Technical Contents

Engineering Guide: Thin Brass Sheet

Engineering Insight: Precision Mastery in Thin Brass Sheet Fabrication

Thin brass sheet manufacturing represents one of the most demanding frontiers in precision metalworking. At thicknesses below 0.5mm, brass transitions from a robust structural material into a delicate engineering medium where microscopic deviations directly impact final product performance. The inherent malleability and springback characteristics of brass alloys like C26000 and C23000 amplify the challenges of maintaining dimensional stability during cutting, forming, and finishing. Precision is not merely desirable; it is the absolute prerequisite for functionality in critical applications. In aerospace shielding, medical micro-components, or high-frequency electrical contacts, a tolerance error of mere microns can trigger catastrophic failure through signal interference, mechanical binding, or compromised corrosion resistance. The cost of imprecision extends far beyond scrap material – it manifests in assembly line stoppages, field failures, and reputational damage for end-product manufacturers. Achieving true precision demands more than advanced machinery; it requires deep material science understanding, meticulous process control, and unwavering attention to thermal management and toolpath optimization to counteract brass’s unique deformation behaviors.

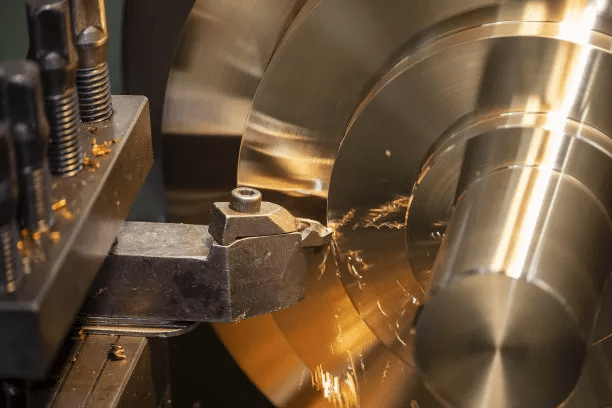

Wuxi Lead Precision Machinery operates at this exact threshold of capability. Our CNC Swiss lathes, multi-axis milling centers, and laser cutting systems are calibrated specifically for sub-0.1mm brass sheet work, utilizing proprietary fixturing and coolant strategies to eliminate vibration and thermal drift. We recognize that surface integrity is as critical as geometric accuracy for applications requiring solderability or optical reflectivity. Our process validation protocols exceed standard industry practices, implementing in-line optical metrology and statistical process control at every stage to ensure consistency batch after batch. This commitment to microscopic accuracy is proven in mission-critical deployments.

Our precision capabilities are rigorously validated through high-stakes projects. We supplied dimensionally perfect decorative and functional brass components for the Beijing 2008 Olympic Stadium infrastructure, where thermal expansion tolerances and aesthetic perfection were non-negotiable under intense public scrutiny. Furthermore, we are a trusted supplier for specialized military communication systems, producing EMI/RFI shielding components from ultra-thin brass where micron-level flatness and edge consistency are essential for signal integrity in battlefield environments. These engagements demanded and proved our ability to deliver where failure is not an option.

The following table outlines the precision benchmarks achievable for thin brass sheet at Lead Precision under controlled production conditions:

| Specification Parameter | Typical Capability (Thin Brass Sheet < 0.5mm) | Critical Application Relevance |

|---|---|---|

| Thickness Tolerance | ±0.005 mm | Ensures consistent electrical conductivity and mechanical spring properties |

| Surface Roughness (Ra) | 0.2 – 0.4 µm | Critical for solderability, coating adhesion, and optical performance |

| Flatness Deviation | ≤ 0.05 mm per 100 mm | Prevents assembly issues and ensures uniform contact in electrical interfaces |

| Feature Position Tolerance | ±0.01 mm | Guarantees precise alignment in multi-part assemblies and micro-mechanisms |

| Burr Height | ≤ 0.003 mm | Eliminates contamination risks in medical devices and sensitive electronics |

Mastering thin brass sheet fabrication requires treating precision as the core product, not just a specification. At Lead Precision, decades of refining processes for the most exacting sectors – from global sporting events to national defense – have forged our capability to transform challenging brass alloys into components where every micron matters. We partner with engineers to solve the hidden complexities of thin-gauge brass, ensuring your design intent translates flawlessly into functional reality.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery specializes in high-precision manufacturing of thin brass sheet components for demanding industrial applications. Our advanced production capabilities are engineered to meet the exacting standards required in aerospace, medical devices, electronics, and precision instrumentation. Central to our technical advantage is the integration of 5-axis CNC machining technology, which allows for complex geometries, tight tolerances, and superior surface finishes on materials as delicate as 0.1 mm thick brass sheet.

The inherent malleability and thermal conductivity of brass present unique challenges in machining, especially when working with thin cross-sections. Conventional methods often lead to deformation, chatter, or dimensional instability. At Wuxi Lead, our 5-axis CNC systems eliminate these issues through multi-directional cutting approaches that minimize tool pressure and optimize material removal. This enables us to produce intricate features—such as micro-gears, sensor housings, shielding enclosures, and lead frames—with exceptional accuracy and repeatability. Simultaneous 5-axis motion ensures that even the most complex 3D contours are machined in a single setup, reducing cumulative error and improving overall part consistency.

Complementing our machining excellence is a rigorous quality control protocol anchored by Coordinate Measuring Machine (CMM) inspection. Every critical dimension on thin brass components is verified using Zeiss CMM systems, providing micron-level measurement accuracy. Our inspection process includes first-article inspection reports (FAIR), production sampling plans, and full-surface scanning for geometric conformity. This data-driven approach ensures compliance with ISO 13084, ASME Y14.5, and customer-specific GD&T requirements.

We maintain strict environmental and process controls to prevent material warpage during and after machining. Temperature-stabilized workshops, low-stress fixturing, and post-machining stress-relief cycles are standard for all thin brass sheet production runs. Surface finishes down to Ra 0.4 µm are routinely achieved, with optional plating, passivation, or coating services available through our certified partner network.

Our technical team works closely with design engineers to optimize manufacturability, offering Design for Manufacture and Assembly (DFM) feedback early in the development cycle. This collaborative approach reduces lead times, minimizes waste, and ensures that every component performs reliably in its end application.

The following table outlines our standard technical specifications for thin brass sheet machining:

| Parameter | Capability |

|---|---|

| Material Thickness Range | 0.1 mm – 3.0 mm |

| Minimum Feature Size | 0.2 mm (internal radii, slots) |

| Positional Tolerance | ±0.005 mm |

| Geometric Tolerance (GD&T) | ±0.01 mm (typical), down to ±0.003 mm |

| Surface Roughness (Ra) | As low as 0.4 µm (machined) |

| Dimensional Repeatability | ±0.002 mm (Cp/Cpk ≥ 1.67) |

| Inspection Accuracy (CMM) | ±0.001 mm |

| Lead Time (Prototype) | 7–12 working days |

| Lead Time (Production Batch) | 15–25 working days |

Wuxi Lead Precision Machinery delivers unmatched precision in thin brass sheet fabrication, combining cutting-edge 5-axis CNC technology with metrology-grade quality assurance.

Material & Finish Options

Material Selection for Thin Brass Sheet Fabrication

Selecting the optimal material for thin brass sheet applications requires balancing mechanical properties, manufacturability, and end-use performance. Brass (primarily C26000 cartridge brass) remains the premier choice for precision thin-gauge components due to its exceptional combination of machinability, corrosion resistance, and electrical conductivity. Its inherent lubricity reduces tool wear during CNC milling and laser cutting, while its moderate strength (tensile strength 300–385 MPa) supports intricate geometries without excessive springback. Critical for thin sheets below 0.5 mm, brass exhibits superior formability compared to harder alloys, minimizing cracking during bending or deep drawing. However, work-hardening necessitates intermediate annealing for complex multi-stage operations—a process our CNC engineers optimize using controlled atmosphere furnaces to prevent oxidation.

For applications demanding higher strength or magnetic properties, alternative materials warrant evaluation. Aluminum offers weight savings but lacks brass’s wear resistance and requires specialized toolpaths to avoid built-up edge. Steel provides structural rigidity yet poses challenges in thin-section corrosion management. Titanium excels in extreme environments but incurs significantly higher machining costs and secondary finishing requirements. The following comparative analysis highlights key considerations:

| Material | Typical Thickness Range (mm) | Tensile Strength (MPa) | Machinability Rating | Key Limitation for Thin Sheets |

|---|---|---|---|---|

| C26000 Brass | 0.05–1.5 | 300–385 | 100 (Reference) | Work-hardening during forming |

| 6061-T6 Aluminum | 0.1–2.0 | 310 | 65 | Edge burring; low wear resistance |

| 304 Stainless Steel | 0.05–1.0 | 515 | 45 | Springback; galling in threads |

| Grade 2 Titanium | 0.1–1.5 | 345 | 20 | High tool wear; oxidation risk |

Surface finishing further defines functional performance. While anodizing is incompatible with brass due to its copper-zinc composition, alternative processes deliver critical enhancements. Electropolishing provides deburring and micro-smoothing for medical or fluid-handling components, improving surface integrity by up to 50%. For decorative or corrosion-critical applications, selective plating with nickel (5–25 µm) or tin (3–15 µm) offers tailored protection while maintaining solderability. Our finishing protocols strictly adhere to ASTM B456 standards, ensuring coating adhesion and porosity control even on 0.1 mm features.

Wuxi Lead Precision Machinery recommends specifying annealed tempers (e.g., C26000-H01) for deep-drawn thin brass parts to mitigate fracture risks. For high-volume production, we implement real-time strain monitoring during stamping to dynamically adjust feed rates. Always consult material test reports for oxygen-free brass variants when vacuum or high-purity environments are required—our quality team validates every batch against ASTM B36 specifications. Partner with our engineering team early to align material selection with your dimensional tolerances and lifecycle demands, avoiding costly rework in thin-sheet fabrication.

Manufacturing Process & QC

Design Phase: Precision Engineering for Thin Brass Sheet Applications

The foundation of flawless thin brass sheet manufacturing begins with meticulous design engineering. At Wuxi Lead Precision Machinery, we initiate every project with a collaborative design review, aligning client specifications with material behavior, geometric complexity, and functional requirements. Thin brass sheets—typically ranging from 0.05 mm to 0.5 mm in thickness—demand exceptional attention to thermal expansion, springback, and tooling clearance due to their inherent malleability and acoustic conductivity. Our engineering team employs advanced CAD/CAM software to simulate forming processes, ensuring stress distribution and dimensional stability are optimized before any physical work begins. Finite element analysis (FEA) is used to predict deformation risks, particularly in fine features such as embossing, perforations, or micro-bending. This digital prototyping phase minimizes downstream errors and establishes a zero-defect baseline.

Prototyping: Validating Performance and Tolerances

Once the design is finalized, we proceed to low-volume prototyping using high-precision stamping, laser cutting, or photochemical etching—selected based on feature resolution and production volume. For thin brass sheets, laser cutting with nitrogen-assisted shielding ensures clean, oxide-free edges, while progressive die stamping is applied for complex multi-feature components. Each prototype undergoes rigorous metrological inspection using coordinate measuring machines (CMM) and optical profilometers to verify conformity to tolerances as tight as ±0.01 mm. Surface integrity, edge burr levels, and flatness are evaluated against industry benchmarks. Any deviations are traced to root causes—material batch variation, tool wear, or clamping force imbalance—and corrected in real time. This closed-loop validation ensures that the transition to mass production is risk-free and fully qualified.

Mass Production: Sustaining Zero Defects at Scale

With prototype approval, we deploy fully automated production lines equipped with in-process monitoring systems. Stamping presses with servo-driven feeders maintain consistent strip alignment, while vision-based inspection systems perform 100% real-time defect detection for cracks, misalignment, or dimensional drift. Statistical process control (SPC) tracks key parameters such as tonnage, stroke speed, and temperature to maintain process capability indices (Cp/Cpk > 1.67). All brass material is sourced from ISO-certified suppliers and subjected to incoming inspection for hardness (typically 90–110 HV) and grain structure uniformity. Finished components are packaged in anti-tarnish materials and delivered with full traceability documentation, including material certificates and first-article inspection reports.

Typical Thin Brass Sheet Production Specifications

| Parameter | Specification Range |

|---|---|

| Material Thickness | 0.05 mm – 0.5 mm |

| Tolerance (Cutting/Forming) | ±0.01 mm – ±0.03 mm |

| Surface Roughness (Ra) | 0.2 µm – 1.6 µm |

| Hardness (Brass H02) | 90 – 110 HV |

| Minimum Feature Size | 0.1 mm (laser/photo etch) |

| Production Volume Capacity | 10,000 – 500,000 pcs/month |

| Lead Time (Mass Production) | 15 – 25 days after approval |

Through disciplined integration of design intelligence, empirical prototyping, and closed-loop manufacturing, Wuxi Lead Precision Machinery delivers zero-defect thin brass sheet components tailored to aerospace, electronics, and medical instrumentation sectors.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Thin Brass Sheet Manufacturing

Thin brass sheet fabrication presents distinct engineering hurdles. Material springback, micro-burring, dimensional instability during machining, and maintaining surface integrity demand exceptional process control. Standard manufacturing approaches often fail to deliver the consistent precision required for high-performance applications in aerospace actuators, medical micro-components, or精密 optical assemblies. At Wuxi Lead Precision Machinery, we specialize exclusively in overcoming these challenges for demanding thin-gauge brass projects. We transform complex design specifications into flawless, high-yield components where tolerances are measured in microns, not thousandths of an inch.

Our dedicated thin brass production cell utilizes advanced Swiss-type CNC Swiss lathes, precision stamping presses with sub-micron feedback, and proprietary fixturing systems designed specifically for materials under 0.5mm thickness. This specialized infrastructure, combined with our deep metallurgical understanding of brass alloys (C26000, C36000, C46400), ensures minimal deformation and superior edge quality. We implement real-time in-process gauging and environmental controls to eliminate thermal drift, guaranteeing that every component meets your exacting blueprint requirements. The following table details our core capabilities for thin brass sheet processing:

| Parameter | Lead Precision Capability | Typical Industry Standard |

|---|---|---|

| Minimum Thickness | 0.05 mm (0.002″) | 0.10 mm (0.004″) |

| Thickness Tolerance | ±0.003 mm (±0.00012″) | ±0.01 mm (±0.0004″) |

| Flatness | ≤ 0.025 mm over 100mm | ≤ 0.10 mm over 100mm |

| Feature Tolerance | ±0.005 mm (±0.0002″) | ±0.025 mm (±0.001″) |

| Burr Height | < 0.002 mm (Ra < 0.4 µm) | < 0.01 mm (Ra < 1.6 µm) |

| Max. Part Size | 300 x 200 mm | 200 x 150 mm |

Beyond machine capability, our value lies in proactive engineering partnership. Our technical team collaborates during your design phase to optimize manufacturability, suggesting subtle geometry adjustments that prevent thin-wall collapse or vibration without compromising function. We provide comprehensive material certification, full first-article inspection reports per AS9102, and rigorous batch traceability. Our ISO 9001:2015 certified quality management system includes 100% visual inspection under 10x magnification for critical surfaces and statistical process control on all key dimensions. This integrated approach consistently achieves yields exceeding 98.5% for complex thin brass components, directly reducing your total cost of ownership.

Choosing Wuxi Lead Precision means selecting a partner invested in your product’s ultimate performance and reliability. We understand that a fraction of a micron deviation can render a thin brass component unusable in its final assembly. Our commitment is to deliver not just parts, but guaranteed functionality and seamless integration into your high-value systems. Do not compromise on the critical thin brass elements of your next project. Contact our engineering team today to discuss your specific requirements and receive a detailed capability assessment.

Initiate your precision thin brass project with confidence. Email [email protected] to connect directly with our application engineers. Provide your design files or specifications for a rapid technical review and actionable quotation. Let Lead Precision become your definitive solution for thin brass manufacturing excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.