Technical Contents

Engineering Guide: Fabrication Parts

Engineering Insight: Precision as the Non-Negotiable Foundation of Fabrication Parts

In high-stakes sheet metal fabrication, precision transcends mere specification; it is the absolute determinant of functional integrity, system longevity, and operational safety. Microscopic deviations in critical dimensions, edge quality, or geometric alignment cascade into catastrophic failures within complex assemblies—vibration-induced fatigue in aerospace structures, compromised seals in fluid systems, or misaligned interfaces in automated production lines. The cost of imprecision extends far beyond scrap material; it manifests as delayed project timelines, costly field repairs, and reputational damage that erodes client trust. At Wuxi Lead Precision Machinery, we treat dimensional accuracy not as a target, but as a rigorously controlled engineering output, embedded within every process from initial laser cutting to final finishing.

Our commitment to uncompromising precision is forged through direct experience with projects where failure is inconceivable. We engineered and delivered critical structural components for the Beijing National Stadium (Bird’s Nest), where complex curved panels demanded micron-level accuracy to ensure structural stability and seamless aesthetic integration under immense thermal and load cycles. Similarly, our work supplying fabrication parts for advanced military vehicle systems necessitates adherence to stringent MIL-STD tolerances, where components must withstand extreme shock, vibration, and environmental exposure without degradation. These projects instilled a culture where statistical process control, advanced metrology (including CMM and laser scanning), and material science expertise are non-negotiable elements of daily operations. We understand that a ±0.1mm tolerance on a consumer appliance bracket carries different risk than the ±0.02mm required for a satellite mounting plate; our value lies in applying the appropriate rigor for your critical application.

This disciplined approach translates into tangible client advantages: minimized assembly rework, extended product service life, and guaranteed compatibility within your larger systems. We proactively identify potential precision challenges during the Design for Manufacturability (DFM) phase, collaborating to optimize geometry and material selection before a single sheet is cut. The table below outlines core precision capabilities underpinning our fabrication parts:

| Feature | Specification | Application Impact |

|---|---|---|

| Geometric Tolerance | ±0.02mm to ±0.1mm | Ensures seamless assembly in high-vibration environments; critical for motion systems |

| Edge Quality (Laser) | Burr height < 0.05mm | Eliminates secondary deburring; essential for fluid-tight seals and safety-critical edges |

| Flatness Tolerance | 0.1mm per 300mm | Guarantees consistent weld fit-up and surface mounting integrity |

| Material Thickness Range | 0.5mm to 6.0mm (Stainless, Aluminum, Steel) | Supports diverse structural and enclosure requirements with consistent precision |

| Finishing Consistency | Ra 0.8μm to Ra 3.2μm | Meets stringent aesthetic and functional surface requirements for medical/aerospace |

Precision in fabrication parts is not an incremental cost—it is foundational engineering insurance. Wuxi Lead Precision Machinery delivers this assurance through proven methodologies, advanced technology, and a deep understanding of what true dimensional control means for mission-critical applications. Partner with us to transform your fabrication requirements from potential risk points into reliable system assets.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions engineered for precision, repeatability, and performance in high-demand industrial applications. Our technical capabilities are anchored in state-of-the-art equipment, rigorous quality assurance protocols, and a deep understanding of complex manufacturing requirements. As a trusted partner for global OEMs and engineering firms, we specialize in transforming raw sheet metal into mission-critical components with exacting specifications.

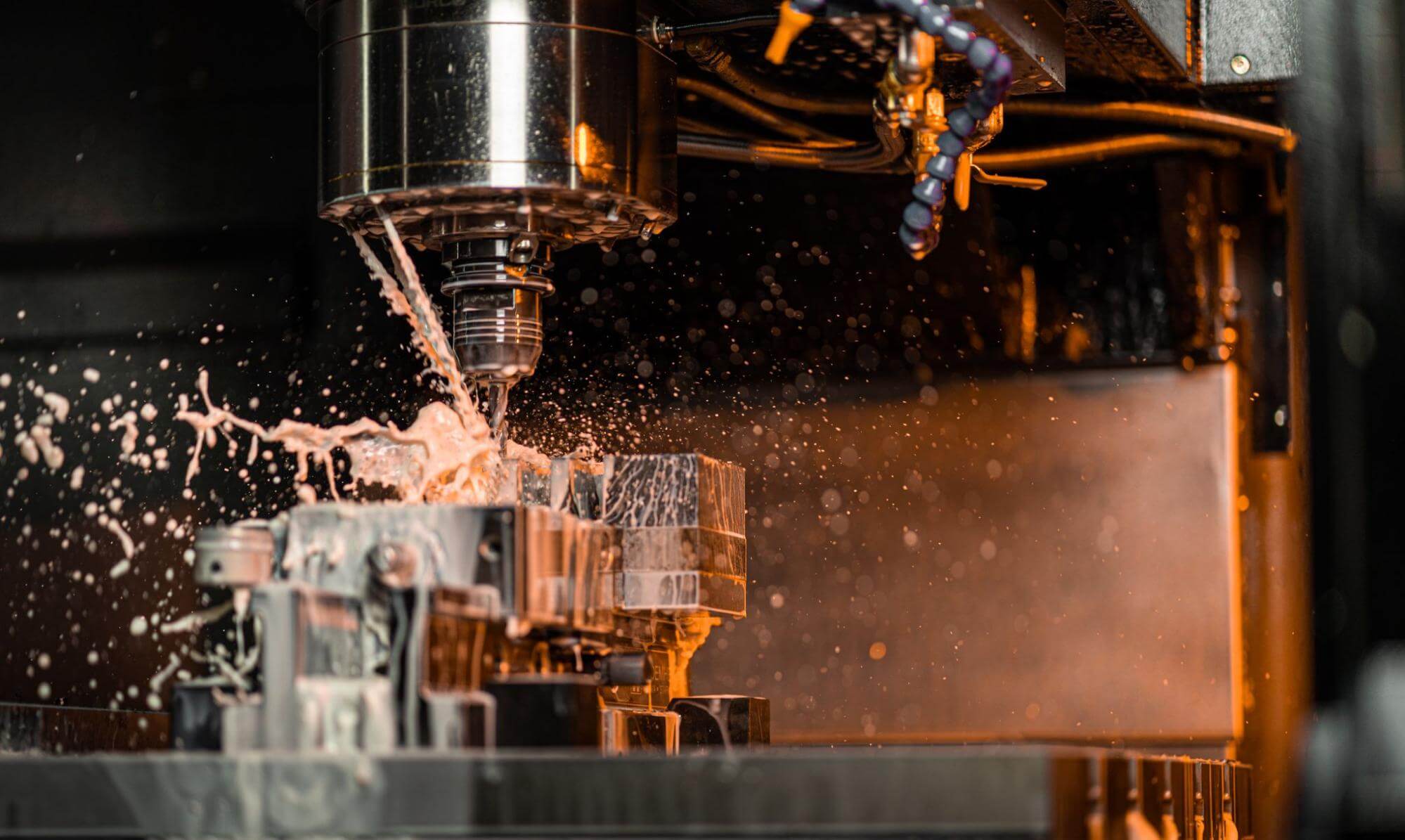

At the core of our fabrication process is our 5-axis CNC machining technology. This advanced system enables multi-directional cutting, milling, and shaping with a single setup, significantly reducing cycle times while enhancing geometric accuracy. The integration of 5-axis CNC allows us to produce highly intricate parts with complex contours, undercuts, and tight internal features that are unattainable with conventional 3-axis systems. Our machines are calibrated for optimal performance across a wide range of materials, including stainless steel, aluminum, carbon steel, and specialty alloys, ensuring dimensional stability and surface integrity in every production run.

Complementing our machining capabilities is a comprehensive suite of sheet metal forming and processing equipment. We utilize high-tonnage press brakes with CNC-controlled backgauges to achieve precise bending angles and consistent fold lines. Our laser cutting systems offer micron-level kerf accuracy, enabling clean, burr-free edges with minimal heat-affected zones. All fabrication workflows are supported by integrated CAD/CAM software, allowing seamless transition from digital design to physical prototype or production part.

Quality control is embedded at every stage of manufacturing. Each component undergoes full inspection using a Coordinate Measuring Machine (CMM), ensuring compliance with geometric dimensioning and tolerancing (GD&T) requirements. Our CMM system provides traceable, high-resolution 3D measurement data, validating critical features such as hole placement, flatness, parallelism, and angularity. All inspection reports are archived for full production traceability and customer audit readiness.

The following table outlines our standard fabrication tolerances, reflecting the precision achievable across common operations:

| Operation | Dimensional Tolerance | Angular Tolerance | Feature Position Tolerance | Surface Flatness (per 100mm) |

|---|---|---|---|---|

| 5-Axis CNC Machining | ±0.005 mm | ±0.1° | ±0.01 mm | 0.02 mm |

| Laser Cutting | ±0.05 mm | ±0.2° | ±0.1 mm | 0.05 mm |

| CNC Press Brake Bending | ±0.1 mm | ±0.5° | ±0.2 mm | 0.1 mm |

| Drilling/Tapping | ±0.02 mm | — | ±0.05 mm | — |

These tolerances are maintained under controlled environmental conditions and verified through routine machine calibration and operator certification. Wuxi Lead Precision Machinery adheres to ISO 9001 standards, ensuring that every fabricated part meets the highest benchmarks for quality, consistency, and performance.

Material & Finish Options

Material Selection for Precision Sheet Metal Fabrication

Selecting the optimal material is foundational to achieving performance, cost efficiency, and longevity in sheet metal fabrication. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your application’s mechanical, environmental, and regulatory demands. Below, we detail critical considerations for aluminum, steel, and titanium—materials we routinely process with micron-level CNC precision.

Aluminum dominates aerospace, electronics, and transportation sectors due to its exceptional strength-to-weight ratio and corrosion resistance. Grade 6061-T6 offers weldability and moderate strength for structural frames, while 5052-H32 excels in marine environments. Aluminum’s low density reduces shipping costs and energy consumption in final assemblies. However, its lower hardness necessitates careful toolpath planning during CNC bending to avoid micro-cracking.

Steel remains indispensable for structural integrity and load-bearing applications. Carbon steel (A36/1018) delivers high tensile strength at economical costs for enclosures and brackets. Stainless steel grades 304 and 316 provide superior corrosion and chemical resistance—critical for medical, food processing, and semiconductor equipment. Note that 316’s molybdenum content enhances pitting resistance in chloride-rich settings but increases machining complexity due to work hardening.

Titanium (Grade 2/5) is the premium choice for extreme conditions: aerospace components, biomedical implants, and offshore energy systems. Its unparalleled strength-to-weight ratio, biocompatibility, and resistance to 500°C+ temperatures justify higher material costs. Titanium’s low thermal conductivity demands specialized CNC tooling and slower feed rates to prevent heat buildup and material galling.

Anodizing: Precision Surface Enhancement

Anodizing transforms aluminum surfaces into durable, corrosion-resistant barriers while enabling color coding for assembly. Type II (sulfuric acid) anodizing provides standard wear resistance (5–25μm thickness) for consumer electronics. For mission-critical parts, Type III (hardcoat) anodizing achieves 25–125μm thickness with Rockwell hardness up to 60 HRc—ideal for hydraulic manifolds or military hardware. Our in-house anodizing line ensures batch consistency and adherence to MIL-A-8625 standards, eliminating supply chain delays.

Material specifications guide fabrication feasibility and cost. Key parameters for common grades include:

| Material | Key Grades | Typical Thickness Range | Key Applications | Special Processing Notes |

|---|---|---|---|---|

| Aluminum | 6061-T6, 5052 | 0.5–12.7 mm | Enclosures, heat sinks | Requires sharp tooling; avoid excessive bending radii |

| Steel | A36, 304, 316 | 0.8–25.4 mm | Structural frames, medical chassis | Stainless grades need high-pressure coolant to prevent work hardening |

| Titanium | Gr 2, Gr 5 | 0.8–6.0 mm | Aerospace brackets, implants | Low thermal conductivity demands reduced RPM and rigid fixturing |

Material choice directly impacts CNC programming, tool wear, and secondary operations. At Wuxi Lead, our engineering team collaborates with clients during DFM to validate material suitability against functional requirements and lifecycle costs. We avoid over-specification—recommending titanium only where its properties justify investment, or standardizing on 6061-T6 for cost-sensitive volume production. Request our material compatibility matrix to align your design with optimal fabrication parameters and surface finishes.

Manufacturing Process & QC

Sheet Metal Fabrication Process: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our sheet metal fabrication process is engineered for precision, repeatability, and zero-defect output. We follow a disciplined workflow that begins with design validation and ends with scalable, high-quality mass production. Every stage is monitored and optimized to ensure compliance with international quality standards and client-specific requirements.

The process begins with design analysis and DFM (Design for Manufacturability). Our engineering team reviews CAD models and technical drawings to identify potential fabrication challenges early. We assess material selection, bend allowances, tolerance stack-ups, and feature geometry to ensure optimal manufacturability. This phase minimizes costly revisions and accelerates time-to-market. Clients receive detailed feedback and recommendations to refine designs before any physical work begins.

Next is prototyping, a critical validation step. Using precision laser cutting, CNC punching, and automated bending, we produce functional prototypes that mirror final production quality. These prototypes undergo rigorous dimensional inspection using CMM (Coordinate Measuring Machine) and form/fit/function testing. This stage confirms design integrity, assembly compatibility, and performance under real-world conditions. Feedback from prototype testing is incorporated into final process adjustments, ensuring a seamless transition to full-scale production.

Once approved, we initiate mass production on our integrated manufacturing lines. Our facility utilizes advanced CNC-controlled equipment, robotic bending cells, and automated welding systems to maintain consistency across thousands of parts. In-process inspections are conducted at key control points, including material intake, cutting, forming, welding, surface finishing, and final assembly. Statistical Process Control (SPC) is employed to monitor variation and maintain tight tolerances.

Our zero-defect philosophy is enforced through a multi-layered quality assurance system. Each batch is traceable via our ERP system, with full documentation of material certifications, process parameters, and inspection reports. Non-conforming parts are immediately quarantined and analyzed using root cause analysis methods. Preventive actions are implemented in real time to eliminate recurrence.

We support a wide range of materials and specifications to meet diverse industrial demands. Key production capabilities are summarized below:

| Parameter | Specification |

|---|---|

| Material Types | Cold Rolled Steel (SPCC), Stainless Steel (SUS304, SUS316), Aluminum (AL5052, AL6061), Galvanized Steel |

| Thickness Range | 0.5 mm – 4.0 mm |

| Tolerance (Cutting) | ±0.1 mm |

| Tolerance (Bending) | ±0.2°, ±0.1 mm |

| Max Part Size | 1500 mm × 3000 mm |

| Production Capacity | Up to 50,000 units/month |

| Surface Finishes | Powder Coating, Anodizing, Passivation, Zinc Plating, Brushing |

At every stage—from initial design to final shipment—Wuxi Lead ensures that fabrication parts meet the highest standards of precision, durability, and consistency. Our integrated approach eliminates variability, reduces waste, and delivers zero-defect components tailored to your application.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Sheet Metal Excellence

In the demanding landscape of precision sheet metal fabrication, selecting a partner transcends cost considerations. It demands a commitment to engineering integrity, process transparency, and unwavering adherence to specifications that define mission-critical components. Wuxi Lead Precision Machinery operates at this elevated standard, serving global leaders in aerospace, medical technology, and advanced industrial equipment where failure is not an option. Our facility in Wuxi integrates 25 years of specialized expertise with Tier 1 supply chain protocols, ensuring every bracket, enclosure, and structural element meets or exceeds the most stringent international quality benchmarks. We do not merely manufacture parts; we engineer reliability into every bend, weld, and surface finish.

Our technical capabilities are engineered for complexity. Utilizing state-of-the-art Amada CNC punching and laser systems alongside precision press brakes with real-time feedback control, we achieve geometric tolerances down to ±0.05mm and surface finishes conforming to ISO 1302. This precision is systematically verified through our in-house metrology lab, featuring Zeiss CMMs and optical comparators calibrated to NIST standards. The table below summarizes core technical parameters governing our sheet metal production:

| Specification Category | Capability Range | Industry Standard Compliance |

|---|---|---|

| Material Thickness | 0.5mm – 6.0mm (Stainless Steel, Aluminum, Cold Rolled Steel) | ASTM A653, EN 10130, JIS G3141 |

| Tolerance Control | ±0.05mm (Linear), ±0.1° (Bend Angles) | ISO 2768-mK, GD&T ASME Y14.5 |

| Max Part Dimensions | 3000mm x 1500mm (Laser), 2500mm x 1250mm (Punch) | Customizable per project |

| Secondary Operations | MIG/TIG Welding, Powder Coating, Anodizing, Precision Hardware Insertion | ISO 15614-1, AAMA 2605 |

| Lead Time (Prototype) | 7-10 Business Days (Ex-Works) | JIT/Lean Manufacturing Supported |

Beyond machinery, our value lies in proactive engineering collaboration. From DFM analysis to first-article inspection reporting, we integrate seamlessly into your product development lifecycle. Our quality management system holds ISO 9001:2015 and IATF 16949 certifications, with full traceability from raw material certs to final shipment documentation. This structured approach eliminates costly revisions and supply chain disruptions, directly protecting your time-to-market and brand reputation.

Initiate a technical dialogue with our engineering team to experience the Lead Precision difference. Forward your fabrication drawings and requirements to [email protected]. Within 24 business hours, you will receive a comprehensive feasibility assessment, including optimized material recommendations, process validation plan, and transparent pricing aligned with your volume and quality targets. We require no NDAs for initial technical review—demonstrating confidence in our ability to deliver immediate value.

For global OEMs and contract manufacturers, partnering with Lead Precision means securing a fabrication resource that operates as an extension of your engineering department. Contact us today to transform your sheet metal challenges into competitive advantage. Your next breakthrough component begins with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.