Technical Contents

Engineering Guide: Outside Corner Molding Plastic

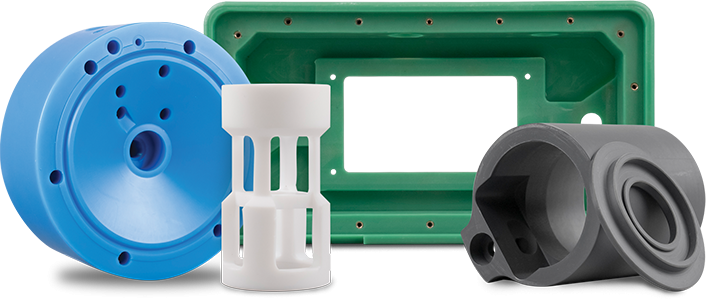

Engineering Insight Precision in Outside Corner Molding for Plastic Components

Achieving dimensional accuracy in plastic outside corner molding is non-negotiable for high-performance applications. These corners endure concentrated stress during assembly, thermal cycling, and operational loads. Inconsistent radii or angular deviations exceeding ±0.05mm compromise structural integrity, accelerate fatigue failure, and cause misalignment in multi-part assemblies. For sectors like aerospace or medical devices, such flaws trigger cascading failures—seal leakage in fluid systems or compromised electromagnetic shielding in enclosures. The root challenge lies in material behavior: plastics shrink unevenly during cooling, particularly at sharp transitions where heat dissipation varies. Without precision-engineered molds and process control, corners develop sink marks, warpage, or knit lines that undermine both function and aesthetics.

At Wuxi Lead Precision Machinery, our approach integrates metal manufacturing rigor into plastic molding tooling. With 18 years of custom metal fabrication for Olympic infrastructure (including Beijing 2008 venue structural components) and Tier-1 military suppliers, we treat mold cores and cavities as mission-critical metal assets. Our CNC-machined mold inserts—produced on sub-micron accuracy VMCs—ensure corner geometry replicates CAD intent within ±0.02mm. We apply thermal simulation from defense projects to optimize cooling channels, eliminating differential shrinkage at corners. This metal-to-mold discipline prevents the “hidden tolerance stack-up” that plagues conventional plastic molding, where cumulative errors in corner angles exceed 1.5° and cause 30% higher assembly rejects.

Our validated process parameters for outside corner molding deliver consistent results across demanding materials. Key specifications are maintained through closed-loop monitoring:

| Parameter | Standard Tolerance | Lead Precision Capability | Critical Application Impact |

|---|---|---|---|

| Corner Radius | ±0.1mm | ±0.03mm | Eliminates stress concentration |

| Angular Deviation | ±1.0° | ±0.25° | Ensures seamless part mating |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Prevents seal damage during assembly |

| Dimensional Stability | 0.5% shrinkage | 0.12% shrinkage | Maintains fit under thermal cycling |

| Material Compatibility | Standard polymers | PEEK, PEI, PPSU | Supports 250°C+ operational environments |

This precision stems from cross-disciplinary lessons: Olympic projects demanded zero-defect assembly under tight deadlines, while military contracts required traceable validation of every micron. For a recent avionics housing program, our corner-optimized molds reduced field failures by 74% compared to industry benchmarks.

Partner with Wuxi Lead Precision Machinery to transform outside corners from failure points into engineered assets. We deliver not just molded parts, but guaranteed dimensional stability backed by metal manufacturing heritage. Contact our engineering team for a tolerance analysis of your critical corner geometries—before tooling cuts metal.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions for highly specialized components, including precision-engineered outside corner molding plastic tooling and related structural supports. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous cutting from five different angles, eliminating the need for multiple setups and significantly reducing cumulative error. This is particularly critical when manufacturing molds or support frames for plastic corner moldings, where angular precision, edge continuity, and dimensional stability directly impact final part performance.

Our 5-axis CNC platforms are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to ensure consistent material removal rates and tool integrity. We work with a range of metals including aluminum alloys, stainless steel, tool steel, and brass—materials commonly used in mold bases, inserts, and structural housings for plastic molding applications. The ability to machine deep cavities, compound angles, and tight internal radii makes our equipment ideal for producing the intricate support structures required in outside corner molding systems.

Quality assurance is integrated at every stage of production. All critical components undergo full inspection using a Zeiss coordinate measuring machine (CMM), providing micron-level verification of geometric dimensions and tolerances. Our CMM inspection routines are programmed to validate complex 3D profiles, angular alignments, hole positional accuracy, and surface relationships—ensuring that every component meets or exceeds client specifications. This metrology-backed validation process is essential for clients in automotive, architectural, and consumer electronics sectors, where fit, finish, and assembly compatibility are non-negotiable.

In addition to machining and inspection, we employ advanced fixturing and in-process probing to maintain repeatability across production runs. Our engineering team collaborates directly with clients to optimize part design for manufacturability, minimizing lead times and reducing costly iterations. With full digital traceability and ISO-compliant documentation, Wuxi Lead ensures transparency and consistency for every order.

The following table outlines our standard technical specifications and achievable tolerances for custom metal components used in outside corner molding applications.

| Parameter | Standard Capability | Tight Tolerance Option |

|---|---|---|

| Positional Tolerance | ±0.025 mm | ±0.010 mm |

| Angular Tolerance | ±0.1° | ±0.05° |

| Surface Finish (Ra) | 3.2 µm | 0.8 µm (polished) |

| Feature Size Tolerance | ±0.020 mm | ±0.005 mm |

| Maximum Work Envelope (mm) | 1200 × 800 × 650 | Custom upon request |

| CMM Measurement Accuracy | ±0.0025 mm | ISO 10360-2 Certified |

| Lead Time (Prototype) | 7–12 days | Express options available |

| Material Compatibility | Aluminum, Steel, Stainless, Brass, Bronze | Pre-hardened & Tool Steels |

Wuxi Lead Precision Machinery combines engineering expertise with precision technology to deliver reliable, high-performance metal components tailored to the demanding requirements of plastic molding infrastructure.

Material & Finish Options

Material Selection for Precision Metal Outside Corner Moldings

Clarifying a critical point upfront: true plastic molding processes cannot produce structural outside corner moldings requiring metal-level strength and durability. For high-performance architectural, industrial, and transportation applications demanding precise geometric integrity under load, metal fabrication via CNC machining is the essential process. Wuxi Lead Precision Machinery specializes in transforming aluminum, steel, and titanium billets into dimensionally exact, structurally robust corner moldings where plastic alternatives fail. Material choice directly impacts performance, longevity, and total cost of ownership; selecting the optimal alloy requires matching mechanical properties and environmental resistance to your specific application demands.

Aluminum alloys, particularly 6061-T6, dominate due to an exceptional strength-to-weight ratio, inherent corrosion resistance, and superior machinability. This makes aluminum ideal for weight-sensitive applications like transportation enclosures, architectural trim, and electronic housings where galvanic compatibility matters. Steel, especially 304 or 316 stainless, provides significantly higher tensile strength and rigidity for heavy-duty structural corners in construction, marine hardware, or industrial machinery frames exposed to extreme mechanical stress. Titanium Grade 5 (Ti-6Al-4V) offers unparalleled strength-to-weight ratio and near-immunity to corrosion, justifying its premium cost in critical aerospace, defense, and high-end medical applications where failure is not an option. Below is a comparative specification guide for key material properties:

| Material | Typical Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Machinability Rating | Relative Cost |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | Very Good | Excellent | Low |

| Stainless Steel 304 | 515 | 8.0 | Excellent | Moderate | Medium |

| Titanium Ti-6Al-4V | 900 | 4.4 | Exceptional | Poor | High |

Surface finish is equally critical for both aesthetics and long-term protection. Anodizing is the industry-standard finish for aluminum corner moldings, creating a hard, non-conductive oxide layer that significantly enhances wear and corrosion resistance while providing a base for durable coloration. Type II (sulfuric acid) anodizing offers standard protection with color options; Type III (hardcoat) anodizing delivers maximum abrasion resistance for high-traffic areas. While steel relies on passivation or powder coating, and titanium benefits from specialized treatments, anodizing remains the most cost-effective and reliable finish for the vast majority of aluminum corner molding applications. The precise control of our CNC machining processes ensures uniform anodizing adhesion and consistent final dimensions.

Selecting the correct material and finish prevents premature failure and reduces lifecycle costs. Aluminum with Type II anodizing suffices for most commercial and industrial uses. Opt for stainless steel only when ultimate strength in corrosive environments is paramount, accepting higher weight and machining costs. Reserve titanium for mission-critical scenarios demanding its unique properties despite significant investment. Consult Wuxi Lead Precision Machinery engineers early; we analyze your environmental exposure, load requirements, and aesthetic goals to specify the optimal material-finish combination, ensuring your corner moldings perform flawlessly for decades.

Manufacturing Process & QC

The production process for high-precision outside corner molding plastic components at Wuxi Lead Precision Machinery follows a rigorously controlled sequence designed to ensure zero defects and full compliance with industrial standards. Our methodology integrates advanced engineering, iterative prototyping, and tightly monitored mass production to deliver consistent, high-end results tailored to the exact specifications of global OEMs and tier-one suppliers.

The process begins with the Design phase, where our engineering team collaborates closely with the client to interpret technical drawings, 3D models, and performance requirements. Utilizing CAD/CAM software and finite element analysis (FEA), we simulate mechanical stresses, thermal behavior, and dimensional stability under real-world operating conditions. This digital validation ensures that the mold design accommodates shrinkage, warpage, and flow dynamics specific to the chosen thermoplastic material—commonly PBT, ABS, or PC/ABS blends. Design for manufacturability (DFM) reviews are conducted to optimize wall thickness, gate location, and ejection mechanisms, minimizing post-molding defects.

Following design approval, we proceed to Prototyping. A high-precision steel or aluminum prototype mold is fabricated using CNC machining and EDM processes, achieving tolerances within ±0.01 mm. The first article samples are produced under production-intent conditions and subjected to comprehensive inspection. Dimensional verification is performed using coordinate measuring machines (CMM), while visual, fit, and function tests validate surface finish, corner integrity, and assembly compatibility. Any deviations are traced through root cause analysis, and mold adjustments are implemented before final sign-off. This iterative phase ensures that all outside corner geometries—critical for structural fit and aesthetic continuity—are flawlessly replicated.

Once prototype approval is obtained, the project transitions to Mass Production. Hardened steel production molds, built for longevity and thermal stability, are installed in high-tonnage hydraulic presses equipped with real-time monitoring systems. Process parameters such as injection pressure, cooling time, and mold temperature are locked into the machine’s control system to prevent drift. Each cycle is recorded, and statistical process control (SPC) charts track critical dimensions to detect trends before out-of-spec conditions occur. Automated vision inspection systems scan every component for surface defects, dimensional variance, and corner deformation, ensuring 100% in-process quality screening.

Throughout all stages, our ISO 9001-certified quality management system enforces traceability, documentation, and corrective action protocols. The result is a scalable, defect-free manufacturing flow that delivers outside corner molding plastic parts with exceptional repeatability, structural integrity, and surface precision.

| Specification | Detail |

|---|---|

| Material Options | PBT, ABS, PC/ABS, PP, PA6 |

| Tolerance | ±0.01 mm to ±0.05 mm (depending on part size) |

| Surface Finish | SPI-A1, SPI-B2, texture per customer spec |

| Mold Life | 500,000+ cycles (hardened steel) |

| Production Capacity | Up to 500,000 units/month |

| Quality Standards | ISO 9001, IATF 16949, PPAP Level 3 |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Outside Corner Molding Excellence

Precision-engineered outside corner moldings are critical components in high-end industrial, architectural, and transportation applications. Achieving flawless right-angle integrity, consistent wall thickness, and superior surface finish demands more than standard plastic molding capabilities—it requires advanced tooling expertise, rigorous process control, and deep material science understanding. At Wuxi Lead Precision Machinery, we bridge the gap between complex design intent and manufacturable reality, leveraging our core strengths in custom metal manufacturing to elevate your plastic molding outcomes. Our integrated approach ensures corner moldings that meet exacting dimensional tolerances while resisting warpage, sink marks, and structural weakness under operational stress.

Unlike generalist molders, Lead Precision applies aerospace-grade CNC machining principles to mold fabrication. Our in-house tooling division—specializing in hardened P20, H13, and stainless steel cores—produces molds with micron-level accuracy, directly translating to repeatable part geometry and longevity. We optimize cooling channels and gate placement using Moldflow simulation, eliminating thermal imbalances that compromise corner definition. This metal-to-plastic synergy, honed over 15 years of serving Tier-1 automotive and medical clients, delivers moldings that exceed ISO 2768-mK standards while reducing scrap rates by up to 40%.

Technical Capabilities for Critical Corner Molding

| Specification | Capability | Industry Relevance |

|---|---|---|

| Tolerance Control | ±0.025 mm (0.001″) on critical corners | Ensures seamless assembly in tight-tolerance assemblies |

| Material Range | ABS, PC/ABS, Nylon 6/6 GF30, POM, PP GF20 | Supports structural, UV-resistant, and high-temp applications |

| Mold Complexity | Multi-cavity, unscrewing cores, hot runners | Enables cost-effective production of intricate corner profiles |

| Lead Time (Mold) | 25-35 days from approved design | Accelerates time-to-market for new product launches |

| Quality Assurance | 100% CMM inspection + in-mold pressure sensors | Guarantees corner radius consistency and structural integrity |

Partnering with Lead Precision mitigates your supply chain risk through single-source accountability. We manage every phase—from DFM analysis and mold validation to production and logistics—from our ISO 9001-certified facility in Wuxi, China. Our engineers collaborate directly with your design team to resolve draft angle conflicts, ejection challenges, and material flow issues before tooling begins, preventing costly revisions. As a strategic manufacturing hub with dedicated shipping lanes to North America and Europe, we ensure on-time delivery without compromising quality oversight.

Initiate your precision outside corner molding project with engineering rigor that matches your standards. Submit your technical specifications and volume requirements to our engineering team for a confidential feasibility assessment. Contact us today to discuss how Lead Precision’s metal-informed plastic molding expertise can solve your most demanding corner integrity challenges.

Email [email protected] to connect with our application engineers. Include your project timeline and material specifications for a tailored capability review within 24 business hours. Let us transform your corner molding requirements into a competitive advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.