Technical Contents

Engineering Guide: Online Cnc Machining Services

Engineering Insight: Precision as Non-Negotiable in Online CNC Machining Services

In the demanding landscape of global manufacturing, precision is not merely a specification; it is the foundational requirement for functional integrity, regulatory compliance, and ultimate product success. When sourcing online CNC machining services, the tolerance capabilities and repeatability of a provider directly dictate the viability of critical components across aerospace, medical, defense, and high-performance industrial applications. Sub-micron deviations can cascade into catastrophic system failures or costly field recalls. True precision engineering demands more than advanced machinery; it requires ingrained process discipline, rigorous metrology, and deep material science expertise applied consistently across every production run. At Wuxi Lead Precision Machinery, we enforce this standard relentlessly. Our engineering protocols are forged in environments where failure is unacceptable, having delivered mission-critical components for Olympic Games infrastructure and stringent military specifications. These projects demanded zero-failure performance under extreme conditions, proving our ability to translate complex designs into flawless physical realities time after time.

The distinction between standard machining and true precision manufacturing lies in the holistic control of the entire production ecosystem. It encompasses thermal stability management in the machine shop, real-time in-process gauging, advanced toolpath optimization to minimize deflection, and material-specific compensation strategies. Our facility operates under AS9100 and ISO 13485 frameworks, ensuring traceability from raw material certification through final inspection. This level of control is non-negotiable for components operating in high-stress, high-value contexts. We understand that your design intent must be realized exactly as specified, without compromise. Our engineers proactively engage during the quoting phase to identify potential manufacturability challenges, ensuring the chosen process guarantees the required geometric accuracy and surface integrity from the first part to the last.

Wuxi Lead Precision Machinery delivers this assurance through dedicated capability:

| Critical Precision Parameter | Our Standard Capability | Industry Typical Capability | Key Enabling Technology |

|---|---|---|---|

| Positional Tolerance | ±0.001 mm | ±0.01 mm to ±0.025 mm | 5-Axis Machines with Laser Calibration |

| Surface Roughness (Ra) | 0.1 µm achievable | 0.8 µm to 1.6 µm | Precision Grinding & Polishing Centers |

| Repeatability (CpK) | ≥1.67 | ≥1.33 | Statistical Process Control (SPC) Integration |

| Material Range | Titanium, Inconel, PEEK, Hardened Steels | Common Aluminum/Steel Alloys | Multi-Tasking Mill-Turn Centers |

| First Article Inspection | Full CMM Report + GD&T | Basic Dimensional Check | Zeiss CONTURA CMMs with Calypso Software |

This capability is proven in action. Components we manufactured for specialized timing systems in the Beijing Winter Olympics required thermal stability within 2µm across -40°C to +70°C ranges. Similarly, military-grade communication housings demanded hermetic sealing surfaces held to 0.0005″ flatness over 300mm diameters – tolerances far exceeding standard industry practice. When you select an online CNC machining partner, verify their demonstrable experience in zero-failure environments. Demand evidence of their metrology infrastructure and process control rigor. At Wuxi Lead, precision is our engineering language, not just a marketing term. Partner with us to transform your most exacting designs into reality, where every micron matters and reliability is engineered in. This is the strategic advantage precision manufacturing delivers.

Precision Specs & Tolerances

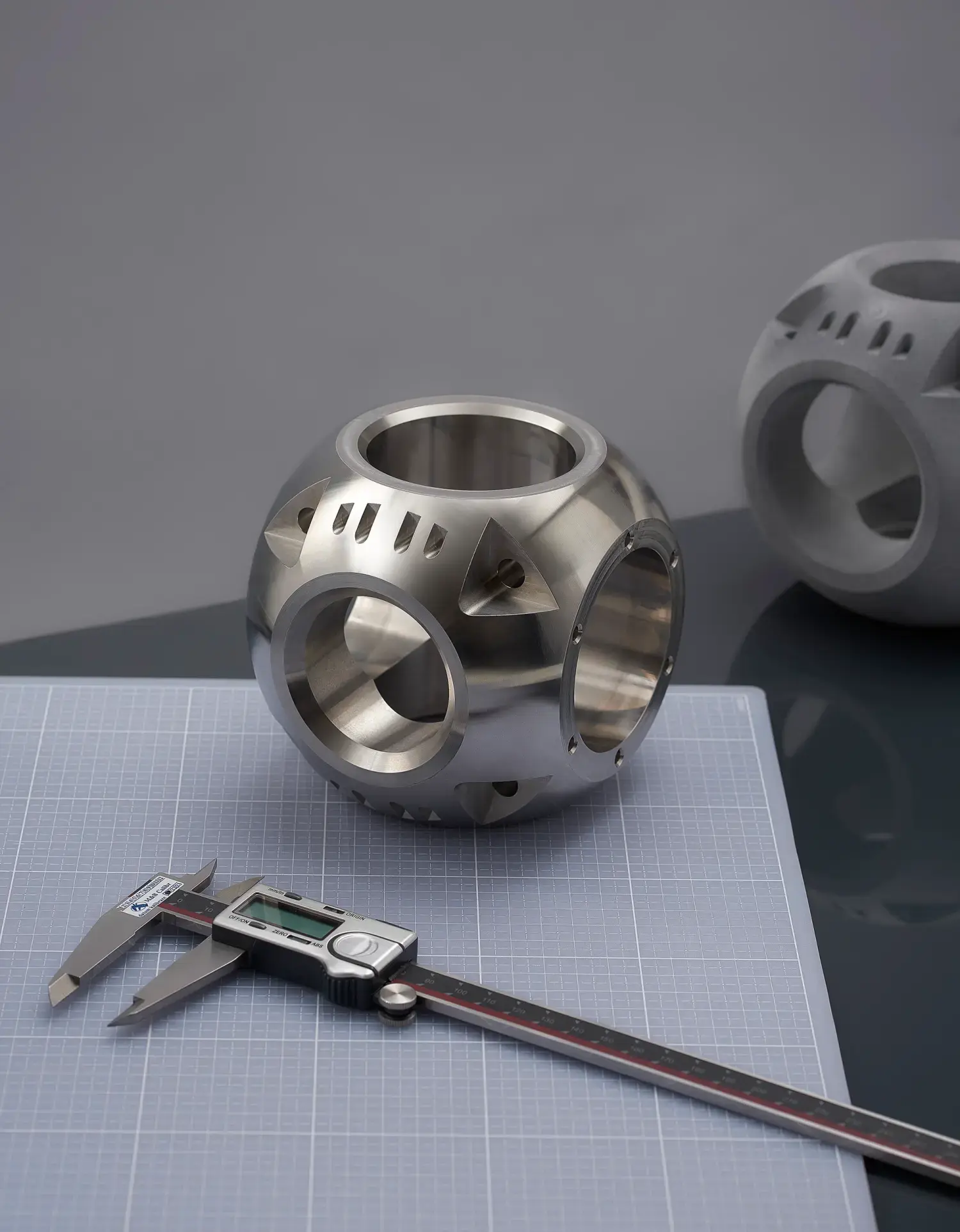

Wuxi Lead Precision Machinery delivers advanced 5-axis CNC machining solutions engineered for high-precision manufacturing across aerospace, medical, automotive, and industrial automation sectors. Our technical capabilities are anchored in state-of-the-art multi-axis machining centers that enable complex geometry production with superior accuracy and surface finish. Unlike conventional 3-axis systems, our 5-axis CNC machines allow simultaneous movement across five planes, significantly reducing setup time and enhancing part consistency. This capability supports the production of intricate components such as turbine blades, impellers, housings, and custom fixtures—parts that demand tight tolerances and high repeatability.

Our facility is equipped with a comprehensive suite of HAAS, DMG MORI, and MAKINO 5-axis machining centers, each integrated with high-precision spindles and automated tool changers. These systems operate under strict environmental controls to minimize thermal drift and ensure micron-level consistency. We support a wide range of engineering materials, including aluminum alloys (6061, 7075), stainless steels (303, 304, 316), titanium (Grade 2, Grade 5), brass, PEEK, and engineering plastics. Material selection is matched to application requirements, including corrosion resistance, structural integrity, and thermal performance.

Quality assurance is embedded throughout our production process. Every critical dimension is verified using state-certified Coordinate Measuring Machines (CMM) from Zeiss and Mitutoyo, ensuring full compliance with ISO 10360 standards. Our inspection protocols include first-article inspection (FAI), in-process checks, and final dimensional reporting. All measurements are traceable, and full inspection reports are provided with every production batch. Additionally, our quality management system is ISO 9001:2015 certified, reflecting our commitment to continuous improvement and process control.

The table below outlines the standard and precision tolerance capabilities achievable across our machining operations. These tolerances are maintained through rigorous machine calibration, skilled programming using Mastercam and Siemens NX, and real-time process monitoring. For mission-critical applications, tighter tolerances can be achieved upon engineering review and process validation.

| Feature | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.05 mm | ±0.01 mm | Up to 500 mm |

| Hole Diameter | ±0.03 mm | ±0.01 mm | Reamed/precision bored |

| Positional Tolerance | ±0.05 mm | ±0.02 mm | Per GD&T standards |

| Surface Roughness (Ra) | 3.2 μm | 0.8 μm | Machined finish |

| Angular Tolerance | ±0.1° | ±0.05° | 5-axis simultaneous control |

| Flatness | 0.05 mm | 0.02 mm | Per 100 mm length |

Our engineering team collaborates closely with clients during the Design for Manufacturability (DFM) phase to optimize part geometry, reduce lead times, and ensure compliance with functional requirements. With integrated CAD/CAM workflows and digital process validation, Wuxi Lead ensures that every component meets the highest standards of precision and reliability.

Material & Finish Options

Strategic Material Selection for Precision CNC Machining

Material selection fundamentally impacts part performance, manufacturability, and total project cost in high-precision CNC machining. Choosing incorrectly risks component failure, extended lead times, or unnecessary expenditure. At Wuxi Lead Precision Machinery, we guide clients through this critical decision based on application demands, environmental exposure, and functional requirements. Understanding the core properties of aluminum, steel, and titanium is essential for optimal outcomes.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate aerospace, automotive, and consumer electronics due to their exceptional strength-to-weight ratio and superior machinability. Aluminum 6061 offers excellent weldability and corrosion resistance for structural components, while 7075 provides near-steel strength for highly stressed parts like aircraft fittings. Its low density significantly reduces weight, though it lacks the hardness of steel for high-wear applications. Steel remains indispensable for strength and durability. Alloy steels like 4140 deliver high tensile strength and toughness for shafts, gears, and tooling, responding well to heat treatment. Stainless steels such as 304 and 316 offer critical corrosion resistance for medical, marine, and food processing equipment, though their work-hardening nature increases machining complexity and cost compared to aluminum. Titanium, primarily Grade 5 (Ti-6Al-4V), is the premium choice for extreme environments demanding unparalleled strength-to-weight ratio, biocompatibility, and resistance to corrosion and high temperatures. It is vital in aerospace critical components and medical implants, but its low thermal conductivity, chemical reactivity, and high cost necessitate specialized tooling and slower machining parameters, impacting lead time and price.

Key mechanical properties guide initial material screening. Refer to the comparative specifications below.

| Material | Key Grades | Tensile Strength (MPa) | Machinability Rating | Common Applications |

|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310, 572 | Excellent (100%) | Enclosures, brackets, drone parts |

| Steel | 4140, 304, 316 | 655, 585, 620 | Moderate (65-75%) | Shafts, valves, medical tools |

| Titanium | Ti-6Al-4V (Gr5) | 900 | Poor (30-40%) | Aircraft fittings, implants |

Surface finish selection, particularly anodizing, is intrinsically linked to material choice. Anodizing is exclusively applicable to aluminum, creating a durable, corrosion-resistant oxide layer that accepts dyes for identification. Type II (sulfuric acid) anodizing is standard for general protection and aesthetics, while Type III (hardcoat) provides significantly enhanced wear resistance for functional surfaces. Crucially, anodizing adds dimensional thickness; precise tolerances require machining undersized to accommodate the coating growth. Steel and titanium require alternative finishes like passivation, plating, or painting for corrosion control, as anodizing is not feasible.

Selecting the right material and finish requires balancing performance needs with manufacturability and budget. Wuxi Lead Precision Machinery leverages deep metallurgical expertise and advanced CNC capabilities to optimize this selection process, ensuring your components meet exacting specifications while maximizing value. Consult our engineering team early in the design phase to avoid costly revisions and achieve the highest precision outcome.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our production process for online CNC machining services is engineered for precision, consistency, and zero-defect delivery. We integrate advanced technology with rigorous quality assurance to ensure every component meets the highest standards of accuracy and reliability. Our workflow is structured into three core phases: Design Evaluation, Prototyping, and Mass Production—each phase designed to minimize risk and maximize performance.

The process begins with Design Evaluation, where our engineering team conducts a comprehensive Design for Manufacturability (DFM) analysis. This step ensures that client CAD models are optimized for CNC machining, identifying potential issues such as wall thickness, tool access, or material constraints before any material is cut. Our specialists provide actionable feedback to refine designs for improved functionality, cost-efficiency, and manufacturability—ensuring seamless transition to the next stage.

Prototyping follows immediately after design validation. Using high-precision 3-axis, 4-axis, and 5-axis CNC machining centers, we produce functional prototypes that mirror the final product in both form and function. These prototypes undergo full dimensional inspection using coordinate measuring machines (CMM) and surface finish analysis to verify compliance with technical drawings and GD&T specifications. This phase allows for design validation, fit testing, and performance evaluation, significantly reducing the risk of errors in full-scale production.

Once the prototype is approved, we initiate Mass Production under a controlled, ISO-compliant manufacturing environment. Each operation is monitored in real time using in-process gauging and automated tool wear compensation systems. Our CNC machines run with minimal human intervention, ensuring repeatability across batches of any size. Every component is subject to 100% visual inspection and random sampling for metrological verification, ensuring dimensional accuracy and surface integrity are maintained throughout the production run.

To support our zero-defect philosophy, we employ a closed-loop quality management system. Non-conformance reports are immediately escalated, root cause analysis is conducted, and corrective actions are implemented in real time. This proactive approach ensures continuous improvement and complete traceability for every order.

The following table outlines the key capabilities of our CNC machining process:

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.4 µm |

| Maximum Work Envelope | 1200 x 800 x 600 mm (5-axis) |

| Tolerance Range | IT6 to IT8 per ISO 286-1 |

| Materials Supported | Aluminum, Steel, Stainless Steel, Titanium, Brass, Plastics |

| Lead Time (Prototype) | 5–7 days |

| Lead Time (Mass Production) | 10–20 days (scalable by volume) |

By integrating precision engineering, advanced metrology, and a relentless focus on quality, Wuxi Lead Precision Machinery delivers CNC-machined components that meet the most demanding industrial requirements—on time, every time.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising CNC Excellence

When your project demands micron-level precision, zero-defect reliability, and seamless scalability, Wuxi Lead Precision Machinery stands as your strategic manufacturing partner. With over 15 years of specialized expertise in high-end CNC machining, we serve global aerospace, medical, and energy sector leaders who refuse to compromise on quality. Our ISO 9001:2015 and IATF 16949 certified facility in Wuxi, China, operates under stringent international quality protocols, ensuring every component meets or exceeds AS9100 and ISO 13485 standards. We transform complex engineering challenges into flawless deliverables through advanced technology and engineering rigor.

Our technical capabilities are engineered for the most demanding applications. The table below outlines our core production specifications:

| Capability | Specification Detail |

|---|---|

| Machine Types | 5-Axis Milling, Swiss-Type Turning, Multi-Tasking Centers |

| Tolerance Range | ±0.005 mm (±0.0002″) for critical features |

| Material Expertise | Titanium, Inconel, Hastelloy, 17-4 PH Stainless, PEEK, Aluminum Alloys |

| Max Work Envelope | 1200 x 800 x 650 mm (47″ x 31.5″ x 25.6″) |

| Lead Time (Prototype) | As low as 3 business days with expedited processing |

| Quality Assurance | CMM, OGP SmartScope, Surface Roughness Testing, First Article Inspection |

Beyond machinery, our value lies in collaborative engineering partnership. We integrate early in your design phase through DFM analysis to eliminate manufacturability risks, optimize cost structures, and accelerate time-to-market. Our dedicated project managers provide real-time production transparency via secure client portals, with full traceability from raw material certification to final inspection documentation. This proactive approach consistently delivers 99.8% on-time delivery and sub-0.1% defect rates for clients managing mission-critical supply chains.

Choosing Wuxi Lead Precision Machinery means aligning with a partner invested in your long-term success. We understand that precision machining is not merely a transaction—it is the foundation of product performance, regulatory compliance, and market trust. Our team commits to becoming an extension of your engineering department, offering continuous improvement insights and scalable capacity to support volume surges without quality trade-offs.

Initiate your next high-stakes project with confidence. Contact our engineering team directly at [email protected] to discuss technical requirements, request a confidential NDA, or schedule a virtual facility tour. Include your project timeline, material specifications, and quality standards for a tailored capability assessment within 24 business hours. For urgent RFQs, reference code LEAD-CTA2024 to prioritize technical review. Your pursuit of manufacturing excellence begins with a single email—let us prove why global innovators trust Lead Precision as their precision machining authority.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.