standards, ensuring optimal clarity and repeatability in every molded part. Whether you’re producing medical devices, optical lenses, consumer electronics, or automotive lighting, our team collaborates closely with your engineers to optimize mold design for flow dynamics, cooling efficiency, and cycle time reduction.

We understand that consistency across production volumes is critical. Our quality control systems incorporate CMM inspection, optical comparators, and environmental testing to verify tolerances as tight as ±0.002 mm. Every component is traceable, documented, and validated to meet ISO 9001 standards. With over 15 years of experience serving global OEMs and Tier-1 suppliers, we bring reliability, scalability, and technical depth to every project.

Our manufacturing specifications reflect our commitment to precision and performance:

| Specification | Detail |

|---|---|

| Maximum Machining Size | 1200 × 800 × 650 mm |

| Tolerance Capability | ±0.002 mm |

| Surface Finish | Up to SPI A1 (Mirror Polish) |

| Materials Supported | NAK80, S136, 2738, 718H, Stainless Steel, Aluminum |

| CNC Equipment | 5-Axis, High-Speed Machining Centers |

| Quality Standards | ISO 9001:2015, Full First Article Inspection |

| Lead Time (Typical) | 15–25 days for mold components, based on complexity |

From concept to production, Lead Precision acts as an extension of your engineering team. We offer DFM analysis, rapid prototyping, and scalable manufacturing solutions that reduce time-to-market without compromising quality. Our facility in Wuxi is equipped for low to mid-volume production runs, with the agility to support iterative design improvements.

For partners seeking precision, transparency, and technical excellence in clear plastic molding tooling and custom metal components, the next step is clear. Contact us today at [email protected] to initiate a technical consultation and discover how we can elevate your manufacturing performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.