Technical Contents

Engineering Guide: Add Steel

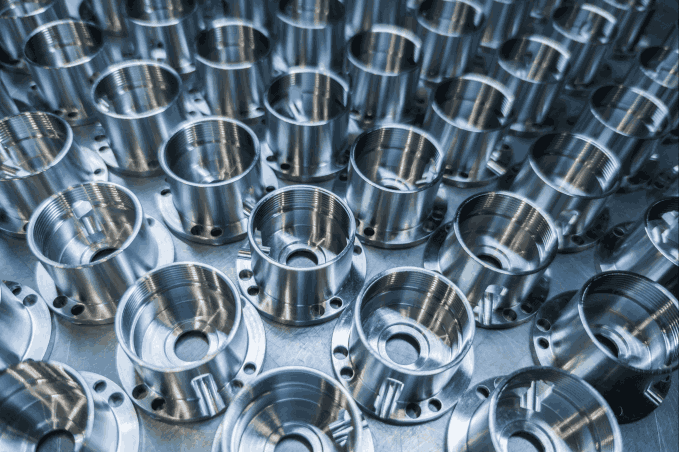

Engineering Insight: The Strategic Addition of Steel in Precision Manufacturing

In high-performance industrial applications, the decision to add steel to a component is not merely a matter of material selection—it is an engineering imperative driven by structural integrity, thermal stability, and long-term reliability. At Wuxi Lead Precision Machinery, we approach the integration of steel with the rigor of aerospace-grade manufacturing, where tolerances are measured in microns and failure is not an option. Our experience supplying mission-critical components for Olympic-standard equipment and military-grade systems underscores our mastery in determining when, where, and how to add steel for optimal performance.

Precision in steel integration begins with design intent. Whether reinforcing a load-bearing joint, enhancing wear resistance, or improving thermal dissipation, the placement and volume of added steel must align with dynamic stress models and operational environments. Poorly executed additions can lead to stress concentrations, warping during heat treatment, or imbalanced weight distribution—flaws that compromise even the most sophisticated assemblies. Our engineering team utilizes advanced finite element analysis (FEA) and 5-axis simulation software to model material behavior before a single chip is cut, ensuring that every steel addition serves a defined mechanical purpose.

Material compatibility is another critical factor. Not all steels respond the same way to welding, machining, or thermal cycling. At Lead Precision, we specialize in pairing base materials—such as aluminum alloys, titanium, or composite structures—with high-strength steels like 4140, 4340, or 17-4 PH stainless, using controlled deposition techniques that minimize residual stress. Our in-house metallurgical lab validates weld integrity and microstructure, guaranteeing that the bond between dissimilar materials meets ASTM and MIL-STD specifications.

Our track record in delivering components for Olympic bobsled chassis and precision-guided defense systems reflects our ability to merge extreme durability with micron-level accuracy. In these applications, adding steel is not an afterthought—it is a calculated enhancement that defines performance. For instance, in one military contract, we integrated hardened steel inserts into aluminum weapon housings, increasing service life by over 300% without compromising weight targets.

Beyond material science, our CNC machining centers—calibrated to ±0.002 mm repeatability—ensure that every steel-reinforced feature is machined to exacting geometric specifications. We combine multi-axis milling, deep-hole drilling, and automated inspection to maintain consistency across production runs, whether fabricating a single prototype or scaling to batch production.

Below are representative specifications from our steel integration projects, illustrating the precision and material control we deliver.

| Specification | Value | Standard |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm | ISO 2768-mK |

| Surface Finish | Ra 0.4 µm (typical) | ISO 1302 |

| Weld Penetration Control | 95–105% of target | ASME IX |

| Material Traceability | Full heat lot documentation | EN 10204 3.1 |

| In-Process Inspection Frequency | 100% critical features | ISO 9001 |

At Wuxi Lead Precision Machinery, adding steel is not a fabrication step—it is an engineered solution. Through decades of refining our processes for the most demanding sectors, we ensure that every gram of steel added contributes directly to performance, safety, and longevity.

Precision Specs & Tolerances

Technical Capabilities: Precision Steel Machining Excellence

Wuxi Lead Precision Machinery delivers uncompromising precision for complex steel components through advanced five-axis CNC machining centers. Our Haas UMC-750 and DMG MORI CTX beta 1250 systems feature simultaneous five-axis interpolation, enabling the complete machining of intricate geometries in a single setup. This capability eliminates cumulative errors from multiple fixtures, significantly reducing lead times while achieving superior dimensional accuracy and surface integrity on challenging steel alloys including 4140, 17-4PH, and tool steels. High-torque spindles and rigid constructions ensure stable material removal rates even in demanding interrupted cuts, maintaining tight tolerances across production volumes. Our programming expertise leverages Mastercam and Siemens NX to optimize toolpaths for minimal vibration and thermal distortion, critical for achieving micron-level consistency in hardened and pre-hardened steel workpieces.

Quality assurance is systematically integrated throughout the manufacturing process, anchored by Zeiss CONTURA and Hexagon GLOBAL S-151510 coordinate measuring machines (CMMs). These metrology-grade systems perform comprehensive first-article inspections and in-process verification against ASME Y14.5 and ISO 1101 standards. Automated inspection routines capture full 3D point clouds, enabling detailed analysis of form, position, and profile tolerances directly traceable to NIST standards. Statistical Process Control (SPC) data from CMM reports drives real-time process adjustments and continuous improvement initiatives. Every critical steel component receives full inspection documentation, including dimensional reports and surface roughness verification, ensuring complete traceability and compliance with stringent aerospace (AS9100) and medical (ISO 13485) requirements.

Tolerance specifications are maintained through environmental controls, rigorous machine calibration schedules, and operator expertise. The following table details achievable capabilities for machined steel components under controlled production conditions:

| Feature Type | Standard Capability | Tight Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | CMM / High-Precision Micrometer |

| Geometric Tolerances | ±0.015 mm | ±0.008 mm | CMM / Optical Comparator |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Portable Profilometer |

| Hole Position | ±0.008 mm | ±0.003 mm | CMM / Ball Bar |

Our integrated approach—combining high-performance five-axis machining with metrology-grade inspection—ensures steel components meet the most demanding functional requirements. From complex hydraulic manifolds to aerospace structural brackets, Wuxi Lead provides the technical rigor necessary for mission-critical steel applications where precision directly impacts performance and safety. This capability set supports seamless transition from prototype validation through high-volume production, delivering consistent quality for global industrial supply chains.

Material & Finish Options

Material Selection in High-Precision CNC Manufacturing

Selecting the appropriate material is a foundational decision in custom metal manufacturing, directly influencing performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision CNC machining of three primary metals: aluminum, steel, and titanium. Each material offers distinct mechanical and thermal properties, making them suitable for different industrial applications.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is ideal for aerospace, automotive, and electronics applications where lightweight components are critical. The most commonly used alloy is 6061-T6, which provides good weldability and moderate strength. For more demanding environments, 7075-T6 offers superior strength, though with reduced corrosion resistance. Aluminum’s natural oxide layer provides inherent protection, but for enhanced surface durability and aesthetics, anodizing is recommended.

Steel remains the backbone of heavy-duty industrial applications due to its high tensile strength, wear resistance, and structural reliability. We work with a range of steel grades, including 4140, 4340, and stainless steels such as 304 and 316. These materials are essential in oil and gas, construction, and machinery components where load-bearing capacity and longevity are paramount. Stainless steels additionally offer excellent resistance to corrosion and high temperatures, making them suitable for medical and marine environments.

Titanium, particularly Grade 5 (Ti-6Al-4V), is the material of choice for extreme performance applications. Its exceptional strength-to-density ratio, biocompatibility, and resistance to high temperatures and corrosion make it indispensable in aerospace, defense, and medical implant manufacturing. While more challenging to machine due to its low thermal conductivity and tendency to gall, our advanced CNC systems are optimized to handle titanium with precision and consistency.

Surface Finishing: The Role of Anodizing

Anodizing is a critical electrochemical process primarily applied to aluminum to enhance surface properties. It increases corrosion and wear resistance, allows for color coding through dye integration, and improves adhesion for paint primers. Type II (sulfuric acid) anodizing is standard for decorative and protective finishes, while Type III (hardcoat anodizing) delivers a thicker, harder surface layer suitable for high-wear applications. Anodizing does not compromise dimensional accuracy when properly controlled—a key advantage in precision manufacturing.

Below is a comparative overview of key material specifications:

| Material | Typical Alloy | Tensile Strength (MPa) | Density (g/cm³) | Common Applications | Key Advantages |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | Aerospace, Electronics | Lightweight, corrosion resistant |

| Steel | 4140 | 655 | 7.85 | Machinery, Automotive | High strength, wear resistant |

| Stainless Steel | 316 | 570 | 8.0 | Medical, Marine | Corrosion resistant, hygienic |

| Titanium | Ti-6Al-4V | 900 | 4.43 | Aerospace, Medical Implants | High strength-to-weight, biocompatible |

At Wuxi Lead Precision Machinery, we ensure material integrity through rigorous sourcing and in-process quality control. Our engineering team collaborates with clients to match material and finish to functional requirements, ensuring optimal performance in the final application.

Manufacturing Process & QC

Precision Steel Manufacturing: From Design to Zero-Defect Production

At Wuxi Lead Precision Machinery, our engineered steel production process delivers uncompromising quality for mission-critical components. We integrate advanced CNC capabilities with rigorous quality management systems to ensure every part meets exacting aerospace, medical, and industrial specifications from initial concept through volume delivery. Our methodology eliminates defects at source, not through final inspection.

The process begins with collaborative engineering. Our technical team partners with clients during the Design for Manufacturability (DFM) phase, analyzing 3D CAD models for optimal material utilization, toolpath efficiency, and geometric dimensioning and tolerancing (GD&T) compliance. We identify potential stress points, machining constraints, and secondary operation requirements early, preventing costly revisions. Finite element analysis (FEA) validates structural integrity under operational loads, ensuring the design translates flawlessly to physical reality. This phase establishes the foundation for zero-defect execution.

Prototyping transitions validated designs into tangible verification. Utilizing high-precision 5-axis CNC milling and turning centers, we produce functional prototypes in the actual production alloy. Each prototype undergoes comprehensive metrology: Coordinate Measuring Machine (CMM) scans verify dimensional accuracy against CAD nominal values, surface profilometry confirms finish requirements, and material testing validates mechanical properties. Client feedback on fit, form, and function triggers rapid design iterations if needed. This stage is not merely a sample run; it is a critical validation checkpoint where process parameters are fine-tuned and documented for mass production.

Mass production leverages the perfected workflow under our Zero Defects Management System. Every steel component is manufactured using documented, validated CNC programs with real-time tool wear monitoring and in-process gauging. Statistical Process Control (SPC) charts track critical dimensions continuously, enabling immediate corrective action before non-conformances occur. Automated optical inspection (AOI) systems supplement manual checks by certified technicians at defined control points. Full material traceability—from certified mill heat numbers through every machining step—is maintained via our digital manufacturing execution system (MES). This closed-loop approach ensures consistent output where defects are statistically impossible, not merely rare.

Our commitment to perfection is reflected in the stringent specifications we consistently achieve across common steel alloys:

| Parameter | Typical Capability | Aerospace/Medical Capability |

|---|---|---|

| Material Grades | 304/316 Stainless, 4140, 1045 | 17-4PH, 15-5PH, Custom Alloys |

| Dimensional Tolerance | ±0.025 mm (±0.001″) | ±0.005 mm (±0.0002″) |

| Surface Finish (Ra) | 1.6 µm (63 µin) | 0.4 µm (16 µin) |

| Geometric Tolerance | ±0.05 mm (±0.002″) | ±0.01 mm (±0.0004″) |

| Process Capability (Cpk) | ≥1.33 | ≥1.67 |

This integrated Design-Prototype-Production sequence, governed by data-driven quality protocols and executed on state-of-the-art equipment, guarantees that Wuxi Lead delivers steel components meeting the highest global standards. Zero defects is our operational reality, not an aspiration. Trust our process to transform your steel component requirements into flawless, reliable products.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

In the world of precision engineering and high-performance manufacturing, the difference between success and compromise lies in the quality of your manufacturing partner. At Wuxi Lead Precision Machinery, we don’t just meet industry standards—we redefine them. As a leading custom metal manufacturing provider based in Wuxi, China, we specialize in delivering complex, high-tolerance components for global industries including aerospace, automotive, energy, and advanced automation. Our commitment to precision, reliability, and innovation makes us the preferred partner for forward-thinking enterprises demanding excellence at every stage of production.

When you choose to partner with Lead Precision, you gain access to a fully integrated manufacturing ecosystem. From initial design consultation and prototyping to full-scale production and quality assurance, our team of seasoned engineers and CNC specialists ensures your project is optimized for performance, cost-efficiency, and scalability. Our state-of-the-art facility is equipped with advanced 3-, 4-, and 5-axis CNC machining centers, precision turning machines, and automated inspection systems, enabling us to handle the most demanding geometries and tightest tolerances with unmatched consistency.

We understand that every client’s needs are unique. That’s why our approach is inherently collaborative. Whether you require low-volume, high-mix production or high-volume standardized runs, we tailor our processes to align with your technical specifications and delivery timelines. Our ISO 9001-certified quality management system ensures compliance with international standards, while our rigorous in-process inspections and final audits guarantee that every component meets or exceeds your expectations.

Below are key technical capabilities that define our manufacturing excellence:

| Specification | Capability |

|---|---|

| CNC Machining | 3-axis, 4-axis, 5-axis milling and turning |

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm (X×Y×Z) |

| Tolerance Range | ±0.005 mm to ±0.02 mm, depending on material and geometry |

| Materials Processed | Aluminum alloys, stainless steel, carbon steel, titanium, brass, copper, and specialty alloys |

| Surface Finishes | As-machined, anodizing, powder coating, passivation, polishing |

| Quality Control | CMM, optical comparators, surface roughness testers, 100% inspection available |

| Production Capacity | High-mix, low-volume to high-volume batch production |

| Lead Times | Typically 15–25 days, expedited options available |

Our global client base trusts us not only for our technical capabilities but also for our transparency, responsiveness, and long-term partnership model. We believe in building relationships that grow with your business—backed by engineering insight, on-time delivery, and a relentless focus on value.

Take the next step toward manufacturing excellence. Contact us today at [email protected] to discuss your project requirements, request a quote, or schedule a technical consultation. Let Wuxi Lead Precision Machinery be the precision behind your innovation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.